AuroraB,

226754 is the type number. maxon is changing his type number system which is sad, as the old system told you which winding the motor used and so voltage of a given maxon could be told in the surplus shop.

Pete gave you the name and data already.

peted,

of course, the sleeved version is to be preferred, no ball race use in TTs , please!

Noise is too bad. And contagious like anyone can judge from rails starting to hiss and sing minutes befor the train comes by.

Why do i use this particular one?

1st, Manfred Huber switched to it, preferring it to the Teres one.

2nd this particular type has all that you wrote above plus

But i do not use it on my old TT where the motor is close to the platter and accordingly the belt wrap angle is small, too small to make use of the high acceleration. I use it for my air bearing design where the motor is far apart from the platter. In any case i use magnetic tape or leader tape as belt.

Smily: meant to teach you how to type it. Typing is easier than clicking.

(Phew, managed to explain it w/o questioning our forum software 🙂 )

Honestly, i don't know.

226754 is the type number. maxon is changing his type number system which is sad, as the old system told you which winding the motor used and so voltage of a given maxon could be told in the surplus shop.

Pete gave you the name and data already.

peted,

of course, the sleeved version is to be preferred, no ball race use in TTs , please!

Noise is too bad. And contagious like anyone can judge from rails starting to hiss and sing minutes befor the train comes by.

Why do i use this particular one?

1st, Manfred Huber switched to it, preferring it to the Teres one.

2nd this particular type has all that you wrote above plus

- it fits into the space i have designed for it, but just hardly,

- it has an acceleration time constant of only 4ms (compared to between 13 and 17 ms for ferrite types),

- i do not want higher rotational inertia, considering i have to cover 16 to 120 rpm.

But i do not use it on my old TT where the motor is close to the platter and accordingly the belt wrap angle is small, too small to make use of the high acceleration. I use it for my air bearing design where the motor is far apart from the platter. In any case i use magnetic tape or leader tape as belt.

Smily: meant to teach you how to type it. Typing is easier than clicking.

(Phew, managed to explain it w/o questioning our forum software 🙂 )

Honestly, i don't know.

Well that WAS fun 😀

Results of initial TT kitchen experiment - for that is what it was folks!

This experiment was to test the concept of an oil damped platter (maybe of wood) running on a simple uniball pivot. A plaster platter running in water was used in this experiment. The principles are the same. It's very Heath Robinson, the real thing would demand a lot more attention to detail, dimension and symmetry!

My motor was ex child's toy, fed with unregulated PSU. In practice a reg supply and proper motor (Maxon??) should almost certainly be used to assure good speed regulation. Sorry - cannot be more scientific than that.

Pics are in camera - (still) don't own a digital one. Put them on when I can - in the meantime we use words...

1) 280mm diam*78mm thick platter cast from plaster of Paris in old paint tub. I know it's too small - just testing the concept.

2) 'Uniball' pivot: 20mm diam (5mm thick) Brass ring - conical 8mm hole in centre, glued into top of platter. This brass ring seats onto top of steel (plinth) post with conical end. Lubricated by very little (actually a dab of washing up liquid - made no discernable difference). Bearing point about 5mm from top of platter. This is the notional uniball but proved that this bearing is (probably - pending listening tests) anything but critical.

3) Platter sitting in a washing up bowl of water. Top 20mmm is out of the water. 58mm immersed.

4) Platter has masking tape around top rim to make it 'sticky' and prevent slippage. Also attempt to make belt surface more parallel.

5) Belt of 2Kg monofilm fishing line looped into 3 loops. Simple fishing type knot used. Dice - noted your use of mag tape.

6) Belt length such that distance from motor to platter spindle about 350mm. No special thinking here - more the distance available on the TT kitchen worksurface! It worked fine, looked right. Smaller it is the bigger the wrap area for the belt (on the platter, but the =smaller= it is for the motor shaft. Where's the best compromise?) I'd think the motor shaft more critical - hence keep motor some way from platter?

7) motor mounted on makeshift frame such that belt tension and motor height can be easily changed.

8) 5mm Motor shaft wrapped with masking tape to fashion a 'waist' for belt to run in. This is important to keep the belt in the right place.

9) The motor shaft must be perpendicular to the plane of the belt.

Well it works just fine considering the Heath Robinson nature of the kit!! OK there is a little wobble because the platter is not statically balanced properly and not quite sized symetrically (remember this was not turned, but came out of the junk bin and was done in an evening give or take plaster curing time). The motor is rubbish (runs at uneven speeds even when unloaded!). The important factor is that platter is stable and quickly self stabilising when 'provoked'.

Important observations:

a) It works!!! Very reasonably.

b) platter DOES self level due to the liquid.

c) platter heavilly damped if you give it a poke - these die away after just a couple of oscillations. Due to lliquid.

d) Height of belt is important - needs to be level with uniball pivot point to prevent tilting from belt tension. When it is wrong the platter is plainly unstable and does not self level properly.

e) Belt tension had a =great= effect on speed of platter. Too loose it slips (poor speed reg, platter runs slow). Too tight it clobbers the motor (poor speed reg, runs slow again). I would advocate motor <> platter distance be easily adjusted (and markable, even have a means to set a specific tension - mabe a gravity weight loaded motor trolley that would auto take up belt slack/wear).

f) I would think (not measured) that apart from overall drive resistance (losses) being at a minimum, overall speed reg is also best at some point between these extremes. Maybe a simple measure of motor current Vs belt tension will find the sweet spot. Then set the gravity tensioner to do it right from then on...

g) It came up to speed pretty quickly. (inside the 30s spec).

h) I can not imagine any issue with stylus pressure causing excess wobble. It's a bit like placing a wrench on the side of a barge - it just doesn't notice it!

i) There was quite a lot of water drag - utlimately caused waves like along the hull of a boat when speed wound up to silly levels. I woulds advocate quite big clearances (10mm min) between platter and sides of liquid bath. A lot of drag in this experiment down to rubbish surfaces, particularly bottom of platter (unsmoothed plaster with air bubble pockets 🙁).

