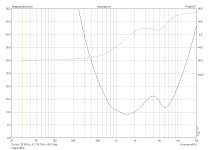

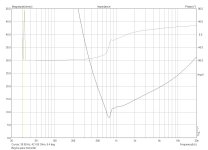

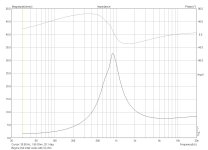

Some measurements. First, using the German filter posted here (I don't think the original is available online anymore):

I copied it blindly to save myself any nasty thinking, & it sounds OK, but measuring the drivers after not using them for a couple of years found the Fs is ~ 100Hz higher than factory specs so want to see If I can make any improvement.

Hi All, First time posting, very long time reader.

I need some assistance in designing a suitable cross over for this driver.

I have a pair of them as a novelty I guess, been sitting in a cupboard for 'awhile'

https://www.beyma.com/speakers/Fichas_Tecnicas/MC115.pdf

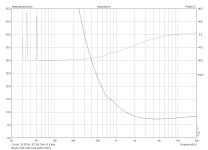

My own DATSv3 measurements don't line up with the spec sheet I found above, both drivers measured very closely.

My results are:-

RE=6.131

Fs=727.4hz

Qts=1.49

Qes=1.883

Qms=7.146

Le=0.2372

I've attached screen caps of xsim and the .frd and .zma files

How can I flatten this out?

Thanks in advance.

I need some assistance in designing a suitable cross over for this driver.

I have a pair of them as a novelty I guess, been sitting in a cupboard for 'awhile'

https://www.beyma.com/speakers/Fichas_Tecnicas/MC115.pdf

My own DATSv3 measurements don't line up with the spec sheet I found above, both drivers measured very closely.

My results are:-

RE=6.131

Fs=727.4hz

Qts=1.49

Qes=1.883

Qms=7.146

Le=0.2372

I've attached screen caps of xsim and the .frd and .zma files

How can I flatten this out?

Thanks in advance.

I copied it blindly to save myself any nasty thinking, & it sounds OK, but measuring the drivers after not using them for a couple of years found the Fs is ~ 100Hz higher than factory specs so want to see If I can make any improvement.

Attachments

Next, cobbled together a simple 2nd order xover with parts on hand (3Mh & 12.3uF). It will need to be tweaked, and the cheap clip cables I used measured .97 ohms, so they would have affected the results.

First, connected in parallel config, and then with 10 ohms across the driver:

First, connected in parallel config, and then with 10 ohms across the driver:

Attachments

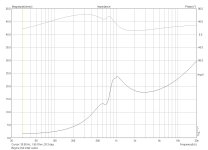

Ready for tweakage; The victims: SEAS CA18RLY, a well behaved & great sounding woofer, ideally I would have gone for bigger woof, but this is what I've got.

SEAS 22TFF tweeter, a great low distortion 3/4" driver; and aforementioned Beyma mid. My gut tells me to go parallel for this xover.

Challenge#1: Baffle step freq is 400Hz, yet mid will be crossed at ~1Khz, so some fiddling will be required

Challenge#2: will the mid behave itself at the low end?

SEAS 22TFF tweeter, a great low distortion 3/4" driver; and aforementioned Beyma mid. My gut tells me to go parallel for this xover.

Challenge#1: Baffle step freq is 400Hz, yet mid will be crossed at ~1Khz, so some fiddling will be required

Challenge#2: will the mid behave itself at the low end?

Attachments

I don't know if you did a sim with this x-over, but at a glance, it looks to me like the padding on the mid is going to create a low impedance. In addition to that, I've found that with tweeters, I prefer the x-over to be working with more than a 4 ohm load. It seems like they are less fussy when higher. Possibly just my tweeter causes this though.

Since you will pad the tweeter anyway, why not go ahead and change the padding?

Since you will pad the tweeter anyway, why not go ahead and change the padding?

