MJ is close. If you simply run a bead of PVA along the joint allowing for a dot or two of hot glue by either leaving a small gap in the bead of PVA or even creating a little circle to add the hot glue into. You might also use tape as a clamp if you are worried about the hot glue not holding it well enough.

Using a needle to apply the PVA will leave you with a rather weak joint I would think.

Using a needle to apply the PVA will leave you with a rather weak joint I would think.

Just for a second, I tried to imagine what would happen if one could construct a hypercube home, i.e. listening room... 😀

Just for a second, I tried to imagine what would happen if one could construct a hypercube home, i.e. listening room... 😀

One of the first images that popped into my head when I first discovered hypercubes was a hypercube concert hall.

Greetings again. Have to dash this off quickly because I have to go somewhere tonight. Wish I joined this site years ago. Overkill, you are on the same page with me with regard to the passive re-radiation. I do indeed think there is a phase reversal effect, but describing it in an airtight (no pun intended) way mathematically is a challenge. I have the beginnings of a theory, but it needs some polishing before I present to people who have put in the time to know more about audio design than I do.

Muddjester, thanks for the cutaway diagram! Since the 45 degree bevel is wider than the tilted thickness of the triangle edge, the only way I have found to make the seams equal width for glueing is to use a thinner square or thicker triangles.

Squeak, yes, I do think wistfully of getting into production again. I have tried a couple of times but with no startup capital it's more self-abuse than a real business.

What we found worked well for wood was simple Elmer's regular or carpenter glue. For a clamp we stretched short lengths of duct tape across the edges on the outside while they were drying so that the tension would press the bevels together. Of course, we paid for that when we found that duct tape tends to leave a residue on the wood that is problematical for staining and sealing. I have since been told that packing tape leaves much less residue.

Muddjester, thanks for the cutaway diagram! Since the 45 degree bevel is wider than the tilted thickness of the triangle edge, the only way I have found to make the seams equal width for glueing is to use a thinner square or thicker triangles.

Squeak, yes, I do think wistfully of getting into production again. I have tried a couple of times but with no startup capital it's more self-abuse than a real business.

What we found worked well for wood was simple Elmer's regular or carpenter glue. For a clamp we stretched short lengths of duct tape across the edges on the outside while they were drying so that the tension would press the bevels together. Of course, we paid for that when we found that duct tape tends to leave a residue on the wood that is problematical for staining and sealing. I have since been told that packing tape leaves much less residue.

Hi,

One things for sure, there is no acoustic black hole in it,

and as a pressure vessel all acoustic output of the walls

will be out of phase with the driver in the bass.

However, just like a port, the main modal resonance

of a panel will be generally be in phase with the driver

if no internal standing waves are involved.

CLD is of limited use in speakers where the edges of

panels are sort of clamped by being glued together.

(CLD is great in something like an open baffle, where

the material towards the edges does the most damping.)

RLD generally works better in the central area of the panel.

Mass dampers can work, basically a disc of rubber and say a

steel disc carefully tuned to the main mode of the panel.

Its not radical, its just an interestingly shaped box,

that doesn't do the pseodotechnobabble claimed for it.

Removing or preferring enclosures without internal

acoustic damping is nothing new, so called "golden

ears" clearly convincing themselves of their bias.

All the evidence is that stuffing is always better.

rgds, sreten.

Foamboard faced off with aluminium sheeting,*

stuck on with contact adhesive is an idea, as

is using a glue that mildly dissolves the foam.

* Commonly known as foilboard, just foam and foil,

but commonly much thicker then typical foamboard.

One things for sure, there is no acoustic black hole in it,

and as a pressure vessel all acoustic output of the walls

will be out of phase with the driver in the bass.

However, just like a port, the main modal resonance

of a panel will be generally be in phase with the driver

if no internal standing waves are involved.

CLD is of limited use in speakers where the edges of

panels are sort of clamped by being glued together.

(CLD is great in something like an open baffle, where

the material towards the edges does the most damping.)

RLD generally works better in the central area of the panel.

