I will have to read this , can't see on iPad even exploded. Scott, it has to do the thermal flux. In the laser world, .

This is not the laser world you are barking up the wrong tree.

No, but semi conductors are semiconductors and they suffere from thermal effects , this is why we package lasers on diamond substrates and thermal electric coolers and high conductive metals. They all have electrons that jump to higher states with temperature, increasing resistivity and noise. I cant imagine packaging them in plastic or a tin can with a heatsink on the lid. Would be interesting, though to repackage the actual chip in a DVD diamond sub mount and then a CuW TO can. Then mount that on an appropriate thermal,management system. I could do it, we have wire bonderss, die bonders, etc. maybe hack one of those LME's in TO can. This is about high fidelity, no?

Last edited:

This is about high fidelity, no?

but its also about bashing monolithic op amps, claiming discrete is better in every instance, using 30 year old op amps process and design limitations as being representative

ignoring simple techniques widely known and used by analog designers for decades

and rather fight with some strawman "conventional engineer" of awesome ignorance and incompetence that audio guru designers make up

it also seems popular to keep tossing out "well there is this effect..". red herrings with easily found or estimated levels decades below noise floors

if you want to add a few more orders of magnitude to reducing (few ppm) monolithic op amp dynamic thermal feedback errors you can simply buffer their output with separate chip for the power output inside a multiloop feedback path

That doesn't address what I have been talking about. If discretet sound better than monolith ices, and some talk in the past has pointed to thermal issues, then why not cool a monolithic and see if there is a difference. I do know ic packaging is all about allowing a component to operate over wide temperature margines. I bet you a cold monolithic will operate differently then a hot one.

Cooling would help just about any electronic device.

The problem with IC's is their densities, they cannot be cooled as efficiently as a comparable discreet component.

You should try some experiments.

The problem with IC's is their densities, they cannot be cooled as efficiently as a comparable discreet component.

You should try some experiments.

Would everyone who contributes, PLEASE read about IC thermal tails as first put up by Solomon, 40 years ago, and INDEPENDENTLY MEASURED by National Semi. in an app note. Let us get on track with this.

How important is it? I do not know. Is it real? YES

How important is it? I do not know. Is it real? YES

there he goes again.. ..with more ~30 year old "examples"

check the chips issue dates please - LM318, 411, LF356?, even OP-07 isn't exactly new although it did have DC precision specs- please spare us

again stringing together innumerate suppositions isn't engineering - particularly in as mature a subject as analog circuit design

dealing with thermal issues at audio line level isn't hard - only those stupids, the audiophile's caricature "conventional engineer" strawmen, have the slightest difficulty reading the standard books, articles, app notes, datasheets for actual precision analog circuit designs, better parts and applying the content to audio electronic design

for an extreme example – try the couple of DSL driver op amps that have “audio” specs shown on their datasheets – that's where my order of ppm performance from on chip thermal modulation spec comes from – while they are delivering Watts into <100 Ohms

check the chips issue dates please - LM318, 411, LF356?, even OP-07 isn't exactly new although it did have DC precision specs- please spare us

again stringing together innumerate suppositions isn't engineering - particularly in as mature a subject as analog circuit design

dealing with thermal issues at audio line level isn't hard - only those stupids, the audiophile's caricature "conventional engineer" strawmen, have the slightest difficulty reading the standard books, articles, app notes, datasheets for actual precision analog circuit designs, better parts and applying the content to audio electronic design

for an extreme example – try the couple of DSL driver op amps that have “audio” specs shown on their datasheets – that's where my order of ppm performance from on chip thermal modulation spec comes from – while they are delivering Watts into <100 Ohms

Last edited:

Often, many designs take liberties with IC's and push them to their limits, rather than 'baby' them. Then, the fur flies! '-)

"Temperature gradients from a few tenths to a few degrees centigrade develop across the chip, with the output section being hotter then the rest. As illustrated in Fig 4, these temperature gradients appear across the input components of the op amp and induce an input voltage which is proportional to the dissipated power" Solomon?

