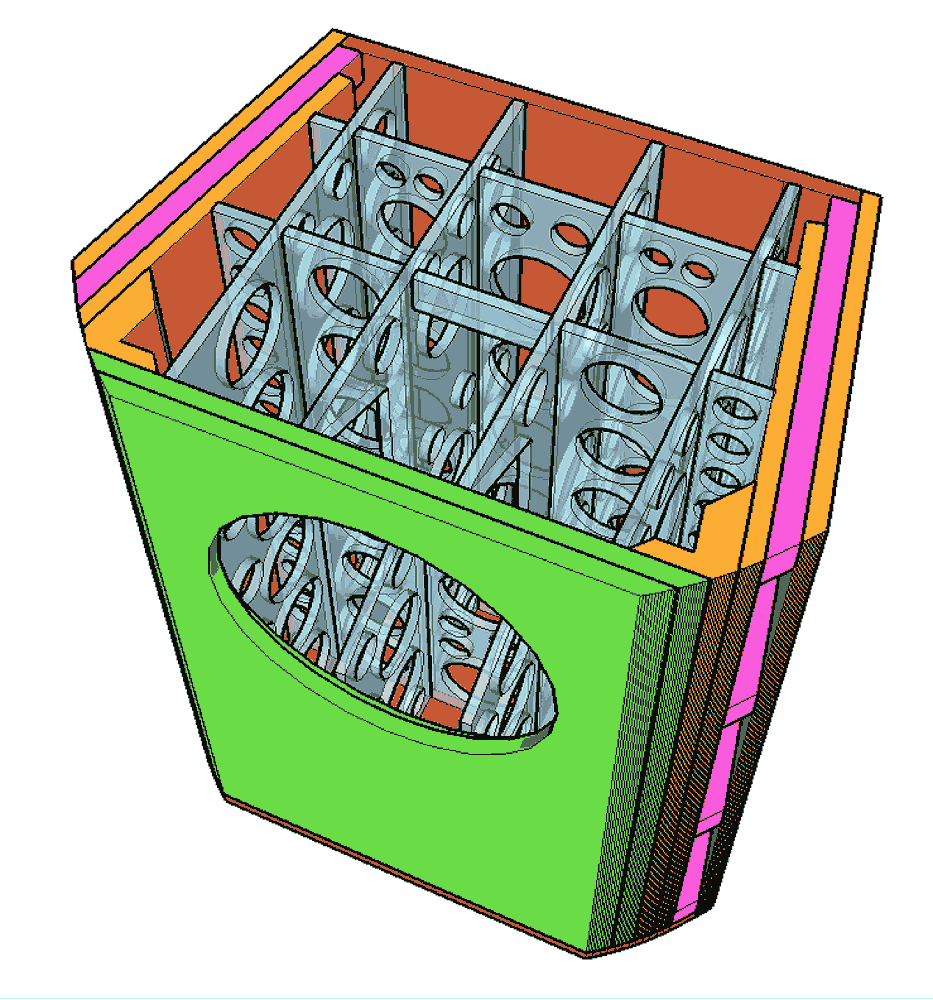

After I had written it, I remembered "holey braces", and was going to edit my post, but I couldn't remember who had posted the idea.That sounds like my Holey Braces. Add a bit of dampimng (lower density) over the holes toincrease resistance/damp down harmonics.

dave

Diffusion is Diffusion absorption is absorption

If you want the Sound pressure to go away

not bounce back = absorption

Aka like any other mid chamber, where wavelengths

are typically, simple to reduce.

You stuff the living heck out of it with absorption material.

All done , the end

No need to run through wild guessing and snooty tooty

" more expensive is magically better"

The hair structure for absorption can be Synthetic or Animal

pressure to heat through friction. The end

If you want the Sound pressure to go away

not bounce back = absorption

Aka like any other mid chamber, where wavelengths

are typically, simple to reduce.

You stuff the living heck out of it with absorption material.

