In a machine...

Don't know what it called in English..

It's a very simple machine, were you bend metal.

But it's not a machine that you have at home I guess...

Guess most metalworkshops have one, and it takes 5 minutes to make all bendning.

Don't know what it called in English..

It's a very simple machine, were you bend metal.

But it's not a machine that you have at home I guess...

Guess most metalworkshops have one, and it takes 5 minutes to make all bendning.

Ok. Thanks.

I would call it a metal press here but that may not be right.

And for sure that is not something I have in my shop... Maybe for Christmas I'll get myself one.. NOT!

Maybe for Christmas I'll get myself one.. NOT!

I would call it a metal press here but that may not be right.

And for sure that is not something I have in my shop...

Maybe for Christmas I'll get myself one.. NOT!

Maybe for Christmas I'll get myself one.. NOT!

Fix said:In a machine...

Don't know what it called in English..

It's a very simple machine, were you bend metal.

But it's not a machine that you have at home I guess...

Guess most metalworkshops have one, and it takes 5 minutes to make all bendning.

A brake.

troystg said:How did you bend that metal so pretty?...

How do you post so many pretty pictures at once without breaking the "download limit" bank?

Nice job, with your "folder" or "press brake"

Brian

Pingrs said:"folder" or "press brake"

Guess it could have been a fly press and vee tool. That's what I use for smaller stuff.

Brian

I opened an account at www.flickr.com and upload my pictures there.

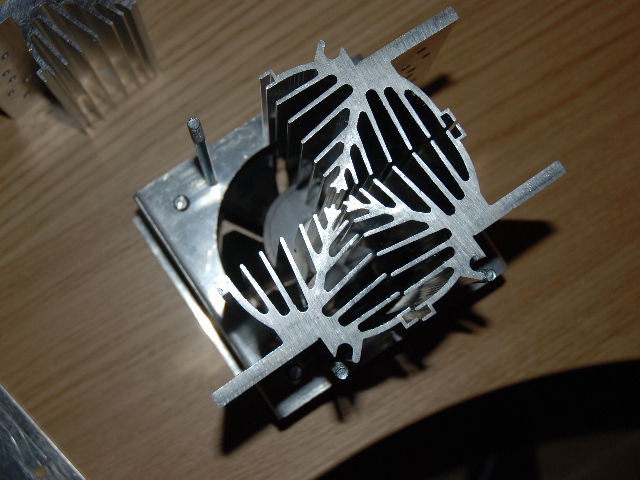

All parts used is in 3mm aluminium.

Big hole done with a holesaw 108mm

Everything drilled in a floormounted drill machine (don't know whats it called in English...)

I havn't tested the amp yet, just made a test run to make sure everything works.

Soon as I mount 120mm fans, and have a working powersupply I can test it for real.

For the moment I'm working on the small pcb for powerrelay and speaker relay.

All parts used is in 3mm aluminium.

Big hole done with a holesaw 108mm

Everything drilled in a floormounted drill machine (don't know whats it called in English...)

I havn't tested the amp yet, just made a test run to make sure everything works.

Soon as I mount 120mm fans, and have a working powersupply I can test it for real.

For the moment I'm working on the small pcb for powerrelay and speaker relay.

Hey Fix, nice work! Can't wait to see the finished amp.

Looks like you got my heatsinks!! Are you the one who bought my extra set?

Yours-

Mine-

I see that you connected the ends together with a panel and screws and have isolated the transistors from the metal sinks with a mica insulator.

Did you know that these sinks are designed to connect firmly with an insulated [phenolic(?)] bar placed in the square cut-outs and an insulated rod as shown?

I see that you have wisely insulated each transistor with a mica washer whereas I bravely have 'live' and charged up heat sinks.

You are smarter! I only touched it once so far with a screwdriver.... nice spark.

You have a KSA 100? Mine is a KSA-50 and it gets to 60 C quite rapidly. Your sinks are 1/2 the size of mine and my guess is that they will burn up without a fast fan speed (I have a fan below blowing up and a fan above blowing up).