Mass dampers can work, basically a disc of rubber and say a

steel disc carefully tuned to the main mode of the panel.

Its not radical, its just an interestingly shaped box,

that doesn't do the pseodotechnobabble claimed for it.

Removing or preferring enclosures without internal

acoustic damping is nothing new, so called "golden

ears" clearly convincing themselves of their bias.

All the evidence is that stuffing is always better.

rgds, sreten.

Foamboard faced off with aluminium sheeting,*

stuck on with contact adhesive is an idea, as

is using a glue that mildly dissolves the foam.

* Commonly known as foilboard, just foam and foil,

but commonly much thicker then typical foamboard.

Last edited:

I will see if I can make some polar measurements of the back side. The front of the driver will have to be covered with a pillow of something to make sure I am measuring radiated emissions from the Hypercube wall only.

BTW I chose the handle Tesserax because that is the name of the corporation we formed back in the day to try to go into production. The problem with the name was that the only people who got the inside joke that is was slang for "tesseracts" were people who were quick to inform me that you cannot build a real tesseract in 3-space.

-- Matthew

-- Matthew

For a clamp we stretched short lengths of duct tape across the edges on the outside while they were drying so that the tension would press the bevels together.

I had no residue. I wonder if my boxes were in a cooler enviro?

Tape residue is usually easily removed with household ammonia.

I used duct tape backed up with fiberglass tape (thin strip on top) for the extra strength while under tension.

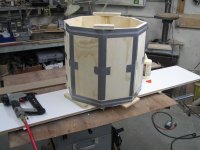

Attachments

Vix, and Greg, I have had the same thought -- a listening room or concert hall in the rhombic dodecahedral shape. Might sound better on the outside though, heh. Could be very resonant in there...

With regard to manufacture, since the patent expired long ago I'd be happy to see anyone take a crack at it,just to promote the design. there cold be other applications of the geometry. Though electromagnetic waves are transverse rather than longituidinal, it is still true that a parabolic dish works for both sound and radio/microwaves.

With regard to manufacture, since the patent expired long ago I'd be happy to see anyone take a crack at it,just to promote the design. there cold be other applications of the geometry. Though electromagnetic waves are transverse rather than longituidinal, it is still true that a parabolic dish works for both sound and radio/microwaves.

Good point Cal. Florida is where we were and the building we rented for manufacturing was not air-conditioned. Maybe if we had tried it further North it would have worked better. Does ammonia give any issues with stain or polyurethane? I should have spent more time researching solvents. Live and learn. I don't repeat mistakes a lot -- but I do seem to make all of them once.

Ammonium hydroxide is residue free so it would depend on the water they use to dilute it for household ammonia.Does ammonia give any issues with stain or polyurethane?

Use gaffer tape. Real gaffer tape, like sound and film technicians use. It's expensive compared to duct tape but is designed to come off cleanly and not lift paint.

