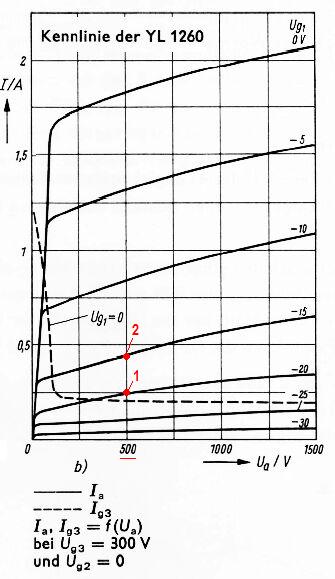

Another question is why is the highest grid voltage -5 volts on the curves?

Did they not have proper curve tracing for that?

Did they not have proper curve tracing for that?

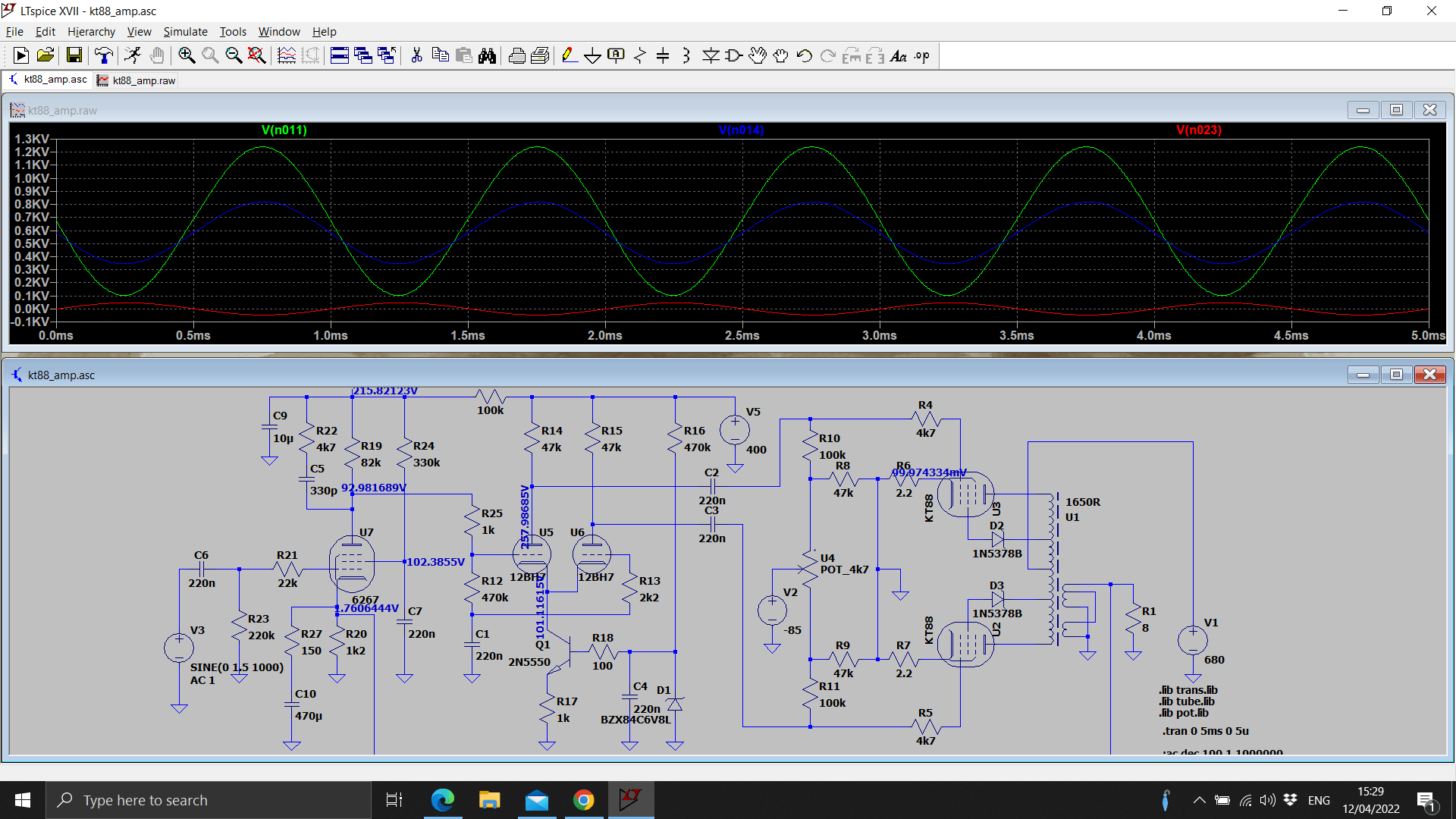

The 6GB5 works rather well in a UL simulation. I put a 100v zener to the screen from the UL taps to drop the voltage.

