Attachments

Last edited:

I think that is exaggerating the frequency effect - maybe non standard PCB copper weight?

http://www.diyaudio.com/forums/loun...ch-preamplifier-part-ii-2373.html#post3049769

I gave my fasthenry sim file for any who want to check

another free toy that seemed to give some plausible result was QuickField Student edition: http://www.quickfield.com/free_soft.htm

http://www.diyaudio.com/forums/loun...ch-preamplifier-part-ii-2373.html#post3049769

I gave my fasthenry sim file for any who want to check

another free toy that seemed to give some plausible result was QuickField Student edition: http://www.quickfield.com/free_soft.htm

Last edited:

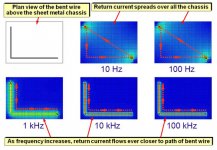

The source, IIRC, is Texas Instruments. Maxim shows same results. But, as spacing between wire and ground plane and width of wire or trace etc all changes the freq but not the characteristic effect. Reason given is: as freq increases, the mutual inductance between the wire or trace and the ground plane beneath it make the ground path of least impedance directly under the trace.

See Dr Archambeault who ran the electromagnetic simulations for signals of different frequencies to see what paths the current would flow.

THx-RNMarsh

See Dr Archambeault who ran the electromagnetic simulations for signals of different frequencies to see what paths the current would flow.

THx-RNMarsh

Last edited:

Learning a few 'actual' things from measuring the assumptions shows this:

View attachment 429770

Why? How could this happen?

What does this mean in terms of inductance and fields? Using this 'real' knowledge would produce better SOTA audio designs, IMO.

THx-RNMarsh

Learned that the hard way roughly 25 years ago. I thought a wire over a ground plane should be quite immune wrt to stray fields from a power transformer located a couple of inches under the ground plane.

I was surprised at first to see a lot of 50 Hz and multiples coupled into the loop even with a free running transformer.

Sometimes it is better to do a calculation first (ok, ok, today, running a multiphysics simulation first).... 😱

I seem to recall jn reminding us of that in another thread where the context was mains leads: the signal return current may use the mains wiring grounds at low frequencies (where resistance dominates) but the interconnect screens/shields at higher frequencies (where inductive coupling dominates).RNMarsh said:Reason given is: as freq increases, the mutual inductance between the wire or trace and the ground plane beneath it make the ground path of least impedance directly under the trace.

I think that is exaggerating the frequency effect - maybe non standard PCB copper weight?

QuickField Student Edition,finite-element,windows,interface,feature,description

There is no standard copper weight for PCB's. I use 9um to 178um depending on the design.

More from Bruce....

Successful PCB grounding with mixed-signal chips - Part 1: Principles of current flow | EDN

http://web.mst.edu/~jfan/slides/Archambeault3.pdf

RNMarsh

Sim software I use uses full 3D field solvers, also will calculate for the etch back on traces, pretty accurate as it has to be for todays high speed interfaces.

.... i have seen the EDN article.

Next up? How do typical pcb with mixed signals and power wiring get mixed up as invisible paths in audio (analog/digital audio)?

And, what are the most common mistakes by DIY'ers here doing their own pcb layouts?

Internal and external wiring.... ac nearby. How could the intentional use of ground planes affect the sound and measurements?

THx-RNMarsh

Next up? How do typical pcb with mixed signals and power wiring get mixed up as invisible paths in audio (analog/digital audio)?

And, what are the most common mistakes by DIY'ers here doing their own pcb layouts?

Internal and external wiring.... ac nearby. How could the intentional use of ground planes affect the sound and measurements?

THx-RNMarsh

Last edited:

I see two areas where pcb could be improved for the DIY'er (or even some mfr's of consumer products)..... where analog and digital are in same chassis. And, especially, power amps with high voltages and currents. Lots of room for improvement work to do there.

What would be some good refer material for DIY'er to learn from? In this forum, we usually touch on things without a macro view of how to integrate all the details.

here's one: "Successful PCB Grounding with Mixed-Signal Chips - Follow the Path of Least Impedance - Tutorial - Maxim."

THx-RNMarsh

What would be some good refer material for DIY'er to learn from? In this forum, we usually touch on things without a macro view of how to integrate all the details.

here's one: "Successful PCB Grounding with Mixed-Signal Chips - Follow the Path of Least Impedance - Tutorial - Maxim."

THx-RNMarsh

Last edited:

in my 30 yrs of board level electronics design for instrumentation and control in the US 1 and 2 oz/ft^2 have been very much the defaults when getting PCB fabbed locally

this would be <1k/yr production, thru hole and "low density" smt - no bga, 0402, "slow" too <100 MHz

I'm sure you can get what you want at higher product volumes, or for a price when electronic and fab limitations require

I once speced heavier Cu needed to keep the soldered faston temp down with 10s of A - and had a visit from the 1st local PCB vendor's sales manager apologizing for being unable to do the board after his new sales guy quoting it - due to the Cu thickness

as I mentioned in my fastHenry post - the thickness of the Cu plane is critical in how far down in frequency that proximity effect dominates over the simple least resistance path - the proximity "image" AC current confinement local to the trace is not strong at low-mid audio frequencies with 2 oz or less Cu plane

this would be <1k/yr production, thru hole and "low density" smt - no bga, 0402, "slow" too <100 MHz

I'm sure you can get what you want at higher product volumes, or for a price when electronic and fab limitations require

I once speced heavier Cu needed to keep the soldered faston temp down with 10s of A - and had a visit from the 1st local PCB vendor's sales manager apologizing for being unable to do the board after his new sales guy quoting it - due to the Cu thickness

as I mentioned in my fastHenry post - the thickness of the Cu plane is critical in how far down in frequency that proximity effect dominates over the simple least resistance path - the proximity "image" AC current confinement local to the trace is not strong at low-mid audio frequencies with 2 oz or less Cu plane

Last edited:

Copper is easily done in .5 - 6 Ounces even our quick turn protos can be done in this range. This is usually just double sided power stuff on FR4 or FR406 types.

