I hope its Ok i use this as a progress Log 😀 for myself too..

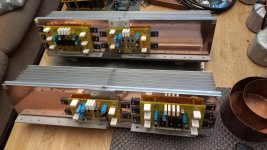

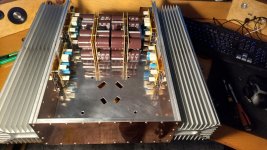

Finished milling the sinks. 🙂 buttem plate and half the chassis struts.

Of course, it is your thread! Nice progress 🙂

I don't know if it was talked about but the heat dissipation on the heatsinks being placed horizontally will be lower than if they were verticle. The heat has a harder time rising. With that being said, you may have so much heatsinking that it is not a problem.

I don't know if it was talked about but the heat dissipation on the heatsinks being placed horizontally will be lower than if they were verticle. The heat has a harder time rising. With that being said, you may have so much heatsinking that it is not a problem.

Yeh i know.. thats why i watercooled them.. 😀 (the core is hollow so ill just run a loop trugh it.. i mean i went purely for looks.

I could even just add a temperature controlled 120mm fan to the back. of the sinks if i wanted to make it easyer for myself.

The fan would make it better than any vertical mounted sink anyway.

:

And as a bonus you would have your very own 600w electric heater under your TV... i mean Win/win right? 😀

I could even just add a temperature controlled 120mm fan to the back. of the sinks if i wanted to make it easyer for myself.

The fan would make it better than any vertical mounted sink anyway.

:

And as a bonus you would have your very own 600w electric heater under your TV... i mean Win/win right? 😀

Ahh, I see. Pretty cool! I suspect that you will be alright. I didn't go back and read through the thread but I assumed that you probably had your bearings straight. Looks good 🙂

I always listen to suggestions. 🙂 theres no way i can think of everything..

i have never made anything like this before at all. not even remotley.

Its my first time working with aluminium. / amplifiers boards / power supplys / cabeling /

never did any metal working so i pirtty much yoloed the cobber domes.

Atm. im pritty much making it all up as i go along. (google is serverley underrated) i mean it. That **** is useful.

.

I work with TAX law on a daily basis. lol...

i have never made anything like this before at all. not even remotley.

Its my first time working with aluminium. / amplifiers boards / power supplys / cabeling /

never did any metal working so i pirtty much yoloed the cobber domes.

Atm. im pritty much making it all up as i go along. (google is serverley underrated) i mean it. That **** is useful.

.

I work with TAX law on a daily basis. lol...

That is some fine metal working on those copper transformer covers.

In the interest of providing extra information, copper will be excellent at shielding electrical fields, but much less effective at shielding magnetic fields. Other metals such as annealed nickel-iron alloys or even tin can help more with magnetic field reduction.

It’s possible that magnetic fields may not be a problem with your channel boards, so this could simply be something to consider for future updates.

In the interest of providing extra information, copper will be excellent at shielding electrical fields, but much less effective at shielding magnetic fields. Other metals such as annealed nickel-iron alloys or even tin can help more with magnetic field reduction.

It’s possible that magnetic fields may not be a problem with your channel boards, so this could simply be something to consider for future updates.

shuldent copper go into the "fine" or "good enough" category here ? i mean its not steel but its 1mm think copper plate.

.

The steel domes you can buy for toroids are only 0.5mm (the ones i found)

.

The steel domes you can buy for toroids are only 0.5mm (the ones i found)

Well, there should be some calculations that you can do to estimate the cooling. Heat sinks have a rating called thermal resistance AKA c/w

There are some compilations that you can do to estimate the cooling. I'm sorry if you already know all this but maybe take a look and see what your amplifier is likely to create and heat and what needs to be dissipated.

If the heat sinks are not too expensive and are available, maybe get two more per side and mount them vertically

There are some compilations that you can do to estimate the cooling. I'm sorry if you already know all this but maybe take a look and see what your amplifier is likely to create and heat and what needs to be dissipated.

If the heat sinks are not too expensive and are available, maybe get two more per side and mount them vertically

@ TungstenAudio

allso i have pure aluminium tape in abundance. Shuld i put that on the inside of the domes? theres plenty of free space for it.

allso i have pure aluminium tape in abundance. Shuld i put that on the inside of the domes? theres plenty of free space for it.

Mikerodrig27

I figured id just use a temperature controller on a seperate powersupply. solves all that.. just set it to work from 45-55c /fans / pump.

.

Minimal effort is good in this case. 1mm steel plate sounds good. Aluminum would not be an improvement over the copper.

Just ordered 8 meters of 0.2mm x100mm steel sheet. ill just add whatevers needed.. thanks.I may be missing the point on the aluminum tape. For magnetic shielding, need ferrous material.

its the same hight as the domes so 0 cutting is needed.

Core chassis is finished. Need kopper plate on the sides tho. (and polish... lots and lots of polish. 😀

Last edited:

- Home

- Amplifiers

- Pass Labs

- Home Built Pass 3 and 5 (design stage)