Hi David,

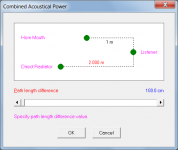

Post #4477: "If you ignore the text description (which perhaps I should remove from the Help file to avoid any ongoing confusion, because it also just applies to a direct radiator in a vented-box enclosure) does viewing the original schematic in isolation make sense - that is, is it clear that the direct radiator is further away from the listener than is the port outlet, and that the offset difference is 20 cm?"

Yes, the confusion only set in after reading the text in the example (it made me change my mind).

Post #4477: "...revert back to the original text-based input form..."

Please, stay with the graphic description - as long as we know, that the bold green dots are the locations of Direct Radiator/Port Outlet/Listener, and the red line indicates the difference - it is much clearer than the text-based input form.

Regards,

Post #4477: "If you ignore the text description (which perhaps I should remove from the Help file to avoid any ongoing confusion, because it also just applies to a direct radiator in a vented-box enclosure) does viewing the original schematic in isolation make sense - that is, is it clear that the direct radiator is further away from the listener than is the port outlet, and that the offset difference is 20 cm?"

Yes, the confusion only set in after reading the text in the example (it made me change my mind).

Post #4477: "...revert back to the original text-based input form..."

Please, stay with the graphic description - as long as we know, that the bold green dots are the locations of Direct Radiator/Port Outlet/Listener, and the red line indicates the difference - it is much clearer than the text-based input form.

Regards,

Question for GM

Hi GM,

When you use the term "polyfil", are you referring to absorbent material generally, or to the specific product having the registered trade name of "Poly-fil"?

You may have noticed that I currently use the term Polyfill (with two l's). I do this because every time I searched for "polyfil", Google kept showing results for "polyfill" by default, so I assumed that this must be the correct spelling.

After a more careful investigation though, I came across the "Poly-fil" product, hence the reason for my question.

I want to change from "Polyfill", but am not sure whether "Polyfil" (general) or "Poly-fil®" (specific) should be used instead. The absorbent material weights I show are derived from data provided by 'just a guy', who I understand no longer posts to the diyAudio forums. I assume that his numbers apply to the Poly-fil product, but I am not 100% certain.

I would appreciate any thoughts / comments / suggestions...

Kind regards,

David

I’ve no clue what a [Fr1] = 200 equates to WRT how much polyfil/whatever is required though.

Hi GM,

When you use the term "polyfil", are you referring to absorbent material generally, or to the specific product having the registered trade name of "Poly-fil"?

You may have noticed that I currently use the term Polyfill (with two l's). I do this because every time I searched for "polyfil", Google kept showing results for "polyfill" by default, so I assumed that this must be the correct spelling.

After a more careful investigation though, I came across the "Poly-fil" product, hence the reason for my question.

I want to change from "Polyfill", but am not sure whether "Polyfil" (general) or "Poly-fil®" (specific) should be used instead. The absorbent material weights I show are derived from data provided by 'just a guy', who I understand no longer posts to the diyAudio forums. I assume that his numbers apply to the Poly-fil product, but I am not 100% certain.

I would appreciate any thoughts / comments / suggestions...

Kind regards,

David

Attachments

The absorbent material weights I show are derived from data provided by 'just a guy', who I understand no longer posts to the diyAudio forums. I assume that his numbers apply to the Poly-fil product, but I am not 100% certain.

Thanks for the mention but to be clear I just ran a bunch of sims. Maybe 50 or 100 sims with varying degrees of stuffing for a couple of different designs IIRC. The real credit goes to MJK's worksheets and your (Mr McBean's) correlation to the units used in Hornresp. I believe MJK's sheets assume the Poly-fil brand product. Definitely not fibreglass or anything like that. The info on my contribution and exactly what I did is buried somewhere in this thread.

Anyway, I probably won't be gone forever, I'm just taking a break. I'm still reading stuff that catches my interest, still available by PM and email and I'll probably still post if I see something important. Maybe one day I'll be a regular contributor again as well, but not anytime soon. If you ever need help with something like this again you know where to find me.

Have fun, guys.

Last edited:

And the Decision is...

