Osvaldo, thanks for that explanation. Very cool. I'll be referring to that a lot, I'm sure, and may be back with some questions at some point. Apologies in advance if they're not intelligent ones.

Last edited:

None was born knowing all. Ready for questions.

During the repairment, get an isolation transformer to avoid a shock when doing measurement with the rig energized.

During the repairment, get an isolation transformer to avoid a shock when doing measurement with the rig energized.

Is this a "hot chassis" device? No galvanic isolation from the line?

That's a very important point actually and something I had missed. It is particularly important when connecting test equipment that might be mains grounded. It would be safest to use a 1:1 isolation transformer while working on this.

I'm still looking at the circuit and can't think of an easy way to troubleshoot this. It is going to be important that the 15v supply is stable.

Small compressed disc ceramic caps are known trouble spots becoming leaky. These type if there are any:

Believe me, I've been very wary of this thing when doing any of the measurements, and gone slowly. But I do need an isolation transformer. Looks like I may need to consult Richard (of RJM Audio / Emerald Help Desk fame) about that. I don't know what the best local (Japan) options are, or the things to watch out for, but I do know that I have nothing but unpolarized two-pin outlets with no earth terminal to hook to (I have no shortage of pigtail cables, but can't earth them to anything). Pretty common in houses here. I use RCDs in the outlets for my gear, and the breakers at the distribution board have RCDs, but that's it.

I hope to get to the 15V measurement this weekend or the next. It checked out last time I measured it, but that was half a year ago.

I don't think I have any of the caps you showed there.

I hope to get to the 15V measurement this weekend or the next. It checked out last time I measured it, but that was half a year ago.

I don't think I have any of the caps you showed there.

Last edited:

Something else worth checking would be the VD-1121 diodes. Some sources say these are 'double diodes' and others say 'single'. This series of diode does give trouble in many amplifiers where it is used for biasing and temperature compensation..

Measure the voltage across them. If they are a double diode you should see about 1.2 to 1.3 volts vs 0.6 volts for a single. If the voltage is wrong or unsteady then worth a try replacing with 1N4148's (two in series if its a double)

Measure the voltage across them. If they are a double diode you should see about 1.2 to 1.3 volts vs 0.6 volts for a single. If the voltage is wrong or unsteady then worth a try replacing with 1N4148's (two in series if its a double)

So far I've just had time to do the 15V test. Adjusting R850, I can get it to hold at 15.00/14.99, once the table comes up to speed.

I also noticed that the platter won't start at all if I place a phone on it (to check rpm) and power the turntable on.

I took some photos of the underside of the turntable, and some detail shots of the circuit board today, so I will sort through those and post a couple. Tomorrow, I'll try and test some of the other things that were suggested.

I also noticed that the platter won't start at all if I place a phone on it (to check rpm) and power the turntable on.

I took some photos of the underside of the turntable, and some detail shots of the circuit board today, so I will sort through those and post a couple. Tomorrow, I'll try and test some of the other things that were suggested.

Is the 15v not correct before it gets to speed? and is the 15v low when the table won't start?I can get it to hold at 15.00/14.99, once the table comes up to speed.

It starts off at about 14.96 straight after power on, up to 14.99 maybe in 8 or 10 seconds. Can I assume that differences this small are negligible?

Can I assume that differences this small are negligible?

I think so, yes. It was just a hazy idea I had.

(I was thinking if the voltage was falling a lot then it might be due to an issue with the driver or output transistor and them being fed to high a base current to compensate and that was pulling the supply down)

I ran a quick check on the diodes (in circuit, power off). All were about 0.57 in one direction, OL in the other, except for D801 and D802. These read 0.57 forward biased, 0.69 in the other direction. Not sure what that means, but perhaps the identical reading for both suggests that they're working as intended?

