Hello,

I want to build a spherical speaker, but I don't really know how to do it.

What exactly do I have to consider when designing the housing and which calculations do I have to make?

How to calculate the size of the case for a normal box is written a thousand times on the internet, but how do I do that for a spherical case?

can someone give me something like a guideline?

I want to build a spherical speaker, but I don't really know how to do it.

What exactly do I have to consider when designing the housing and which calculations do I have to make?

How to calculate the size of the case for a normal box is written a thousand times on the internet, but how do I do that for a spherical case?

can someone give me something like a guideline?

Hello, it should be floorstanding speakers. Nothing really big now that takes up the whole room, but nothing really small for the desk either.

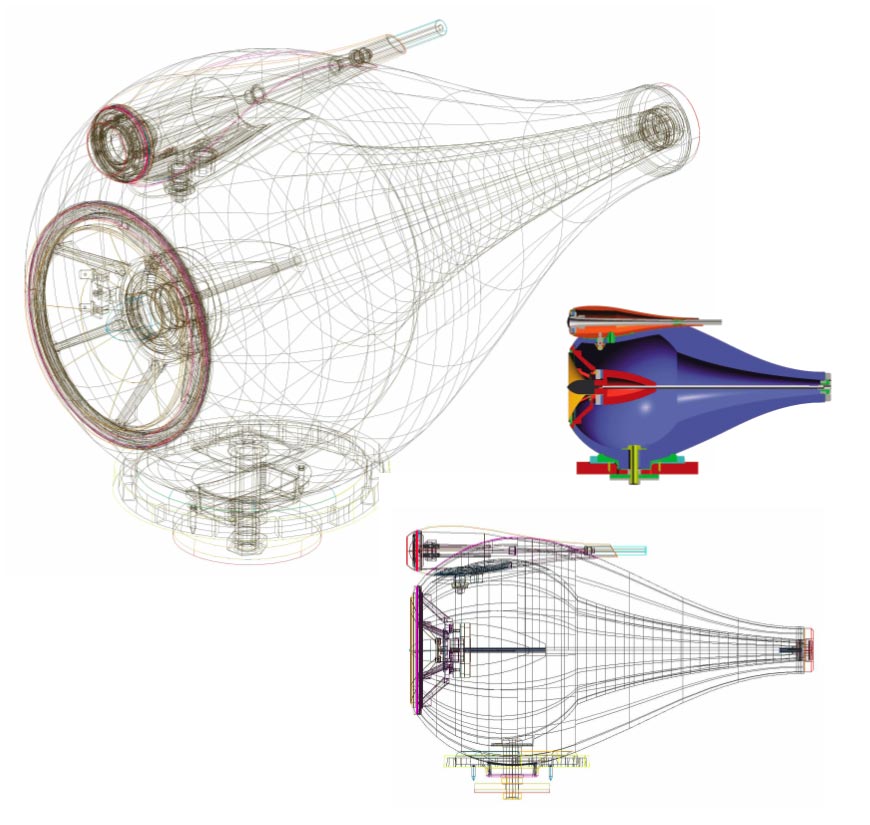

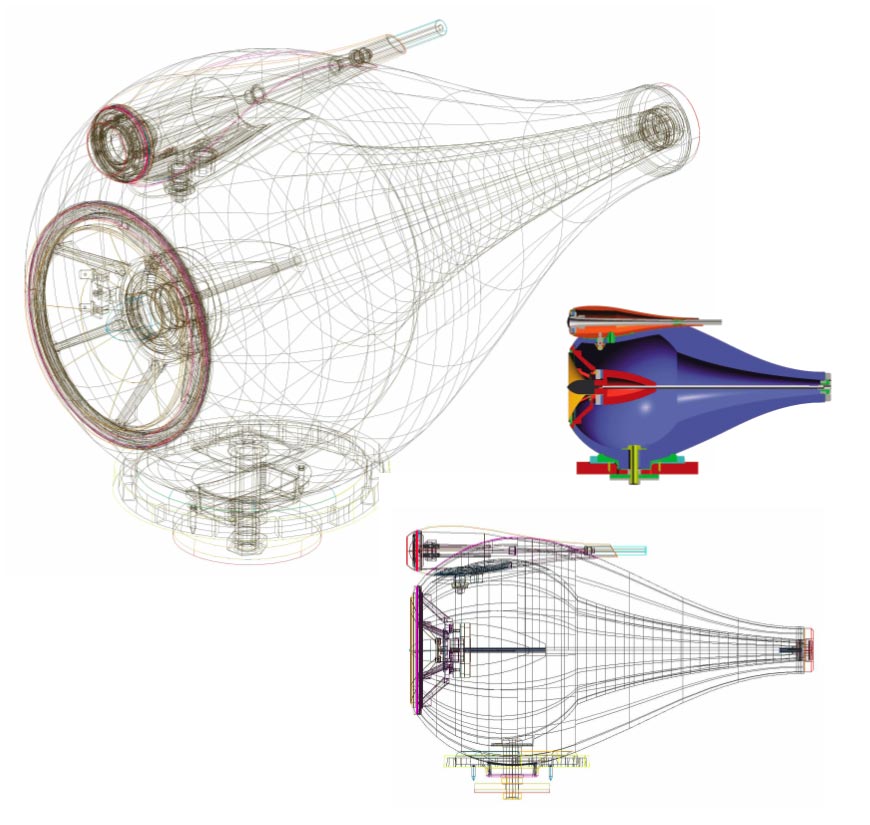

Cabasse La Sphere serves as a visual template. Only in smaller and thinner. Unfortunately, I don't have the exact dimensions yet.

Cabasse La Sphere serves as a visual template. Only in smaller and thinner. Unfortunately, I don't have the exact dimensions yet.

Last edited:

Ikea Blanda bowl made in bamboo comes to mind. 28 cm diameter and you need two to make a sphere. There are 2 or three threads along here on DIYaudio about 'spherical bowl', be it wood or metal.

I don't know the acoustic properties ( soundproof-ness) of those materials, but additional work should be done to get it 'dead'

I don't know the acoustic properties ( soundproof-ness) of those materials, but additional work should be done to get it 'dead'

The volume of a sphere is 4.1888 * r * r *r where r is the radius (i.e. half the inside diameter of the sphere). E.g If the sphere has an internal diameter of 1.0 metre:

r = 0.5m

v = 4.1888 * 0.5 * 0.5 * 0.5 = 0.5236 cubic metres.

Care: You also need to allow for any internal space lost due to battens, drivers etc...

r = 0.5m

v = 4.1888 * 0.5 * 0.5 * 0.5 = 0.5236 cubic metres.

Care: You also need to allow for any internal space lost due to battens, drivers etc...

Here's a link to a design by the well respected speaker magician Mr Curt Campbell:

Exclamations

Speaker houses a Dayton RS180 and RS28 tweeter.

Geoff

Exclamations

Speaker houses a Dayton RS180 and RS28 tweeter.

Geoff

A ready made housing: BLANDA MATT Servierschussel, Bambus. Bestell es noch heute - IKEA Deutschland

You only need a front baffle for your driver!