All done , the end

No need to run through wild guessing and snooty tooty

" more expensive is magically better"

The hair structure for absorption can be Synthetic or Animal

pressure to heat through friction. The end

Thank you for your insight, I love your name.Diffusion is Diffusion absorption is absorption

If you want the Sound pressure to go away

not bounce back = absorption

Aka like any other mid chamber, where wavelengths

are typically, simple to reduce.

You stuff the living heck out of it with absorption material.

All done , the end

No need to run through wild guessing and snooty tooty

" more expensive is magically better"

The hair structure for absorption can be Synthetic or Animal

pressure to heat through friction. The end

Now, once upon a time I did an experiment on a closed enclosure, I took all the damping materials out side and instead placed a large pvc tube filled with insulation directly behind a large 10inch midrange. For my surprise I could hear a clear upgrade. Since then I am more careful with damping materials and more searching for this magical diffuser and it's interaction with closed cabinets.

In my experience, damping is killing dynamics.

What I would like to creat is a closed box that can simulat an open baffle clarity.

I am not sure about the practicality of this experiment but it sure a lot of fun to think of

I am more fixed on the loudspeaker Id like to build. the CNO Grande from Troels Gravesen...

http://www.troelsgravesen.dk/CNO-GRANDE.htm

I have the design pretty much fixed. to me it looks a bit like a Stenheim speaker.

what about the spiral in the picture below? could be a nice experiment.

http://www.troelsgravesen.dk/CNO-GRANDE.htm

I have the design pretty much fixed. to me it looks a bit like a Stenheim speaker.

what about the spiral in the picture below? could be a nice experiment.

Or maybe this???

+1 for this design. I really like the lines.

Extreme case in the other direction - extremely minimalist holey braces. I'd forgotten how minimalist they were until I took the driver out for the picture, they seem to be effective though, perhaps helped by the considerable quantities of cotton wool stuffing that was inside

Out of all the best sounding speakers I've listened to, the ones that stood out in terms of the most natural sounding lower midrange quality used thick, profiled acoustic urethane foam as the predominant dampening method / material. The foam was applied to the side and rear walls. The enclosure was made from very lossy, medium grain particle board - the type used in cheap, disposable furniture... yes, the worst quality wood based material you can imagine. It sounds fantastic. I'm dead serious.

With larger cone drivers, over 12", crossed over higher and covering the lower mids, I prefer a U shaped baffle 8" behind behind the driver magnet, made from rockwool or merino wool sandwiched by thin wire screen. Its held in place with staples or screws by the top and bottom of the enclosure or other nearby bracing. The remaining walls are covered in 3" thick open cell urethane foam.

With larger cone drivers, over 12", crossed over higher and covering the lower mids, I prefer a U shaped baffle 8" behind behind the driver magnet, made from rockwool or merino wool sandwiched by thin wire screen. Its held in place with staples or screws by the top and bottom of the enclosure or other nearby bracing. The remaining walls are covered in 3" thick open cell urethane foam.

I can relate to this.Out of all the best sounding speakers I've listened to, the ones that stood out in terms of the most natural sounding lower midrange quality used thick, profiled acoustic urethane foam as the predominant dampening method / material. The foam was applied to the side and rear walls. The enclosure was made from very lossy, medium grain particle board - the type used in cheap, disposable furniture... yes, the worst quality wood based material you can imagine. It sounds fantastic. I'm dead serious.

With larger cone drivers, over 12", crossed over higher and covering the lower mids, I prefer a U shaped baffle 8" behind behind the driver magnet, made from rockwool or merino wool sandwiched by thin wire screen. Its held in place with staples or screws by the top and bottom of the enclosure or other nearby bracing. The remaining walls are covered in 3" thick open cell urethane foam.

A very very fine speaker (to my ears) are the living voice rw. The cabinet is flexing with the music and gives a very full envelopig sound.

Interesting. To my ears foam does relatively little to the sound. It has to be a special kind of foam to have any damping effect. Modern acoustic foam is getting better though.Out of all the best sounding speakers I've listened to, the ones that stood out in terms of the most natural sounding lower midrange quality used thick, profiled acoustic urethane foam as the predominant dampening method / material. The foam was applied to the side and rear walls. The enclosure was made from very lossy, medium grain particle board - the type used in cheap, disposable furniture... yes, the worst quality wood based material you can imagine. It sounds fantastic. I'm dead serious.