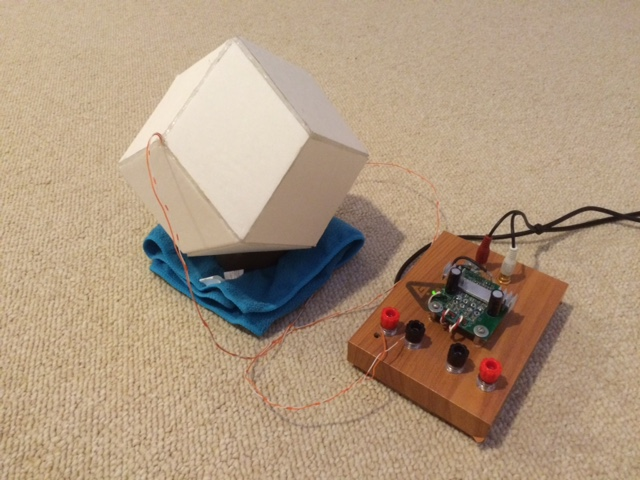

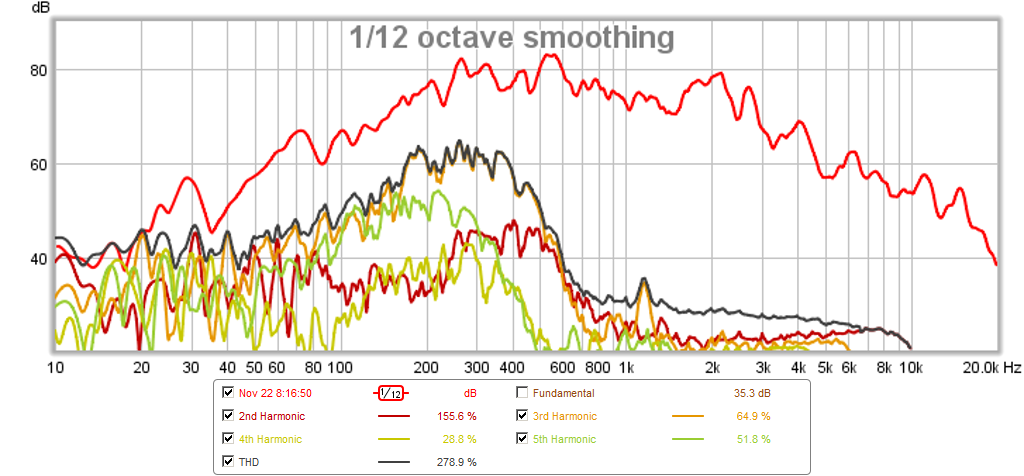

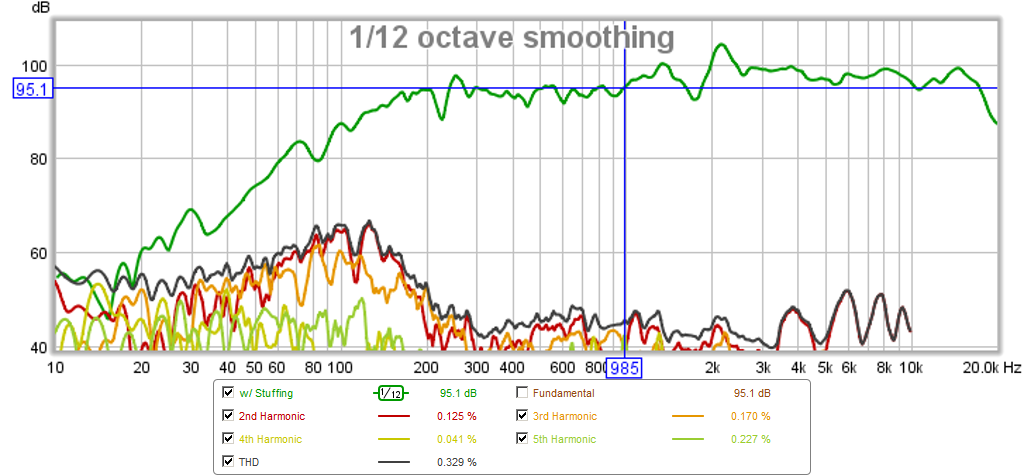

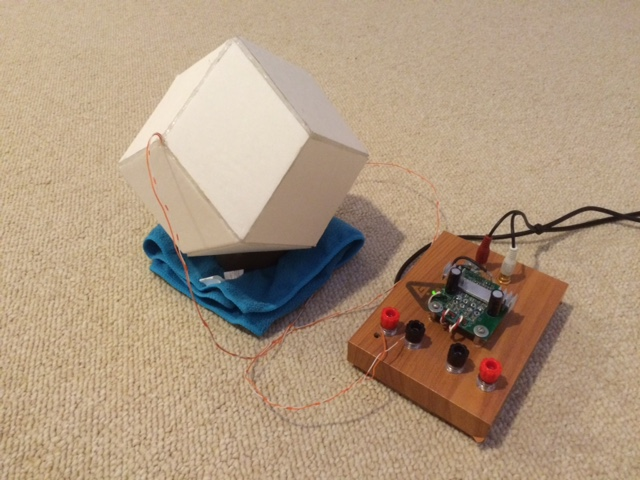

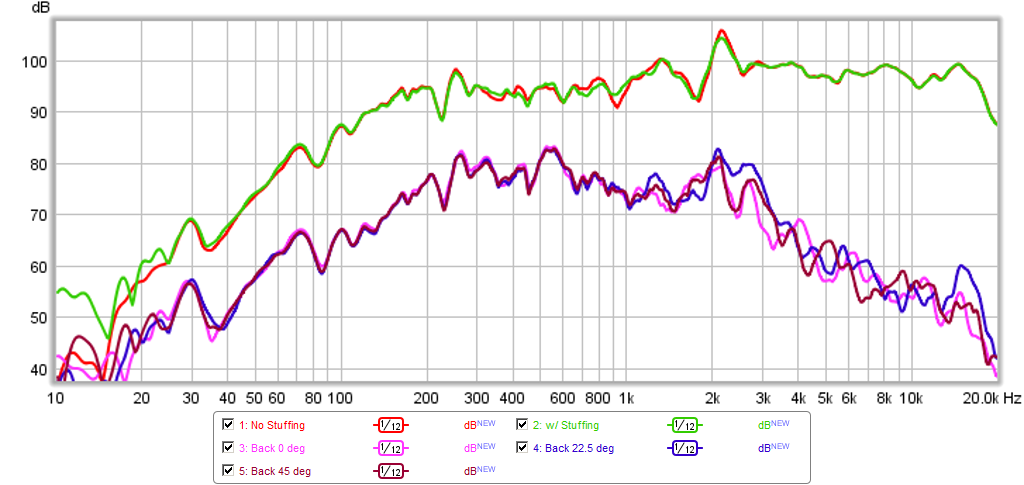

Backside Radiated Emission

I aimed the front of the driver into a 3in dia paper tube sitting on microfiber cloth to limit output only to rear re-radiated emission. The driver face is pointing down and the mic is horizontal at 0.5m away. There is quite a bit of emission and it sounds pretty good playing saxaphone jazz (Paul Desmond). It sounds