Yes, more rigidity shifts the resonant vibration to higher frequencies...

In my case, shifting from 18 to 25mm thickness will increase the mass by 39%, and I am not sure that I will obtain a great improvement on a 900x400x360mm enclosure, I mean : for the resulting overweight.

At usual moderate volume, there's no vibrations of the panels on my 375L. At higher levels, vibrations are detectable by touch, but again, I am not sure that this have a so great influence compared to the high level of loudness.

Of course, it is not perfection, I admit it... But at least, it is a compromise between sufficient panel damping and transportability !

T

In my case, shifting from 18 to 25mm thickness will increase the mass by 39%, and I am not sure that I will obtain a great improvement on a 900x400x360mm enclosure, I mean : for the resulting overweight.

At usual moderate volume, there's no vibrations of the panels on my 375L. At higher levels, vibrations are detectable by touch, but again, I am not sure that this have a so great influence compared to the high level of loudness.

Of course, it is not perfection, I admit it... But at least, it is a compromise between sufficient panel damping and transportability !

T

18 to 25mm thickness will increase the mass by 39%

The mass is not really relevant. Stiffness goes up with the cube. So almost twice as stiff.

If it was thicker and didn’t weigh mire would be better. But in real life that would mean a change in material.

Perhaps the 18mm quality BB would be as stiff as 25mm MDF and weigh a bunch less, so resonance/vibration goes even further up.

I’d still put braces.

dave

Nothing like putting $1k worth of drivers and Xo parts in a resonant enclosure……

Well, If you want to build your speakers using reinforced concrete, it's up to you - don't forget the crane when you will have to move them.

I personally made the choice of a compromise : enclosures with enough vibration damping and reasonable weight, in order to have the ability to carry them without hassle.

I think things are very clear... At least for those who want to make the effort to understand it.

T

113L no? Guess 3.75 cubic feet.About the mass : my 375L weight 30.0kg each, in working order. For a HxWxD at 750x420x360mm enclosure made from 18mm Beech hardwood glulam, including internal bracing / filling / crossover, etc. I think that it stays reasonable vs. the damping of the panels.

Of course, you can always do better, and rent a forklift to carry your speakers. Sorry, not for me ! 😆😉

T

113L no? Guess 3.75 cubic feet.

Well, to obtain the neat (free) inside volume of the 375L, you have to substract :

- the Midrange "Flower Pot" cavity.

- the internal bracing.

- the internal volume of the speakers (minus the Midrange, which is already in its cavity).

- the crossover.

- the lateral and back integrated handles

- the port.

Finally, the inside volume of the 375L Bass-Reflex shifts from 89L brut to 75L neat for that 3 ways speaker.

With the addition of the filling material (100%), the acoustic volume reaches 85-88L.

The same calculations give also 75L neat for the 4 ways project 475L Sealed Isobaric also... 😉

T

Xo parts in a resonant enclosure……

The speakers need their outlets separately.the crossover.

The crossover will need development so it will stay out for some time, and...

It doesn't really need to stay inside a resonant ( or not ) enclosure

You missed my point….sorry it was laced with sarcasm. The issue I have is the investment in the drivers for a four way AND all of the required XO components only to put them in what will be large single enclosures of resonant material given the long panel lengths of at least 90cm……and isobaric?…..two 12’s pumping?……makes no sense to me from an engineering/design perspective. Another exercise of ‘could I’ instead of ‘should I’.…..makes me cringe as the ‘could I’ effort isn’t breaking any new frontiers…..it’s all well known accepted acoustic science.…..the same science that led to the demise of these monkey coffins decades ago. One could make the argument that it’s ‘retro’…….sure…ok…….build a better mouse trap……why not.

@mayhem13 'The same science that led to the demise of these monkey coffins decade ago'

Could you please point/share to the science which demises large box please? Maybe you think marketing is a science but otherwise i never met anything science related which say large box are bad... Not even met a small loudspeaker in real life that was able to put enough level/bandwidth to be compared to a 'big box'...

Could you please point/share to the science which demises large box please? Maybe you think marketing is a science but otherwise i never met anything science related which say large box are bad... Not even met a small loudspeaker in real life that was able to put enough level/bandwidth to be compared to a 'big box'...

Big boxes with or without big woofers

because there are little Pencils with a Fostex 87mm that are >1m height

then, with or without waveguide...oh, yes! the baffle is a 0° WG...

So we should define big first.

Then the room and the listener(s)

because there are little Pencils with a Fostex 87mm that are >1m height

then, with or without waveguide...oh, yes! the baffle is a 0° WG...

So we should define big first.

Then the room and the listener(s)

Last edited by a moderator:

You missed my point….sorry it was laced with sarcasm. The issue I have is the investment in the drivers for a four way AND all of the required XO components only to put them in what will be large single enclosures of resonant material given the long panel lengths of at least 90cm……and isobaric?…..two 12’s pumping?……makes no sense to me from an engineering/design perspective. Another exercise of ‘could I’ instead of ‘should I’.…..makes me cringe as the ‘could I’ effort isn’t breaking any new frontiers…..it’s all well known accepted acoustic science.…..the same science that led to the demise of these monkey coffins decades ago. One could make the argument that it’s ‘retro’…….sure…ok…….build a better mouse trap……why not.