I siphoned off the water while it was running - hee hee - well this dastadely trick backfired because the platter became undamped (literally 😀) - took to wobbling big-time and the belt came off. While emptying no great speed difference was noticed. Possibly the increase in load on my dubious uniball took it's friction through the roof - I had expected big speed increase due to loss of water drag.

So, conslusions: (IHMO of course) A resounding success 😉

I would say it paves the way for a proper prototype rig involving turning, oil and wood sealing (Liberon floor seals?) Also a proper motor/PSU. I will work on this over the next months.

I have no idea of power input to this test rig, but the small shaft diam and therefore relatively high speed mean a small fast motor seems to cope. Dice mentioned the frequency of pulley eccentricity - At least 10mm pulley - puts it <= 20Hz to be inaudible. I don't question the theory, only if a properly turned and mounted pulley would exhibit so much eccentricity anyway - (when not constructed from masking tape). My test motor is brain damaged and pulls 7 amps at no load so I could not judge it's real output.

I do not think the uniball pivot need be sophisticated - the simple cone running in a cone I used tonight seemed just fine but there are other factors like wear and running noise to consider. How long would my brass ring on steel spike last - maybe 'forever' with a little simple grease. It's carrying maybe 1.5Kg only. Running noise may be the biggest factor - opinions please...

What is the best shape of the rim to naturally keep the belt aligned? What I found was the motor pulley was critical to stability (a parallel shaft was rubbish), but this may be because I had so many dubious dimensions and poor surfaces. I would think a slightly waisted motor pulley with a simple parallel rim is all that is necessary (and easy to make).

Another consideration - when placing the vinyl on platter, it'll tip no matter what. Remember we have big (>10mm) clearance all around platter to keep drag/turbulance down. Imagine a thin (a few mm) circular rim (at more or less max platter radius) projecting down from platter bottom with just 2-3 mm clearance to the oil bath floor. This will limit the tilt when loading vinyl and still allow normal running. It needs to be turned when making the platter.

A hole is needed through platter to allow air to come out when placing on oil bath.

Any of you CADders fancy illustrating some of this?

Hope all this inspires some more time in your TT kitchen....

Pete

Results of initial TT kitchen experiment - for that is what it was folks!

This experiment was to test the concept of an oil damped platter (maybe of wood) running on a simple uniball pivot. A plaster platter running in water was used in this experiment. The principles are the same. It's very Heath Robinson, the real thing would demand a lot more attention to detail, dimension and symmetry!

My motor was ex child's toy, fed with unregulated PSU. In practice a reg supply and proper motor (Maxon??) should almost certainly be used to assure good speed regulation. Sorry - cannot be more scientific than that.

Pics are in camera - (still) don't own a digital one. Put them on when I can - in the meantime we use words...

1) 280mm diam*78mm thick platter cast from plaster of Paris in old paint tub. I know it's too small - just testing the concept.

2) 'Uniball' pivot: 20mm diam (5mm thick) Brass ring - conical 8mm hole in centre, glued into top of platter. This brass ring seats onto top of steel (plinth) post with conical end. Lubricated by very little (actually a dab of washing up liquid - made no discernable difference). Bearing point about 5mm from top of platter. This is the notional uniball but proved that this bearing is (probably - pending listening tests) anything but critical.

3) Platter sitting in a washing up bowl of water. Top 20mmm is out of the water. 58mm immersed.

4) Platter has masking tape around top rim to make it 'sticky' and prevent slippage. Also attempt to make belt surface more parallel.

5) Belt of 2Kg monofilm fishing line looped into 3 loops. Simple fishing type knot used. Dice - noted your use of mag tape.

6) Belt length such that distance from motor to platter spindle about 350mm. No special thinking here - more the distance available on the TT kitchen worksurface! It worked fine, looked right. Smaller it is the bigger the wrap area for the belt (on the platter, but the =smaller= it is for the motor shaft. Where's the best compromise?) I'd think the motor shaft more critical - hence keep motor some way from platter?

7) motor mounted on makeshift frame such that belt tension and motor height can be easily changed.

8) 5mm Motor shaft wrapped with masking tape to fashion a 'waist' for belt to run in. This is important to keep the belt in the right place.

9) The motor shaft must be perpendicular to the plane of the belt.

Well it works just fine considering the Heath Robinson nature of the kit!! OK there is a little wobble because the platter is not statically balanced properly and not quite sized symetrically (remember this was not turned, but came out of the junk bin and was done in an evening give or take plaster curing time). The motor is rubbish (runs at uneven speeds even when unloaded!). The important factor is that platter is stable and quickly self stabilising when 'provoked'.

Important observations:

a) It works!!! Very reasonably.

b) platter DOES self level due to the liquid.

c) platter heavilly damped if you give it a poke - these die away after just a couple of oscillations. Due to lliquid.

d) Height of belt is important - needs to be level with uniball pivot point to prevent tilting from belt tension. When it is wrong the platter is plainly unstable and does not self level properly.

e) Belt tension had a =great= effect on speed of platter. Too loose it slips (poor speed reg, platter runs slow). Too tight it clobbers the motor (poor speed reg, runs slow again). I would advocate motor <> platter distance be easily adjusted (and markable, even have a means to set a specific tension - mabe a gravity weight loaded motor trolley that would auto take up belt slack/wear).

f) I would think (not measured) that apart from overall drive resistance (losses) being at a minimum, overall speed reg is also best at some point between these extremes. Maybe a simple measure of motor current Vs belt tension will find the sweet spot. Then set the gravity tensioner to do it right from then on...

g) It came up to speed pretty quickly. (inside the 30s spec).

h) I can not imagine any issue with stylus pressure causing excess wobble. It's a bit like placing a wrench on the side of a barge - it just doesn't notice it!

i) There was quite a lot of water drag - utlimately caused waves like along the hull of a boat when speed wound up to silly levels. I woulds advocate quite big clearances (10mm min) between platter and sides of liquid bath. A lot of drag in this experiment down to rubbish surfaces, particularly bottom of platter (unsmoothed plaster with air bubble pockets 🙁).

