Boy, you like living on the edge. I could just see myself breaking out the code book to explain to a residential inspector article 392. I would prefer to just do it such that he is comfortable with what he sees and expects to see. I assume you used aluminum. Did you use the #14 jumpers tray to tray? At work, we ran a #2 stranded bare copper along every tray, used clamps for all the bonds.

jn

I only had #8 uninsulated on hand to bond the tray, so that is what I used. It is not open ladder style but solid pan with drain holes in case of water, so it meets the intent of a protective running board.

To keep the electrical inspector happy I gave him a submittal having all the products used with data sheets and applicable code sections. Only time I have had a problem with an inspector I was a subcontractor and did not do that. Inspector was silly wrong of course, but changing things to his ideas were not unsafe, cheap and kept work on schedule. Later the problem guy had a new boss a friend who knew about the issue.

BTY I usually warn the novices not to test for AC with their tongues. But no warning for you, maybe Max.

I have a Hallicrafters S-38 shortwave radio (basically an All-American 5 with shortwave additions, it's a project I haven't gotten around to fixing). It has an inner hot chassis in an outer metal chassis insulated by rubber grommets and whatnot that have surely rotted by now ...The way things were made in the past was to insulate the chassis from the user with a non conductive case and plastic knobs. This way, it did not matter which way a plug was put in.

I wondered about the timing of the polarized plugs. About 20 years ago my mother said a friend of hers had some radio or lamp that "the plug wouldn't go into the wall outlet." I may have tried suggesting turning the plug over, but I don't think either her or her friend understood, and there was no telling whether it was an older, unpolarized outlet.I had both radios (all American 5) and TV's that were built around this principle. Later, they polarized the plugs by making one pin larger than the other. Even UL accepted this back in the early '60's.

I've heard the quote "Standards are great, there's so many of them!" and it's even more fun over time as the standards change.

There was a discussion about modifying the house AC mains wiring and safety earthing. It has been deleted.

This is absolutely against all ideas and practices of safety, is an unsafe and unlawful modification, it would invalidate your home insurance, and might literally kill you.

We don't want to see anyone doing this anywhere in the world. It's dangerous where ever you are.

Don't do it, and don't post about it.

In amongst all the hubris I forgot to mention that all circuits are RCD protected.Thank goodness for RCDs Residual-current device - Wikipedia

JN, the twisted and soldered earth connections photo I posted was standard practice and is perfectly valid means of connecting such wires before the days of screw terminal strips and I have seen it hundreds of times in houses of varying ages.

If this is still in current code I am not sure, if I could find a free copy of current regs I would check.

Dan.

Why use the tongue when a wet finger works fine, lol.BTY I usually warn the novices not to test for AC with their tongues. But no warning for you, maybe Max.

Ed, did you revisit the guitar cable experiment ?.

Dan.

I have worked code from 2005 through 2017. Soldering a bonding jumper has not been allowed within code during that time frame.In amongst all the hubris I forgot to mention that all circuits are RCD protected.

JN, the twisted and soldered earth connections photo I posted was standard practice and is perfectly valid means of connecting such wires before the days of screw terminal strips and I have seen it hundreds of times in houses of varying ages.

If this is still in current code I am not sure, if I could find a free copy of current regs I would check.

Dan.

Code is of course, for the USA. All nations can adopt the NEC code as desired, or parts of it (which I would worry about as all of code is about safety).

There is a specific reason soldering of bonding jumpers is not allowed. I've seen many seemingly good solder joints fail over time. Even though soldering is a 2000 year old technology, many still do it poorly. Remember, CERN had to spend about 150 million dollars as a result of one bad solder joint.

At least they did not allow humans in the tunnel while the magnets were energized. I suspect not too many people would survive having a 45 ton magnet landing on them after leapfrogging other 50 foot long magnets..

That said, insertion of any device with reactance within the bonding run is absolutely forbidden. If in the future NEC allows UL listed devices within the bonding path, that would be great. Until then, I can not recommend using anything in that path, no matter how good anybody thinks it sounds..

jn

I have worked code from 2005 through 2017. Soldering a bonding jumper has not been allowed within code during that time frame.

I have never seen a soldered joint in any home installation but...