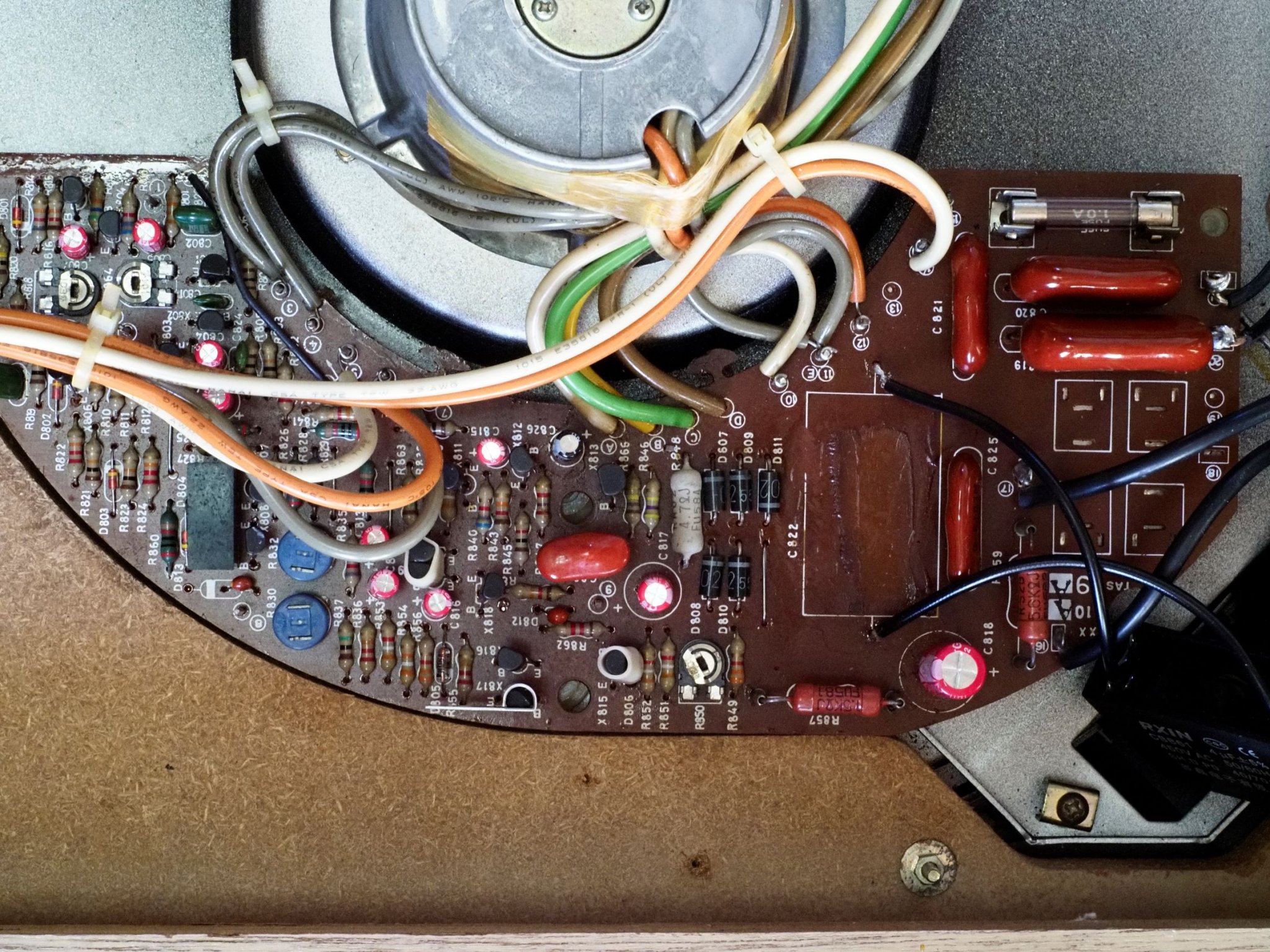

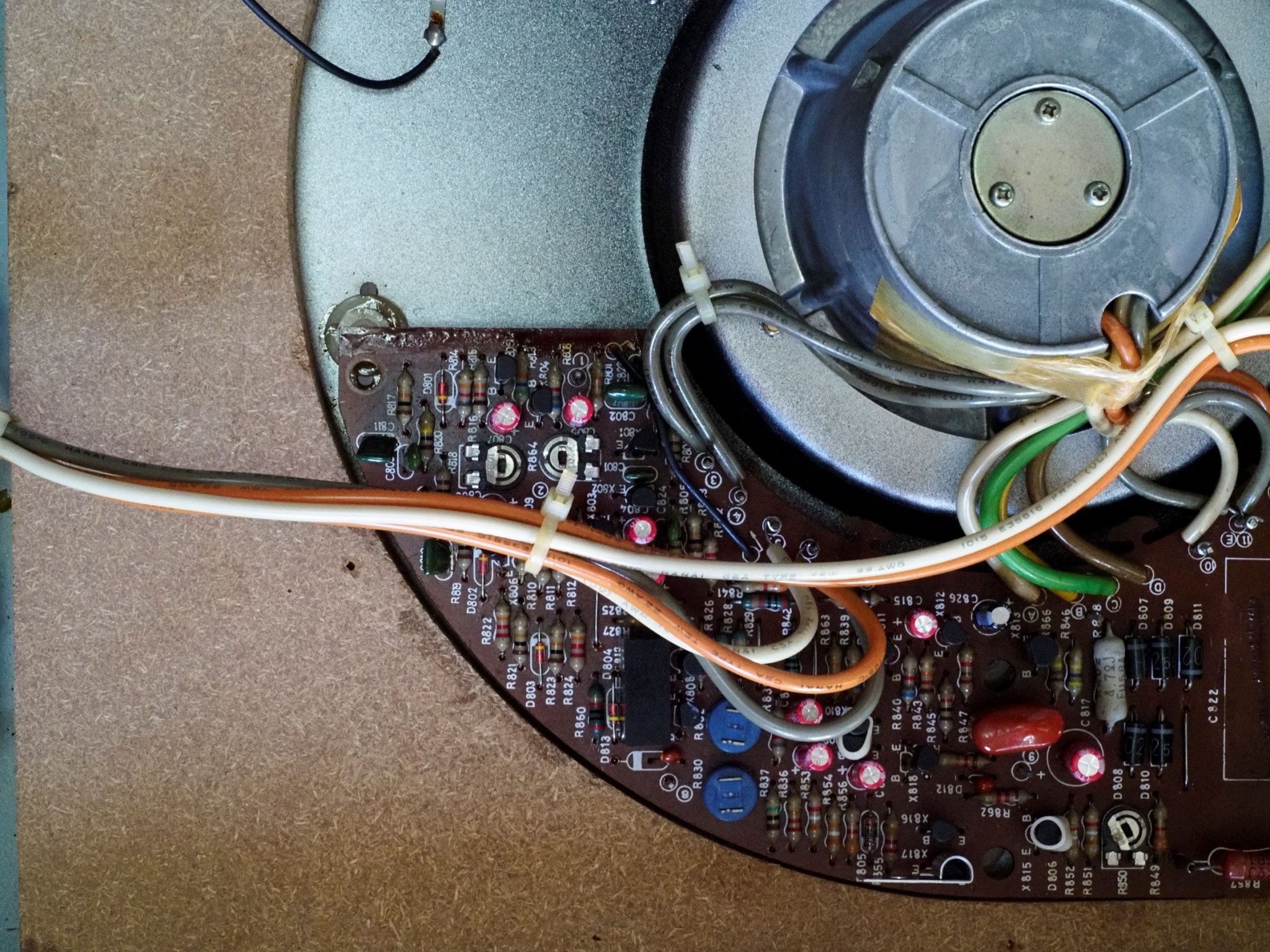