Last edited:

re:'a sim with this x-over' - no, not a method I use, too time consuming

re:'padding on the mid' - no padding, what probably looks like an R is actually an L

re:'you will pad the tweeter anyway' - probably not, remember this is a 'starting point' xover. At this stage I'm thinking a single R to pad both mid & tweet together slightly, but all the drivers are close in sensitivity

re:'padding on the mid' - no padding, what probably looks like an R is actually an L

re:'you will pad the tweeter anyway' - probably not, remember this is a 'starting point' xover. At this stage I'm thinking a single R to pad both mid & tweet together slightly, but all the drivers are close in sensitivity

Rock'n & Rollin' - first impression after feeding with Jan Gabarek, Tool & Johnny Cash - very mid forward, the Beymas will need to be knocked back a few dB. Still a good sound though. Not as open or balanced as the MTMWWs beside them, which are my reference (Those non-ferrofluid Vifa tweeters are the biz!!)

Attachments

padding the mids down by~ 2dB (1.5 ohm in series) - better, but still some congestion

-4 dB (L pad 2.2 ohm & 10 ohm) - pretty good balance, I think I could live with that,

Next, some extended listening to see where to go next. So far, I think the low end of the Beymas won't be problematic, but it hasn't got loud yet.....

-4 dB (L pad 2.2 ohm & 10 ohm) - pretty good balance, I think I could live with that,

Next, some extended listening to see where to go next. So far, I think the low end of the Beymas won't be problematic, but it hasn't got loud yet.....

This time I'm using an unfamiliar material, some soft ply laminated with plastic on both sides (Scavenged from a nearby industrial estate, I think it was a reject counter top). So it'll be very reflective inside the box. Time to glue something to the walls, as well as add a large brace, methinks. And add a bit more stuffing for good measure.

FWIW/YMMV, etc., way back when; scrap packing crate corrugated cardboard made for a good underlayment/liner for my typically large void free/'slick' marine grade plywood cabs. Also is what I used to make my early speakers including a Karlson K15 and full size EV BLH thanks to the neighbor that got me hooked on this hobby at age 10.

Bracing was typically scrap 1x boards of differing widths glued vertically on edge. Much later I would learn that best to set at panel odd harmonics and only ~0.707x the panel height and randomly offset vertically to keep from having any continuous 'hot spot' joints, allow for crush zones.

One can learn an incredible amount about cab design from drop testing very heavy, large, prototype corrugated cardboard/wood frame w/plywood stiffeners packing crates (up to 120" x 90" x 48") from up to 50 ft high where the goal was finding the lightest/cheapest practical crating system. These systems included sensitive instruments, so rear corners became 'crush zones' with hanging dollies, component panels offset to ensure that's where they landed.

These systems included sensitive instruments, so rear corners became 'crush zones' with hanging dollies, component panels offset to ensure that's where they landed.

Bracing was typically scrap 1x boards of differing widths glued vertically on edge. Much later I would learn that best to set at panel odd harmonics and only ~0.707x the panel height and randomly offset vertically to keep from having any continuous 'hot spot' joints, allow for crush zones.

One can learn an incredible amount about cab design from drop testing very heavy, large, prototype corrugated cardboard/wood frame w/plywood stiffeners packing crates (up to 120" x 90" x 48") from up to 50 ft high where the goal was finding the lightest/cheapest practical crating system.

These systems included sensitive instruments, so rear corners became 'crush zones' with hanging dollies, component panels offset to ensure that's where they landed.

These systems included sensitive instruments, so rear corners became 'crush zones' with hanging dollies, component panels offset to ensure that's where they landed.Knocked back the mids another 2 dB, results in a better match between woofer baffle step fall off & the mids, and a better balance overall. Sound nice at med/high volume. Now at a point where I can tweak other xover components, but I don't think any changes will be extreme. Not as bright/forward as my reference speakers, but those have more lively tweeters as well as supertweeters.

Finally buttoned these up. Ended up with 9dB attenuation on the Beymas (3.3 ohm resistors on the parallel leg of the L pad damp them nicely), and a couple of tweaks to inductor values. It was sounding a bit dull, then my 'D'oh' moment came when I realised that the mids needed to be reversed in phase. After fixing that - there it was - the sound I'd been looking for. I'll pair them with a couple 2x8" sealed cabs with nice old school high Q woofers. That'll add some oomph to the bottom, and they're the perfect height as stands.

- Home

- Loudspeakers

- Multi-Way

- Impedance nulling filter