Those $3 mini XLR's with all the right bits are looking better and better every moment, eh? 😀

Beside all justified critique on questionable physics we should at least admit that the nextgen connectors are an ingenious development as it is afaik the only rca connector (combined with the suitable jack) that offers 75 Ohm wave impedance.

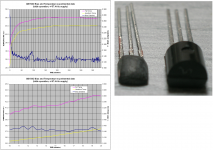

Why.Thanks, but I simply need the temperature of the plastic case, not the die or the junction temperature.

se

Dan.

This RCA Crap Connector story seems to be a never ending problem.

For the tests and experiments at my worksop I buy and use a lot of very cheap RCA connectors both male and female. I notice that often there is an issue with the mating firmness due to the thin and soft male sleeve . Improper mating always causes buzz. No hiss or frequency response alteration.

In such cases, I slightly deform the (thin) barrel shield of the male plug so a mechanical contact is achieved even not all around 360 degrees.

Once good metal contact is re-established, FFTs show no variation in noise floor or in frequency response. The readings are very consistent even with single digit mV signal level.

The surprise is that 10-20 disconnects/reconnects with these crapy connectors and the result can be repeatable.

Thanks. I'll fool around with the IR thermometer and a simple touch of the thermocouple first and see if I can get some

Steve

Try to make the target surface as non reflective as possible when you use IR thermometer.

In the case of a black mat (or a hole in the surface larger than the IR spot acting as IR trap) as a target, IR reading is more close to the true surface temp than a non miniaturised tc reading.

[a relic would use a $1 temperature sensor in a TO92 package, LMx35 series]

surviving in the pockemon go era

(LM335 hand file down encapsulation. Cut leads very short, use very thin connecting wires, all for reducing thermal inertia)

George

Attachments

Has anyone done any testing on the cheap FLIR units. Low res but given you can get the CAT S60 phone with one built in seems a boon.

Rugged Phones & Accessories | Cat phones US

I have, shiny metal surfaces have to have black electrical tape stuck on them to get a reliable reading...

Beside all justified critique on questionable physics we should at least admit that the nextgen connectors are an ingenious development as it is afaik the only rca connector (combined with the suitable jack) that offers 75 Ohm wave impedance.

I do believe that no RCA connector can be truly 75 ohm... it is down to the dimensions of the connector.

ha, Bear launches into standard forum troll line #9 ' you clearly don't listen'. As the only person I am aware of on this forum that has live performances in his house I think SY listens a lot. The fact that he prefers not to give subjective fluff statements, whilst it may upset you is more accurate than trying to describe veils, soundstage changes and wife in kitchen feedback. You might not even like the same music!

Obviously, you are not very aware, if you think that?

Please do tell more about your live venue?

Do you make recordings available?

What you think about SY is pure conjecture. He can speak for his own habits, I expect.

There is no troll bait.

There is a whole lot of dancing around and discussing very very fine points. All well and good. I enjoy these discussions. But where do they relate to reality. Reality being the result.

Ignorant and poorly educated readers, myself included, are left to wonder how significant these details are or are not in terms of what effect they will (likely?) have on the sound rendered. You call this a "troll line"??

No, this is reality. Practical. I did not ask for any descriptive adjectives, just IF something fairly objective made any difference - measured, or difference audible.

I asked about the -120dB & wide bandwidth high performance regulators, and now SY's cables.

Does one need the super regulators? Does one? How would one know WHEN I need them?

Are YOU saying that they are needed (as was suggested) with some circuits? Which ones? Why, what happens to the sound in those circuits if you DO NOT use them? Where's the performance threshold of the regulator vs. the perceived sound? Etc. What is your answer.

Either it has an audible effect or it doesn't.

Otherwise why does it matter?

If it does not have an audible effect, why bother with the engineering exercises, unless you like to play with engineering??

And then, let's try very hard to recall the actual TOPIC of this very good, long, interesting but rambling thread: John Curl's BLOWTORCH Preamp. That device sounds the way it does not only because of the on-paper engineering, but because of that combined with real-world implementation. This being similar then to the two questions, simple ones, that I raised based on statements made in the course of the wide-ranging conversation...