I siphoned off the water while it was running - hee hee - well this dastadely trick backfired because the platter became undamped (literally 😀) - took to wobbling big-time and the belt came off. While emptying no great speed difference was noticed. Possibly the increase in load on my dubious uniball took it's friction through the roof - I had expected big speed increase due to loss of water drag.

So, conslusions: (IHMO of course) A resounding success 😉

I would say it paves the way for a proper prototype rig involving turning, oil and wood sealing (Liberon floor seals?) Also a proper motor/PSU. I will work on this over the next months.

I have no idea of power input to this test rig, but the small shaft diam and therefore relatively high speed mean a small fast motor seems to cope. Dice mentioned the frequency of pulley eccentricity - At least 10mm pulley - puts it <= 20Hz to be inaudible. I don't question the theory, only if a properly turned and mounted pulley would exhibit so much eccentricity anyway - (when not constructed from masking tape). My test motor is brain damaged and pulls 7 amps at no load so I could not judge it's real output.

I do not think the uniball pivot need be sophisticated - the simple cone running in a cone I used tonight seemed just fine but there are other factors like wear and running noise to consider. How long would my brass ring on steel spike last - maybe 'forever' with a little simple grease. It's carrying maybe 1.5Kg only. Running noise may be the biggest factor - opinions please...

What is the best shape of the rim to naturally keep the belt aligned? What I found was the motor pulley was critical to stability (a parallel shaft was rubbish), but this may be because I had so many dubious dimensions and poor surfaces. I would think a slightly waisted motor pulley with a simple parallel rim is all that is necessary (and easy to make).

Another consideration - when placing the vinyl on platter, it'll tip no matter what. Remember we have big (>10mm) clearance all around platter to keep drag/turbulance down. Imagine a thin (a few mm) circular rim (at more or less max platter radius) projecting down from platter bottom with just 2-3 mm clearance to the oil bath floor. This will limit the tilt when loading vinyl and still allow normal running. It needs to be turned when making the platter.

A hole is needed through platter to allow air to come out when placing on oil bath.

Any of you CADders fancy illustrating some of this?

Hope all this inspires some more time in your TT kitchen....

Pete

Congrats on your initiative. That's a lot of useful information.

Instead of a deep rim, couldn't the platter be very thick

with the contact point up towards the top surface? Then most of the weight is below the pivot and the belt drive area is at the top of the platter

Best would be to have the cone receptor cup near the top of the platter, with most of the platter hanging below. A spike is attached to the plinth to set the platter on. The end of the spike could be a point or a small ball bearing Can the receptor cup be a jeweled bearing? or is the platter too big and heavy?

The oil now seems to be pure damping not any float action?, or is this just an experimental simplification? I think the floating is a very good idea. It is good to keep in mind that the platter doesn't have to float completely, as long as it is lighter than the fluid, it will help: as the platter tilts, more volume is submerged on that side and the increased bouyancy flattens the platter. After all we don't want the platter floating off the pin! I think the platter could be reasonably heavy AND bouyant as long as it was made of a material with significantly less density than the fluid, very thick and the bath pretty deep. Wood would probably work, but would require balancing after turning! then the epoxy treatment?

What is the specific density of castor oil?

Water is 1 of course.

One would have to be careful to keep the oil off the belt!

Will keep thinking-

Dice, I would love to do the trade, but (seriously) what are the chances of two small bottles with peculiar fluids getting through the mail to you? Probably pretty good I guess, (but if I included some wire and components probably 0%) 😉

I don't want to end up in jail while Bush decides if I am a terrorist!

You are doing a good job as moderator IMHO - because you are being moderate!

MArk

Instead of a deep rim, couldn't the platter be very thick

with the contact point up towards the top surface? Then most of the weight is below the pivot and the belt drive area is at the top of the platter

Best would be to have the cone receptor cup near the top of the platter, with most of the platter hanging below. A spike is attached to the plinth to set the platter on. The end of the spike could be a point or a small ball bearing Can the receptor cup be a jeweled bearing? or is the platter too big and heavy?

The oil now seems to be pure damping not any float action?, or is this just an experimental simplification? I think the floating is a very good idea. It is good to keep in mind that the platter doesn't have to float completely, as long as it is lighter than the fluid, it will help: as the platter tilts, more volume is submerged on that side and the increased bouyancy flattens the platter. After all we don't want the platter floating off the pin! I think the platter could be reasonably heavy AND bouyant as long as it was made of a material with significantly less density than the fluid, very thick and the bath pretty deep. Wood would probably work, but would require balancing after turning! then the epoxy treatment?

What is the specific density of castor oil?

Water is 1 of course.

One would have to be careful to keep the oil off the belt!

Will keep thinking-

Dice, I would love to do the trade, but (seriously) what are the chances of two small bottles with peculiar fluids getting through the mail to you? Probably pretty good I guess, (but if I included some wire and components probably 0%) 😉

I don't want to end up in jail while Bush decides if I am a terrorist!

You are doing a good job as moderator IMHO - because you are being moderate!

MArk

TT motors

For European TT builders it might be easier to get motors from this company in Holland..'

http://www.premotec.com/product_catalogue.html

The CL series ( 29 or 40 series ) should be very good for the task, being Coreless DC motors .

These are the motors used in "Le Platine Verdier". Originally it was made by Philips so I guess Premotec is a Philips offspring....

BTW,- I bought one 10 years ago when I started a Platine-project that later just stopped 😉

For European TT builders it might be easier to get motors from this company in Holland..'

http://www.premotec.com/product_catalogue.html

The CL series ( 29 or 40 series ) should be very good for the task, being Coreless DC motors .

These are the motors used in "Le Platine Verdier". Originally it was made by Philips so I guess Premotec is a Philips offspring....

BTW,- I bought one 10 years ago when I started a Platine-project that later just stopped 😉

Polyethelene rope floats, so I guess it might float in other liquids.

A polyethelene platter would be pretty easy to machine I would think. Also well damped and more similar to vinyl in mass than some materials. Best source? cutting boards for the kitchen.