Hello , all)

I askes Tung-Sol and EH at their official websites about triode connection and curves at diagram, but no answer(

Why they dont have it?

I askes Tung-Sol and EH at their official websites about triode connection and curves at diagram, but no answer(

Why they dont have it?

I came to the conclusion 2xKT88 on each side of the PP would be a better option for all sorts of reasons.

Rather delayed reply, I know 🙄. Anyway, what happens when the plate voltage is pulled down below 100 volts in the relative half cycle? I'd be afraid of severe distortions.The 6GB5 works rather well in a UL simulation. I put a 100v zener to the screen from the UL taps to drop the voltage.

Best regards!

this KT170 borrowed heavily from the TV tube designs, so i will run the screens at much lower voltage and supply them from a low impedance voltage source just like any other tv tube...

UL with 100V zeners show that the principle is OK. The green is the plate, the blue the screen. The red is the output ~+/- 45V into 8R. You could use a cathode follower instead or a MOSFET and mix HT, plate and GND in the correct proportions to get a virtual UL tap.

Most are designed for HIGH impedance loads. You can do that with tuned circuits. Not so easy in iron-core audio transformers.use a large transmitting tube and be done with it?

Likewise many are scaled for class-C plate pulses and high narrow grid pulses.

The 6L6-6550 family are good audio tubes with ample output and moderate grid requirements. They ended up doing a lot of servo amplifiers and such; 6L6 is a capless 807 which was the common small ratio transmitter and even diathermy and radio-knife. I suspect development of these types was more random than the later histories suggest, but they did know audio had a market.

The 8417 is a 6550 size of a tube with extra easy grid drive. There was also a unique twin-pentode to drive it. Both were "invented" by Fisher asking tube makers what they could do to holistically lower distortion. Certainly a for-audio tube.

304TL is a wonderful output valve, but a serious commitment. The H&Ks and their descendant Eimacs with splattered-anode getters and giant heaters tend to have excellent curves, and are available and inexpensive, but need to be run with a red enough anode to keep them gettered. (This is after an initial gettering process, because their seals are older than most of us.) One unique advantage of the 304TL is that the two filament pairs are brought out separately, so can be connected (ideally) in opposite polarity across an AC supply to (ideally) cancel the signal modulation from AC heating. One disadvantage is that this AC supply is for 5VAC at 25 Amps - not trivial. Another is that they'd really like a kiloVolt and up B+ ,about like a 211 or 845. One 304TL bottle is very similar to three 211s in parallel, and runs very lightly loaded into 5K Ohms.

A sleeper from the H&K/Eimac family is the earlier 4E27/Gammatron 257B (also 5-125) connected as a triode. Restricted to 600VDC (maybe 700? at a stretch) and with a lower mu of 5-ish. Still needs red-plated anodes for gettering, and 5VAC heating at 15 Amps. Maybe an alternative to 845s, at a lower output impedance and excellent linearity into 5K Ohms, much lower than the 50-watters.

But there are good reasons why we're still using the 6L6/6550 family today. Any steps beyond them is a big step. 600VDC is a red line in the sand for lots of folks. Heater power requirements, etc.

All good fortune,

Chris

A sleeper from the H&K/Eimac family is the earlier 4E27/Gammatron 257B (also 5-125) connected as a triode. Restricted to 600VDC (maybe 700? at a stretch) and with a lower mu of 5-ish. Still needs red-plated anodes for gettering, and 5VAC heating at 15 Amps. Maybe an alternative to 845s, at a lower output impedance and excellent linearity into 5K Ohms, much lower than the 50-watters.

But there are good reasons why we're still using the 6L6/6550 family today. Any steps beyond them is a big step. 600VDC is a red line in the sand for lots of folks. Heater power requirements, etc.

All good fortune,

Chris

https://frank.pocnet.net/sheets/030/q/QE08-200.pdf

100 Watt, 600V Beam tetrode

may not be that many around though

100 Watt, 600V Beam tetrode

may not be that many around though

Last edited:

Very, very nice!! Why can't we get production of tubes like this?

YL1260 plate curves (courtesy of Wolfgang Holtmann at: YL 1260, Tube YL1260; Rohre YL 1260 ID20456, HEXODE )

Looks like the knees might be down around 100V where it could still be used with like 600V B+. Quite linear curve spacing for the top curves. I'll bet it has great triode curves too.

That QE08/200 had high V plate knees, not as nice.

