57May I kindly ask your age (roughly). Mine = 58 --> not so young 😉

jn

When you, PMA, who is known to be 'skilled' at electronic engineering, RFI proofing, and circuit simulation, can also make a 'successful' audio product, independently verified by other experts in the audio evaluation field, then we will welcome you to the 'Society of Successful Audio Designers' like Nelson Pass, Charles Hansen and me, for example. Thanks for all you have contributed, so far.

Better known from its acronym 'SoSAD'.

Honestly, I dont care who you are, what you have done, or who you know, this stuff is GOLD on any level!! thanks JN and you too Scott.

John, that you dont seem to care about running through the EMC and thermal design with this man is insane and quite stubborn, especially as your products will have more and more vulnerability to noise in the modern world, with modern devices and as mentioned, dont assume your engineers are up to speed with it.

its quite ironic that you talk of just wanting to share, but when anything threatens to make it easier, or even possible to build, you shun it and start throwing insults around, then change the subject after alluding to its exclusive impossibility.

that you made such a huge deal about these devices being the only possible way and then when work towards a solution to USE them starts 'making sense' you alude to an as yet incomplete cascoded schematic in your mind and say you arent interested anymore.

it has value even as an intellectual exercise for you and your partners for future products, who btw you seem to often conveniently blame for any shortcomings after theve been exposed...

We havent seen any apology for the ridiculous insinuation that JN may not know anything about the different component packaging and device internal structure wrt heat; but then I dont expect to. He has just demonstrated an intimacy with the subject matter that I expect is rarely seen, especially on such a nuts and bolts level for scratch building, so is VERY handy for us solder monkeys without access to a die attach welder and small numbers of high end passivated die samples.

btw vacuphile, SoSAD? HA!

John, that you dont seem to care about running through the EMC and thermal design with this man is insane and quite stubborn, especially as your products will have more and more vulnerability to noise in the modern world, with modern devices and as mentioned, dont assume your engineers are up to speed with it.

its quite ironic that you talk of just wanting to share, but when anything threatens to make it easier, or even possible to build, you shun it and start throwing insults around, then change the subject after alluding to its exclusive impossibility.

that you made such a huge deal about these devices being the only possible way and then when work towards a solution to USE them starts 'making sense' you alude to an as yet incomplete cascoded schematic in your mind and say you arent interested anymore.

it has value even as an intellectual exercise for you and your partners for future products, who btw you seem to often conveniently blame for any shortcomings after theve been exposed...

We havent seen any apology for the ridiculous insinuation that JN may not know anything about the different component packaging and device internal structure wrt heat; but then I dont expect to. He has just demonstrated an intimacy with the subject matter that I expect is rarely seen, especially on such a nuts and bolts level for scratch building, so is VERY handy for us solder monkeys without access to a die attach welder and small numbers of high end passivated die samples.

btw vacuphile, SoSAD? HA!

Top of the die? Or top of the plastic.

I cringe to think of the aluminum smearing. Hexfets were especially troublesome with top smears, the polysilicon gate structure was easily damaged.

jn

No, ground it down to just before the bond loops (took a few trys).😀

Gets fairly thin actually.

No, ground it down to just before the bond loops (took a few trys).😀

Gets fairly thin actually.

Just before the bond loops??? Is that like ""torque the nut till it breaks, then back up a quarter turn??""😀

btw, I've used the bipax epoxies before, they work quite well. You need filled epoxy for bonding or encapsulation?

jn

Better distortion than the LT1210 then ... 😉 ?Could be, much faster application though.

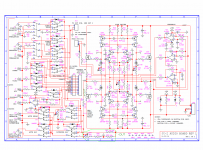

OK everybody, here is a 'dated' example of how we make line level preamps 'today' rather than 30 years ago. This design, known as the Parasound JC-2, is more versatile and measures better than either the CTC Blowtorch or the JC-80.

Why don't we discuss this schematic, instead of trying to turn a T0-92 into a TO-5?

Always glad to help. '-)

Why don't we discuss this schematic, instead of trying to turn a T0-92 into a TO-5?

Always glad to help. '-)

Attachments

OK everybody, here is a 'dated' example of how we make line level preamps 'today' rather than 30 years ago. This design, known as the Parasound JC-2, is more versatile and measures better than either the CTC Blowtorch or the JC-80.