I've got one 18"x24" and about 3/4" thick. Could be turned on a wood lathe or drill press if necessary. (machinist is better of course)

We can increase the density of a fluid by making it a solution like salt water or sugar syrup. AND add oil on top to stop evaporation.

(the mercury story from Dice comes through here!)

Boy, this would be a mess when one of our earthquakes comes through!

A polyethelene platter would be pretty easy to machine I would think. Also well damped and more similar to vinyl in mass than some materials. Best source? cutting boards for the kitchen.

I've got one 18"x24" and about 3/4" thick. Could be turned on a wood lathe or drill press if necessary. (machinist is better of course)

We can increase the density of a fluid by making it a solution like salt water or sugar syrup. AND add oil on top to stop evaporation.

(the mercury story from Dice comes through here!)

Boy, this would be a mess when one of our earthquakes comes through!

Great job, peted! 🙂

All,

psst, hushhush --- off topic --- hushhush,

have you discovered the new music board already? (peterr, no need to respond 🙂 )

peted,

Great job! my lust is growing to build a swimming unipivot, just to try it out! 🙂

Water probably is the best choice, any other healthy fluid's specific densitiy is below 1gr/cm^2, water is 1. Cannot find out the density of plaster of Paris must be somewhere around 1.6; PVC has 1.38 .

So, as there are other reasons to use PVC for a platter (i have elebaorated about the topic above) and PVC is commonly used for all sorts of chemical processes including water-refurbishing,

why not use a combination of PVC and water bath. Water vapours certainly are not dangerous.

Repeat: we do **not** need the bath to carry the platter, a trustplate and ruby ball will do the job gorgeously.

Motor:

AuroraB, could well be the Premotec motor could be up to the task and comparable to maxon. i found a acceleration time constant of 13ms .. comparable to theTeres maxon of dia 26.

But this maxon has 7W of sahaft power and 6 times the torque at about same outer dimensions. The REmax has 11 times the torque and 4 ms time constant.

Another point: if you clamp the maxon at its outer diameter in an airtight blind bushing, or IOW if you pot its butt, the precious metal finger commutator is dead silent. Can the Premotec do that?

And ... concentricity of running shaft is not as good as the maxons.

I somehow have the hunch the maxon (yes, and the Faulhaber) brand is technically superior.

And, as we Munich folks have tried out, maxon is very cooperative and willing to supply small quantities.

At a local surplus shop, there is a big lot of maxon 2028.949-61.121-025.

dia 28 and a 42Volts winding, it is roughly comparable to the maxon the Teres uses. I repeat my offer from before: I could buy the whole lot, remove the gear wheel, put a 10mm dia pulley on it, mail it to you. Price would be probably ¤10 without the pulley and without shipping, i have no idea what my buddy will charge me for the pulley if i tell him this is sort of boyscout action and needs boyscout pricing.

Another thing, he has a CNC lathe meanwhile but it will take atleast 4 weeks until he gets the thing working, but he is eager to have test parts. And nice looking pulleys are a rough job without CNC, an easy one with. I could have him make a pulley suited for both, fishing line and magnetic tape.

What i can tell you: i will do it once, but if you folks cannot make up your mind in time, tough luck

Another thing, maxons are to be used within their specs, particularly AFA radial force is concerned. Else they die soon.

My idea to that: i mount the blind bushing carrying the motor on an outwardly slanted sled. For that i use a linear ball race. The motor runs downhill and the belt is put under tension. Tension never exceeds radial force rating.

Another, simpler but more space consuming option is to mount the motor on a lever rotating around a vertical shaft and let a thead/weight or a U-bent pull spring exert the bent-tensioning force.

Variac,

forgetabout evaporation. No oils please if you can avoid it.

You 'll have it everywhere, particularly silicone oil, particularly polluting the grooves of your Coltrane Giant Steps, bullseye or green label (that being your most precious and cherished record 🙂 ). Water is fine!

Polyethylene: more expensive than PVC, a pain to manufacture to precision, mechanical impedance matching worse. PVC indeed is the ideal choice IMO. 🙂

Thankyou very much for the nice compliment, it soothes me a bit 🙂 ... we all moderators try to be moderate .. well ... wrongdoers not always give us the chance to do so and we have minors to protect and elders, too. Men In Black, so to speak, just we haven't got neuralizers 🙂

Have received less than acknowledging comments, too, and not only from disturbers immune to friendly tries to set them straight. Also from friends who think that moderation-in-itself is evil and an inevitable sign of coming end of a web forum. Remarks like "police state" were a'plenty {sigh} 🙁

You concerns about mailing epoxy are well worth to be considered. Maybe you mail me the manufacturer's adress and i try to order it there myself. I have made nothing but best experiences with US companies int'lly selling stuff.

My motor offer is open to all, of course, provided i can process it in a single run.

All,

psst, hushhush --- off topic --- hushhush,

have you discovered the new music board already? (peterr, no need to respond 🙂 )

peted,

Great job! my lust is growing to build a swimming unipivot, just to try it out! 🙂

Water probably is the best choice, any other healthy fluid's specific densitiy is below 1gr/cm^2, water is 1. Cannot find out the density of plaster of Paris must be somewhere around 1.6; PVC has 1.38 .

So, as there are other reasons to use PVC for a platter (i have elebaorated about the topic above) and PVC is commonly used for all sorts of chemical processes including water-refurbishing,

why not use a combination of PVC and water bath. Water vapours certainly are not dangerous.

Repeat: we do **not** need the bath to carry the platter, a trustplate and ruby ball will do the job gorgeously.

Motor:

AuroraB, could well be the Premotec motor could be up to the task and comparable to maxon. i found a acceleration time constant of 13ms .. comparable to theTeres maxon of dia 26.

But this maxon has 7W of sahaft power and 6 times the torque at about same outer dimensions. The REmax has 11 times the torque and 4 ms time constant.

Another point: if you clamp the maxon at its outer diameter in an airtight blind bushing, or IOW if you pot its butt, the precious metal finger commutator is dead silent. Can the Premotec do that?

And ... concentricity of running shaft is not as good as the maxons.

I somehow have the hunch the maxon (yes, and the Faulhaber) brand is technically superior.

