Yes, it is a boron cantilever with FG-S stylus.

Is there any specific reason (or reasons) that you chose Boron as a cantilever material instead of ruby/sapphire?

I have already machined a new short adjustable headshell for my Air bearing Eminent Technogoly ET2 that will replace the arm with a 1.4" pivot to stylus to duplicate a Versa Dynamics TT style tonearm.

Pictures please 🙂

I think Boron has better tensile strength with less density compared to ruby/sapphire making it a superior beam material overall.

The top cartridges such as Lyra use boron for good reason.

I have 3 MC,s that have the ruby type cantilevers and they sound excellent however.

Tip mass favors Boron I would imagine overall IMHO.

Regards

David

The top cartridges such as Lyra use boron for good reason.

I have 3 MC,s that have the ruby type cantilevers and they sound excellent however.

Tip mass favors Boron I would imagine overall IMHO.

Regards

David

Analog, I have 2 styles almost done, one solid with no azimuth and one with it making additional headshell changes easier.

Their made out of 6061 T6 billet Alum.

I will use the paddle with the ET silicone trough

Have no idea how it will sound overall.

The arm lift has to be modified for a more agressive ramp due to the short pivot of 1.4"

I, ll post some pics when done. My camera technique needs modding as well...

Regards

David

Their made out of 6061 T6 billet Alum.

I will use the paddle with the ET silicone trough

Have no idea how it will sound overall.

The arm lift has to be modified for a more agressive ramp due to the short pivot of 1.4"

I, ll post some pics when done. My camera technique needs modding as well...

Regards

David

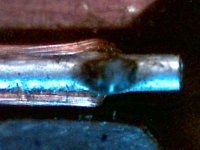

Neumann DST-62

Saw this thread with photos of a Lumiere DST-62 knockoff and thought I’d post some photos of a Neumann DST-62 I acquired many years ago. Sorry my photos are not of the highest standards, but I think there’s enough resolution to compare the two. I hadn’t seen the internals of a Lumiere before, thanks for the photos. The internals of the Lumiere look like a glob-job in comparison to the Neumann. I’m not sure if that was the result of a botched repair attempt, or evidence of poor OEM quality control. Not visible in the photo, the Neumann also has a vertical post or brace attached to the top of the cantilever, but I can’t tell if the other end goes into a damping block or how it’s attached without disassembling it. I’m not going to take it apart to find out. The diamond tip has no visible flat spots, the coils have continuity, and read identical resistance L & R. Having said that, my ‘fingerometer’ test reads VERY low compliance and, together with the visually minute excursion space available between the pole pieces, I’m afraid to try any of my good vinyl on this at the recommended 6.5g VTF. In a review of this cartridge in an old issue of Stereophile, J Gordon Holt noted observable record wear after only a few playings, and elected not to use his valuable test records to make any objective measurements of its technical performance. I can’t imagine that this could have been used by a recording engineer for checking masters without inflicting some permanent groove deformation. I get the idea of the desirability of picking off the signal on the stylus end of the cantilever and not see-sawing the signal through a fulcrum, but all this copper right behind the stylus is adding a boatload of mass for the groove to shove around and not lose contact with the diamond tip. I would expect the magical ‘x‘ sound character of the Neumann to be along the lines of a Decca 4RC that I had, but havn’t motivated myself enough to make an adapter for the non-SME pinout of the Neumann to try it out.

Ray K

Saw this thread with photos of a Lumiere DST-62 knockoff and thought I’d post some photos of a Neumann DST-62 I acquired many years ago. Sorry my photos are not of the highest standards, but I think there’s enough resolution to compare the two. I hadn’t seen the internals of a Lumiere before, thanks for the photos. The internals of the Lumiere look like a glob-job in comparison to the Neumann. I’m not sure if that was the result of a botched repair attempt, or evidence of poor OEM quality control. Not visible in the photo, the Neumann also has a vertical post or brace attached to the top of the cantilever, but I can’t tell if the other end goes into a damping block or how it’s attached without disassembling it. I’m not going to take it apart to find out. The diamond tip has no visible flat spots, the coils have continuity, and read identical resistance L & R. Having said that, my ‘fingerometer’ test reads VERY low compliance and, together with the visually minute excursion space available between the pole pieces, I’m afraid to try any of my good vinyl on this at the recommended 6.5g VTF. In a review of this cartridge in an old issue of Stereophile, J Gordon Holt noted observable record wear after only a few playings, and elected not to use his valuable test records to make any objective measurements of its technical performance. I can’t imagine that this could have been used by a recording engineer for checking masters without inflicting some permanent groove deformation. I get the idea of the desirability of picking off the signal on the stylus end of the cantilever and not see-sawing the signal through a fulcrum, but all this copper right behind the stylus is adding a boatload of mass for the groove to shove around and not lose contact with the diamond tip. I would expect the magical ‘x‘ sound character of the Neumann to be along the lines of a Decca 4RC that I had, but havn’t motivated myself enough to make an adapter for the non-SME pinout of the Neumann to try it out.

Ray K

Attachments

Hy Vencel

Lumiere magnets alnico or neo? I use alnico 2x10ohms wiring and 40-1 step transformers. track from 4.5gr .Its ok?

Hello, I am not sure, but I think it is AlNiCo.

Glad to see you here again Vencel !

May I ask what epoxy you use when gluing a boron rod inside a broken shaft?

I have been researching and testing various 2 part epoxys and most 5 minute ones after a 2 week cure have a film skin that I don’t like.

Shore D ratings are not very hard when poked under a scope. (75-80 )

Even UV rated epoxys are no better in hardness, they are just for a fast cure rate.

The only hard surface one tested was JB weld steel epoxy.

This is for a strain gauge so any magnetism of this particular epoxy is of no consequence.

The diameter of the Namiki shaft is .010” and the ID of the cut cantilever is .015” so I don’t think I will have to sleeve it at this point.

I am not sure of any capillary action type of epoxy available either..,

Appreciate your expertise before committing as I want to do it right the first time

Regards

David

May I ask what epoxy you use when gluing a boron rod inside a broken shaft?

I have been researching and testing various 2 part epoxys and most 5 minute ones after a 2 week cure have a film skin that I don’t like.

Shore D ratings are not very hard when poked under a scope. (75-80 )

Even UV rated epoxys are no better in hardness, they are just for a fast cure rate.

The only hard surface one tested was JB weld steel epoxy.

This is for a strain gauge so any magnetism of this particular epoxy is of no consequence.

The diameter of the Namiki shaft is .010” and the ID of the cut cantilever is .015” so I don’t think I will have to sleeve it at this point.

I am not sure of any capillary action type of epoxy available either..,

Appreciate your expertise before committing as I want to do it right the first time

Regards

David

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Inside the cartridge