Still alive and kicking ....Parasound Shares its Strengths in San Jose | Stereophile.com

Good to see some recent pictures of John Curl. That was nice of Parasound to put on this event.

I doubt if you will find 1-2 oz copper used in any audio/video gear from Asia companies made for low-mid level consumer use. Its much thinner. BUT --- Anyway --

It is NOT the copper thickness that influences the freq via mutual coupling --- it is primarily the thickness of the dielectric between the two conductors. Then trace width etc. Copper thickness has little to do with this.

THx-RNMarsh

It is NOT the copper thickness that influences the freq via mutual coupling --- it is primarily the thickness of the dielectric between the two conductors. Then trace width etc. Copper thickness has little to do with this.

THx-RNMarsh

Last edited:

Still alive and kicking ....Parasound Shares its Strengths in San Jose | Stereophile.com

Stereophile said:Also attributable to Curl, we were told, are the virtual elimination of higher-order odd harmonic distortion, and the discovery of the ideal idle current level for an optimal transfer function in output transistors.

Really? I was taught it was Barney Oliver, of HP.

Really? I was taught it was Barney Oliver, of HP.

John was taught the same thing- he was nice enough to give me a copy of the Oliver paper.

I doubt if you will find 1-2 oz copper used in any audio/video gear from Asia companies made for low-mid level consumer use. Its much thinner. BUT --- Anyway --

It is NOT the copper thickness that influences the freq via mutual coupling --- it is primarily the thickness of the dielectric between the two conductors. Then trace width etc. Copper thickness has little to do with this.

THx-RNMarsh

sorry but you are wrong there - the resistivity of the plane is critical in determining the balance between the least resistance/DC current path and the inductance reducing proximity effect "trace following"/ "image current" confinement of the current at very high frequencies

if the plane resistivity is high it "costs" more to bend the current path to reduce the inductance - a superconducting plane would have even "DC" current follow the trace since there is no added resistance loss

a thicker Cu PCB plane has lower resistivity and the current follows the trace down to a lower frequency than the same geometry with thinner plane Cu

once the conductor is considerably closer to the plane than the length of the trace the exact PCB dielectric thickness/layer spacing has little influence on the low frequency loop inductance of a bent trace over a gnd plane current return path - it is then well approximated as the 2D loop area in the PCB plane

Last edited:

Hate to admit it, but at this point I think I would welcome John popping in with one of his "40 years ago..." tales.

se

se

Hi,

It's only plain and simple electron propagation, Steve. You didn't have a clue 10 years ago or so. So why should you now?

Just testing your memory. 😛

Ciao, 😉

Hate to admit it, but at this point I think I would welcome John popping in with one of his "40 years ago..." tales.

It's only plain and simple electron propagation, Steve. You didn't have a clue 10 years ago or so. So why should you now?

Just testing your memory. 😛

Ciao, 😉

sorry but you are wrong there - the resistivity of the plane is critical in determining the balance between the least resistance/DC current path and the inductance reducing proximity effect "trace following"/ "image current" confinement of the current at very high frequencies

if the plane resistivity is high it "costs" more to bend the current path to reduce the inductance - a superconducting plane would have even "DC" current follow the trace since there is no added resistance loss

a thicker Cu PCB plane has lower resistivity and the current follows the trace down to a lower frequency than the same geometry with thinner plane Cu

once the conductor is considerably closer to the plane than the length of the trace the exact PCB dielectric thickness/layer spacing has little influence on the low frequency loop inductance of a bent trace over a gnd plane current return path - it is then well approximated as the 2D loop area in the PCB plane

I agree with most of this ... it is consistant with others writings. But still not convinced the affect of thickness is very great. Its there but its influence is something fully covered else where. I was quoting excerpted text of others who are 'experts' in the field. But, to just note the affect on current signal paths changes with freq which have impact in many ways which should be discussed and bad layouts practices noted and how to do it best way.

What are those bad practices you have seen?

-THx-RNMarsh

Last edited:

Most 3.5mm jack and RCA terminal connections are Gold-plated Nickel.

Nickel has high resistivity, right next to Lithium and Zinc.

This is the reason for resistivity within metals

To solve the riddle in the maze, you must call 555-phonon and say six cats backwards.

Nickel has high resistivity, right next to Lithium and Zinc.

This is the reason for resistivity within metals

- n=5 implies that the resistance is due to scattering of electrons by phonons (as it is for simple metals)

- n=3 implies that the resistance is due to s-d electron scattering (as is the case for transition metals)

- n=2 implies that the resistance is due to electron–electron interaction.

To solve the riddle in the maze, you must call 555-phonon and say six cats backwards.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II