And, as we Munich folks have tried out, maxon is very cooperative and willing to supply small quantities.

At a local surplus shop, there is a big lot of maxon 2028.949-61.121-025.

dia 28 and a 42Volts winding, it is roughly comparable to the maxon the Teres uses. I repeat my offer from before: I could buy the whole lot, remove the gear wheel, put a 10mm dia pulley on it, mail it to you. Price would be probably ¤10 without the pulley and without shipping, i have no idea what my buddy will charge me for the pulley if i tell him this is sort of boyscout action and needs boyscout pricing.

Another thing, he has a CNC lathe meanwhile but it will take atleast 4 weeks until he gets the thing working, but he is eager to have test parts. And nice looking pulleys are a rough job without CNC, an easy one with. I could have him make a pulley suited for both, fishing line and magnetic tape.

What i can tell you: i will do it once, but if you folks cannot make up your mind in time, tough luck

Another thing, maxons are to be used within their specs, particularly AFA radial force is concerned. Else they die soon.

My idea to that: i mount the blind bushing carrying the motor on an outwardly slanted sled. For that i use a linear ball race. The motor runs downhill and the belt is put under tension. Tension never exceeds radial force rating.

Another, simpler but more space consuming option is to mount the motor on a lever rotating around a vertical shaft and let a thead/weight or a U-bent pull spring exert the bent-tensioning force.

Variac,

forgetabout evaporation. No oils please if you can avoid it.

You 'll have it everywhere, particularly silicone oil, particularly polluting the grooves of your Coltrane Giant Steps, bullseye or green label (that being your most precious and cherished record 🙂 ). Water is fine!

Polyethylene: more expensive than PVC, a pain to manufacture to precision, mechanical impedance matching worse. PVC indeed is the ideal choice IMO. 🙂

Thankyou very much for the nice compliment, it soothes me a bit 🙂 ... we all moderators try to be moderate .. well ... wrongdoers not always give us the chance to do so and we have minors to protect and elders, too. Men In Black, so to speak, just we haven't got neuralizers 🙂

Have received less than acknowledging comments, too, and not only from disturbers immune to friendly tries to set them straight. Also from friends who think that moderation-in-itself is evil and an inevitable sign of coming end of a web forum. Remarks like "police state" were a'plenty {sigh} 🙁

You concerns about mailing epoxy are well worth to be considered. Maybe you mail me the manufacturer's adress and i try to order it there myself. I have made nothing but best experiences with US companies int'lly selling stuff.

My motor offer is open to all, of course, provided i can process it in a single run.

Variac:

I reckon my platter was about 10% more dense than water (it had not fully cured in my case too much water in the mix). Hence a material more dense than the liquid seems to work also - I had been assuming it had to be able to float but have changed my mind on this.

Specific density of caster oil: 0.957 - 0.961

AuroraB:

Pete

I seem to have introduced some confusion mentioning my rim under ther platter. Yes - platter is deep and solid (78mm deep in my test case). This additional rim underneath is only to prevent tipping when loading the vinyl - it stops 2-3mm short of bottom of bath.Instead of a deep rim, couldn't the platter be very thick

Exactly that - pity I couldn't do pics - will work on it. Belt was 5mm from top of platter level with uniball/cone pivot point.Best would be to have the cone receptor cup near the top of the platter, with most of the platter hanging below. A spike is attached to the plinth to set the platter on. The end of the spike could be a point or a small ball bearing Can the receptor cup be a jeweled bearing? or is the platter too big and heavy?

No - the float action is important to make it self level and also overcome the 'too big too heavy' aspect. The damping is a desired and essential side effect and the point of the whole concept. I estimate 10-15% of the platter weight was on the uniball. This self levelling effect seems to be present even with a material that would sink (that doesn't feel right - any offers?).The oil now seems to be pure damping not any float action?,

I reckon my platter was about 10% more dense than water (it had not fully cured in my case too much water in the mix). Hence a material more dense than the liquid seems to work also - I had been assuming it had to be able to float but have changed my mind on this.

Specific density of caster oil: 0.957 - 0.961

AuroraB:

Maybe - but Maxon seem to have distributors in all major countries e.g. www.maxonmotor.nlFor European TT builders it might be easier to get motors from this company in Holland..'

Pete

I agree - but for me it doesn't have the appeal of well machined and finished wood.A polyethelene platter would be pretty easy to machine I

Re: Great job, peted! 🙂

I am impressed with how this project is coming along, and will continue to watch and support it, but due to a change in circumstances, I doubt I will be able to commit to the TT in the foreseeable future.

Bernhard,

Even though I am not able to participate in the diyaudio TT project, if you are to do a batch of motors and pulleys, may I please be included in the group? We exchanged a couple of emails last year about a similar project, and I'd be keen to try DC motors on my other TTs, especially with leader tape drive. If two were available that would be even better. There is no one within a long distance of here who could do the work if I attempted it myself.

Regards

Brett

Hello Everyone,dice45 said:Motor:

At a local surplus shop, there is a big lot of maxon 2028.949-61.121-025.

dia 28 and a 42Volts winding, it is roughly comparable to the maxon the Teres uses. I repeat my offer from before: I could buy the whole lot, remove the gear wheel, put a 10mm dia pulley on it, mail it to you. Price would be probably ¤10 without the pulley and without shipping, i have no idea what my buddy will charge me for the pulley if i tell him this is sort of boyscout action and needs boyscout pricing.

Another thing, he has a CNC lathe meanwhile but it will take atleast 4 weeks until he gets the thing working, but he is eager to have test parts. And nice looking pulleys are a rough job without CNC, an easy one with. I could have him make a pulley suited for both, fishing line and magnetic tape.

What i can tell you: i will do it once, but if you folks cannot make up your mind in time, tough luck

I am impressed with how this project is coming along, and will continue to watch and support it, but due to a change in circumstances, I doubt I will be able to commit to the TT in the foreseeable future.

Bernhard,

Even though I am not able to participate in the diyaudio TT project, if you are to do a batch of motors and pulleys, may I please be included in the group? We exchanged a couple of emails last year about a similar project, and I'd be keen to try DC motors on my other TTs, especially with leader tape drive. If two were available that would be even better. There is no one within a long distance of here who could do the work if I attempted it myself.

