The essay The Art of Speaker Design by Lynn Olson put all such questions in perspective beautifully for me. Vance Dickason, the bible of speaker building, does not address this question well enough -- at least not the edition I read. I suggest that you read Olson's (large) essay end-to-end.Vivek said:Do Kevlar woofers sound far better than paper ones?

That said, the Peerless India Kevlar is much better damped than usual Kevlars -- this much is obvious from the SPL graphs. It does not have the usual prominent cone-breakup peak that most hard-cone drivers exhibit. In that sense, I found it remarkably easy to work with the driver. You can compare its SPL curves with other Kevlar-cone midbass drivers from other brands.

Thanks for the instant reply i realy appriciate ur views and ur advice ..i plan to build my 5.1 speakers soon as i have already have build a sub 2 years back..its a 12 inch kenwood sub in a good MDF wood cabnet ...nicely braced and thick baffle and it realy rocks when connected to a simple amp (2 channel) localy made and shatters all the window panes...but still a lot of work to do with it..i will be having my brother send a sub amp plate from the usa that would be helping a lot..i will be building a set of 5 speakers 2 flor standing just like urs two surround and one centre channel....i will be using MDF as i think it helps a lot in leting a speaker sound good...i hope i end up making good speaker set ...the main drawback will be making a good crossover as i am not into engenering lol......but u will be surprized with any knowldge of enegnering i was manufactureing my own UPS (power back up) and was selling it some years back but the rising steel prices made me wind up the manufacturing..i duplicated a UPS that was sucessfull in the market copied the pcb and ended up making my own brand as i had no idea what every single component did..soldred every single part on the pcb got the transformer winded and fixed the EI myself and after some experiments the UPS was ready and gave a back up of 12 mins with my pc....so i have confident i can built one good set of speakers but with those dbs and frequencies that i dont know what they do or mean it will be a dream come tru is i get to build a good set of 5.1 and a floor standing like ur speakers

...i dont know what project are u in right now but today its a relief for me that peerless is available in india..my brother brought 4 vifa drvers 6.5 inches and vifa tweeterm..the vifa driver is glassfiber cone made and cast frame and tweeters are simple....dome kinda....i have not given my thoughts to the crossover but i think that it is the most important part as it can make or break a speaker end results.

Thanks for the reply will be in touch

kamal

...i dont know what project are u in right now but today its a relief for me that peerless is available in india..my brother brought 4 vifa drvers 6.5 inches and vifa tweeterm..the vifa driver is glassfiber cone made and cast frame and tweeters are simple....dome kinda....i have not given my thoughts to the crossover but i think that it is the most important part as it can make or break a speaker end results.

Thanks for the reply will be in touch

kamal

Hi Navin

Can you please tell me which of these would be good in bass response i mean tight punchy bass

http://www.madisound.com/catalog/product_info.php?manufacturers_id=136&products_id=1504

or this driver

http://www.madisound.com/catalog/product_info.php?manufacturers_id=136&products_id=1509

Thanks

Can you please tell me which of these would be good in bass response i mean tight punchy bass

http://www.madisound.com/catalog/product_info.php?manufacturers_id=136&products_id=1504

or this driver

http://www.madisound.com/catalog/product_info.php?manufacturers_id=136&products_id=1509

Thanks

kamal6767 said:

Can you please tell me which of these would be good in bass response i mean tight punchy bass

Tight punchy bass can be achived with either of these 2 drivers it is more a matter of box and XO design than paper specs.

Between these 2 drivers I'd opt for the Kevlar coned mahcine although it does require a box that is twice the size of the poly cone.

I'd agree. The driver makes relatively little difference to the sound of the finished speaker; other factors are much more important.navin said:Tight punchy bass can be achived with either of these 2 drivers it is more a matter of box and XO design than paper specs.

I remember someone asking me: will a Kevlar cone Peerless India speaker sound better than the Vifa TG midbass (or some such question). This sort of question is very hard to answer. The final sound you hear from a speaker depends much more on enclosure and crossover than on the drivers. Mediocre drivers in excellent enclosures and carefully designed crossovers sound much better than top-class drivers in boom-box enclosures and carelessly designed crossovers.

Asking whether a Kevlar cone speaker will sound better/deeper/smoother than an XYZ cone driver is like asking whether a petrol car will make the Bombay-Pune commute faster than a diesel car.