Bon. Et alors ?

So what ?

T

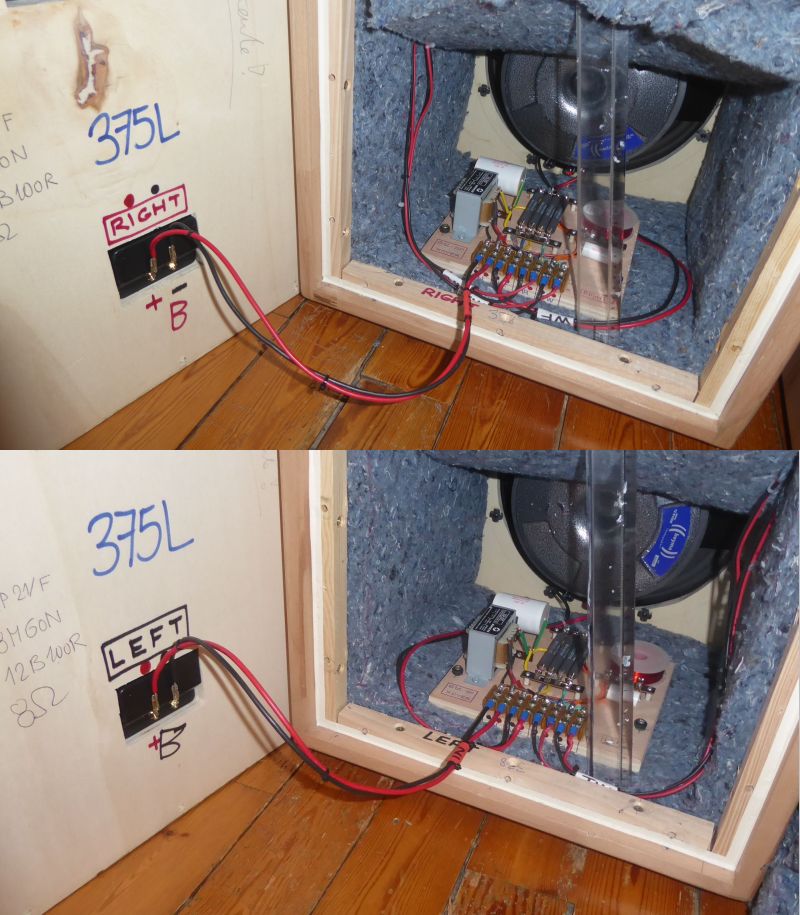

The speakers need their outlets separately.

The crossover will need development so it will stay out for some time

Yes indeed, with temporary 8-terminals plate.

That's what I did by the way when I worked on my 375L crossover, but without the temporary plate, since it was a Bass-Reflex and the wires could come out through the port... 😉