Regards

Brett

If we make the hole in the platter that the spike extends into only a little larger than the spike, then that will limit the tilt of the platter. No need for the fin at the rim then.

Hey, those threaded steel speaker spikes might do the job as the pivit point! The little disks that they supply to protect your floor with the concave receptor for the point could go into the platter as the cup.

Boy this is embarassing, the Greeks figured this out quite awhile ago: I think things heavier than water are still buoyed by the water, i.e. are lighter. Your experiment confirmed this I think.

Can someone confirm this? Please don't make fun of us!!🙄

I agree that the wood platter has appeal.

That also points out a big advantage of this design: people could make it out of materials they desire, and report back. I can see the turntable conventions now, where people compare their 'tables 😉

The penetrating epoxy is available at West Marine stores in the U.S. You could check other boat supply stores.

It is called Clear Penetrating Epoxy Sealer

Smith & Company

5100 Channel Ave.

Richmond , CA 94804

West marine is probably better for small quantities: westmarine.com

Dice: Maybe I could mail the motors in the U.S.

to all those that order from here if and when we get to that point!

Hey, those threaded steel speaker spikes might do the job as the pivit point! The little disks that they supply to protect your floor with the concave receptor for the point could go into the platter as the cup.

Boy this is embarassing, the Greeks figured this out quite awhile ago: I think things heavier than water are still buoyed by the water, i.e. are lighter. Your experiment confirmed this I think.

Can someone confirm this? Please don't make fun of us!!🙄

I agree that the wood platter has appeal.

That also points out a big advantage of this design: people could make it out of materials they desire, and report back. I can see the turntable conventions now, where people compare their 'tables 😉

The penetrating epoxy is available at West Marine stores in the U.S. You could check other boat supply stores.

It is called Clear Penetrating Epoxy Sealer

Smith & Company

5100 Channel Ave.

Richmond , CA 94804

West marine is probably better for small quantities: westmarine.com

Dice: Maybe I could mail the motors in the U.S.

to all those that order from here if and when we get to that point!

Bernhard:

"A" Program motor - as Teres unit

28mm diam

Type 943 winding (??)

Type 61 shaft/drive (??)

Sleeve bearing - good

Precious metal brushes - good

"Version" 025 (??)

Cannot translate exactly to new number system. But it looks good - you quote 7W - same as the Teres which is a type 110189 in new order code speak.

How sure are you that the gear can be removed without damage/introducing eccentricity? Have you given one of these a fine once over to establish why they are in a surplus shop?

The 110189 new is GBP 49:50 in the UK without pulleys /shipping not that they are heavy beasts.

Bernhard:

Bernhard:

Cheers

Pete

In principal I'm interested pending price. What unit of currency is a "¤" please?! The order number you quote translates to:could buy the whole lot, remove the gear wheel, put a 10mm dia pulley on it, mail it to you. Price would be probably ¤10 without the pulley and without shipping, i have no idea what my buddy will charge me for the pulley if i tell him this is sort of boyscout action and needs boyscout pricing.

"A" Program motor - as Teres unit

28mm diam

Type 943 winding (??)

Type 61 shaft/drive (??)

Sleeve bearing - good

Precious metal brushes - good

"Version" 025 (??)

Cannot translate exactly to new number system. But it looks good - you quote 7W - same as the Teres which is a type 110189 in new order code speak.

How sure are you that the gear can be removed without damage/introducing eccentricity? Have you given one of these a fine once over to establish why they are in a surplus shop?

The 110189 new is GBP 49:50 in the UK without pulleys /shipping not that they are heavy beasts.

Bernhard:

OK - have to admit I have no idea what a trustplate looks like - please explain.Repeat: we do **not** need the bath to carry the platter, a trustplate and ruby ball will do the job gorgeously

Bernhard:

This is down to our ingenuity and native cunning to make sure it cannot escape short of being knocked on floor. My experiments suggested no risk from spash at normal speeds. I'd not worry about it. DIY overkill will ensure the whole unit weighs at least 20Kg and therefore isn't going anywhere 😉. I feel there are many such potentially risky items already in the domestic environment that we have no problem living with, so I'd not accept this a reason not to do an oil based prototype. ==MUCH== bigger risk of soiling LPs having a manky cat in the house who despite lack of critical rear end components still feels strong urge to mark all and sundry! Zen monoblock amps included 😡No oils please if you can avoid it.

You 'll have it everywhere

Cheers

Pete

Variac:

Variac

Pete

Yes - good call - although maybe a little tricky to get the clearances right. Centre spike would need to be substantial to prevent accidental damage if platter received accidental heavy knock. KISS rules!If we make the hole in the platter that the spike extends into only a little larger than the spike, then that will limit the tilt of the platter. No need for the fin at the rim then.

Variac

Ah - but they had less distractions (no diyaudio.com) - and we are still playing catch-up.the Greeks figured this out quite awhile ago: I think things heavier than water are still buoyed by the water,

Pete

Dice meant thrust plate I'll bet.

That's the piece that sits on top of the ball. It's stuck up the hole in the platter. Probably a disk of metal with a depression in it. It could be just the top of the hole in the platter if the platter was an appropriate material.

He has mentioned soft stuff I've heard metal is better.

More experiments in the far future...

A steel ball would work also instead of ruby- More options

I agree - no problem with the oil, the crack around the outside of the platter can be only a few millimeters wide , depending on your taste for precision over KISS. The oil level can be kept well below the top of the platter.

That's the piece that sits on top of the ball. It's stuck up the hole in the platter. Probably a disk of metal with a depression in it. It could be just the top of the hole in the platter if the platter was an appropriate material.

He has mentioned soft stuff I've heard metal is better.

More experiments in the far future...

A steel ball would work also instead of ruby- More options

I agree - no problem with the oil, the crack around the outside of the platter can be only a few millimeters wide , depending on your taste for precision over KISS. The oil level can be kept well below the top of the platter.

