I think Karlsons will stay a curiosity. The sound is interesting, in the same way as Greebsters history lesson.

Can always paint it with liquid plastic like polyester. I will probably do that on my Sonotube subwoofer. Thanks for mentioning it!

I cross my k tube at 3500 Hz. I have much better horns and drivers below that.

you will have to turn your head I cannot make the picture rotate. Tube at ear level three sided equal sided triangle stage and image are excellent. Best regards Moray James.

________

image fixed.

image fixed.Attachments

Last edited by a moderator:

one of my tubes in a bedroom - not the best highpass filter - the other horn/driver was a Speakerlab wide-angle version of an EV T35 - there's no offset in the graph so that K-tube was ~10dB louder

input impedance of Transylvania Power's "The Tube" with a DE250 - the other Z is a homemade 1"ID pvc K-tube 5.3" long with a 2.5" extension. Both IG and myself have seen that little extension create a narrow notch

IG's tube with 3 different drivers - not sure of the perspective - looks like he may have had the tube tilted 30 degrees from horizontal

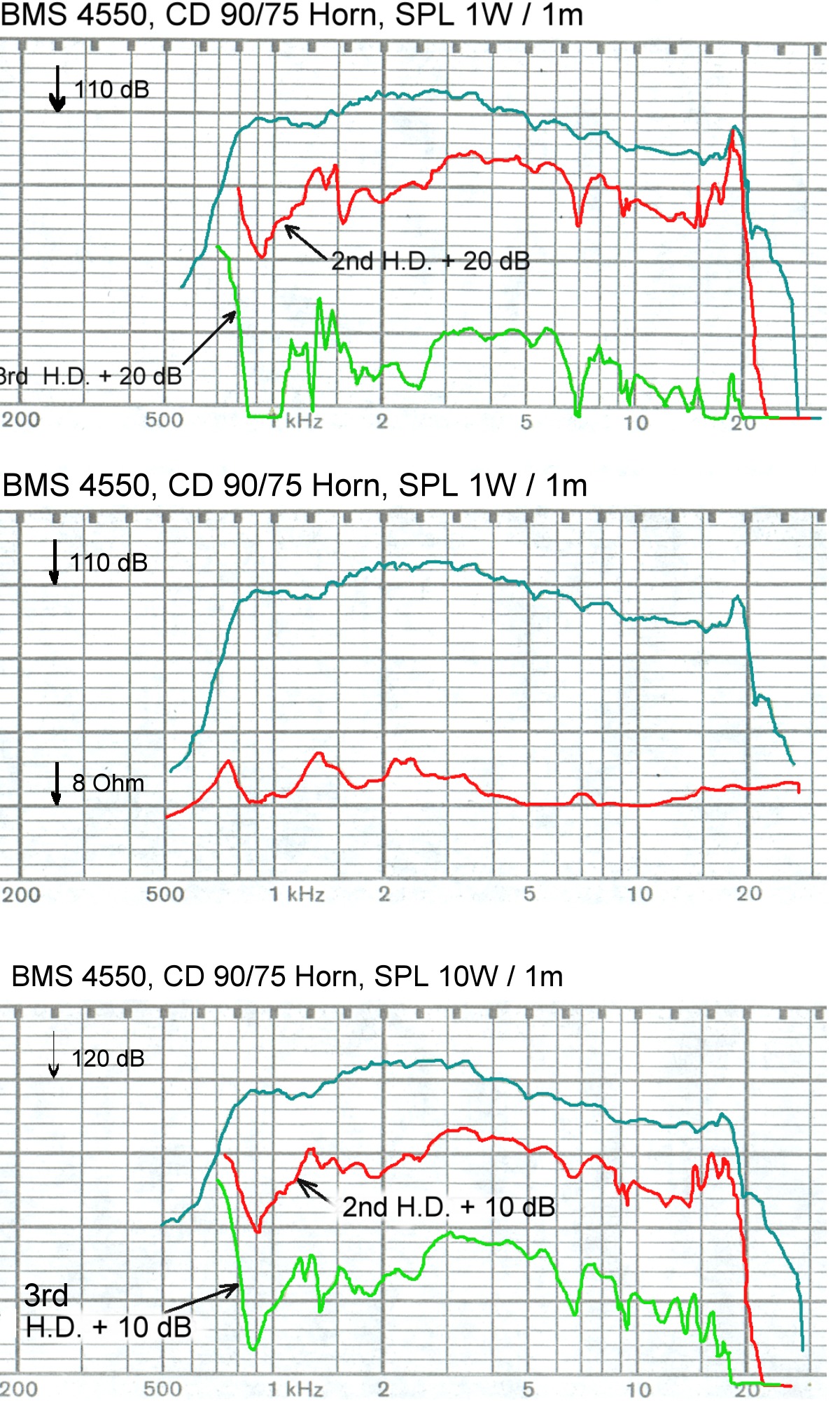

Blue = BMS 4550 - Green = P-Audio BMD440 - Red = Selenium D220Ti

An externally hosted image should be here but it was not working when we last tested it.

input impedance of Transylvania Power's "The Tube" with a DE250 - the other Z is a homemade 1"ID pvc K-tube 5.3" long with a 2.5" extension. Both IG and myself have seen that little extension create a narrow notch

An externally hosted image should be here but it was not working when we last tested it.

IG's tube with 3 different drivers - not sure of the perspective - looks like he may have had the tube tilted 30 degrees from horizontal