T

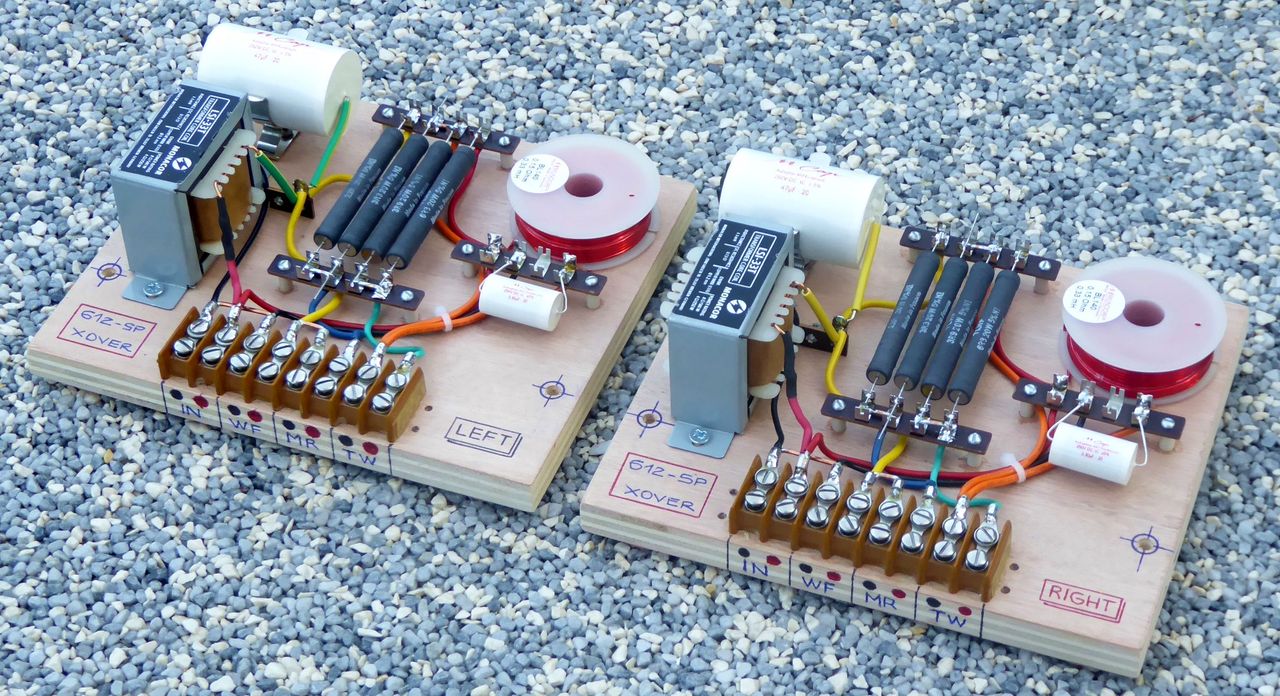

Cabling a speaker... that's another topic, but since thickness, bracing and all the enclosure construction have been examined, in the end there'll be speakers attached firmly on the baffle and... cables and... passive components.

I guess that you have made the choice that has been successful along all these years, which is to put everything in the box. I've seen some manufacturers that use to soak all the components in some resin compound to make the blob inert.

This happen if you fear about the vibrations for the ultimate results but you want to keep it inside the box.

Some provide some closed volume to place the crossover, often in the base.

The best is: no binding posts but direct copper connection from speaker coil terminals to the last component of the x-over. The components well away from the enclosure. Cables are elastic and adapt...

I guess that you have made the choice that has been successful along all these years, which is to put everything in the box. I've seen some manufacturers that use to soak all the components in some resin compound to make the blob inert.

This happen if you fear about the vibrations for the ultimate results but you want to keep it inside the box.

Some provide some closed volume to place the crossover, often in the base.

The best is: no binding posts but direct copper connection from speaker coil terminals to the last component of the x-over. The components well away from the enclosure. Cables are elastic and adapt...

[*]the internal volume of the speakers (minus the Midrange, which is already in its cavity).

[*]the crossover.

Crossover ideally outside the box.

I have taken many of the drivers i work with and it turns out that the impingment of the driver on the box volume is almost exactly equal to the increased volume from adding a chamfer to thre back of the driver cutout.

With a sealed box alignment, the cabinet volume is pretty tolerant above a certain minimum volume.

dave

little Pencils with a Fostex

Pensils only support Markaudio drivers (their tradmark as it were). A Fostex Pensil is called L’Stylo and Scott only did 2 of those.

dave

Crossover ideally outside the box.

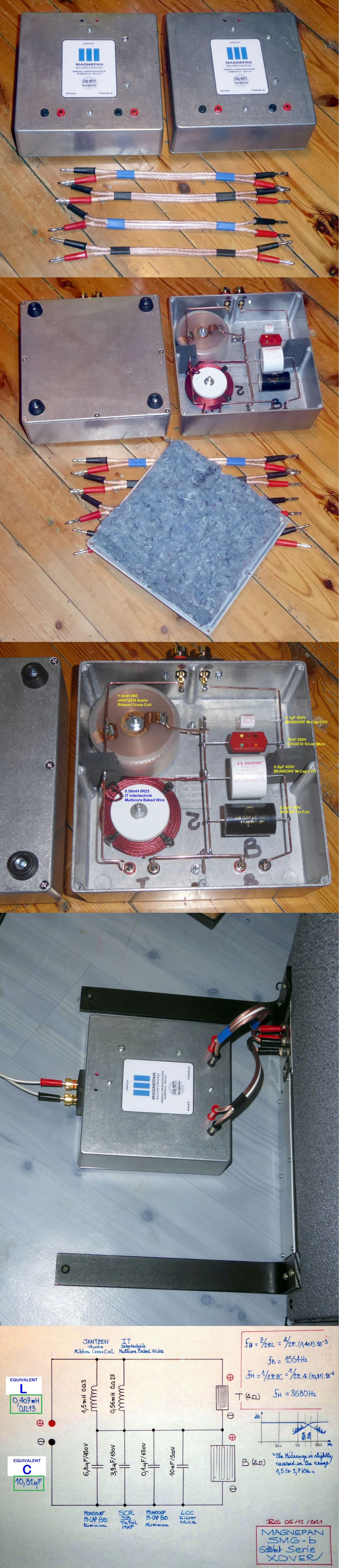

I did this when I rebuilt / modded the crossovers fo my Magnepan SMGb...

... Simply because there was not enough room in the OEM crossover cavity :

Otherwise, I integrate the crossover inside the cabinet - I found that more practical :

I expect to start the cabinet construction of the 475L Isobaric in the days to come... If all goes accordingly ! 🤔 😆😉

T

Last edited:

The metal cases used around xovers I never see as a good idea. The aluminum will reduce inductance due to how the field and metal cage interact. I had to increase a steel laminate coil from 0.8mH to 1.2mH to maintain the 0.8mH value inside a Minimus 7 aluminum cabinet. Steel cases will of course make the inductance go up.

Stainless steel, brass, resin, carbon fiber, or wood would be better enclosures for xovers.

Stainless steel, brass, resin, carbon fiber, or wood would be better enclosures for xovers.

- Home

- Loudspeakers

- Multi-Way

- ISOBARIC sealed enclosure... Any experiences? Any advantages?