Variac:

For peace of mind (only), the top of the bath could have a little horizontal rim adjacent to the platter side, covering most of the gap. Or mount same on platter - if it didn't cause resonance.

Best just live dangerously and keep kidz/catz, fluff 'n stuff away from it!

Pete

Just wary of keeping clearances BIG to keep drag/turbulance down. Here's where a bit of theory would help - differential speed is a little over 0.5m/s between platter and bath wall at 33rpm. My water experiments (with somewhat uneven platter walls) showed very little disurbance of the water, certainly none that would splash out of the gap or even break the surface. All very civilised really. Now if the gap were only 2-3 mm I might expect to see some wooshing (note good scientific term) effects as the small gap had that 0.5m/s shear effect across it.the crack around the outside of the platter can be only a few millimeters wide , depending on your taste for precision over KISS

For peace of mind (only), the top of the bath could have a little horizontal rim adjacent to the platter side, covering most of the gap. Or mount same on platter - if it didn't cause resonance.

Best just live dangerously and keep kidz/catz, fluff 'n stuff away from it!

Pete

peted,

congratulations 😛

I am very glad to hear that the unipivot&oil (albeit water) concept works!

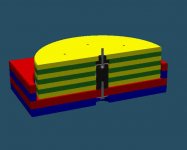

At the moment I am working on my own prototype. It will be a little more sophisticated than yours so it takes a little longer. Hope to have it running by the end of next week. Note that I say hope😉 . My platter will be 320mm dia 84mm thick and weigh about 10kg. it will be made as a sandwich of 7 sheets of 12mm Trespa. the base will by from plywood.

I plan an opening of 5mm around the platter. I have designed the bearing to be height adjustable ( in a very basic way) so I can experiment with bottom clearance.

The biggest difference with your concept is that I do not intend the platter to float at all. I will use the oil for damping only. Selflevelling is guaranteed because the bearing is above center of gravity.

The turbulation you noticed will be caused mainly by the irragularity of the surfaces I expect. Therefore I will try to get them as smooth as is possible for me.

Peter

congratulations 😛

I am very glad to hear that the unipivot&oil (albeit water) concept works!

At the moment I am working on my own prototype. It will be a little more sophisticated than yours so it takes a little longer. Hope to have it running by the end of next week. Note that I say hope😉 . My platter will be 320mm dia 84mm thick and weigh about 10kg. it will be made as a sandwich of 7 sheets of 12mm Trespa. the base will by from plywood.

I plan an opening of 5mm around the platter. I have designed the bearing to be height adjustable ( in a very basic way) so I can experiment with bottom clearance.

The biggest difference with your concept is that I do not intend the platter to float at all. I will use the oil for damping only. Selflevelling is guaranteed because the bearing is above center of gravity.

The turbulation you noticed will be caused mainly by the irragularity of the surfaces I expect. Therefore I will try to get them as smooth as is possible for me.

Peter

Attachments

Nice one Peterr!

What is Trespa (a cladding material - but from wood or what?).

Re floating Vs not floating, strictly I suppose it's not floating as there is still (maybe 15-20%) weight on the bearing. The bearing being above the C of G does ensure it hangs straight (if everything else is true too) - but I noticed that while my test platter hung a little squint in air (due to dimensional tolerances 😱 ), it immediately squared up beautifully with the water added. The dynamics when prodded around are of course completely different (i.e. miles better) with the fluid present.

The expectation and IHMO the major design point, is that the fluid will not just damp and stabilise the raw mechanical platter movement (wobble/tilt etc.) - which it appears to do very well, but will damp the platter at a sonic level too and provide a good coupling to the massive plinth. This of course remains to be proven. Cue next experiment...

Peterr:

Plea for help please:

I have a JH Labs Formula 4 (Aussi version of the U.K. built Mayware formula 4) unipivot arm destined for this TT if it happens. I'm still looking for ideas on a good matching cartridge - high compliance, probably MM or hi-o/p MC. Any ideas please and not too expensive. Do I see a new thread "Let's make a DIYAUDIO Cartridge" looming in the distance?

Good stuff..

Pete

What is Trespa (a cladding material - but from wood or what?).

Re floating Vs not floating, strictly I suppose it's not floating as there is still (maybe 15-20%) weight on the bearing. The bearing being above the C of G does ensure it hangs straight (if everything else is true too) - but I noticed that while my test platter hung a little squint in air (due to dimensional tolerances 😱 ), it immediately squared up beautifully with the water added. The dynamics when prodded around are of course completely different (i.e. miles better) with the fluid present.

The expectation and IHMO the major design point, is that the fluid will not just damp and stabilise the raw mechanical platter movement (wobble/tilt etc.) - which it appears to do very well, but will damp the platter at a sonic level too and provide a good coupling to the massive plinth. This of course remains to be proven. Cue next experiment...

Peterr:

I hope so - and that my findings have been useful too! My experiment was a proof of proof of concept 😉 Its role is over, the platter has been trashed and the clamped together lumps of timber for motor mount returned to the wood pile!It will be a little more sophisticated than yours so it takes a little longer

Plea for help please:

I have a JH Labs Formula 4 (Aussi version of the U.K. built Mayware formula 4) unipivot arm destined for this TT if it happens. I'm still looking for ideas on a good matching cartridge - high compliance, probably MM or hi-o/p MC. Any ideas please and not too expensive. Do I see a new thread "Let's make a DIYAUDIO Cartridge" looming in the distance?

Good stuff..

Pete

Peted,

Trespa is made from paper!. It consists of sheets of paper that are soaked in some kind of epoxy resin and then are pressed together with extreme force. Some info can be found here:

I work as designer at an Office and school furniture maker. We use it a lot as table tops.

Anyway I think it is the coupling that counts and fluids are very good at that. Sound travels much further in fluid than in air. (just think of those old war movies with submarines listening to each others smallest sounds).

Peter

Trespa is made from paper!. It consists of sheets of paper that are soaked in some kind of epoxy resin and then are pressed together with extreme force. Some info can be found here:

I work as designer at an Office and school furniture maker. We use it a lot as table tops.