You only need a front baffle for your driver!

I actually wanted to have the enclose 3D printed. I also have CAD knowledge, but what exactly do I have to pay attention to with the enclosure?

Many years ago, I used one of those big exercise balls and covered with several layers cling wrap, then multiple layers of fiberglass built up around it. It was part of a 3 way build with progressive smaller spherical enclosures for LF, MF and HF drivers. For the mid enclosure I used a cheap kids 12" playground ball as the mold (also used cling wrap to protect from fiberglass resin) and a similar, smaller 6" ball for the HF driver enclosure.

I chose those items for molds because they are dimensionally stable and accurately round, unlike something flimsy like a beach ball. The exercise ball gives you some flexibility in range of size depending on how much you inflate it. The only thing to watch out for is large temperature swings while the multiple layers of fiberglass cures, so the air doesn't expand or contract inside during that time changing its size. You're probably forced to do this outdoors due to fiberglass resin fumes, so pick a day where temps will be mild and constant. There will be some heat release during the curing process of the resin, but it shouldn't affect the inside air pressure noticeably.

Some tips- you will need to leave a small hole open on each sphere to deflate and remove your mold ball. In the case of the smaller molds, the balls may end up being sacrificial because they don't hold up well to the resin fumes which may attack the material they're made from, so buy as many balls as you will need for additional enclosure molds. Fortunately these are pretty cheap. The excercise ball will survive more than one mold as long as you keep any resin from getting on it.

Hopefully that helps someone get started.

I chose those items for molds because they are dimensionally stable and accurately round, unlike something flimsy like a beach ball. The exercise ball gives you some flexibility in range of size depending on how much you inflate it. The only thing to watch out for is large temperature swings while the multiple layers of fiberglass cures, so the air doesn't expand or contract inside during that time changing its size. You're probably forced to do this outdoors due to fiberglass resin fumes, so pick a day where temps will be mild and constant. There will be some heat release during the curing process of the resin, but it shouldn't affect the inside air pressure noticeably.