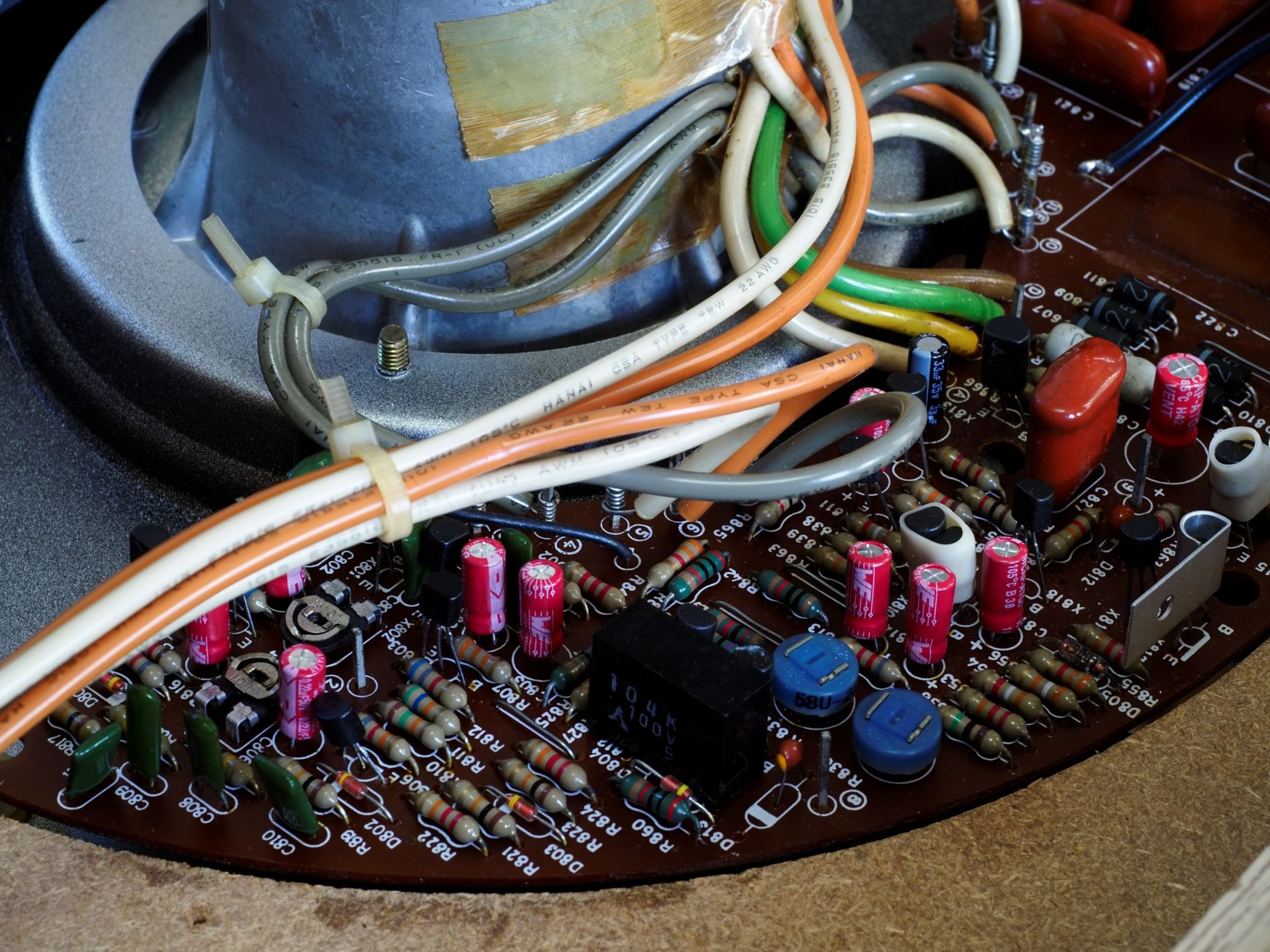

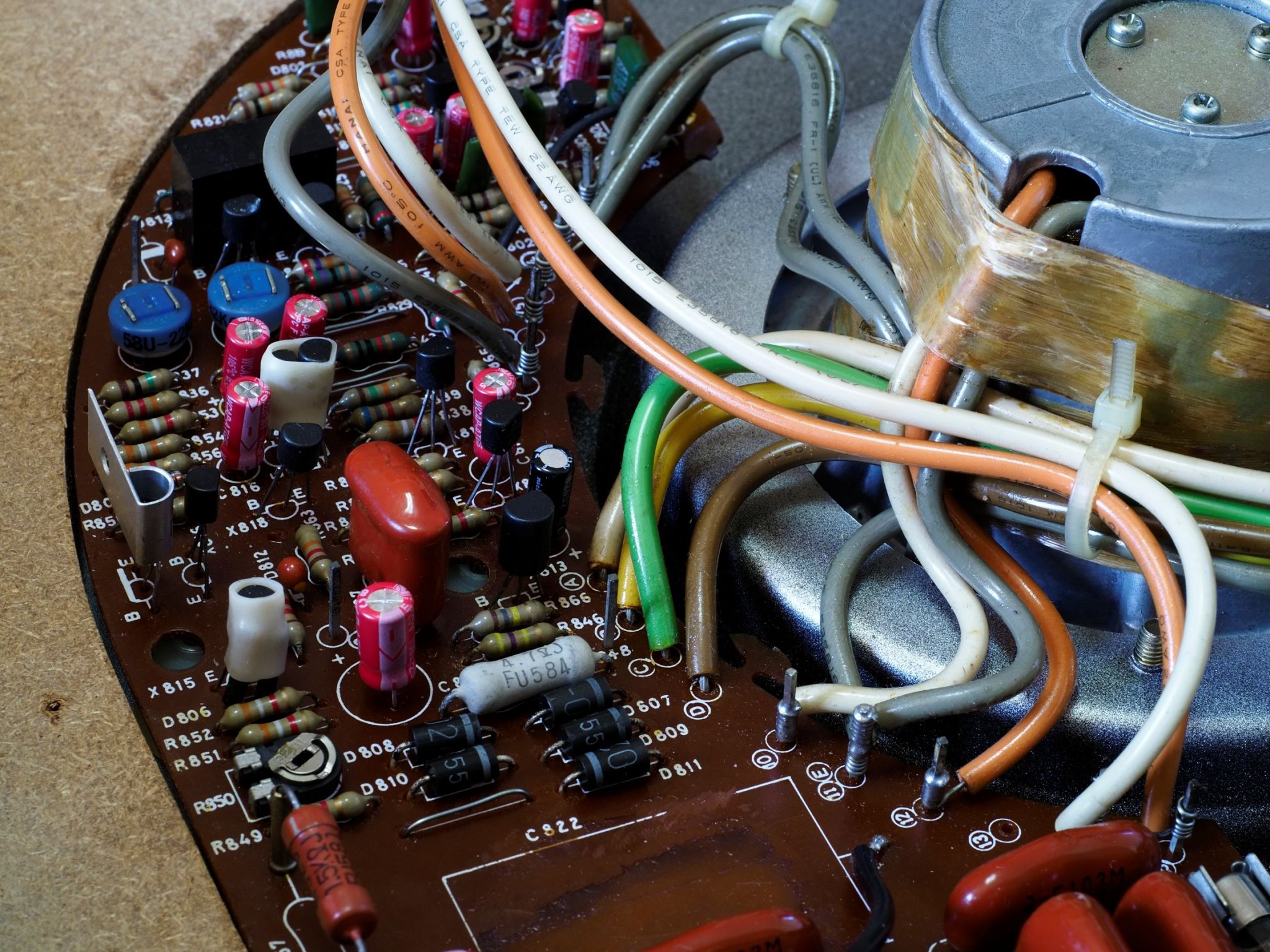