> Is it real? YES

That's why TO-3 transistors are best

for any application possible

(assuming other needed parameters met)

That's why TO-3 transistors are best

for any application possible

(assuming other needed parameters met)

with a simple output buffer there no reason for the input chip to modulate by mW driving >100 kOhm, few 10s pF of the buffer amp input

so even 0.1 C isn't expected if you care to design out the "problem"

and then you have the fact that the designers of today's higher performance chips have had to do better than 1970's jelly bean specs to keep their premiums

any serious about calling themselves "audio designers" has to be familiar with SG-Acoustics · Samuel Groner · IC OpAmps - which includes a few more recent chips

what do Groner's plots say about OPA827 generation parts?

compare with some of the same chips for the Pease article that Groner also shows?

so even 0.1 C isn't expected if you care to design out the "problem"

and then you have the fact that the designers of today's higher performance chips have had to do better than 1970's jelly bean specs to keep their premiums

any serious about calling themselves "audio designers" has to be familiar with SG-Acoustics · Samuel Groner · IC OpAmps - which includes a few more recent chips

what do Groner's plots say about OPA827 generation parts?

compare with some of the same chips for the Pease article that Groner also shows?

Unfortunately, not everybody uses buffers, or OPA827's. Let us see comparable measurements.

Last edited:

in a thread titled "Blowtorch"? - the $20k preamp? - we can't make comparisons to $5-10 current SOTA monolithic op amps, maybe even 2 of them in a multiloop for $10-20 per channel?

Groner's Op amp Distortion paper does compare multiple generation of monolithic and discrete with the same array of tests, including varying output loads, transfer linearity

Groner's Op amp Distortion paper does compare multiple generation of monolithic and discrete with the same array of tests, including varying output loads, transfer linearity

JCX, assuming 2V into 100kOhm and a 1.5 X .5 um area in the output section of the chip, this produces a flux of 44-E06 W/m^2. Now grant you, the heat is getting sunk,but by what, a really good thermal transfer material like plastic? If the ceramic some of the packages is indeed AlN, at least it has the thermal conductivity of aluminum. This is why in my industry we have moved to DVD diamond.

about as as useful as "here be dragons"

which op amp output Q are we talking about?

the chips are engineered as systems with their packaging, thermal design by professional design teams, usually perfomance testing by a independant group from the design team

today it is easy to choose those chips for we can find relevant plots in the datasheet that simply don't show "thermals" of the magnitude of the effect in the Solomon paper

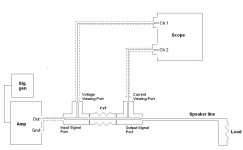

we can even test on our bench with a little ingenuity, a $200 sound card, some buffers, filters, loads, summing/differencing circuits for the effect at -130-140 dB levels if you're truely concerned

and we can design for orders of magnitude improvement over individual chips with multiloop circuits

where's the beef?

which op amp output Q are we talking about?

the chips are engineered as systems with their packaging, thermal design by professional design teams, usually perfomance testing by a independant group from the design team

today it is easy to choose those chips for we can find relevant plots in the datasheet that simply don't show "thermals" of the magnitude of the effect in the Solomon paper

we can even test on our bench with a little ingenuity, a $200 sound card, some buffers, filters, loads, summing/differencing circuits for the effect at -130-140 dB levels if you're truely concerned

and we can design for orders of magnitude improvement over individual chips with multiloop circuits

where's the beef?

I say we slap a cooler on some op amps in an audio circuit and see if there is a change in the audio. If there isn't, we need not go further. I have the parts to do so, the tester just needs to provide a power supply.

As far as design teams, unless you are working for the Jet Proplusion Laboratory, which I have, everything is a comprimise in the commercial world. Just look at the performance distribution histograms in data sheets. Why don't they just sell the best ones? Why do they even have a distribution?

As far as design teams, unless you are working for the Jet Proplusion Laboratory, which I have, everything is a comprimise in the commercial world. Just look at the performance distribution histograms in data sheets. Why don't they just sell the best ones? Why do they even have a distribution?

Last edited:

Let's see an AD711 Scott! Did you really improve its thermal properties?

Again you speak about one hundred years old part. Why to bother with it today, because you once used it in hca 3500??

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II