Some tips- you will need to leave a small hole open on each sphere to deflate and remove your mold ball. In the case of the smaller molds, the balls may end up being sacrificial because they don't hold up well to the resin fumes which may attack the material they're made from, so buy as many balls as you will need for additional enclosure molds. Fortunately these are pretty cheap. The excercise ball will survive more than one mold as long as you keep any resin from getting on it.

Hopefully that helps someone get started.

Thanks in any case for all the answers. Does anyone know of simulation software for sphere speakers?

Same has a bafle. It has a bafle step but more regular with less peaks and dips, you just see when measuring the two drivers in each ball into your filter soft (Vitruix, XSim, etc), the work on the filter like any loudspeaker. You always could reduce an internal volume load seen by the driver by reducing it with a solid thing you add, like a tennis ball for instance, or stuffing it with wool (it is said to enlarge the load up to 20% with 100% stuffing, which is anyuway advised with a sealed load -if it's your goal-

You can for instance use as shown, Ikea Salad bowls. Bamboo is internally better damped than aluminium ones, you also can use for the demi sphere behind for aesthetical -temperature?- behavior.

The great balls of prestige thread was a cool thread and trhe author also published a spheric synergy with the same round idea in mind for miniminize difractions (more exactly to smooth them) and of course for aesthetic (See Elipson sphere from the 70s')

You can for instance use as shown, Ikea Salad bowls. Bamboo is internally better damped than aluminium ones, you also can use for the demi sphere behind for aesthetical -temperature?- behavior.

The great balls of prestige thread was a cool thread and trhe author also published a spheric synergy with the same round idea in mind for miniminize difractions (more exactly to smooth them) and of course for aesthetic (See Elipson sphere from the 70s')

Last edited:

Nice! But this is bamboo, has anyone tried that for the cabinet 😀

Yes, bamboo is probably some of the best material next to aluminium for speaker cabinets, especially bamboo phenol resin material, for me reaches the sweet spot of not being too dead that you can get from delignit/panzerholz and good sound characteristics. Unfortunately its quite expensive to buy boards of bamboo even compared to baltic birch today😉 Usually twice as expensive as baltic birch. There are quite a few bamboo high end speaker manufacturers a that swear by bamboo and people using Ikea as a cheap source of bamboo is super well known, e.g. the choppingboards for plinths or boards. Ikeas buys and processes so much bamboo that unless you buy huge amounts you will not find bamboo boards cheaper. Maybe line the inside with alubutyl to give it more strength and weight. The only issue I see with the bowls.

Good luck

It's the internal volume of the enclosure that counts, not the shape of it. Spherical, cubical, monkey coffin--makes no difference. Just get the internal volume right for the drivers you have using Thiel Small parameters.

Here is a 4-sphere floor standing speaker (about 40" tall) using Ikea bamboo bowls. Bottom two spheres are the 11" large bowls used to house a down-firing 6.5" subwoofer and forward firing 7" woofer. Each of these spheres are heavily damped inside using 3 materials. Next is the 8" midrange sphere using a sealed 2" dome (the sphere is purely for aesthetics and exterior acoustics), and finally the 5" tweeter sphere using a sealed 1" dome driver. Crossover is contained in the woofer sphere. Very complex to make these but end result is an excellent system absent of the typical internal resonances and external diffractions of more conventional shapes. Very tight bass and open mid and highs.

Attachments

Spheres are typically either made with found items (like the blanda bowls), other semi-sperical forms. Or use of something round as a base to create a fiberglass/composite creation (sort of like you are making a pair of bowls (can it come out of the mold any other way. this also points to big chunck of wood and a lather or high-z CNC.

Translam is a laour intensive method with high materials cost.

Ready made sphers can be bought as well.

A sphere has the worst possible internal resonance signature, one needs to at least have significant damping at the centre. If you are going the way of doinf anything but repurposing something already Spherical (like bowls) i would suggest taking it a step further and follow the R&D that created these:

dave

Translam is a laour intensive method with high materials cost.

Ready made sphers can be bought as well.

A sphere has the worst possible internal resonance signature, one needs to at least have significant damping at the centre. If you are going the way of doinf anything but repurposing something already Spherical (like bowls) i would suggest taking it a step further and follow the R&D that created these:

dave

Last edited:

- Home

- Loudspeakers

- Multi-Way

- How to build a spherical speaker?