Well then put me down for 2!

Ill send one to you kevin and we will both know!

Oh, I missed the "K" after the seven. Woops!

Nice thought while it lasted!

Ill send one to you kevin and we will both know!

Oh, I missed the "K" after the seven. Woops!

Nice thought while it lasted!

Neumann used this design and it certainly sounds different and in my opinion in a very good way. Neumann DSTs were used to listen back the masters on the lathe. Similar to SPU these sound fantastic on older records.

That does not explain what is the advantage.

SPU s are made the usual way, but here i see just tons of moved mass in comparison to usual MCs.

The suspension material is different and on other place, yes, but the suspension/cantilever makes the same kind of movement like usual MCs, just the limitations and damping are different.

So i don't see any reason what should be better.

Maybe there is also a reason why this design did not found more acceptance.

Do SPUs not sound good on new records, just on old ones? And if, why that?

ok, a few more questions if i may.

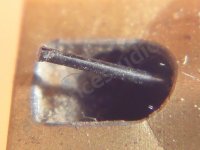

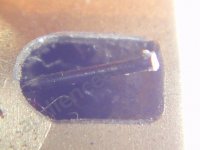

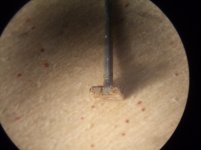

from the comments, this type of suspention isnt the normal way of doing it? i take that back normal sound bad. this isnt the common way a, say, denon mc dose it"

and you hint that this was poorly rebuilt, correct?

if so, what is poorly done? to much goop?

or somthing else?

i find this very cool thanks!

please please post the finished bad boy.

im so darn intrested im gunna start looking for one to get......as long as its not a million $

I will post photos of the finished product.

It is hard to tell if the rebuild was done incorrectly or originally it was already bad. I feel that both are true. Lumiére had qaulity issues, some were perfect but some were almost unusable when received new.

This unit seems to suffer from manufacturing quality issues but company who rebuilt it should not accept the money for the repair as it was not done correctly. If the person would listen to and test the cartridge he would realize that the cartridge is not sounding good.

A cartridge is very prices unit of different elements that have to be perfectly aligned. Unfortunaly in many cases it is not built properly. I've seen coils winded very poorly, incorrectly set suspension, incorrectly aligned styluses and awful assembly of brand new cartrdiges, but I am not going to mention any brands here.

Yes, this kind of suspension is different from the conventional one that most manufacturers (like Denon, Audio Note, Kiseki, Koetsu, Jan Allaerts and many others) use.

That does not explain what is the advantage.

SPU s are made the usual way, but here i see just tons of moved mass in comparison to usual MCs.

The suspension material is different and on other place, yes, but the suspension/cantilever makes the same kind of movement like usual MCs, just the limitations and damping are different.

So i don't see any reason what should be better.

Maybe there is also a reason why this design did not found more acceptance.

Do SPUs not sound good on new records, just on old ones? And if, why that?

I am not saying that SPU do not sound good on new records but most people prefer to use them on older records. Earlier the records were cut slightly differently.

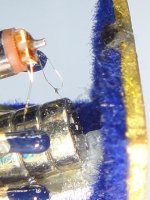

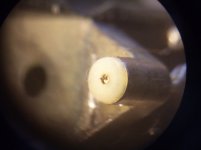

The reason for this design not becoming widely used is simple. Neumann did not let anybody to use their patented technology and it is more complicated to manufacture such cartridge than the conventional ones. Look at the coils. Those are not convetional as they do not have any solid core.

Its a coil. Following Induction. 2/3 of the windings are not effective. So its just mass. Mounted on the cantilever,. enhancing the moved mass in square.

Thats the reason that the Neumann DST had tip resonance around 15 Khz , then the frequency response drop down.

Neumann coils were slightly different mountet than this japanes clone, but the basics are the same, like the problems the Neumann had.

The Neumann DST was made for tracking weight 4-5 gramms,had a spheric stylus around 18 mikrometers radius and the suspension was very hard around 3,5 to 4 and for sure and the trackability was far away from good.

