Yes 2 by 1 is under 50x25, it's about 48x24. Well under 2" by 1"

And if it's planed it's even smaller.

Unless you ask the supplier for a custom thickness of 1", then he'll give you that at an increased cost.

He might be able to get 2.5" by 1.25" and plane it down to 2" by 1" and charge you for the wasted wood and the extra labour.

But he might have to buy in nominal 3" by 1.5" (~72x37) and custom thickness it for even more wasted wood.

And if it's planed it's even smaller.

Unless you ask the supplier for a custom thickness of 1", then he'll give you that at an increased cost.

He might be able to get 2.5" by 1.25" and plane it down to 2" by 1" and charge you for the wasted wood and the extra labour.

But he might have to buy in nominal 3" by 1.5" (~72x37) and custom thickness it for even more wasted wood.

Last edited:

Most sheet goods in the U.S. are actually Metric dimensions. 18 mm for nominal 3/4" and 12mm for nominal 1/2" 6 mm for 1/4"

Even the U.S. inch is based on the Metric system! 25.4 mm is the standard for an inch in the U.S.

Even the U.S. inch is based on the Metric system! 25.4 mm is the standard for an inch in the U.S.

Does Hornresp account for the exponentially increasing effect of mass inertia of the particle velocity within a quarter wave resonator?

I have been searching for this but I can only find some old comments from the live audio board from old times.

Regards,

Johannes

I have been searching for this but I can only find some old comments from the live audio board from old times.

Regards,

Johannes

Does Hornresp account for the exponentially increasing effect of mass inertia of the particle velocity within a quarter wave resonator?

Should say:

Does Hornresp account for the exponentially increasing effect of mass inertia with increasing spl - of the particle velocity within a quarter wave resonator?

Regards,

Johannes

Does Hornresp account for the exponentially increasing effect of mass inertia with increasing spl - of the particle velocity within a quarter wave resonator?

Hi Johannes,

No it doesn't.

Would it make much difference to the results if it did?

Do you perhaps know of a loudspeaker simulation program that takes air particle mass inertia into account when calculating volume velocity?

Kind regards,

David

Thanks for your answer David. This really helps me a lot. 🙂

Great! Then this explains what we are experiencing with our new ROAR series and why we don't see it in the simulations.

Yes, I believe it would. It seems to make quite a substantial difference.

I hope I can make some better measurements soon. I will post them and my findings if I can document them in a clear and easy to understand (for myself) way.

No, I don't. I do think it would be a great feature though. I am not well versed with loudspeaker simulation programs. Hornresp is usually more then enough. It is a great tool, and I am spending way to much time in front of Hornresp.

I would like to learn how to use CFD software, but I find it way over my head. It would be a great additional tool for the development of bass horn loudspeakers.

Regards,

Johannes

No it doesn't.

Great! Then this explains what we are experiencing with our new ROAR series and why we don't see it in the simulations.

Would it make much difference to the results if it did?

Yes, I believe it would. It seems to make quite a substantial difference.

I hope I can make some better measurements soon. I will post them and my findings if I can document them in a clear and easy to understand (for myself) way.

Do you perhaps know of a loudspeaker simulation program that takes air particle mass inertia into account when calculating volume velocity?

No, I don't. I do think it would be a great feature though. I am not well versed with loudspeaker simulation programs. Hornresp is usually more then enough. It is a great tool, and I am spending way to much time in front of Hornresp.

I would like to learn how to use CFD software, but I find it way over my head. It would be a great additional tool for the development of bass horn loudspeakers.

Regards,

Johannes

Most sheet goods in the U.S. are actually Metric dimensions. 18 mm for nominal 3/4" and 12mm for nominal 1/2" 6 mm for 1/4"

Even the U.S. inch is based on the Metric system! 25.4 mm is the standard for an inch in the U.S.

18mm does not seem to be accurate if 25.4 mm × 0.75 = 19.05 mm.

I can't even let the 12 mm slide when 12.7 should be rounded up to 13 mm.

18mm does not seem to be accurate if 25.4 mm × 0.75 = 19.05 mm.

I can't even let the 12 mm slide when 12.7 should be rounded up to 13 mm.

Can't argue against you. But it is what it is.

The world is a whole lot bigger than the U. S. of A.

The world is a whole lot bigger than the U. S. of A.

I agree!

I agree!

Of course coming from the mighty populous nation of Canada. 😉 California I believe is a little larger in population of our mighty 36 million!😱

In addition to imperial vs. metric:

- Birch Plywood often is not calibrated, so a variance in the thicknes of 0,3 mm can easily found when buying from different batches / suppliers

- In addition to this, moisture and temperature make a difference, too

- Birch Plywood often is not calibrated, so a variance in the thicknes of 0,3 mm can easily found when buying from different batches / suppliers

- In addition to this, moisture and temperature make a difference, too

In addition to imperial vs. metric:

- Birch Plywood often is not calibrated, so a variance in the thicknes of 0,3 mm can easily found when buying from different batches / suppliers

- In addition to this, moisture and temperature make a difference, too

Hi all,

At my old supplier the thickness of Plywood had a lot to do with how it was finished.

The highest quality finish (super smooth surface) had gone trough a 3 stage sanding process and was 18,1 to 18,2 mm.

A 2 stage finishing process had a thickness of 18,2 to 18,3 mm.

Standard finish was 18,3 to 18,4 mm.

But I guess this varies from manufacturer to manufacturer.

Regards,

Djim

At my old supplier the thickness of Plywood had a lot to do with how it was finished.