Hi Tarun (tcpip)

I didnt see any pictures of the passive XO. if you have them could you please mail me at raikamaljit@hotmail.com.

Thanks

I didnt see any pictures of the passive XO. if you have them could you please mail me at raikamaljit@hotmail.com.

Thanks

tcpip said:

I'd agree. The driver makes relatively little difference to the sound of the finished speaker; other factors are much more important.

I remember someone asking me: will a Kevlar cone Peerless India speaker sound better than the Vifa TG midbass (or some such question). This sort of question is very hard to answer. The final sound you hear from a speaker depends much more on enclosure and crossover than on the drivers. Mediocre drivers in excellent enclosures and carefully designed crossovers sound much better than top-class drivers in boom-box enclosures and carelessly designed crossovers.

Asking whether a Kevlar cone speaker will sound better/deeper/smoother than an XYZ cone driver is like asking whether a petrol car will make the Bombay-Pune commute faster than a diesel car.

What you say is true but don't drivers have different tonal qualities. A Vifa P17 sounds much better in the midrange region as compared to a TC18 for instance. Don't drivers add their own colour to the signal?

Vivek

Hi Tarun

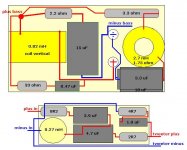

Asked you about the pics of XO of asawaris. i doubt u have them, i have attached a pic in this post of a XO , if you can draw the XO of Asawaris like thisit will be easy for me to construct the XO on a bread board PCB and also if you can provide me with the detail of parts that you used in the XO

Thanks

Asked you about the pics of XO of asawaris. i doubt u have them, i have attached a pic in this post of a XO , if you can draw the XO of Asawaris like thisit will be easy for me to construct the XO on a bread board PCB and also if you can provide me with the detail of parts that you used in the XO

Thanks

Attachments

I don't have any pictures of the XO. I thought that building a passive XO using point-to-point wiring is easy. Follow the following points:kamal6767 said:I didnt see any pictures of the passive XO. if you have them could you please mail me at raikamaljit@hotmail.com.

- Use a sheet of 3mm plywood to mount all the xo components on.

- Mount this plywood sheet on the internal surface of the XO chamber's door, and raise the sheet by mounting on 1" call buffers of the kind that carpenters fit below the feet of chairs and tables. The 1" raised height allows me to put fingers below the sheet and manipulate wires or cable ties.

- Lay out your components on the plywood sheet, mark their positions, and then mark their wiring connections. Keep inductors as far away from each other as possible.

- Drill small 3mm and 4mm holes in this plywood sheet on either side of each component.

- Fit each component to the sheet using cable ties. I bought one packet of each of 4", 8", and 12" cable ties. (The 12" ties became very useful for the large 1.5mH inductor.) These cable ties hold each component down very tightly to the board. Thread each tie around the component, then through one hole to the far side of the plywood sheet, then up through the hold on the other side of the component, and then tie its ends. Do not use adhesive to fix components to the plywood sheet.

- After components are fixed this way, do point-to-point wiring using thick copper wire (sometimes the leads of the components are not long enough to allow direct soldering.

- The fix the leads. There will be leads coming into the XO board from the speaker terminals at the back, as well as from the drivers. Each lead must be brought onto the xo board and then tied down first using cable ties before being soldered. This tying dows acts as strain relief, and prevents any yanks/jerks from pulling at the solder joins.

Yes, they do, if you let them. The grosser coloration is removed by a well-designed xo. (This includes resonant peaks from hard-cone mid-woofers, or distortion at lower freq ranges from over-strained tweeters, etc)Vivek said:What you say is true but don't drivers have different tonal qualities. A Vifa P17 sounds much better in the midrange region as compared to a TC18 for instance. Don't drivers add their own colour to the signal?

What remains is the coloration due to the driver's small unevennesses in their "flat" and "comfortable" range, i.e. not at the extremities of their performance envelope. I am sure these unnevennesses are audible, but they only make audible differences "all other things being equal." And "all other things" are never equal between two fully constructed speakers in real life. Therefore, this question of differences in tonal qualities of drivers becomes more of an academic question in real life.

