john curl said:Jan, you have been blindsided. I worked with B&K, decades ago on this problem. Schoeps is a compromiser, when it comes to SOTA. I know this from real contact, and schematics.

[snip]

How can they be a compromiser, if their preamp/buffer noise is lower than the intrinsic diaphragm noise? Are you not barking up the wrong tree, for the last 35 years or so?

Jan Didden

Jan, everything is a compromise, it just depends on how much you allow. IF you want to believe in your friend, completely, go for it. However, there is more to the spectrum than just the midrange noise.

This reminds me of when I was working on the next generation of mag recording electronics back in 1968. I was laughed at by my associates, because my 'incremental' improvements by using better reproduce heads, fets, and higher frequency bias, were considered not worthwhile, (level 2). Of course, 5 years later, they 'invented' them (level 3), and used them in the next generation of tape electronics.

This reminds me of when I was working on the next generation of mag recording electronics back in 1968. I was laughed at by my associates, because my 'incremental' improvements by using better reproduce heads, fets, and higher frequency bias, were considered not worthwhile, (level 2). Of course, 5 years later, they 'invented' them (level 3), and used them in the next generation of tape electronics.

I had an opposite experience, John. 😎

I had to work as a lead engineer in support of railway communications and electronics.

There was such a system among others I supported that had posts 5 kilometers each side from a station. Posts measured temperatures of bearing boxes and when overheated transmitted a message on a station so maintenance will be made immediately.

Missing my previous design freedom, I was bored by doing inspections, meetings, material reports, supervising, and other related to technical support stuff...

I decided to improve things, first of all a technician had to come to the post regularly checking pulsations of power supplies by a scope, and when they are out of specs send the PS for a maintenance. Sometimes they would be waked up because of errors caused by ripples.

So, I redesigned one PS rerouting wires, that dropped down pulsations significantly.

Then, we started getting reports that one oscillator won't start, and it is needed to take off then put on the PCB, sometimes several times, before it starts oscillating. Also, this oscillator had frequency drift, so needed to be checked periodically by a frequency counter, and when out of specs it had to be sent for a maintenance.

So, I redesigned the oscillator using pair of opamps instead of pair of transistors it used. The frequency became stable like a rock: I put a thermo-compensated Zener on the "compensation" pin of the opamp that was used as a comparator (it was a VAS output pin). Also, could be no starting problems.

However, I got some premiums for this improvements (each time about $15 dollars per improvement); my designs were studied in the central laboratory of railways, but...

...but later I had a tough talk with my boss who demanded to remove my improved blocks out of service and to forget about that!

Why?

Because technician no longer needed to come and check the equipment so frequently. Coming to check PS ripples and oscillator frequencies when waked up during the night because of errors they were obliged each time to calibrate germanium bolometers that sensed infra-red radiation from bearing boxes. A laboratory train with an electric oven element on a bearing box passed that station, but was not stopped for the maintenance. The technician who supported the equipment was vary busy on his private garden, because there were no so many things to worry about anymore... 😎

I had to work as a lead engineer in support of railway communications and electronics.

There was such a system among others I supported that had posts 5 kilometers each side from a station. Posts measured temperatures of bearing boxes and when overheated transmitted a message on a station so maintenance will be made immediately.

Missing my previous design freedom, I was bored by doing inspections, meetings, material reports, supervising, and other related to technical support stuff...

I decided to improve things, first of all a technician had to come to the post regularly checking pulsations of power supplies by a scope, and when they are out of specs send the PS for a maintenance. Sometimes they would be waked up because of errors caused by ripples.

So, I redesigned one PS rerouting wires, that dropped down pulsations significantly.

Then, we started getting reports that one oscillator won't start, and it is needed to take off then put on the PCB, sometimes several times, before it starts oscillating. Also, this oscillator had frequency drift, so needed to be checked periodically by a frequency counter, and when out of specs it had to be sent for a maintenance.

So, I redesigned the oscillator using pair of opamps instead of pair of transistors it used. The frequency became stable like a rock: I put a thermo-compensated Zener on the "compensation" pin of the opamp that was used as a comparator (it was a VAS output pin). Also, could be no starting problems.