Blue = BMS 4550 - Green = P-Audio BMD440 - Red = Selenium D220Ti

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

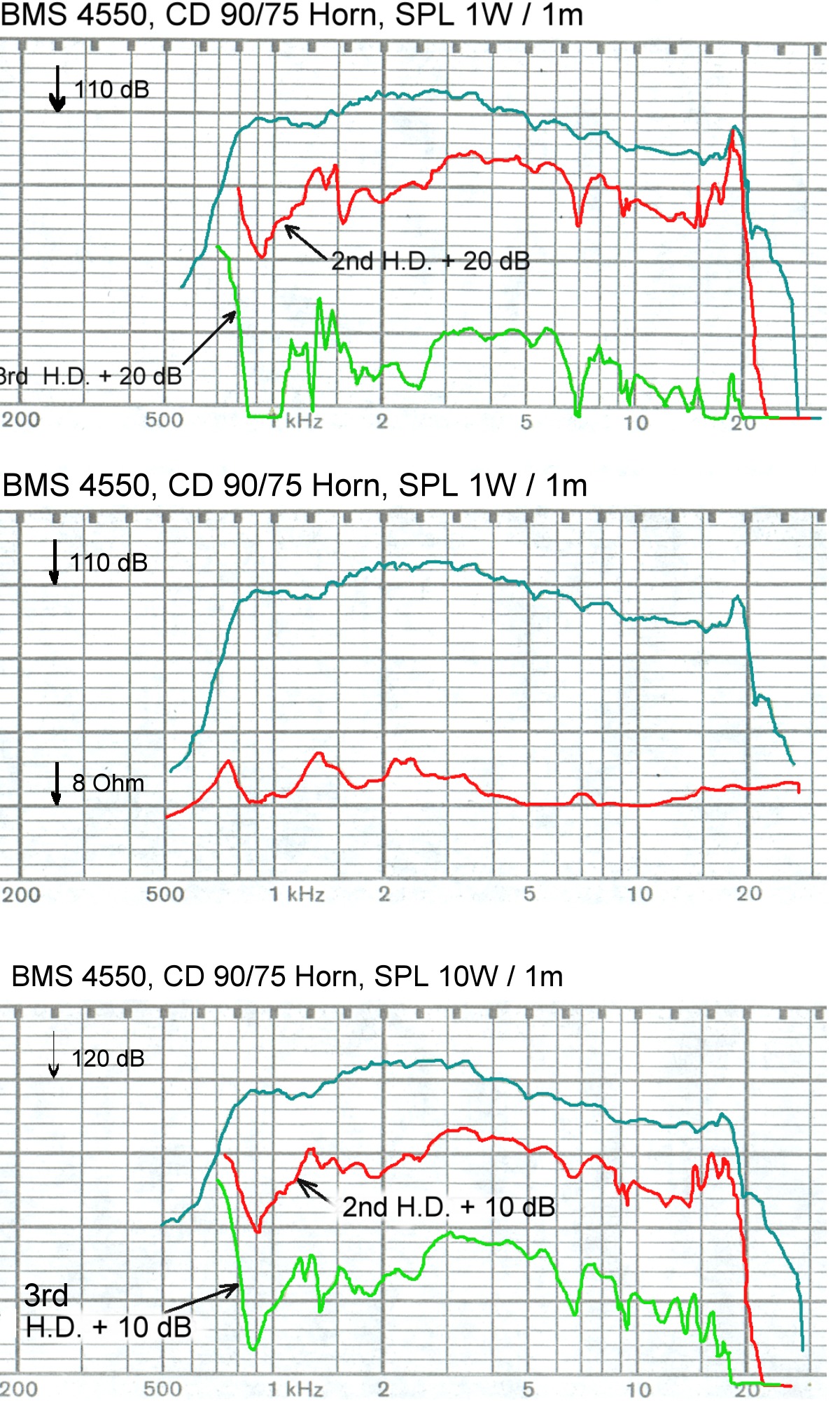

The BMS 4550 driver and the K-tube looks like a great combo. What is the efficiency compared to a traditional horn? The 4550 is a 117 dB driver, are we getting close to that efficiency with the K tube or is there a loss compared to say an conical or tractrix horn?

The DT220Ti isn't bad either at 109 dB and a lot less expensive. I am looking for a good match for the mother of all Karlsonators that I am working on in the Slay the Pendragon thread.

The DT220Ti isn't bad either at 109 dB and a lot less expensive. I am looking for a good match for the mother of all Karlsonators that I am working on in the Slay the Pendragon thread.

Looks like it kills the low frequency extension compared to the standard application for that CD

I knew it did that by how small it is, but it could work with the Beta 10CX and the 2.5 kHz crossover. The wide directivity is the key thing, does anyone have polar plots of the K tube? I made polar directivity measurements of my mini Karlsonator and it was a real pain but glad I did to prove to myself that my ears were not making it up that it was as wide as I thought it was.

