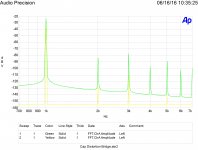

The last comparison was made by replacing all three Wien bridge capacitors (two of them in parallel) in my 1kHz oscillator board - I have one old semi-experimental board for these purposes. Oscillator output ~2,7V RMS.

Sounds like a good test to evaluate capacitor quality. It might be interesting to try polyester capacitors and see how much worse it gets.

Cheers,

Bob

Now, that should be interesting. My money is on the little sand bugs and not the big clunkers.

I am planning to use discrete amp modules.

AD4897 in a composite with one of the DSL line drivers might be a better solution for this application. (Assuming you need the speed)

Sounds like a good test to evaluate capacitor quality. It might be interesting to try polyester capacitors and see how much worse it gets.

Cheers,

Bob

Yes, but this test is not so easy and quick. Needs to match capacitors, and needs to check, that the AGC works in the same proper condition...

, but I have the new fresh results.

As a joke, chinese polyester 0.01uF 100V:

http://content6-foto.inbox.lv/albums/e/elterra/COGvsFKP2/chpolyester10n.jpg

and..., I do not believe my eyes, The Winner is -Xicon polystyrene 0.01uF 50V:

http://content6-foto.inbox.lv/albums/e/elterra/COGvsFKP2/Xicon10n.jpg

🙂

Polystyrene is a very good dielectric, so I guess I'm not surprised. I am always worried about my soldering technique when using polystrene caps though.

Polystyrene capacitors are my first choice unless the area is hot. These days it's hard to get the values you want at the voltages you need. I used to use Siemens, and they were excellent. Matching the Xicon caps means buying many and / or padding the capacitors.

The next best thing is Polypropylene, and you have to measure the DA on those. They are definitely not all equal! Teflon is of course the cap of choice if you can afford them. That's why I didn't include them in my list. Can't afford them.

-Chris

The next best thing is Polypropylene, and you have to measure the DA on those. They are definitely not all equal! Teflon is of course the cap of choice if you can afford them. That's why I didn't include them in my list. Can't afford them.

-Chris

They are definitely not all equal! Teflon is of course the cap of choice if you can afford them.

-Chris

Not necessarily. Don't they suffer from a good deal of pinholes when you make the film super thin? Yes, it make for a nice dielectric.

Yes, but this test is not so easy and quick. Needs to match capacitors, and needs to check, that the AGC works in the same proper condition...

, but I have the new fresh results.

As a joke, chinese polyester 0.01uF 100V:

http://content6-foto.inbox.lv/albums/e/elterra/COGvsFKP2/chpolyester10n.jpg

and..., I do not believe my eyes, The Winner is -Xicon polystyrene 0.01uF 50V:

http://content6-foto.inbox.lv/albums/e/elterra/COGvsFKP2/Xicon10n.jpg

🙂

Amazing results. Congratulations.

HI DPH,

Which, the Teflon (no) or the polypropylene capacitors? I use the high voltage parts, 250V to 630V usually. I am very suspicious of all low voltage capacitors. Can't trust them, and the higher voltage parts test better for DA usually. This is especially true of electrolytic capacitors.

I have some polypropylene capacitors where some brands measure not great for DA and others that measure as good as the polystyrene capacitors I have. How badly do you have to make a capacitor so that the dielectric becomes lossy?

-Chris

Which, the Teflon (no) or the polypropylene capacitors? I use the high voltage parts, 250V to 630V usually. I am very suspicious of all low voltage capacitors. Can't trust them, and the higher voltage parts test better for DA usually. This is especially true of electrolytic capacitors.

I have some polypropylene capacitors where some brands measure not great for DA and others that measure as good as the polystyrene capacitors I have. How badly do you have to make a capacitor so that the dielectric becomes lossy?

-Chris

Teflon, which is why the films must be thicker and bulkier to achieve equivalent capacitance.

My point wasn't to be contentious, but more that there's pluses and minuses to every material. 🙂

My point wasn't to be contentious, but more that there's pluses and minuses to every material. 🙂

Hi Daniel,

That's okay, I didn't take it that way. I genuinely didn't know which material you were talking about.

I agree with you, and I'm sure that's true for all materials to some degree. I don't know why the Teflon parts are so expensive though. Teflon as a material is in wide use everywhere.

-Chris

That's okay, I didn't take it that way. I genuinely didn't know which material you were talking about.

