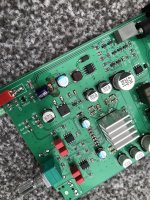

Received mine but unfortunately I got ill. Now things are a little better I modded the thing without even having listened to it. The 3.5 mm connector is gone and the heatsink was loose so I glued it to the chip. It is now being powered on and will be listened to later. My board is a later revision without PCB pads for the ferrite beads as discussed in post #590. It seems to have TI TL072.

The amplifier was sent to me in a plastic bag and it is damaged because of that. Pity!

The amplifier was sent to me in a plastic bag and it is damaged because of that. Pity!

See posts # 587 and #588Why do they list the amp as having a 19V upper limit?

See posts # 587 and #588

Thanks. Looking at the pictures of the board, the only component I see that could potentially be a problem is the 30V AO4409 MOSFET. Maybe some of the ceramic caps as well.

I definitely don't need one of these, but for $24 I might pick one up to play around with. I'll even risk it for the biscuit and throw 26V at it after changing that MOSFET.

It is part limits all over the place. What would the benefit be to kill it in a few minutes?

BTW the device has extra circuitry to switch it on with the MOSFET. Before the MOSFET there appears to be no decoupling. I changed that.

BTW the device has extra circuitry to switch it on with the MOSFET. Before the MOSFET there appears to be no decoupling. I changed that.

Today I discovered some mistakes in the device. I also listened to it and while it has potential it is not THE device 😉 One of the mistakes is in the input circuitry. The film caps are in series with ceramic caps. They are AFAIK not used before the potentiometer.

That's what I thought it looked like from the picture in post #589. Not the end of the world. I'll jumper the film caps and replace each of the 8x 2.2uF ceramics with 3x parallel ECPU1C105MA5 each. Maybe even replace the 10k/10k bias circuit with a TLE2426 and swap the opamps with OPA1642. These are parts I've already had for years, so no extra cost.

Nice, yes. Looks like it will be a tight squeeze on the other 4 caps.

Hope mine isn't the updated board like yours. I actually have the ferrite beads that go where the wire links were on the other board.

I plan on redoing the output filter based on the application note. I'll use SER1052-322 inductors.

Changed my mind about experimenting with getting it to work at 26V. I thought of a use for it and I'll use a 65W GaN USB-C adapter and 20V USB-C trigger cable.

Hope mine isn't the updated board like yours. I actually have the ferrite beads that go where the wire links were on the other board.

I plan on redoing the output filter based on the application note. I'll use SER1052-322 inductors.

Changed my mind about experimenting with getting it to work at 26V. I thought of a use for it and I'll use a 65W GaN USB-C adapter and 20V USB-C trigger cable.

I have another idea. I'm thinking of bypassing the op-amp front end all together and bodging in a couple OPA1632 instead. Feeding VOCM with CREF should allow removal of the 4x coupling caps. Biasing the OPA1632 at 2.5V on a single supply won't leave much output swing, but it should be more than enough. I could also throw in a DC-DC isolated converter to get a dual supply and get rid of the input caps as well, but that might be going too far.

That is a lot of work and high risk of damaging I guess. The PCB material is so so. I enjoy listening to it now and wait for a device that simply does not have SMD caps at the inputs and to the IC. It makes a large difference to use film caps. Again a confirmation that despite all the supposedly nice features of ceramic SMD caps they are simply not suitable as coupling caps in good audio. Period. In original form the device is not usable with regards to sound quality IMO, the cause being the 2.2 µF film caps (on the PCB it says 105...) in series with the 2.2 µF ceramic caps. Maybe the reason to design it like that is to mitigate the level of DC bias at the ceramic caps?! The film caps looked suspiciously like Wima caps but no "Wima" printed on them. Font type being the old one that Wima uses?!

Last edited:

Is that 'polyurethane goo' some kind of clear coat on spray bottle, and why applying it, damping mechanical noise?Tried to parallel the other caps but things are tight indeed. Initially I shorted an input but it is OK now and it sounds quite good. The goo is polyurethane but in the color red.

Last edited:

Yes it seals the PCB and it dampens piezoelectrical effect of ceramic caps. Normally I use the clear type and no one notices but I only had the red version which is plain ugly (but works the same).

Anyway, only good experience with this stuff. It can easily be removed too.

BTW the rumour is that the Argon Audio SA1 has MA12070 inside.....

Anyway, only good experience with this stuff. It can easily be removed too.

BTW the rumour is that the Argon Audio SA1 has MA12070 inside.....

Last edited:

Yes. I have used various brands but this one is Kontakt Chemie Plastik 70 (in the wrong RED version). It is not polyurethane but an acrylic based paintlike stuff. The Urethan 71 is also a good product but more difficult when one needs to rework a PCB. Both types prevent dust/dirt to make contact or leakage between pins that are very close together. Out of curiosity I once put a sprayed PCB under voltage in water. No issue.

http://www.kontaktchemie.com/KOC/KOCproductdetailV2.csp?product=PLASTIK 70

Specifications: https://asset.re-in.de/add/160267/c...-70-74313-AA-Isolier-und-Schutzlack-400ml.pdf

http://www.kontaktchemie.com/KOC/KOCproductdetailV2.csp?product=PLASTIK 70

Specifications: https://asset.re-in.de/add/160267/c...-70-74313-AA-Isolier-und-Schutzlack-400ml.pdf

Last edited:

Thanks - do you also know of some "stuff" that can completely fill a void of a few cc that contains electronics? I would like to dampen out any vibrations inside a small cavity...

//

//

Of course. I did not get answers myself and those who know often don't point you to the right direction probably to be able to stay on their self created island. So I tested and tried quite a few products but all professional products share common features: they are hard to find for consumers and they are even harder to find in "normal" quantities. By coincidence I once was given large containers of pro molding epoxy and I used that for years till it started to deteriorate. Today I use this quite similar slow curing epoxy to seal transformers etc. and it is affordable too. Again, one has to use the stuff and not let it stay unused for years. Once mixed and hardened nothing bad happens.

https://trollfactory.de/anwendungen...-laminierharz-bis-10mm-inkl.-einweghandschuhe

It works very good and indeed takes 2 days to cure. As a result it does not heat up. Of course transformers that are molded need to be overdimensioned and then derated. Toroids become almost silent when molded. Electronics can be molded too but once molded repair is out of the question.

https://trollfactory.de/anwendungen...-laminierharz-bis-10mm-inkl.-einweghandschuhe

It works very good and indeed takes 2 days to cure. As a result it does not heat up. Of course transformers that are molded need to be overdimensioned and then derated. Toroids become almost silent when molded. Electronics can be molded too but once molded repair is out of the question.

Last edited:

- Home

- Amplifiers

- Class D

- Infineon MA12070 Class D