Hi Oliver, Andrew and Zero D,

Thanks for your valuable feedback. I have taken careful note of all your comments, and have ultimately decided to go with the "second alternative" schematic layout proposal, as shown in the attachment. Although the path length difference is not specifically indicated in the diagram, it is nevertheless the simplest and "cleanest" overall representation, and hopefully there is no ambiguity as to how it should be interpreted.

I am using centimetres as the unit for path length difference and metres as the unit for the overall path length because they seem to me to be the most appropriate for the ranges of values likely to be encountered in each case. I trust that this will not confuse too many people.

The text description will be retained in the Help file on the understanding that it applies to a bass-reflex system.

The above changes will be made in the next release.

Kind regards,

David

Hi Oliver, Andrew and Zero D,

Thanks for your valuable feedback. I have taken careful note of all your comments, and have ultimately decided to go with the "second alternative" schematic layout proposal, as shown in the attachment. Although the path length difference is not specifically indicated in the diagram, it is nevertheless the simplest and "cleanest" overall representation, and hopefully there is no ambiguity as to how it should be interpreted.

I am using centimetres as the unit for path length difference and metres as the unit for the overall path length because they seem to me to be the most appropriate for the ranges of values likely to be encountered in each case. I trust that this will not confuse too many people.

The text description will be retained in the Help file on the understanding that it applies to a bass-reflex system.

The above changes will be made in the next release.

Kind regards,

David

Attachments

Thanks for the mention but to be clear I just ran a bunch of sims. Maybe 50 or 100 sims with varying degrees of stuffing for a couple of different designs IIRC. The real credit goes to MJK's worksheets and your (Mr McBean's) correlation to the units used in Hornresp. I believe MJK's sheets assume the Poly-fil brand product. Definitely not fibreglass or anything like that. The info on my contribution and exactly what I did is buried somewhere in this thread.

Anyway, I probably won't be gone forever, I'm just taking a break. I'm still reading stuff that catches my interest, still available by PM and email and I'll probably still post if I see something important. Maybe one day I'll be a regular contributor again as well, but not anytime soon. If you ever need help with something like this again you know where to find me.

Have fun, guys.

Hi just a guy,

Many thanks for the clarification. I for one, miss you not being around.

From what I can gather, Martin used Dacron Hollofil II fibre stuffing in his simulation examples. I wasn't sure if you had done that also.

Kind regards,

David

Hi David

I time ago I was busy with a tapped horn and try to solve the cone correction, a lot of people dit try, and and even number of people has not exact solution with damage the woofer, this afcourse in the PA bussiness not for home.

I post some pictures where I have use the vtc and atc, I did measure the cone surface with rise, it give a lower number then with hornresp driver volume calculation sho did 2181 cc and with rise i get 1330 cc.

I have include the baffle, make atc such thet it is like the baffle thickness 1.8 cm and vtc is speaker + baffle cutout.

Now I can make the S1 and S2 smaller so that respons is good, and see that now I have included cone corrections without the possible cone damage and there is no obstruction in the horn throat.

Did I do this the right way? I did see that respons did better then without that correction.

Now I can do this also in the mouth, include there the driver magnet displacement.

On last photo you see that it has quite a high sensitivity, 105 dB 1 watt fire from corner, a little coil do smoothe things out..

regards

kees

Hi Kees,

As indicated in Post #4134, I suspect that there is not much to be gained by trying to include cone correction in your tapped horn simulations. Just specify an appropriate throat chamber taking the driver front volume into account.

Kind regards,

David

Hi just a guy,

Many thanks for the clarification...

From what I can gather, Martin used Dacron Hollofil II fibre stuffing in his simulation examples...

Kind regards,

David

Yeah, you are correct. I did a quick search for "polyfil site:quarter-wave.com" and got nothing. I then searched "dacron site:quarter-wave.com" and got several hits for Dacron Hollofil II. So I guess that's the correct answer. Never heard of the stuff. I've seen lots of references to him using polyfil but I guess it's a generic term or something.

I wasn't sure if you had done that also.

There's no choice on the worksheet, you either use stuffing (in any quantity you choose) or you don't, and apparently if you do it's Dacron Hollofil II. You can't specify any different type of stuffing.