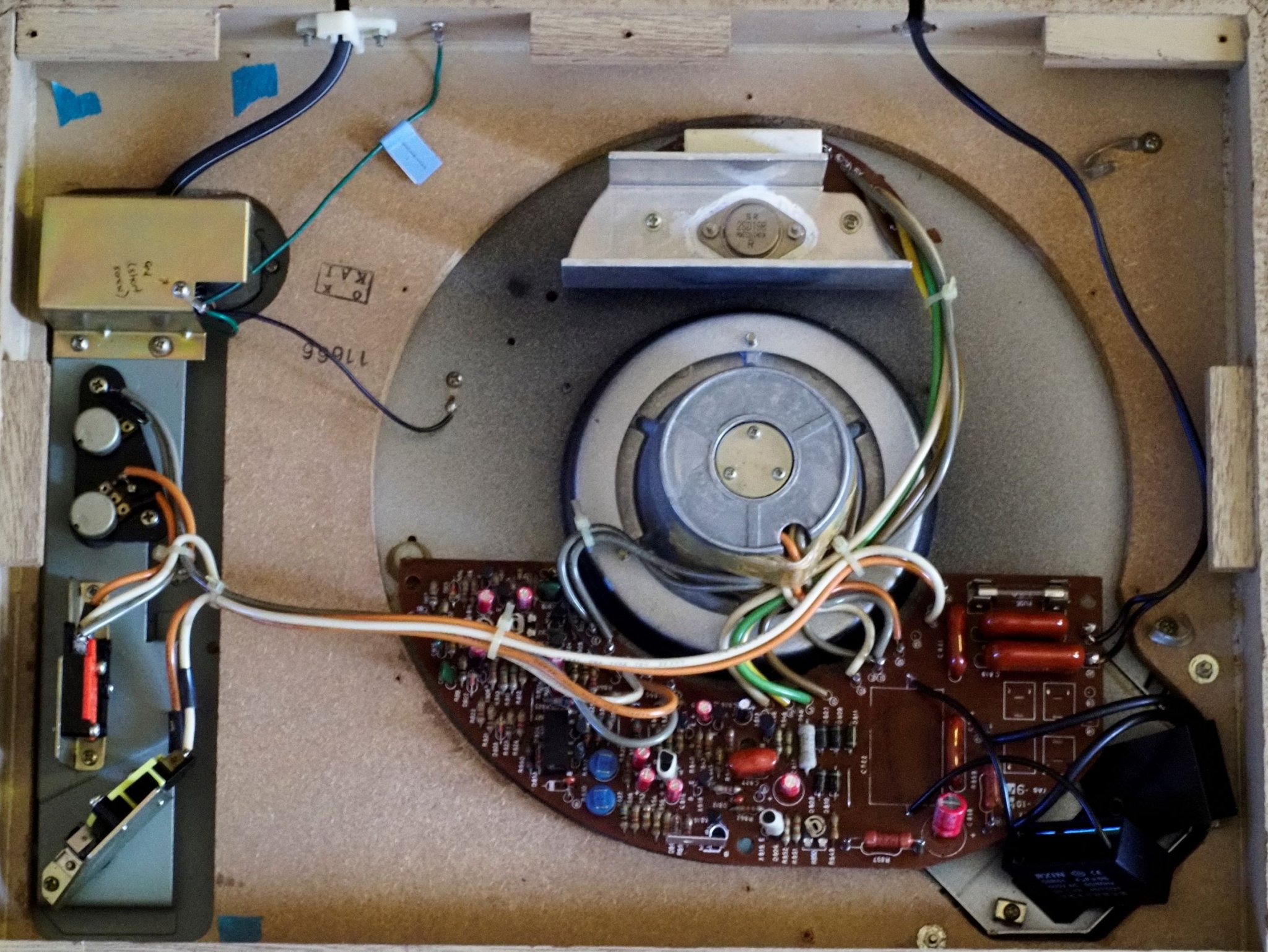

For a general idea of the physical circuit layout, I'll put some photos of the underside of the tt in the post below.

For a general idea of the physical circuit layout, I'll put some photos of the underside of the tt in the post below.