Next production problems creating huge tolerances, this kind of suspension makes no real sense.

Records are cutted different, of course, there were different cutting heads, using different angles in every direction.

Round spheric tips works better, the change the tracking angle like every other tip and thus also the phase, but since they are round, they have more proper contact to the groove.

So i still see absolute no benefit in this kind of suspension.

Thats the reason that the Neumann DST had tip resonance around 15 Khz , then the frequency response drop down.

Neumann coils were slightly different mountet than this japanes clone, but the basics are the same, like the problems the Neumann had.

The Neumann DST was made for tracking weight 4-5 gramms,had a spheric stylus around 18 mikrometers radius and the suspension was very hard around 3,5 to 4 and for sure and the trackability was far away from good.

Next production problems creating huge tolerances, this kind of suspension makes no real sense.

Records are cutted different, of course, there were different cutting heads, using different angles in every direction.

Round spheric tips works better, the change the tracking angle like every other tip and thus also the phase, but since they are round, they have more proper contact to the groove.

So i still see absolute no benefit in this kind of suspension.

Diffrent strokes G.T.

Might be right, might have no good reason.

Might be wrong.

But, anyway you look at it.... He's got one, he's redoing it, he's posting pics that are interesting (to me at least) enjoy the ride cat.

Vencel, thanks for the info

Might be right, might have no good reason.

Might be wrong.

But, anyway you look at it.... He's got one, he's redoing it, he's posting pics that are interesting (to me at least) enjoy the ride cat.

Vencel, thanks for the info

I use only SPUs to play my records, and have several different models. I can't afford anything in the short term that would work better IMO. They seem to do more than just fine with current pressings. I know this has been discussed before but I genuinely prefer the models (lots of them) with elliptical styli as opposed to spherical which in general I have found to have issues tracking HF at high velocities. (tip mass?)

Old SPUs had spheric tips and worked fine.

Need heavy arms and proper tracking weight around 2,5 grams.

Antiskating forces tend to be not necessary.

Building quality and material of actual SPUs them is not the same like in the 60s.

If you like the modern sound more, thats ok. I stick on sound as closed as possible to the Mastertapes.

My cartridge with spheric tip tracks anything called music without problems, except scratches.

If it shows distorsions, its the record containing them.

Allmost all Neumann Cutting machines were equipped with tracing simulators, precompensating some errors caused by cartridges with spheric tips.

Using other tips are not compensated, causing different errors, for sure a lot more, creating a sound you may like more.

Need heavy arms and proper tracking weight around 2,5 grams.

Antiskating forces tend to be not necessary.

Building quality and material of actual SPUs them is not the same like in the 60s.

If you like the modern sound more, thats ok. I stick on sound as closed as possible to the Mastertapes.

My cartridge with spheric tip tracks anything called music without problems, except scratches.

If it shows distorsions, its the record containing them.

Allmost all Neumann Cutting machines were equipped with tracing simulators, precompensating some errors caused by cartridges with spheric tips.

Using other tips are not compensated, causing different errors, for sure a lot more, creating a sound you may like more.

Its a coil. Following Induction. 2/3 of the windings are not effective. So its just mass. Mounted on the cantilever,. enhancing the moved mass in square.

Thats the reason that the Neumann DST had tip resonance around 15 Khz , then the frequency response drop down.

Neumann coils were slightly different mountet than this japanes clone, but the basics are the same, like the problems the Neumann had.

The Neumann DST was made for tracking weight 4-5 gramms,had a spheric stylus around 18 mikrometers radius and the suspension was very hard around 3,5 to 4 and for sure and the trackability was far away from good.

Next production problems creating huge tolerances, this kind of suspension makes no real sense.

Records are cutted different, of course, there were different cutting heads, using different angles in every direction.

Round spheric tips works better, the change the tracking angle like every other tip and thus also the phase, but since they are round, they have more proper contact to the groove.

So i still see absolute no benefit in this kind of suspension.