Lynn Olson says that paper cone midbass drivers are perhaps the best. He says that soft-cone drivers, e.g. poly cones, do not reproduce sound accurately enough. Yet, for his top-class Ariels, he uses Vifa poly-cone midbass drivers. Why? Because, IMHO, "all other things are rarely equal." He must've believed that he'll get sufficiently accurate reproduction from his poly-cone drivers because other trade-offs are more important, and because they fit into his minimalist design philosophy better.

When he goes on to talk about bass units for his Ariels, he talks of designing sub-woofers. For those sub-woofers, he recommends Scanspeak hard-cone 10" drivers, of the kind he generally avoids because of their resonant-peak colorations. Why does he choose these, then? It's not because the tonal colorations of the hard-cone Scanspeaks have suddenly become palatable to him. it's because he knows how to design an xo which will keep those colorations out.

I am sure that if you take two 1.5litre engines, one petrol and one CRDI diesel, in cars of equal weight, wheelbase and similar suspension, then you'll see differences between the two engines. But this is an academic question... the bigger tradeoffs come from things other than engine's fuel type when assessing total performance of a real-life car, IMHO.

If you still want to investigate the midrange tonal colorations of two different drivers, then I suggest that the only way to do this would be:

- fit them in boxes large enough for the box's acoustic effects to not influence the driver, and in boxes sufficiently well-made to completely deaden the rear sound from the driver.

- do measurements and design an xo which will give identical Fc and identical slope for all drivers under test. So, even if you could have taken one midrange driver to work over a wider range, you can't do it for these tests... you'll have to confine all drivers to the range of the smallest-range driver, to ensure identical results.

- set up amplification such that drivers are level-matched to within 0.5dB, if not better.

- then play some test tones, white/pink noise, and music through these drivers, and see what you hear.

There are experienced speaker builders who just mount a naked driver on an open baffle and listen to music on it, and they can tell which driver is more "natural sounding" than which other. I can't do this. I must first put in an xo to get the driver to perform in its optimal frequency range before I can form an opinion of what it sounds like. If naked-driver testing was so easy, then all metal-cone drivers would have failed the test, because they all have terribly sharp resonant peaks. But with a sufficiently aggressive low-pass xo (maybe Cauer-Elliptic), you can get them to sound warm, smooth, and very natural indeed. (See Jon Marsh's design of the MTM using Dayton RS metal-cone drivers on htguide.com's forums.) If metal-cone drivers can be made to sound this good, then of what relevance is the tonal quality of the naked driver?

Bottom line: I'm not saying tonal coloration differences do not exist. I am saying that you and I only hear finished speakers, not drivers fitted into test setups like I described above. Therefore, you and I don't know which bit of the overall tonal character of a finished speaker is due to the raw driver's coloration, and which parts are due to the grosser problems.

I am also saying that when people like you and me build speakers, the sound of those speakers will be much more influenced by the mistakes we make in xo design or enclosure design than the raw limitations of the drivers. You have to be a Neil Patel to justify switching to ceramic-cone drivers... only after you do as much work as he has done do you reach the point where the raw driver's tonal character begins to limit your speaker quality.

I suggest you take an in-room measurement of your speaker without MLS gating, and look at the low-freq part of the curve. See what it looks like.Vivek said:I was thinking I should try a tranmission line to try and squeeze more bass out of my TC18s. I am fine with the mids and highs on my speaker.

What details do you need which are not there by looking at the schematic of the xo circuits?kamal6767 said:Can u please provide me with the details of the parts used in the XO i think i will have them made from Corrson.

Dear Tarunda ,

Your website content is excellent .But sadly Asawari(is it Asabari ?) is too big for my room as it is only 10' by 12' and full of furniture .

Your other articles were also excellent and were indeed very absorbing

I want more such articles on your site

Hope you will have a bookshelf design which novices like us can copy and build as most of the measurements go tangentially over my head as I dont have a science background .

With Regards ,

Somak

Your website content is excellent .But sadly Asawari(is it Asabari ?) is too big for my room as it is only 10' by 12' and full of furniture .

Your other articles were also excellent and were indeed very absorbing

I want more such articles on your site

Hope you will have a bookshelf design which novices like us can copy and build as most of the measurements go tangentially over my head as I dont have a science background .

With Regards ,

Somak

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- [INDIA] The Asawari