With larger cone drivers, over 12", crossed over higher and covering the lower mids, I prefer a U shaped baffle 8" behind behind the driver magnet, made from rockwool or merino wool sandwiched by thin wire screen. Its held in place with staples or screws by the top and bottom of the enclosure or other nearby bracing. The remaining walls are covered in 3" thick open cell urethane foam.

I've found that cheap particle board works fairly well as a speaker building material, it's pretty stiff for it's weight and if you double it up it works great. Heck it's strong enough for Mama's counter top, and weight doesn't matter as much as stiffness.

The treatment you use for 12" woofers works well on other sizes too. I use wool or cotton batting instead of foam though. Actually, if you use fiberglass and wool you will use far less of it than the amount of foam.

I think mid bass or lower midrange is the most difficult to get right. there is so much going on there in the boundary where the room becomes a pressure vessel. The room plays a huge part in the sound of lower midrange, I'm guessing the room is a big part of what we are hearing.

The ideal enclosure material isn't necessarily infinitely stiff despite not being achievable in practice. A combination of dampening and elasticity sounds better in the midrange, where a stiffer enclosure with less dampening will ring excessively. Medium density larger grain particle board is close to ideal being it produces lower amplitude resonance peaks across a wider frequency range. Going through great lengths attempting to brace the enclosure using stiffer materials create taller individual resonant peaks which are harder to mask and become very audible even at lower output levels. The BBC got it right with their enclosure construction, allowing higher internal dampening of the enclosure walls through the use of softer materials and a combination of materials with varying densities.Interesting. To my ears foam does relatively little to the sound. It has to be a special kind of foam to have any damping effect. Modern acoustic foam is getting better though.

I've found that cheap particle board works fairly well as a speaker building material, it's pretty stiff for it's weight and if you double it up it works great. Heck it's strong enough for Mama's counter top, and weight doesn't matter as much as stiffness.

Midbass and lower midrange are the most critical frequencies to get right if accurate reproduction of acoustic instruments is desired. The dampening of enclosure air space is the first line of defense against the negative effects of the speaker's rear radiated energy. The better this back wave energy is dealt with to start with, the less enclosure resonances will be excited and can contaminate the direct radiated speaker sound. Absorbing the majority of vibrational energy coming from the driver's chassis itself through its mounting points is a large portion of what usually produces much of enclosure vibrating modes. Using sheets of dampening polymer material between chassis and enclosure walls has a big impact on suppressing midrange energy from the chassis making its way into the enclosure walls.I think mid bass or lower midrange is the most difficult to get right. there is so much going on there in the boundary where the room becomes a pressure vessel. The room plays a huge part in the sound of lower midrange, I'm guessing the room is a big part of what we are hearing.

The delicate balance of having just the right amount of vibrational airborne energy absorbed from the chassis backwave while not affecting or reducing the rebounding spring effect of the enclosure air volume is important, so that subtle lower midrange detail isn't lost. Slowing the air speed via extra dampening is an effective way to mimick a larger enclosure, but it comes at the expense of reducing lower midrange detail retrieval. This overdampening can leave you with a speaker that doesn't sound detailed at lower volume levels and requires more drive to "come alive", mainly from the effective added mass of the dampening material increasing enclosure losses.

Using the correct type of dampening material(s) is critical if you want a balanced sounding speaker. Sheeps wool usually does a good job of dampening overall just the right amount across a wider band of frequencies. Materials like Rockwool and fiberglass have too much mass and couple strongly with air vibration, creating greater internal loss and removing too much detail. Open cell foam is better for surface application to enclosure walls, having more subtle influences on midrange detail and linearity. Diffusing rather than absorbing is usually better at preserving midrange detail, but may not be sufficient to correct all standing waves, especially in tall enclosures with poorly chosen wall to wall dimensional ratios.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Loudspeaker Chaos theory- inside diffuser