I am not a cartridge manufacturer so I don't want to protect this design. YOu might be right, but I think that people have different musical tastes, ears and playback system so one cartridge can be a winner in one system while a loser in another.

Thank you very much for all the information you provided and I really do respect your opinion and knowledge. Good to hear such comments.

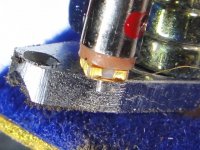

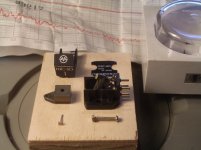

J.A. ALLAERTS MC2 FINISH GOLD

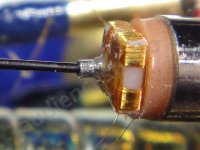

Here is another unusual and interesting cartridge. It is built the usual way but the used materials and the inside is not at all average 🙂

Here is another unusual and interesting cartridge. It is built the usual way but the used materials and the inside is not at all average 🙂

Attachments

-

J.A._MC2_FINISH_GOLD_001.jpg65.9 KB · Views: 435

J.A._MC2_FINISH_GOLD_001.jpg65.9 KB · Views: 435 -

J.A._MC2_FINISH_GOLD_016.jpg64.7 KB · Views: 153

J.A._MC2_FINISH_GOLD_016.jpg64.7 KB · Views: 153 -

J.A._MC2_FINISH_GOLD_015.jpg72.5 KB · Views: 185

J.A._MC2_FINISH_GOLD_015.jpg72.5 KB · Views: 185 -

J.A._MC2_FINISH_GOLD_014.jpg74.9 KB · Views: 183

J.A._MC2_FINISH_GOLD_014.jpg74.9 KB · Views: 183 -

J.A._MC2_FINISH_GOLD_013.jpg54.5 KB · Views: 147

J.A._MC2_FINISH_GOLD_013.jpg54.5 KB · Views: 147 -

J.A._MC2_FINISH_GOLD_012.jpg53.3 KB · Views: 148

J.A._MC2_FINISH_GOLD_012.jpg53.3 KB · Views: 148 -

J.A._MC2_FINISH_GOLD_008.jpg115.1 KB · Views: 398

J.A._MC2_FINISH_GOLD_008.jpg115.1 KB · Views: 398 -

J.A._MC2_FINISH_GOLD_007.jpg93.2 KB · Views: 407

J.A._MC2_FINISH_GOLD_007.jpg93.2 KB · Views: 407 -

J.A._MC2_FINISH_GOLD_003.jpg73.4 KB · Views: 413

J.A._MC2_FINISH_GOLD_003.jpg73.4 KB · Views: 413 -

J.A._MC2_FINISH_GOLD_002.jpg83 KB · Views: 414

J.A._MC2_FINISH_GOLD_002.jpg83 KB · Views: 414

J.A. ALLAERTS MC2 FINISH GOLD

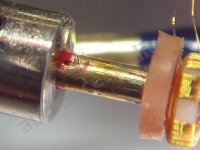

Very good manufacturing quality.

Very good manufacturing quality.