Its loud enough to keep up with a JBL 4638 2-15" 2035H reflex and 20dB louder than 2.5" Peerless type cone tweeter - I had a graph - but images$$t has lost maybe 20% of my uploads = not good for a paid service - the tubes sound very natural - open - smooth - require no EQ in the highpass filter - their high vertical pattern makes them a natural to mesh with Karlson midbass -couplers

Last edited:

one of my 4638 back behind these two K's - - - IG made the beautiful brass K-tube perched upon a K10 size couipler loaded w. Delta 10A

An externally hosted image should be here but it was not working when we last tested it.

Sorry for the novice question, but what's the best way to cut the exponential shape? I'm just trying with paper for now.

I have the Pyle PDS521, and so far I'm not sure what I'm meant to be listening for 🙂 There's an increase in sensitivity around 2kHz, but other than that I don't hear much difference compared to the driver when it's unloaded.

The shape I cut may have been a damaging factor there.

I have the Pyle PDS521, and so far I'm not sure what I'm meant to be listening for 🙂 There's an increase in sensitivity around 2kHz, but other than that I don't hear much difference compared to the driver when it's unloaded.

The shape I cut may have been a damaging factor there.

Ok. Also from what I've been reading, I need to make the diameter of the tube smaller, as it's 1.375 inches at the moment (I just wrapped the paper around the compression driver's thread).