uniform like a sphere emission - uniform everywhere in 2pi space. I was listening to it on the floor and it sounds good. For the measurement I elevated onto a stool at about 30 in high.

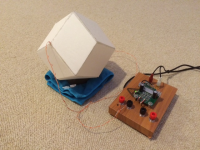

Here is a photo of it as spherical radiator on the floor:

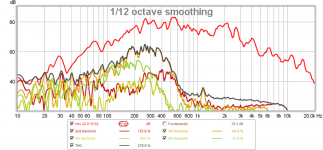

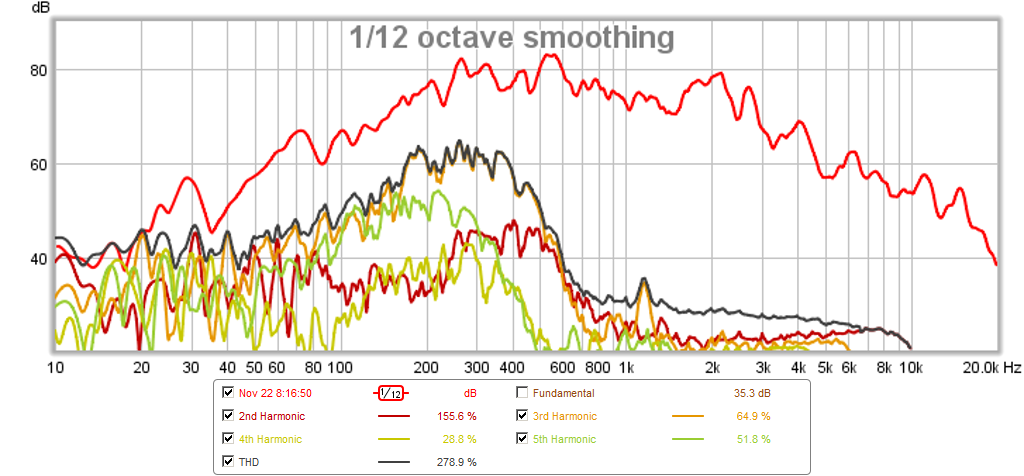

Here is the measured response (with stuffing):

This is probably the ambiance that this speaker adds that may explain why it sounds pleasing. It is broadband with some resonance peaks.