The highest quality finish (super smooth surface) had gone trough a 3 stage sanding process and was 18,1 to 18,2 mm.

A 2 stage finishing process had a thickness of 18,2 to 18,3 mm.

Standard finish was 18,3 to 18,4 mm.

But I guess this varies from manufacturer to manufacturer.

Regards,

Djim

Yes, it does. It takes extra effort to keep the wood in a certain moisture and temperature range while processing it, the machines cutting the single layers have to be calibrated, which is expensive and the final finish of the top layers is extra work, too....

Most of the times, this is no serious problem..

Most of the times, this is no serious problem..

Sorry to break up the wood talk woodsters.

Need some help here. I am designing a variation of the LaScala. In this design the woofer is reversed facing the back and the sound energy is split as it exits into the horn from the baffle. Would just measuring the sound path on one side be sufficient? See attachment.

I also wanted to show the baffle to explain why I have so many sections. I'm using reflectors back there to create a bit more expansion.

Need some help here. I am designing a variation of the LaScala. In this design the woofer is reversed facing the back and the sound energy is split as it exits into the horn from the baffle. Would just measuring the sound path on one side be sufficient? See attachment.

I also wanted to show the baffle to explain why I have so many sections. I'm using reflectors back there to create a bit more expansion.

Attachments

Hi Johannes,

Interesting. What form does the difference take? Is there any chance that it could perhaps be due instead to thermal power compression, resulting from heating of the voice coil causing the value of Re to increase?

That would be really excellent.

Unfortunately a little bit beyond the capabilities of Hornresp, I suspect 🙂.

Kind regards,

David

It seems to make quite a substantial difference.

Interesting. What form does the difference take? Is there any chance that it could perhaps be due instead to thermal power compression, resulting from heating of the voice coil causing the value of Re to increase?

I hope I can make some better measurements soon. I will post them and my findings if I can document them in a clear and easy to understand (for myself) way.

That would be really excellent.

I do think it would be a great feature though.

Unfortunately a little bit beyond the capabilities of Hornresp, I suspect 🙂.

Kind regards,

David

Hi johnnyjo,

🙂.

Yes, that will correctly specify the axial length of the bifurcated horn system.

(The cross-sectional areas of the two sides of the horn need to be added together, however, when determining the values of S1, S2, etc).

Kind regards,

David

Sorry to break up the wood talk woodsters.

🙂.

Would just measuring the sound path on one side be sufficient?

Yes, that will correctly specify the axial length of the bifurcated horn system.

(The cross-sectional areas of the two sides of the horn need to be added together, however, when determining the values of S1, S2, etc).

Kind regards,

David

Interesting. What form does the difference take?

Since I don't have my ROAR12 at home so that I can measure it, I will try to describe why I am curious about the effect of air particle inertia and momentum.

Tom Danley is a pure genius and this makes his products very interesting to analyze and learn from.

His BC412 and BC415 is very interesting basshorns. Tom Danley states that they are exponential horns with a small constriction to set up the expansion so that the inside horn couples better to the large outside baffle area. One of the special characteristics I have found with my large front resonator enhanced tapped pipe (my ROAR12) is that it has a very small dispersion of the sound. It has a very narrow beam of high intensity sound.

Sound intensity - Wikipedia

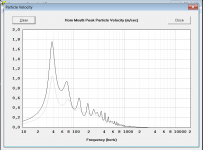

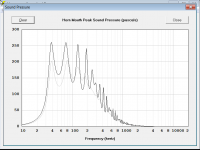

(I = pv. - Sound intensity is sound pressure times particle velocity)

A "normal" exponential horn has a large mouth, a spherical sound wave emanating from the mouth and a low air particle velocity at the mouth. Only the large mouth size will limit the radiation angle.

One of the interesting effects of the rather large front resonator and the constricted "port" of the BC line of bass horns is the large increase in air particle velocity it creates.

This is quite similar to my ROAR12.

I have never seen anyone make a demonstration of an exponential horn by blowing out candles or blowing hair before. My experience of large exponential horns is that they don't create a large air particle velocity.

I have been pondering this for some time, and given the ingenuity of Tom Danley I gather there is something else going on here.

The most obvious effect of a large increase of air particle velocity is the exponentially increasing effect of inertia and momentum.

The ROAR12 has a 130 gram "slug" of air in the mouth. At 10 meters a second peak air particle velocity in contains a lot of momentum. I know air is compressible and the air column in the front resonator will not behave exactly the same way as a passive radiator at the low end of the passband (40 - 60 Hz), but I do think the inertia and momentum will effect the behavior exponentially more with increasing the spl.

Regards,

Johannes

Last edited:

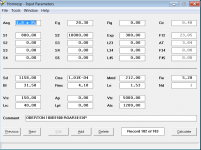

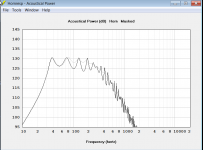

I tried to simulate a normal exponential horn and a front resonator enhanced exponential horn with roughly equal behavior in the bass range.

Grey lines is the pure exponential horn and the black line is the front resonator enhanced exponential horn.

The constriction in the open end of the quarter wave resonator (front resonator) creates a substantial increase in particle velocity. If Hornresp does not account for the exponential increase in air particle momentum and the effects of inertia which get quite substantial at 140 dB and above, then I don't think it will predict the maximum spl and power compression correct.

Regards,

Johannes

- Home

- Loudspeakers

- Subwoofers

- Hornresp