Why don't we discuss this schematic, instead of trying to turn a T0-92 into a TO-5?

Always glad to help. '-)

Thank you John this is a huge step forward. I think everyone here would like to talk "shop" rather than all the back-biting.

Better distortion than the LT1210 then ... 😉 ?

I should hope so, I am getting my own eval card to do audio measurements since this has nothing to do with audio.

Always my pleasure.

EMI was not taught back in the day. It still is an orphan child. It's changing very slowly however. Most my age and older simply have no real understanding.

jn

Most but not all. Its a specialty field. But there have been a lot of books published and courses available for a very long time. Just depends on what type of systems you are working with whether you will get heavily involved in the subject or not.

I'll be 67 in June. You'll never catch up... I'll always be 10 years ahead. 🙂

-Richard Marsh

OK everybody, here is a 'dated' example of how we make line level preamps 'today' rather than 30 years ago. This design, known as the Parasound JC-2, is more versatile and measures better than either the CTC Blowtorch or the JC-80.

Why don't we discuss this schematic, instead of trying to turn a T0-92 into a TO-5?

Always glad to help. '-)

NOW we can move forward and discuss what everyone has wanted to discuss... after the past has been explored... which it has. John, you'll get a lot out of this as well..... more ideas for you to take to the next level.

men (ladies, too)... sharpen your sim's.

Thx-

your old timey friend "Dick" Marsh

Last edited:

OK everybody, here is a 'dated' example of how we make line level preamps 'today' rather than 30 years ago. This design, known as the Parasound JC-2, is more versatile and measures better than either the CTC Blowtorch or the JC-80.

Why don't we discuss this schematic, instead of trying to turn a T0-92 into a TO-5?

Always glad to help. '-)

Thank you John this is a huge step forward. I think everyone here would like to talk "shop" rather than all the back-biting.

^^ this, indeed every single one of us I dare say. still plenty of 'almost completely' unobtainium, but more easily substituted and nobody can blame you for using the parts you have on hand, its not a public project afterall.

thanks John, I do believe you will get something out of this as well.

NOW we can move forward and discuss what everyone has wanted to discuss... after the past has been explored... which it has. John, you'll get a lot out of this as well..... more ideas for you to take to the next level.

men (ladies, too)... sharpen your sim's.

Oh boy. Another numbers game. 🙄

se

This Parasound, being a later design than the Blowtorch, surprises me by not being a folded cascode. Better numbers with more open loop gain and loop feedback? Easier manufacture? Surprising, anyway.

Thanks,

Chris

Thanks,

Chris

you are welcome to replace any and all gain sections with lumps of permalloy Steve if you so desire 😉

Zener diodes for opamp supplies? I guess there is some secret sauce in the line stage supply net not shown though.

Zener diodes for opamp supplies? I guess there is some secret sauce in the line stage supply net not shown though.

Last edited:

What this thread needs is a schematic of Nelsons

latest preamp !

http://www.diyaudio.com/forums/atta...blowtorch-preamplifier-part-ii-jc2-schema.pdf

I hope it's clearer than that one ... 🙂

latest preamp !

http://www.diyaudio.com/forums/atta...blowtorch-preamplifier-part-ii-jc2-schema.pdf

I hope it's clearer than that one ... 🙂

Well I feel positively youthful, amongst you older mentors at a mere 52 yrs on this planet.

EMI/EMC is so critical these days, yet quite often on this site I see the phrase "it doesn't matter as this is DIY"😱

Look forward to your discourse on the schematic.

EMI/EMC is so critical these days, yet quite often on this site I see the phrase "it doesn't matter as this is DIY"😱

Look forward to your discourse on the schematic.

OK everybody, here is a 'dated' example of how we make line level preamps 'today' rather than 30 years ago. This design, known as the Parasound JC-2, is more versatile and measures better than either the CTC Blowtorch or the JC-80.

Why don't we discuss this schematic, instead of trying to turn a T0-92 into a TO-5?

Always glad to help. '-)

Is this correct???

Please note very different load resistance (and different location of loading resistors) for +OUT and -OUT. Suspicious parts in green circle.

Attachments

EMI/EMC is so critical these days, yet quite often on this site I see the phrase "it doesn't matter as this is DIY"😱

True in the sense that DIYers don't have to fret over EN55022, CSA or FCC.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II