I also cut the shape into the tube by flattening it, and then cutting the curve with scissors. Is that the correct way to do it?

How is it done with a PVC pipe? I have a bandsaw that I could cut the profile, but I've seen that people use Dremel tools to do the same thing. I suppose what I'm trying to understand is how the exponential aperture 'maps' onto the face of a pipe.

I also cut the shape into the tube by flattening it, and then cutting the curve with scissors. Is that the correct way to do it?

How is it done with a PVC pipe? I have a bandsaw that I could cut the profile, but I've seen that people use Dremel tools to do the same thing. I suppose what I'm trying to understand is how the exponential aperture 'maps' onto the face of a pipe.

I used a 4in. cutoff wheel on an electric hand drill, and grinding wheel. I sent a picture to freddyi. he was concerned that they were not perfect. I was using 1016 goldwood piezo glued on to the end. they worked well. I still listen to them every day.

Thanks walters. How did you map the exponential curve onto the pipe? Is the curve just printed out on a piece of paper and then wrapped around it, or while the pipe is being cut, does the cutter follow the exponential path? I'd imaging the different approaches give a slightly different aperture shape.

I do have that paper stencil somewhere, I did it by eye. but it is packed away and I cant find it.

ig on this forum has a couple originals from Transylvania co. I think the stencil was by snkby. I do not know what happened to the fullrange driver forum. it probably went the way of karlson loudspeaker discussion. im sure some members will be here soon to help.

ig on this forum has a couple originals from Transylvania co. I think the stencil was by snkby. I do not know what happened to the fullrange driver forum. it probably went the way of karlson loudspeaker discussion. im sure some members will be here soon to help.

John Karlson's Waveguide - Forgotten technology for high quality tweeter application - YouTube heres original. a lot of karlson info is on you tube. this will give you a better idea. search

K-Tube Template for 28mm OD pipe

I made a printable K-Tube template for UK 28mm OD pipe (common for UK/EU copper and polymer plumbing pipe). Thought it might be useful for some forum members so I've attached the PDF below.

I'm part-way through a 3-way TL enclosure build which has them piercing the front baffle. I like the sound, but further work is needed on the crossover. Please note, the stub is shorter in the pictured tubes than the template as they're being mounted in a rebated bezel.

I made a printable K-Tube template for UK 28mm OD pipe (common for UK/EU copper and polymer plumbing pipe). Thought it might be useful for some forum members so I've attached the PDF below.

I'm part-way through a 3-way TL enclosure build which has them piercing the front baffle. I like the sound, but further work is needed on the crossover. Please note, the stub is shorter in the pictured tubes than the template as they're being mounted in a rebated bezel.

Attachments

k-tube ID...

K-Tube ID should be identical to the exit ID of your driver or else you are going to get all manner of reflections. This is by the way the same truth for horns though it is often ignored by companies who well know better. I prefer the double cutaway tube I position it at seated ear height parallel to the floor solid sections of the tube in the horizontal plain (facing to the left and to the right). I prefer my K-tubes to any of my horns.

Ok. Also from what I've been reading, I need to make the diameter of the tube smaller, as it's 1.375 inches at the moment (I just wrapped the paper around the compression driver's thread).

I also cut the shape into the tube by flattening it, and then cutting the curve with scissors. Is that the correct way to do it?

How is it done with a PVC pipe? I have a bandsaw that I could cut the profile, but I've seen that people use Dremel tools to do the same thing. I suppose what I'm trying to understand is how the exponential aperture 'maps' onto the face of a pipe.

K-Tube ID should be identical to the exit ID of your driver or else you are going to get all manner of reflections. This is by the way the same truth for horns though it is often ignored by companies who well know better. I prefer the double cutaway tube I position it at seated ear height parallel to the floor solid sections of the tube in the horizontal plain (facing to the left and to the right). I prefer my K-tubes to any of my horns.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Karlson tube HF waveguides - how many have tried them?