Last edited:

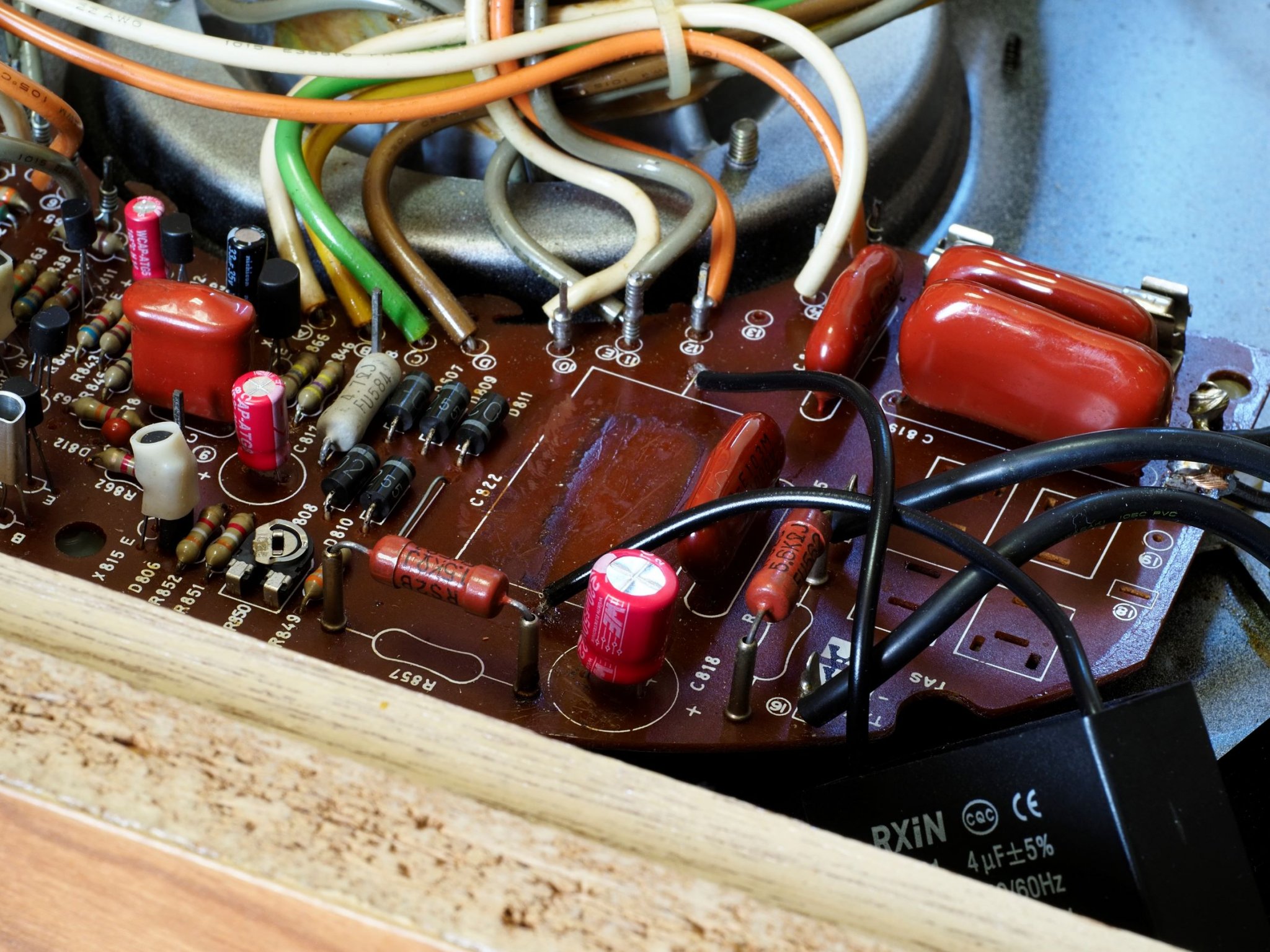

A few photos from various angles.

At some point I will replace the butt-ugly 4uF cap I used at C822.

At some point I will replace the butt-ugly 4uF cap I used at C822.