Why is everyone afraid of defining ANY relationship between these engineering ideas/details and SOUND??

You both DF 96 and Billshurv , I have to say are, utterly rigid dogmatists.At the same time you underestimate and insulting my listening experience with arrogant attitude based on your dogma.I know I am right and I am enjoying my audio system much.

You both DF 96 and Billshurv , I have to say are, utterly rigid dogmatists...I know I am right...

Irony Meter pegged.

I fail to see why you are agonizing over the accuracy of your temp reading in your application. To within 5 degrees will be fine.

Use the damn $20 IR meter and get done with it.

No need for T/C's, PT100's or any of that crap.

Use the damn $20 IR meter and get done with it.

No need for T/C's, PT100's or any of that crap.

Jensen transformers have the same goal (GD).

THx-RNMarsh

For audio, GD is a fairly irrelevant metric, as I have explained in the past.

He meant mine.

Lovely!

So, do you have any recordings?

PM if you wish to be discreet.

Of course the obvious question revolves around the natural question, as to do any of the played back recordings reproduce the original experience, and to what extent?

And here I thought that billshruv was the maven.

_-_-

Last edited:

So, do you have any recordings?

They've been used as demos at some audio shows (e.g., Lowther at AXPONA, and in Pete Millett's room at Lone Star Lone Star Audio Fest 2012 Show Report), but I don't release most of them publicly because of licensing and label issues- I have respect for artists' IP rights. There's a few scattered ones on Soundcloud as Bill said. I think our daughter posted some other ones somewhere or other, including videos of the Peter Mulvey show, but I have no idea where.

I see someone knows how to make the right impression with people 🙂Also on display were some headphone amps through which could be heard Stuart's startlingly realistic high-resolution digital recordings of Austin musicians Lee Barber and Southpaw Jones. Beer was also available.

Pete and I bought a keg of a nice microbrew. But Dave Slagle outdid us and had three or four, plus the brewmaster. Everybody was a winner.

How does that affect the thermal resistance to the heatsink?

se

Look at TT-PT sensors.

TEWA ELECTRONICS GROUP - High Precision NTC Thermistors and Customized Temperature Sensors

Take off some material of heatsink an put ceramic sensor under BD 139, partially. With a lot of thermal paste.

Error is less than 5%.

Also it is possible to measure (minimal)effect to heatsink, measuring temperature with and without these "construction".

Yes, I was going to suggest a similar course of action.

Except you want to diode connect the transistor to measure Vbe at some collector current and ambient temperature. Extrapolating back to the bandgap voltage at -273C gives a good guess for Vbe vs T at I.

The base current does not matter.

🙄

🙄Maximum junction temp is 150°C, but derating is based on case temp. The junction to case temp derates at 10°C/W. So I just need the case temp, and I don't think the case temp will vary by a huge amount from one point to another.

se

Tjc has always been from the junction to the backside of the case wehre the metal contacts the heatsink.

If a manu actually specifies to the top of the case at a specific point on the plastic encapsulation, that is a heck of a lot easier to measure.

SE,

Steel filled JB Weld will work as an epoxy with some heat transfer value. Otherwise get some unfilled epoxy and add as much aluminum oxide powder as it will take and use that.

I would go with some Tracon Bi-pax kits. Two part heavily filled with alumina epoxy in one package, separated by a clip. Remove the clip, knead the mix, cut the pak, and squeeze it out.

I do believe that no RCA connector can be truly 75 ohm... it is down to the dimensions of the connector.

It can be done. It requires increasing the inductance at the connector. The typical answer is it cannot be done because the geometry would require a relative permittivity less than 1 to meet Z, but raising the inductance locally does the same thin. They use either one strip or two along the connector to give the added inductance, but this function is destroyed if a normal female is used. jck stated correctly that it requires the proper mate.

ps..guys, are you trying to make a thermal junction test setup for offline measurements, or in situ? I've designed built and used a bench tester for that, and can give a little info if you guys want.

John

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II