I make my own iron cored chokes, so I can write with certain criteria that measured inductance with a RLC meters always is erroneous. Most of those bridges use about 1KHz signal at a very low level and without DC premagnetization. So discard this measurements, and try it in circuit.

Which part of Argentina are you from? I work in CABA but native from GBA.

Osvaldo soy de Las Flores a 170km de BsAs.

Estoy armando un 6s45p, 45, 300B , con trafos interetapa y de salida Lundahl.

Algo medio Sakuma.

Una DHT como la 45 , manejando otra DHT como la 300B.

Capaz has leido algun post de esos.

Mi cel 02244 15 420595

Santiago

If we say we've measured an inductance to be such and so, without detailing exactly the measuring conditions, we haven't said anything. Iron-cored inductors vary wildly with applied AC voltage and DC current, and somewhat with frequency, as everyone has already said.

IOW, there is no single number for inductance. It's more a family of curves, like the more familiar valve "plate curves" and transconductance curves.

All good fortune,

Chris

IOW, there is no single number for inductance. It's more a family of curves, like the more familiar valve "plate curves" and transconductance curves.

All good fortune,

Chris

> Is this method completely wrong?

If I measure my blood pressure in the morning it is low; in afternoon it is high. Lots of things depend on conditions.

Let it read a little low on the meter, then put it in the supply and load it! Read DCV, DC current, and ripple voltage. These days a broken-in first filter capacitor is probably within 15% of label, or you could measure that also. (E-caps don't vary much with voltage; high-K ceramics do.) Since you already(?) computed the predicted ripple with the *assumed* choke value, any difference tells you if the choke is a little off or a lot off.

And of course if the choke is +high+, ripple is low, then that is even better. (Unless you will make a million for profit, then you want to cheapen the plan to just-meet your spec.)

If I measure my blood pressure in the morning it is low; in afternoon it is high. Lots of things depend on conditions.

Let it read a little low on the meter, then put it in the supply and load it! Read DCV, DC current, and ripple voltage. These days a broken-in first filter capacitor is probably within 15% of label, or you could measure that also. (E-caps don't vary much with voltage; high-K ceramics do.) Since you already(?) computed the predicted ripple with the *assumed* choke value, any difference tells you if the choke is a little off or a lot off.

And of course if the choke is +high+, ripple is low, then that is even better. (Unless you will make a million for profit, then you want to cheapen the plan to just-meet your spec.)

So, my conclusion is that when choosing a choke, the most helpful specs are physical dimensions and DC resistance.

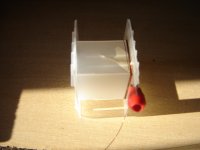

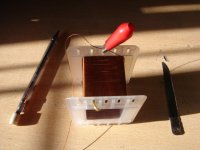

To take the biggest advantage from a choke filter, it MUST be designed for the task. Off the shelf inductors are a poor solution. I'm talking with knowledge from a guy who make my own chokes from scrapped transformers or chokes. It's easy and ready to make.

Attachments

-

Choke 01.JPG149.4 KB · Views: 89

Choke 01.JPG149.4 KB · Views: 89 -

Choke 02.JPG146.4 KB · Views: 96

Choke 02.JPG146.4 KB · Views: 96 -

Choke 03.JPG145.4 KB · Views: 87

Choke 03.JPG145.4 KB · Views: 87 -

Choke 04.JPG153.6 KB · Views: 84

Choke 04.JPG153.6 KB · Views: 84 -

Choke 05.JPG144.1 KB · Views: 79

Choke 05.JPG144.1 KB · Views: 79 -

Choke 06.JPG159.9 KB · Views: 57

Choke 06.JPG159.9 KB · Views: 57 -

Choke 07.JPG159.5 KB · Views: 59

Choke 07.JPG159.5 KB · Views: 59 -

Choke 08.JPG135.3 KB · Views: 55

Choke 08.JPG135.3 KB · Views: 55 -

Choke 09.JPG144.5 KB · Views: 54

Choke 09.JPG144.5 KB · Views: 54 -

Choke 11.JPG143.7 KB · Views: 58

Choke 11.JPG143.7 KB · Views: 58

As others have indicated, the inductance presented in an operating power supply depends on the AC and DC conditions imposed on the inductor (choke).I bought a 10H inductor for a power supply tube amplifier.

I test the inductor and have 6H.

There are diy testing ways to measure that operating inductance value, if you are so inclined, such as shown in the link:

https://www.dalmura.com.au/static/Choke%20measurement.pdf

- Home

- Amplifiers

- Tubes / Valves

- Inductance of inductor.