Attachments

-

J.A._MC2_FINISH_GOLD_047.jpg101.8 KB · Views: 243

J.A._MC2_FINISH_GOLD_047.jpg101.8 KB · Views: 243 -

J.A._MC2_FINISH_GOLD_039.jpg107.6 KB · Views: 240

J.A._MC2_FINISH_GOLD_039.jpg107.6 KB · Views: 240 -

J.A._MC2_FINISH_GOLD_037.jpg458.1 KB · Views: 239

J.A._MC2_FINISH_GOLD_037.jpg458.1 KB · Views: 239 -

J.A._MC2_FINISH_GOLD_036.jpg553.4 KB · Views: 272

J.A._MC2_FINISH_GOLD_036.jpg553.4 KB · Views: 272 -

J.A._MC2_FINISH_GOLD_035.jpg429.5 KB · Views: 242

J.A._MC2_FINISH_GOLD_035.jpg429.5 KB · Views: 242 -

J.A._MC2_FINISH_GOLD_033.jpg119.6 KB · Views: 119

J.A._MC2_FINISH_GOLD_033.jpg119.6 KB · Views: 119 -

J.A._MC2_FINISH_GOLD_032.jpg65.5 KB · Views: 125

J.A._MC2_FINISH_GOLD_032.jpg65.5 KB · Views: 125 -

J.A._MC2_FINISH_GOLD_022.jpg120.8 KB · Views: 113

J.A._MC2_FINISH_GOLD_022.jpg120.8 KB · Views: 113 -

J.A._MC2_FINISH_GOLD_021.jpg71.5 KB · Views: 115

J.A._MC2_FINISH_GOLD_021.jpg71.5 KB · Views: 115 -

J.A._MC2_FINISH_GOLD_017.jpg102.5 KB · Views: 139

J.A._MC2_FINISH_GOLD_017.jpg102.5 KB · Views: 139

J.A. ALLAERTS MC2 FINISH GOLD

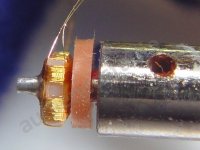

Hand-built.

Hand-built.

Attachments

-

J.A._MC2_FINISH_GOLD_062.jpg124.9 KB · Views: 162

J.A._MC2_FINISH_GOLD_062.jpg124.9 KB · Views: 162 -

J.A._MC2_FINISH_GOLD_063.jpg49.4 KB · Views: 177

J.A._MC2_FINISH_GOLD_063.jpg49.4 KB · Views: 177 -

J.A._MC2_FINISH_GOLD_065.jpg114.2 KB · Views: 189

J.A._MC2_FINISH_GOLD_065.jpg114.2 KB · Views: 189 -

J.A._MC2_FINISH_GOLD_068.jpg93.9 KB · Views: 189

J.A._MC2_FINISH_GOLD_068.jpg93.9 KB · Views: 189 -

J.A._MC2_FINISH_GOLD_061.jpg107.5 KB · Views: 181

J.A._MC2_FINISH_GOLD_061.jpg107.5 KB · Views: 181 -

J.A._MC2_FINISH_GOLD_059.jpg96.6 KB · Views: 179

J.A._MC2_FINISH_GOLD_059.jpg96.6 KB · Views: 179 -

J.A._MC2_FINISH_GOLD_055.jpg116.3 KB · Views: 169

J.A._MC2_FINISH_GOLD_055.jpg116.3 KB · Views: 169 -

J.A._MC2_FINISH_GOLD_053.jpg108.3 KB · Views: 189

J.A._MC2_FINISH_GOLD_053.jpg108.3 KB · Views: 189 -

J.A._MC2_FINISH_GOLD_052.jpg119.8 KB · Views: 187

J.A._MC2_FINISH_GOLD_052.jpg119.8 KB · Views: 187 -

J.A._MC2_FINISH_GOLD_050.jpg102.7 KB · Views: 229

J.A._MC2_FINISH_GOLD_050.jpg102.7 KB · Views: 229

J.A. ALLAERTS MC2 FINISH GOLD

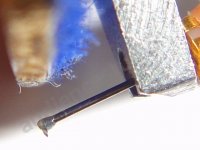

Phones switched off...concentrating only on the repair.

Phones switched off...concentrating only on the repair.