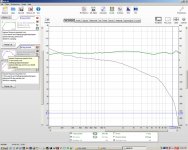

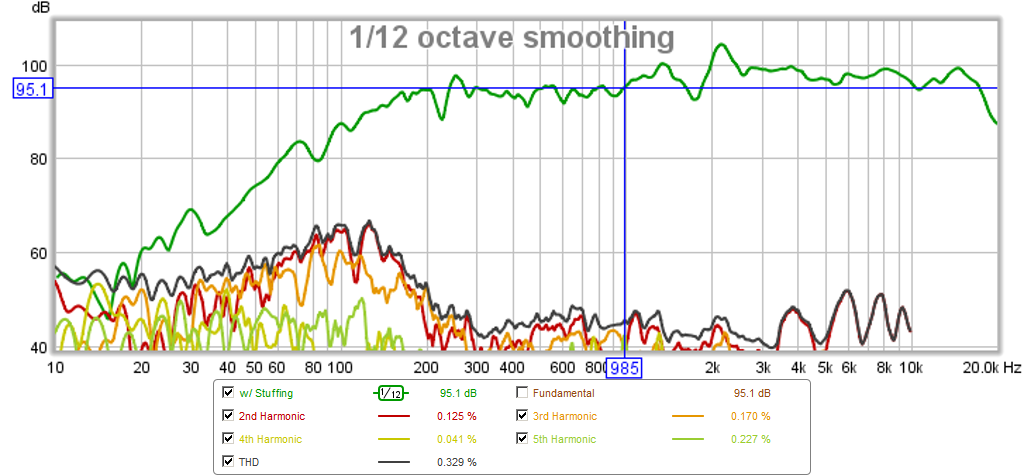

For reference, here is the previous on axis direct radiator measurement:

I aimed the front of the driver into a 3in dia paper tube sitting on microfiber cloth to limit output only to rear re-radiated emission. The driver face is pointing down and the mic is horizontal at 0.5m away. There is quite a bit of emission and it sounds pretty good playing saxaphone jazz (Paul Desmond). It sounds uniform like a sphere emission - uniform everywhere in 2pi space. I was listening to it on the floor and it sounds good. For the measurement I elevated onto a stool at about 30 in high.

Here is a photo of it as spherical radiator on the floor:

Here is the measured response (with stuffing):

This is probably the ambiance that this speaker adds that may explain why it sounds pleasing. It is broadband with some resonance peaks.

For reference, here is the previous on axis direct radiator measurement:

Attachments

Last edited:

VERY cool and interesting, xrk971. Your tests are confirming what witnesses have been telling me for decades. We obtained this sort of effect (anecdotally, alas) even with heli-arc welded 1/8 inch aluminum. On occasion, we have constructed the shape out of much thicker materials sic as 1 inch particle board. When we did that. what we tended to notice was much the the same quality of sound in the frontwave as before, but a reduction of the passive radiation. In other words, same fidelity and transient response, but less omnidirectional sound.