I for one, miss you not being around.

I'll be back, I'm just letting you guys have some peace and quiet for awhile. Thanks for the thought.

Hi just a guy,

Perhaps to be safe, I should just use the generic term "Polyfil", rather than refering to the Poly-fil product specifically, and assume that the absorbent properties of Hollofil II and Poly-fil are much the same, for equivalent weights.

It seems that people are more familiar with Polyfil / Poly-fil as an absorbent material, rather than Hollofil.

I will wait to see if GM has any comments, before making any changes.

Kind regards,

David

Never heard of the stuff. I've seen lots of references to him using polyfil but I guess it's a generic term or something.

Perhaps to be safe, I should just use the generic term "Polyfil", rather than refering to the Poly-fil product specifically, and assume that the absorbent properties of Hollofil II and Poly-fil are much the same, for equivalent weights.

It seems that people are more familiar with Polyfil / Poly-fil as an absorbent material, rather than Hollofil.

I will wait to see if GM has any comments, before making any changes.

Kind regards,

David

Hi Kees,

As indicated in Post #4134, I suspect that there is not much to be gained by trying to include cone correction in your tapped horn simulations. Just specify an appropriate throat chamber taking the driver front volume into account.

Kind regards,

David

Hi david

I have include that, and indeed it do not much, I did use vtc, and make thoat chamber S1 some smaller with setting S2 to automatic.

The change on damage the cone is a lot more dangereus than the little gain I can possible have, some tapped horns with big woofers need more attention.

regards

kees.

Perhaps to be safe, I should just use the generic term "Polyfil", rather than refering to the Poly-fil product specifically, and assume that the absorbent properties of Hollofil II and Poly-fil are much the same, for equivalent weights.

It seems that people are more familiar with Polyfil / Poly-fil as an absorbent material, rather than Hollofil.

I will wait to see if GM has any comments, before making any changes.

Kind regards,

David

Many use the term Polyester Fiber.

Like what I'm seeing. And your diagram makes sense as to the explanation of where each radiating area is.

Perhaps to be safe, I should just use the generic term "Polyfil", rather than refering to the Poly-fil product specifically, and assume that the absorbent properties of Hollofil II and Poly-fil are much the same, for equivalent weights.

It seems that people are more familiar with Polyfil / Poly-fil as an absorbent material, rather than Hollofil.

I will wait to see if GM has any comments, before making any changes.

Kind regards,

David

Many use the term Polyester Fiber.

Like what I'm seeing. And your diagram makes sense as to the explanation of where each radiating area is.

@ David McBean

Re - second alternative schematic layout proposal

Thanks for listening & implimenting 🙂

Re - Polyfil Poly-fil

To avoid © etc situations, maybe Polyfill or Polyfiber would suit ?

EDIT

The reason why mm are better than cm is beacause, we don't build to the nearest cm, rather mm

Re - second alternative schematic layout proposal

Thanks for listening & implimenting 🙂

Re - Polyfil Poly-fil

To avoid © etc situations, maybe Polyfill or Polyfiber would suit ?

EDIT

The reason why mm are better than cm is beacause, we don't build to the nearest cm, rather mm

Last edited:

I will wait to see if GM has any comments, before making any changes.

Hmm, I don't like/use the stuff and only familiar with the cheap pillow stuffing and sheet stock available at Wal-Mart, etc., though according to his 'damping coefficent' doc, MJK based his research on 'Dacron Hollofil II, which many folks call 'polyfil', but haven't researched it to see if these are actually 'same-same' acoustically: http://www.quarter-wave.com/TLs/Damping_Coefficient.pdf

Given my druthers, the conversion would be to 1" acoustic fiberglass [FG] insulation as I only line the walls or at worst, hang an acoustic 'blanket' of it diagonally across the cab. If I need to stuff, it's with R-19 'pink' FG of the appropriate thickness.

MJK's software is popular and AFAIK well proven up to a 1.0 lb/ft^3 stuffing density, so being able to get a 'close enough' match to his work would be nice. I just wish he'd researched it to at least 3.0 lbs/ft^3 for ~aperiodic alignments.