Isn't damping contradictory to coupling? I would say that damping is similar to DEcoupling....but will damp the platter at a sonic level too and provide a good coupling to the massive plinth

Anyway I think it is the coupling that counts and fluids are very good at that. Sound travels much further in fluid than in air. (just think of those old war movies with submarines listening to each others smallest sounds).

Very!🙂I hope so - and that my findings have been useful too!

Peter

Variac,

Take your pick folks, any material with good self-greasing and dryfirction behaviour will do fine. Copper, bronze, brass, why not? Works, i tried it out.

PTFE: works forever, after intitial indenting no wear. POM/Delrin: harder than PTFE, almost as slippery, alsl works forever.

Forgetabout real hard and brittle stuff like tungsten carbide, ruby/saphhire, diamond etc. Works for a few hours. Then broken. ooooh !!! ($$$$ ... 😡§$%& !! 😡 )

Not because ruby is so hard.

Ruby calibration balls simply have the smallest sphericity deviation and the smoothest surface....

PTFE thrust plate + steel ball: 3 weeks.

PTFE thrust plate + ruby ball: forever

Peterr,

Gorgeous! dead platter, will work fine. You maybe consider to provide some cavities for a vacuum system? You v'e got enough space inside the platter; 0.5 or 1 litre will do fine. Maybe slots in the bottom and a bottom plate closing them?

you bet right, probably my typo.Dice meant thrust plate I'll bet.

Forgetaboutit! think about wear !! 🙁That's the piece that sits on top of the ball. It's stuck up the hole in the platter. Probably a disk of metal with a depression in it. It could be just the top of the hole in the platter if the platter was an appropriate material.

He has mentioned soft stuff I've heard metal is better. More experiments in the far future...

Take your pick folks, any material with good self-greasing and dryfirction behaviour will do fine. Copper, bronze, brass, why not? Works, i tried it out.

PTFE: works forever, after intitial indenting no wear. POM/Delrin: harder than PTFE, almost as slippery, alsl works forever.

Forgetabout real hard and brittle stuff like tungsten carbide, ruby/saphhire, diamond etc. Works for a few hours. Then broken. ooooh !!! ($$$$ ... 😡§$%& !! 😡 )

Take ruby, trust me. doesn't cost a fortune.A steel ball would work also instead of ruby-

Not because ruby is so hard.

Ruby calibration balls simply have the smallest sphericity deviation and the smoothest surface....

PTFE thrust plate + steel ball: 3 weeks.

PTFE thrust plate + ruby ball: forever

Peterr,

Gorgeous! dead platter, will work fine. You maybe consider to provide some cavities for a vacuum system? You v'e got enough space inside the platter; 0.5 or 1 litre will do fine. Maybe slots in the bottom and a bottom plate closing them?

A Bit Of History

Some now very old broadcast turntables used ebony wood as the thrust bearing and whale oil as the lubricant.

I have not seen an example but I understand that this can give a very low noise thrust bearing, especially probably with the ruby balls mentioned.

Ornamental ebony elephants are a source of ebony.

Eric.

Some now very old broadcast turntables used ebony wood as the thrust bearing and whale oil as the lubricant.

I have not seen an example but I understand that this can give a very low noise thrust bearing, especially probably with the ruby balls mentioned.

Ornamental ebony elephants are a source of ebony.

Eric.

Variacs latest drawing

From Mark's PC thru my Mac to you:

<a href="http://p10hifi.net/tlinespeakers/pivotTT.gif"><img src="http://p10hifi.net/tlinespeakers/pivotTT-s.gif"></a>

clik on image to get bigger drawing with text

dave

From Mark's PC thru my Mac to you:

<a href="http://p10hifi.net/tlinespeakers/pivotTT.gif"><img src="http://p10hifi.net/tlinespeakers/pivotTT-s.gif"></a>

clik on image to get bigger drawing with text

dave

Thank You Dave!!!!

What an imposition, but I appreciate you posting for me.

Everyone, please be aware that the arrow pointing to the fluid is pointing to the plinth instead. I guess I screwed up. The fluid is higher up!

Peterr s design might be almost the same- I can't make out details.

I DO like his record locating pin sticking up through the platter.

It could be the threaded part of a bolt inserted through the bottom of the platter so we could have a thread-on disk weight.

the head is below the platter and if it were a recessed socket hex

bolt, the recess would be facing down. We could epoxy the ball on that and then epoxy the thrust plate on top of the bigger bolt that I show coming up through the plinth.

I feel another drawing coming on.......

The reason I thought that a steel ball would work is I used to have a 25 year old Thorens pro TT with a steel ball on the end of a long rod extending through bushings in the plinth and resting on a thrust plate. I don't think that wouls ever wear out! It felt like new. I guess the thrust plate is an important factor. I assumed theirs was brass, but who knows. I trust Dices opinion of course, so am interested in the ruby cost. Has a good marketing sound!

Are ebony elephants endangered? 😉

Actuallly my local shop has ebony, but a chunk 50x50x40

What an imposition, but I appreciate you posting for me.

Everyone, please be aware that the arrow pointing to the fluid is pointing to the plinth instead. I guess I screwed up. The fluid is higher up!

Peterr s design might be almost the same- I can't make out details.

I DO like his record locating pin sticking up through the platter.

It could be the threaded part of a bolt inserted through the bottom of the platter so we could have a thread-on disk weight.

the head is below the platter and if it were a recessed socket hex

bolt, the recess would be facing down. We could epoxy the ball on that and then epoxy the thrust plate on top of the bigger bolt that I show coming up through the plinth.

I feel another drawing coming on.......

The reason I thought that a steel ball would work is I used to have a 25 year old Thorens pro TT with a steel ball on the end of a long rod extending through bushings in the plinth and resting on a thrust plate. I don't think that wouls ever wear out! It felt like new. I guess the thrust plate is an important factor. I assumed theirs was brass, but who knows. I trust Dices opinion of course, so am interested in the ruby cost. Has a good marketing sound!

Are ebony elephants endangered? 😉

Actuallly my local shop has ebony, but a chunk 50x50x40

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Let's make a DIYAUDIO TT