I agree with you, and I'm sure that's true for all materials to some degree. I don't know why the Teflon parts are so expensive though. Teflon as a material is in wide use everywhere.

-Chris

No worries Chris! Teflon is really hard to work with, both in terms of getting thin films and in terms of metallizing/metal film adhesion. Less about the raw material cost.

Last edited:

you could use your aluminium clip on sink to keep the temperature down where the axial lead enters the capacitor roll.Polystyrene is a very good dielectric, so I guess I'm not surprised. I am always worried about my soldering technique when using polystrene caps though.

Polystyrene capacitors are my first choice unless the area is hot. These days it's hard to get the values you want at the voltages you need. I used to use Siemens, and they were excellent. Matching the Xicon caps means buying many and / or padding the capacitors.

The next best thing is Polypropylene, and you have to measure the DA on those. They are definitely not all equal! Teflon is of course the cap of choice if you can afford them. That's why I didn't include them in my list. Can't afford them.

-Chris

Only $5.40 for 4.5pF.

Roll you own from teflon wire rap wire.

Attachments

How would be the performance of your suggested configuration, as example - open loop gain @1kHz?AD4897 in a composite with one of the DSL line drivers might be a better solution for this application. (Assuming you need the speed)

Only $5.40 for 4.5pF.

Roll you own from teflon wire rap wire.

I can provide some LSK389 likely - if you still need some, drop me a line.

and..., I do not believe my eyes, The Winner is -Xicon polystyrene 0.01uF 50V:

http://content6-foto.inbox.lv/albums/e/elterra/COGvsFKP2/Xicon10n.jpg

🙂

You know this means we need to buy new oscillators. . .

The dual opamps are a limitation. The AD797 (Scott's work) is viable but a single. They are expensive but still in production. I think you only need two for critical locations.

Polystyrene caps are very good for this. They became hard to get for two reasons- heat, they don't lend themselves to surface mount, and moisture sensitivity, you can't wash them with the rest of the board. They are really a hand operation. 2% PS caps should not be difficult to get. Relcap Reliable Capacitors still makes them for a price and the Xicons are fine. That factory has been making them for many years.

The PS caps are always film and foil. Same for most Teflon caps. Teflon is a pain, you need two or three layers because of the pinholes and then the foil. The yield is not great.

Both Teflon and PS have very good temperature stability. Same for COG(NPO). Everything else goes downhill. To be really obsessive you match the residual tempcos between the caps and the resistors. You can get remarkable stability with care.

A discrete circuit will quickly turn into something like the Shibasoku, large and expensive to build.

RE Gimmick- The problem with wire wrap wire for a small cap is first its Tefzel not PTFE (not too important) and second, they tend to unwind over time. I use some 24 AWG solid Teflon wire I got a surplus years ago. New 100' is close to $50. or about $.05 for a small trim cap.

How would be the performance of your suggested configuration, as example - open loop gain @1kHz?

Something like a AD815 should be around 120 dB loop gain (transimpedance) and the ADA4897 around 100 dB at 1kHz. Being a composite with both UGBW >100 MHz, you should be able to get pretty close to 200 dB loop gain at 1kHz. I could easily see this combo getting away from you, though with that much bandwidth available in a composite structure.

(loop gain on the 4897 datasheet starts at 10k, but looks dominant pole out to its UGBW of ~100-200 MHz).

Inherent distortion of the ADA4897 is incredibly low, too.

http://www.analog.com/media/en/technical-documentation/data-sheets/ADA4896-2_4897-1_4897-2.PDF

Last edited:

Hi David,

Your image doesn't expand when I click on it, so I can't see what it is easily.

Hi Demian,

I am now resigned to the knowledge that I need to pick up a Shibasoku THD meter / analyser or similar. The work I just did on a Marantz 2325 has readings very close to the residual noise on my 339A (amp only). I didn't expect this performance, yet here it is. These should be 6 dB worse easily. It would be nice to be able to see what is buried in the noise.

-Chris

Your image doesn't expand when I click on it, so I can't see what it is easily.

Hi Demian,

I am now resigned to the knowledge that I need to pick up a Shibasoku THD meter / analyser or similar. The work I just did on a Marantz 2325 has readings very close to the residual noise on my 339A (amp only). I didn't expect this performance, yet here it is. These should be 6 dB worse easily. It would be nice to be able to see what is buried in the noise.

-Chris

- Home

- Design & Build

- Equipment & Tools

- Low-distortion Audio-range Oscillator