GM

english is not my native language but ive heard the word "wadding " or "damping"?

ofcource its clear what you mean by polifil.😉

.

ofcource its clear what you mean by polifil.😉

.

Hi sladdbarn,

The settings shown in your screenprint should give you what you want.

The horn side panels will flare as illustrated in the attachment (the blue profile is a straight line).

Kind regards,

David

Thanks alot David!

Had some trouble with points and commas but solved it after a while 🙂

Do you have a paypal account where people can send donations to you?

You´re doing great things for the diy-community!

If I need to stuff, it's with R-19 'pink' FG of the appropriate thickness.

GM

Wow, I thought I was the only one on this site to use house insulation for stuffing. I remember using the pink stuff for a pair of sealed Pyle 1240's in my 1981 Honda civic 4 door in 1990!

Hi Zero D,

The irony is, I now appear to have ended-up back where I started from 🙂.

It seems that it may be best to stick with the original choice of "Polyfill" (with two l's).

Reasons:

1. Users seem to readily understand that "Polyfill" means polyester filling of some sort.

2. I would prefer not to use "Poly-fil" specifically, because the weights shown are not actually based on the Poly-fil product.

3. I would prefer not to use "Dacron Hollofil II" because it appears that users are not particularly familiar with this product.

4. I would prefer not to use "Polyfil" (with one l) because users may interpret this as meaning the Poly-fil product .

The Polyfill weights given in Hornresp, while being based on Dacron Hollofil II, are hopefully indicative of most of the absorbent materials likely to be used in damped transmission lines.

That's why I show the path length difference value (in centimetres) to one decimal place, and the distance from the output to the listener (in metres) to three decimal places, so that the offset can be specified down to the nearest millimetre 🙂.

Kind regards,

David

To avoid © etc situations, maybe Polyfill or Polyfiber would suit ?

The irony is, I now appear to have ended-up back where I started from 🙂.

It seems that it may be best to stick with the original choice of "Polyfill" (with two l's).

Reasons:

1. Users seem to readily understand that "Polyfill" means polyester filling of some sort.

2. I would prefer not to use "Poly-fil" specifically, because the weights shown are not actually based on the Poly-fil product.

3. I would prefer not to use "Dacron Hollofil II" because it appears that users are not particularly familiar with this product.

4. I would prefer not to use "Polyfil" (with one l) because users may interpret this as meaning the Poly-fil product .

The Polyfill weights given in Hornresp, while being based on Dacron Hollofil II, are hopefully indicative of most of the absorbent materials likely to be used in damped transmission lines.

The reason why mm are better than cm is because, we don't build to the nearest cm, rather mm

That's why I show the path length difference value (in centimetres) to one decimal place, and the distance from the output to the listener (in metres) to three decimal places, so that the offset can be specified down to the nearest millimetre 🙂.

Kind regards,

David

Many use the term Polyester Fiber.

Like what I'm seeing. And your diagram makes sense as to the explanation of where each radiating area is.

Hi Mark,

Your "stutter" is worse than mine!

I just repeat a word - you repeat whole messages... 🙂.

Kind regards,

David

Hmm, I don't like/use the stuff and only familiar with the cheap pillow stuffing and sheet stock available at Wal-Mart, etc., though according to his 'damping coefficent' doc, MJK based his research on 'Dacron Hollofil II, which many folks call 'polyfil', but haven't researched it to see if these are actually 'same-same' acoustically: http://www.quarter-wave.com/TLs/Damping_Coefficient.pdf

Given my druthers, the conversion would be to 1" acoustic fiberglass [FG] insulation as I only line the walls or at worst, hang an acoustic 'blanket' of it diagonally across the cab. If I need to stuff, it's with R-19 'pink' FG of the appropriate thickness.

MJK's software is popular and AFAIK well proven up to a 1.0 lb/ft^3 stuffing density, so being able to get a 'close enough' match to his work would be nice. I just wish he'd researched it to at least 3.0 lbs/ft^3 for ~aperiodic alignments.

Thanks GM.

It seems that all things considered, I will probably not change from "Polyfill" after all... 🙂.

Kind regards,

David

- Home

- Loudspeakers

- Subwoofers

- Hornresp