And why the Coca-Cola in #2274? Where is the beer?

But serioulsy, nice job, this was a lot of effort and I hope you enjoy it in the end.

Fix = Reach The Beach, at least to me (from the '80s)

Looks like you got my heatsinks!! Are you the one who bought my extra set?

Yours-

Fix said:OK... more pictures...

***

Moving forward... next week both cooling towers will be ready..

Mine-

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I see that you connected the ends together with a panel and screws and have isolated the transistors from the metal sinks with a mica insulator.

Did you know that these sinks are designed to connect firmly with an insulated [phenolic(?)] bar placed in the square cut-outs and an insulated rod as shown?

I see that you have wisely insulated each transistor with a mica washer whereas I bravely have 'live' and charged up heat sinks.

You are smarter! I only touched it once so far with a screwdriver.... nice spark.

You have a KSA 100? Mine is a KSA-50 and it gets to 60 C quite rapidly. Your sinks are 1/2 the size of mine and my guess is that they will burn up without a fast fan speed (I have a fan below blowing up and a fan above blowing up).

And why the Coca-Cola in #2274? Where is the beer?

But serioulsy, nice job, this was a lot of effort and I hope you enjoy it in the end.

Fix = Reach The Beach, at least to me (from the '80s)

guys, you've got a nice looking nuclear reactor out there !

I hope to populate my boards soon.

I hope to populate my boards soon.

Some more pictures...

Soon ready to assemble the cooling tower, just mounted PCB to make sure that everything fits.

Bought some 14 & 16AWG wires to hook everything, will try to complete it next week.

Guess it's pretty close to the original.

How many would be interested in a DIY-Kit where you get pre-drilled heatsinks, 8 pcbs, pre-drilled/bent aluminium and rest of the parts needed to complete a cooling tower.

Price, more people less price..

For the moment just want to know if there is any intrest.

Soon ready to assemble the cooling tower, just mounted PCB to make sure that everything fits.

Bought some 14 & 16AWG wires to hook everything, will try to complete it next week.

Guess it's pretty close to the original.

How many would be interested in a DIY-Kit where you get pre-drilled heatsinks, 8 pcbs, pre-drilled/bent aluminium and rest of the parts needed to complete a cooling tower.

Price, more people less price..

For the moment just want to know if there is any intrest.

Nice to see that there is little intrest in a Heatsink/PCB DIY-Kit.

Soon as I'm ready with my amp, and everything works as expected I'll decide about the kits.

I've ordered some PCB cards from a manufacter, guess they will arrive next 2-3 weeks. Output relay pcb and Powercontrol relay pcb.

Also everything is ready to make the kits quite easy.

Most of my metalwork is now done, just need to drill some holes in the chassi for speakers,line in and powerswitch.

Also done with mounting my trafos, used a L-Shape Aluminium so I could have the trafos standing up and saving space.

If lucky I can test the amp next 1-2 weeks...

Soon as all metalwork is done, I'll start with the cables...

The chassi is from Italy, Pessante with no heatsinks.

Hifi2000, I've posted link before.

Soon as I'm ready with my amp, and everything works as expected I'll decide about the kits.

I've ordered some PCB cards from a manufacter, guess they will arrive next 2-3 weeks. Output relay pcb and Powercontrol relay pcb.

Also everything is ready to make the kits quite easy.

Most of my metalwork is now done, just need to drill some holes in the chassi for speakers,line in and powerswitch.

Also done with mounting my trafos, used a L-Shape Aluminium so I could have the trafos standing up and saving space.

If lucky I can test the amp next 1-2 weeks...

Soon as all metalwork is done, I'll start with the cables...

The chassi is from Italy, Pessante with no heatsinks.

Hifi2000, I've posted link before.

- Home

- Amplifiers

- Solid State

- Krell KSA 100mkII Clone