However, I got some premiums for this improvements (each time about $15 dollars per improvement); my designs were studied in the central laboratory of railways, but...

...but later I had a tough talk with my boss who demanded to remove my improved blocks out of service and to forget about that!

Why?

Because technician no longer needed to come and check the equipment so frequently. Coming to check PS ripples and oscillator frequencies when waked up during the night because of errors they were obliged each time to calibrate germanium bolometers that sensed infra-red radiation from bearing boxes. A laboratory train with an electric oven element on a bearing box passed that station, but was not stopped for the maintenance. The technician who supported the equipment was vary busy on his private garden, because there were no so many things to worry about anymore... 😎

The distortion (I posted actual measurements a few weeks ago) can be trimmed to a -90dB null by simple bias adjustment on the JFET and this trim absorbs all the sources of seconds.

Scott, are you talking about this trim? Have I missed something?

Attachments

john curl said:Jan, everything is a compromise, it just depends on how much you allow. IF you want to believe in your friend, completely, go for it. However, there is more to the spectrum than just the midrange noise. [snip]

You appear to miss my point, and somehow I don't think it is by accident.

This person is not my friend. This person makes money by making better and better mikes, with noise levels approaching 6dBA.

He does not spend research money on lower noise preamps/buffers because it doesn't lower the mike noise. You doggedly continue to try to persuate us to put low-noise efforts in something that doesn't lower the mike noise.

That doesn't strike me as particular smart.

But mayby you just do it for fun. That's OK also.

Jan Didden

Here is one more story: now, of a good work that could lead me to a jail...

A boss of one autobus park wanted to show how well he manages his collectivity, how good is discipline, and how happy they are.

He hired me to design and build the best sounding equipment for his rock band, and to design and build the system to monitor autobus traffic.

However, he had no such position, but he had a vacant one, of a technician for electric speedometers. The job was creative and interesting, salary was very good.

I started working on my projects, but according to position that I occupied I had time to time put on a dirty robe to check and fix speedometers. To simplify the task, I made a device of a small battery powered TV: I put coils from a speedometer on tube's neck, so could see how well the sensor produces 3-phase signals when the bus moves.

Also, I made a 3-phase oscillator with a knob graduated in kilometers per hour. I could check a sensor on the screen; I could check a speedometer feeding it from an oscillator.

Suddenly drivers started approaching me asking for a "wondertool" so they check their speedometers while I am busy soldering my electronic toys. I suspected nothing, until the boss called me and explained that according to his information some drivers started running away from their assigned paths, made illegal money on private charters, and to show "the work" they used my tool to adjust odometers in garage... They were not doing their job, were using buses for own illegal business, they were stealing gas, so If I don't stop giving them my "wondertool" I can go to jail, since I am warned!

Good work, but bad result...

A boss of one autobus park wanted to show how well he manages his collectivity, how good is discipline, and how happy they are.

He hired me to design and build the best sounding equipment for his rock band, and to design and build the system to monitor autobus traffic.

However, he had no such position, but he had a vacant one, of a technician for electric speedometers. The job was creative and interesting, salary was very good.

I started working on my projects, but according to position that I occupied I had time to time put on a dirty robe to check and fix speedometers. To simplify the task, I made a device of a small battery powered TV: I put coils from a speedometer on tube's neck, so could see how well the sensor produces 3-phase signals when the bus moves.

Also, I made a 3-phase oscillator with a knob graduated in kilometers per hour. I could check a sensor on the screen; I could check a speedometer feeding it from an oscillator.

Suddenly drivers started approaching me asking for a "wondertool" so they check their speedometers while I am busy soldering my electronic toys. I suspected nothing, until the boss called me and explained that according to his information some drivers started running away from their assigned paths, made illegal money on private charters, and to show "the work" they used my tool to adjust odometers in garage... They were not doing their job, were using buses for own illegal business, they were stealing gas, so If I don't stop giving them my "wondertool" I can go to jail, since I am warned!