Could be a sticky motor, (or loose belt).

Clean off the old lube, and use Teflon or front axle grease, add a little light oil.

It could be that the motor is slow to respond, and the correction circuit is trying to set the speed, which is the cause of oscillating speed.

Had that problem on a VCR, it would spit back cassettes after loading tape over the head.

We tried different tapes, took it to a tech, he changed the loading motor belt, told me there was a timer, and if the loading was not complete within a set time, it would think fault and spit the tape out.

Conclusion: do check the mechanical parts first.

Clean off the old lube, and use Teflon or front axle grease, add a little light oil.

It could be that the motor is slow to respond, and the correction circuit is trying to set the speed, which is the cause of oscillating speed.

Had that problem on a VCR, it would spit back cassettes after loading tape over the head.

We tried different tapes, took it to a tech, he changed the loading motor belt, told me there was a timer, and if the loading was not complete within a set time, it would think fault and spit the tape out.

Conclusion: do check the mechanical parts first.

I will go back to the motor. I couldn't find any problem before, but I may just clean and relube anyway. I think I did that step before, but possibly I didn't relube.

Loose belt though? Probably not, on this deck!

Loose belt though? Probably not, on this deck!

The loose belt comment was in general, for people looking at this thread later.

Your unit appears to be direct drive, no belt.

Do check for wear on the shaft and bearings as well.

Your unit appears to be direct drive, no belt.

Do check for wear on the shaft and bearings as well.

Last edited:

Just saw this thread for first time, I suspect the motor is needing oil. Are the bearings sintered brass ‘oillite’ type?

I ran a quick check on the diodes (in circuit, power off). All were about 0.57 in one direction, OL in the other, except for D801 and D802. These read 0.57 forward biased, 0.69 in the other direction. Not sure what that means, but perhaps the identical reading for both suggests that they're working as intended?

For a general idea of the physical circuit layout, I'll put some photos of the underside of the tt in the post below.

The diode result is to be expected. Look at the circuit 🙂 These diodes are across a base/emitter junction that will appear as an inverse parallel diode to the one you are measuring. So all normal at a basic level of testing in circuit.

An apology to everyone who has pitched in to help.

Disaster. While I had the motor section open, the rotor fell to the floor when I moved the worktable. As that section is a thin copper cup, it has been dented out of shape. A stupid thing to do. Dammit. I can't see any way that it can be returned to perfectly circular, so after I reinsert it, it won't rotate even by hand. That, I think, is the end of this turntable.

Thanks so much to everyone who made suggestions, and sorry to have messed this up.

Disaster. While I had the motor section open, the rotor fell to the floor when I moved the worktable. As that section is a thin copper cup, it has been dented out of shape. A stupid thing to do. Dammit. I can't see any way that it can be returned to perfectly circular, so after I reinsert it, it won't rotate even by hand. That, I think, is the end of this turntable.

Thanks so much to everyone who made suggestions, and sorry to have messed this up.

There's a motor on Yahoo Auction, I may buy that. I'll think that over for a few days. That would most likely put me back in the position of relying on help again to troubleshoot the circuit. Really, looking at the turntable, I managed to find the one part that is really fragile and prone to irreversible damage. A lesson learned, anyway.

An alternative route would be to keep an eye open in the coming months for the whole TT to come up for sale cheaply. Part of this project was learning to reveneer the plinth with wood to replace the crappy-looking plastic that JVC used - I made the mistake of doing that before fixing the deck speed; another lesson learned - so I ended up with a plinth I am quite happy with. Just needs a working turntable sitting in it!

An alternative route would be to keep an eye open in the coming months for the whole TT to come up for sale cheaply. Part of this project was learning to reveneer the plinth with wood to replace the crappy-looking plastic that JVC used - I made the mistake of doing that before fixing the deck speed; another lesson learned - so I ended up with a plinth I am quite happy with. Just needs a working turntable sitting in it!

- Home

- Source & Line

- Analogue Source

- Inconsistent speed: JVC JL-B31