Attachments

-

J.A._MC2_FINISH_GOLD_153.jpg66.1 KB · Views: 187

J.A._MC2_FINISH_GOLD_153.jpg66.1 KB · Views: 187 -

J.A._MC2_FINISH_GOLD_156.jpg71.7 KB · Views: 130

J.A._MC2_FINISH_GOLD_156.jpg71.7 KB · Views: 130 -

J.A._MC2_FINISH_GOLD_157.jpg112.4 KB · Views: 176

J.A._MC2_FINISH_GOLD_157.jpg112.4 KB · Views: 176 -

J.A._MC2_FINISH_GOLD_160.jpg93.8 KB · Views: 212

J.A._MC2_FINISH_GOLD_160.jpg93.8 KB · Views: 212 -

J.A._MC2_FINISH_GOLD_147.jpg103.8 KB · Views: 189

J.A._MC2_FINISH_GOLD_147.jpg103.8 KB · Views: 189 -

J.A._MC2_FINISH_GOLD_125.jpg92.1 KB · Views: 170

J.A._MC2_FINISH_GOLD_125.jpg92.1 KB · Views: 170 -

J.A._MC2_FINISH_GOLD_111.jpg73.3 KB · Views: 190

J.A._MC2_FINISH_GOLD_111.jpg73.3 KB · Views: 190 -

J.A._MC2_FINISH_GOLD_103.jpg84.6 KB · Views: 194

J.A._MC2_FINISH_GOLD_103.jpg84.6 KB · Views: 194 -

J.A._MC2_FINISH_GOLD_074.jpg91.1 KB · Views: 198

J.A._MC2_FINISH_GOLD_074.jpg91.1 KB · Views: 198 -

J.A._MC2_FINISH_GOLD_071.jpg96 KB · Views: 210

J.A._MC2_FINISH_GOLD_071.jpg96 KB · Views: 210

J.A. ALLAERTS MC2 FINISH GOLD

Victory 🙂

Victory 🙂

Attachments

-

J.A._MC2_FINISH_GOLD_181.jpg85.7 KB · Views: 180

J.A._MC2_FINISH_GOLD_181.jpg85.7 KB · Views: 180 -

J.A._MC2_FINISH_GOLD_183.jpg55.8 KB · Views: 170

J.A._MC2_FINISH_GOLD_183.jpg55.8 KB · Views: 170 -

J.A._MC2_FINISH_GOLD_186.jpg74.1 KB · Views: 173

J.A._MC2_FINISH_GOLD_186.jpg74.1 KB · Views: 173 -

J.A._MC2_FINISH_GOLD_189.jpg86.2 KB · Views: 176

J.A._MC2_FINISH_GOLD_189.jpg86.2 KB · Views: 176 -

J.A._MC2_FINISH_GOLD_178.jpg116.4 KB · Views: 176

J.A._MC2_FINISH_GOLD_178.jpg116.4 KB · Views: 176 -

J.A._MC2_FINISH_GOLD_173.jpg97.8 KB · Views: 173

J.A._MC2_FINISH_GOLD_173.jpg97.8 KB · Views: 173 -

J.A._MC2_FINISH_GOLD_171.jpg95.8 KB · Views: 178

J.A._MC2_FINISH_GOLD_171.jpg95.8 KB · Views: 178 -

J.A._MC2_FINISH_GOLD_166.jpg87.1 KB · Views: 182

J.A._MC2_FINISH_GOLD_166.jpg87.1 KB · Views: 182 -

J.A._MC2_FINISH_GOLD_164.jpg96.3 KB · Views: 177

J.A._MC2_FINISH_GOLD_164.jpg96.3 KB · Views: 177 -

J.A._MC2_FINISH_GOLD_162.jpg109.5 KB · Views: 222

J.A._MC2_FINISH_GOLD_162.jpg109.5 KB · Views: 222

Is it a boron cantilever ?

The same as you can see on a Technics EPC-310MC.

Yes, it is a boron cantilever with FG-S stylus.

The coil wire size is .0002"😱 and one layer. i have plans to rewind this and eventually mill a solid body into the headshell and incorporate everything solid.

The magnet feels more powerful than a neo of similiar size..

I have already machined a new short adjustable headshell for my Air bearing Eminent Technogoly ET2 that will replace the arm with a 1.4" pivot to stylus to duplicate a Versa Dynamics TT style tonearm. This would be on a vacuum platter and wouldn,t work well with this short pivot arc.

the MC cartridge is a Win Labs Megasonics as a base platform soon to built into the short headshell eventually.

regards

David

Phones switched off...concentrating only on the repair.

So you do repair cartridges... wondefull work 🙂

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Inside the cartridge