Good work, but bad result...

Jan, PLEASE don't try to guess my intentions, here. I just presumed that he was a friend of yours, because you believed him so thoroughly. He is right, in his way, but he is compromising, nevertheless.

Let me give a parallel to everyone:

Back in 1962 or so, AMPEX had a Danish designer, Erling Skov, design a vacuum tube reproduce stage that is STILL one of the quietest in the industry, even today! This was put into the MR-70, master recorder, still a wonder, among tape recorders.

Later, my former boss, designed the AG 440 reproduce stage. It was solid state and NOT as quiet as the MR-70 reproduce stage, made years before. Why? Could it be that it was a cost effective, compromised design? We used to call them 'noisy' 440's and for good reason.

Still, the AG 440 was not a bad design, compared to some, just a commercial tradeoff. When I tried to IMPROVE the 440 reproduce stage, I got all kinds of static, just like I said before. In return, I transfered over to the research department, but I left a paper behind that I might publish here sometime, that will show that I gave them the input they needed. And years later, they used the ideas in the paper.

Let me give a parallel to everyone:

Back in 1962 or so, AMPEX had a Danish designer, Erling Skov, design a vacuum tube reproduce stage that is STILL one of the quietest in the industry, even today! This was put into the MR-70, master recorder, still a wonder, among tape recorders.

Later, my former boss, designed the AG 440 reproduce stage. It was solid state and NOT as quiet as the MR-70 reproduce stage, made years before. Why? Could it be that it was a cost effective, compromised design? We used to call them 'noisy' 440's and for good reason.

Still, the AG 440 was not a bad design, compared to some, just a commercial tradeoff. When I tried to IMPROVE the 440 reproduce stage, I got all kinds of static, just like I said before. In return, I transfered over to the research department, but I left a paper behind that I might publish here sometime, that will show that I gave them the input they needed. And years later, they used the ideas in the paper.

i attended an illinois audio group meeting some years ago in which the late bob crump brought in a blowtorch.

as the young folks say, it was all that and a big bag of chips.

🙂

mlloyd1

as the young folks say, it was all that and a big bag of chips.

🙂

mlloyd1

Ray Chuck said:Has anyone actually seen or heard one of these blowtorch pre-amps ??

How do we know it's any good apart from the claims made by its designer ??

dimitri said:

Scott, are you talking about this trim? Have I missed something?

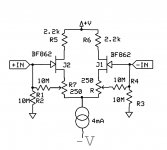

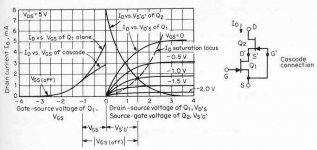

Sorry Dimitri there was another one that did the same thing with one cascoded JFET as a source follower. The seconds can be trimmed by adjusting the DC bias current. I used a 2SK170 cascoded with a J305 and 2.2K source resistor.

Scott, can you remember about what month? I looked but I could not find it. I think that this is important.

this one

mlloyd1

edit - sorry wrong one i think! 😱

i think this is the one

mlloyd1

edit - sorry wrong one i think! 😱

i think this is the one

john curl said:Scott, can you remember about what month? I looked but I could not find it. I think that this is important.

john curl said:Scott, can you remember about what month? I looked but I could not find it. I think that this is important.

http://www.diyaudio.com/forums/showthread.php?postid=1659420#post1659420

mlloyd1 said:

This one is really nice, it is what I personally prefer: bootstrapped device loaded on a counter-modulated current source. Why such outputs are not used in audio ICs?

dimitri said:Scott, so with variable resistor you adjusted the position of operating point?

This is not a cascode, Dimitri. This is a bootstrapped source follower.

The resistor is not shown, it trims voltage to current converter that works counter-phase with this follower.

john curl said:Not a thing for you, Ray.

It sounds like vapour ware so it's not for anybody John 😀

John;

While Scott is out, can you please share with us your experience with synchronous rectification?

While Scott is out, can you please share with us your experience with synchronous rectification?

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- John Curl's Blowtorch preamplifier