NEC “110.14 (B) Splices. Conductors shall be spliced or joined with splicing devices identified for the use, or by brazing, welding, or soldering with a fusible metal or alloy. Soldered splices shall first be spliced or joined so as to be mechanically and electrically secure without solder and then be soldered. All splices and joints and the free ends of conductors shall be covered with an insulation equivalent to that of the conductors or with an identified insulating device.

Code is of course, for the USA. All nations can adopt the NEC code as desired, or parts of it (which I would worry about as all of code is about safety).

jn

AS/NZS 3000:2018 Electrical installations - Known as the Australian/New Zealand Wiring Rules applies in Dan's case.

Soldered connections are NOT allowed. And never have been

A possible 10 kA current fault inside the house is crazy scary. There must be some part of the code being violated.... current faults on the order of up to 10 kilo amps (in the USA) before a breaker can trip magnetically.... I have a double oven at home, it has a 50 amp run...it's fault currents would be even higher...

This was probably meant as a short impulse wave.

Current Impulse - an overview | ScienceDirect Topics

Current Impulse - an overview | ScienceDirect Topics

AS/NZS 3000:2018 Electrical installations - Known as the Australian/New Zealand Wiring Rules applies in Dan's case.

Soldered connections are NOT allowed. And never have been

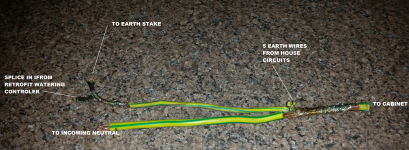

The pic does not show the complete assembly.

The right hand end of the heavy cable had a large crimp eye which bolted to the the cabinet and the left hand end of the heavy cable was terminated to the Neutral bar.

Standard practice in West Australia was to strip a section of the the insulation of the heavy cable, wrap the house circuits PE wires and the earthing rod wire around the bared section of the heavy cable, solder with gas torch and then wrap with green/yellow tape.

It is normal to see droplets of solder in the base of the cabinet after this operation.

Dan.

I am interested to hear what you have found, drop me a PM if you want to keep this stuff away from the usual amateur comedians.In progress

There is much interesting stuff to discuss about this.

Regards, Dan.

Soldered connections are NOT allowed. And never have been

Same for NEC in America. Ground must be a continuous wire to the terminating place. No crimps, solders etc. not even a splice from Mfr in making the wire.

-RNM

A possible 10 kA current fault inside the house is crazy scary. There must be some part of the code being violated.

It's the rating of the breaker, so that it doesn't explode if a short occurs. It can be seen as the number on the front face of the breaker. I just googled square d breaker, this pic showed up instantly.

The assumption is that 10ka is the absolute maximum that can occur. The actual will of course depend on the severity of the short, and the length of wire involved.

https://images.homedepot-static.com...uare-d-tandem-breakers-homt3020cp-64_1000.jpg

jn

keep this stuff away from the usual amateur comedians.

Regards, Dan.

Like you are?

Standard trip curve. The curvy left part is the thermal portion, the flat at the bottom is magnetic. Note that at the bottom, they already show where the multiples are for a 10 kilo amp current for 15, 20, and 25 ampere breakers.

Also note, they state this is cold start, 40 C ambient. if the breaker has been running high currents for a while, like 80% of rating, the thermal will trip faster, and if the panel is in a cold enviro, the thermal will be slower.

I am not sure how the magnetic portion is affected by warm start or ambient.

https://download.schneider-electric...curves&p_File_Name=910-03.pdf&p_Doc_Ref=910-3

Edit: had mentioned a burned jacket on a dryer feed. On autopsy, the neutral conductor screw connection to the plug was obviously very charred, the clamp at wire exit apparently helped the heat to char the jacket there. The screw connection didn't appear to be very loose, but it is possible the charring was noticed and someone retightened it. Wire was appropriate #10 copper. However, it was a 3 wire plug, and there is this totally wimpy frame grounding wire from the chassis to the copper pipe above, maybe 16 awg twisted..ugh. I purchased a 4 conductor plug and receptacle, 15 feet of 10-3, and I'll bond the frame using the 4 wire plug (was really peeved that HD didn't have a torque wrench on the electric tool display, the new receptacle requires 25 inch lbs torque and I'm 5 hours from home.). Old code allowed 3 conductor plugs, new requires 4. As a side note, Home Depot employees are not allowed to give advice on what plug to use nor how to wire it. So either you come in knowing code, or you get a qualified electrician to do the work.