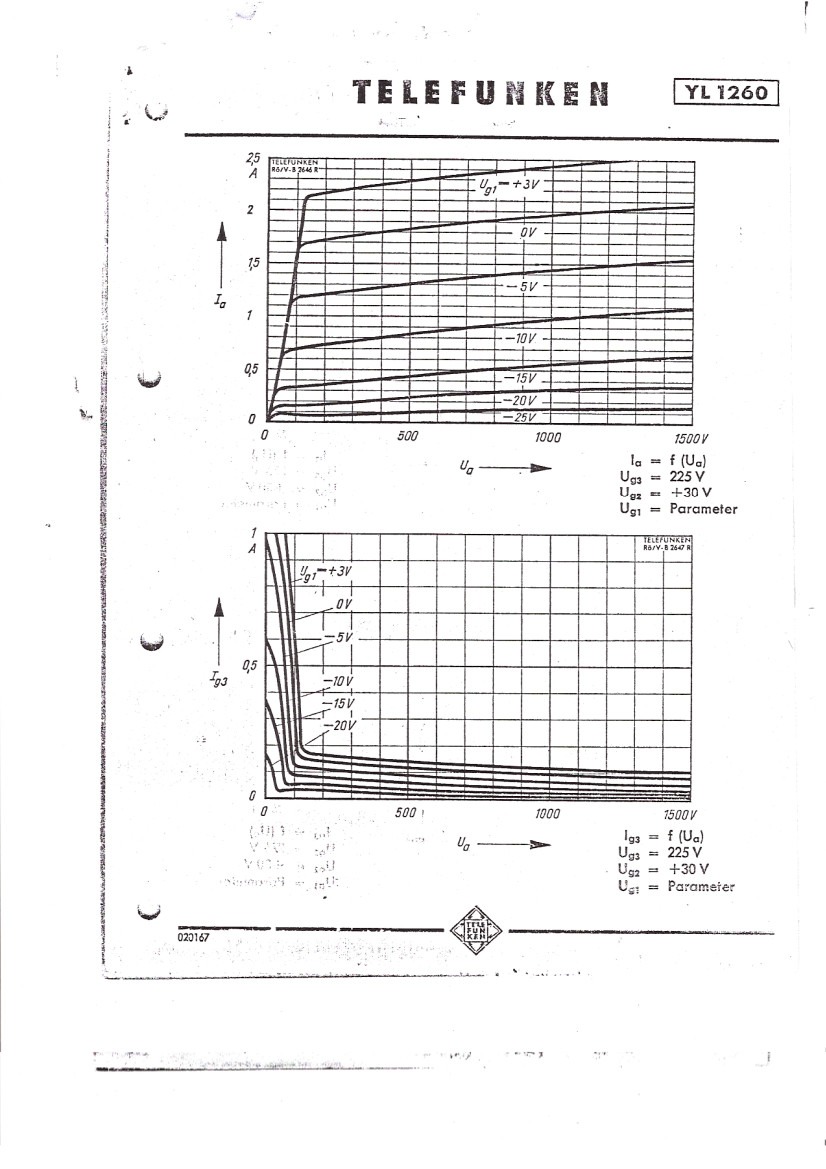

another curve set, courtesy of Davorin:

YL1260 plate curves (courtesy of Wolfgang Holtmann at: YL 1260, Tube YL1260; Rohre YL 1260 ID20456, HEXODE )

Looks like the knees might be down around 100V where it could still be used with like 600V B+. Quite linear curve spacing for the top curves. I'll bet it has great triode curves too.

That QE08/200 had high V plate knees, not as nice.

another curve set, courtesy of Davorin:

Last edited:

https://frank.pocnet.net/sheets/030/q/QE08-200.pdf

100 Watt, 600V Beam tetrode

may not be that many around though

View attachment 1044144

a pair will do 300 watts at 750 volts plate......

Transmitting tubes require a lot of shoehorning to work in audio service. Their biggest issue is that most of them require approximately 1.2 @$$loads of air blown past their seals every second. Even the 304TL should be forced-air cooled with a blower and chimney. I'm not aware of any way to make such an amp quiet. Running without air, or with air from a lazy computer fan, is a good way to kill the tubes.

811A and 572Bs might be good ones to look into, since they don't require forced-air cooling and are readily available for use in linear amplifiers, and they'll run well at a "reasonable" B+ in the 1200 V range. Might have to do some shoehorning to make them behave linearly in an audio application (it's been a while since I looked at their plate curves), but I'm sure it could be done.

Honestly though, the big limitation in any big tube amp is trying to come up with a good 300 W output transformer. That's a serious chunk of iron and not and easy one to wind.

811A and 572Bs might be good ones to look into, since they don't require forced-air cooling and are readily available for use in linear amplifiers, and they'll run well at a "reasonable" B+ in the 1200 V range. Might have to do some shoehorning to make them behave linearly in an audio application (it's been a while since I looked at their plate curves), but I'm sure it could be done.

Honestly though, the big limitation in any big tube amp is trying to come up with a good 300 W output transformer. That's a serious chunk of iron and not and easy one to wind.

- Home

- Amplifiers

- Tubes / Valves

- KT170