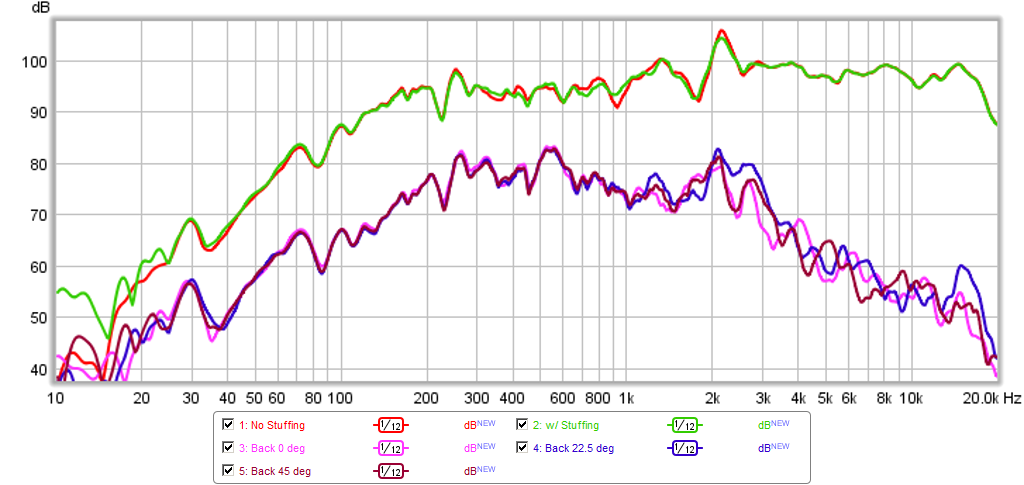

I did a few more measurements at 22.5 deg, 45 deg, at 90 deg it is symmetric so would look like 0 deg. It is pretty uniform. Overlaid are the on axis direct radiator measurements. Same distance, same amplitude drive.

Attachments

You beat me! I'm just setting up the mic now. Very nice job, and thanks for your efforts. Mine will be without isolating the driver and with and without stuffing. Also want to try and see what's going on with the efficiency compared to the sealed box...

Gmad and xrk971, I cannot overstate how grateful I am for your work and testing on this design that has lain mostly neglected and ridiculed for 34 years. If a picture is worth a thousand words, a well-executed graphical rendering of objective test data is probably worth a million words of my own ramblings. The fact that your results appear to be validating decades of observation and are visible to the global community now is a badly needed shot-in-the-arm for the aged "mad scientist" I have become.

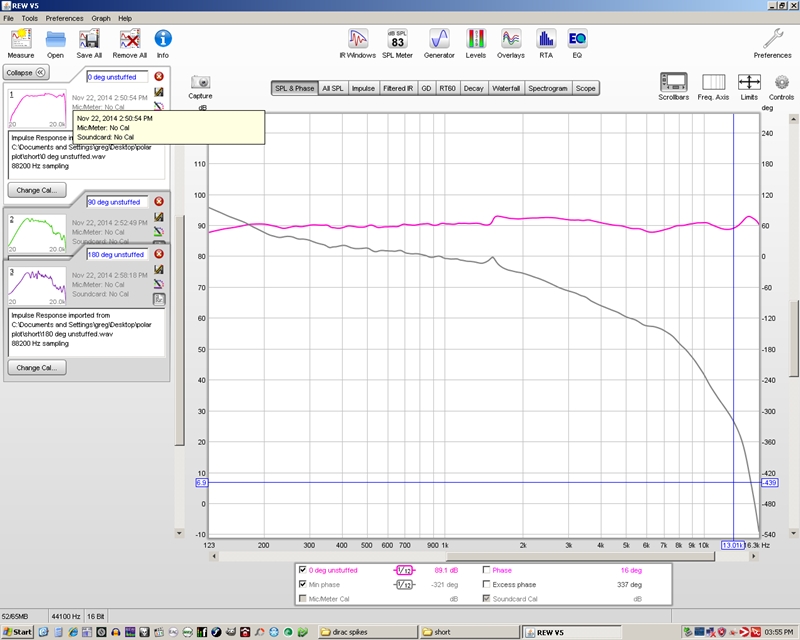

Freq and minimum phase response at 0, 90 and 180 degrees with and without stuffing.

Attachments

Freq and minimum phase response at 0, 90 and 180 degrees with and without stuffing.

Those measurements look very nice - the 0deg is very flat - what driver is this and how far away are you measuring? I know of no full range driver that is this flat and reaches 20kHz without breakup modes.

The 180deg starts dropping off at 3kHz like mine.

How far away are the walls in your room?

A tip for getting images in REW: click in the camera icon on top left corner of plot to save as png file. That way you don't need to do screen shot.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Hypercube Loudspeakers