With panel off, all the 20 amp breakers look to have #12 wires. Whenever the homeowner needed a branch, he would simply add a junction box, and splice in new wires. Unfortunately, he did not consider ampacity for the branches, using 14 awg on a 20 amp branch circuit. Luckily, no fires were caused.

jn

Also note, they state this is cold start, 40 C ambient. if the breaker has been running high currents for a while, like 80% of rating, the thermal will trip faster, and if the panel is in a cold enviro, the thermal will be slower.

I am not sure how the magnetic portion is affected by warm start or ambient.

https://download.schneider-electric...curves&p_File_Name=910-03.pdf&p_Doc_Ref=910-3

Edit: had mentioned a burned jacket on a dryer feed. On autopsy, the neutral conductor screw connection to the plug was obviously very charred, the clamp at wire exit apparently helped the heat to char the jacket there. The screw connection didn't appear to be very loose, but it is possible the charring was noticed and someone retightened it. Wire was appropriate #10 copper. However, it was a 3 wire plug, and there is this totally wimpy frame grounding wire from the chassis to the copper pipe above, maybe 16 awg twisted..ugh. I purchased a 4 conductor plug and receptacle, 15 feet of 10-3, and I'll bond the frame using the 4 wire plug (was really peeved that HD didn't have a torque wrench on the electric tool display, the new receptacle requires 25 inch lbs torque and I'm 5 hours from home.). Old code allowed 3 conductor plugs, new requires 4. As a side note, Home Depot employees are not allowed to give advice on what plug to use nor how to wire it. So either you come in knowing code, or you get a qualified electrician to do the work.

With panel off, all the 20 amp breakers look to have #12 wires. Whenever the homeowner needed a branch, he would simply add a junction box, and splice in new wires. Unfortunately, he did not consider ampacity for the branches, using 14 awg on a 20 amp branch circuit. Luckily, no fires were caused.

jn

Last edited:

Probably, he has his sights set on becoming professional though, and soon as he takes over from Gwyneth.Like you are?

This also points out why you should never use the neutral as a bonding conductor, and you should never allow the bonding conductor to carry normal current.

For this dryer wire, the loose neutral clearly dropped voltage while heating, and eventually it would be severely compromised. You never want your bonding ground to be compromised like that. When code changed to 4 wire, they meant to have a bonding ground totally independent of neutral at the appliance. Even though both neutral and ground are connected at the same terminal block in the primary breaker panel, it is absolutely important that they be independent from that terminal to the appliance frame.

Since the dryer uses 240, neutral current is a 120 load, not 240. I assume that perhaps the motor within is a 120 unit, and the motor current is what was toasting the neutral.. I guess it is possible the electric heating elements are 120 in series with the common tied to neutral, that would allow the dryer to partially work if one element opened. Problem is, such a load imbalance with a compromised neutral can pull the neutral voltage away from center of the 240, and the smart electronics package could see voltages far in excess of 120. Consistent with a house that loses the neutral incoming feed, half the branch circuits lowering voltage, other half raising. (a transient dimming lights can be simple IR drop, but if any lights get brighter, you have a bad neutral and absolutely have to call an electrician.)

On examination, I also found that the 4 gauge single to the water main was not even tight in the main panel. No help there...

jn

ps...sorry for the run on verbiage...

For this dryer wire, the loose neutral clearly dropped voltage while heating, and eventually it would be severely compromised. You never want your bonding ground to be compromised like that. When code changed to 4 wire, they meant to have a bonding ground totally independent of neutral at the appliance. Even though both neutral and ground are connected at the same terminal block in the primary breaker panel, it is absolutely important that they be independent from that terminal to the appliance frame.

Since the dryer uses 240, neutral current is a 120 load, not 240. I assume that perhaps the motor within is a 120 unit, and the motor current is what was toasting the neutral.. I guess it is possible the electric heating elements are 120 in series with the common tied to neutral, that would allow the dryer to partially work if one element opened. Problem is, such a load imbalance with a compromised neutral can pull the neutral voltage away from center of the 240, and the smart electronics package could see voltages far in excess of 120. Consistent with a house that loses the neutral incoming feed, half the branch circuits lowering voltage, other half raising. (a transient dimming lights can be simple IR drop, but if any lights get brighter, you have a bad neutral and absolutely have to call an electrician.)

On examination, I also found that the 4 gauge single to the water main was not even tight in the main panel. No help there...

jn

ps...sorry for the run on verbiage...

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III