I finally cracked it. Final layout!

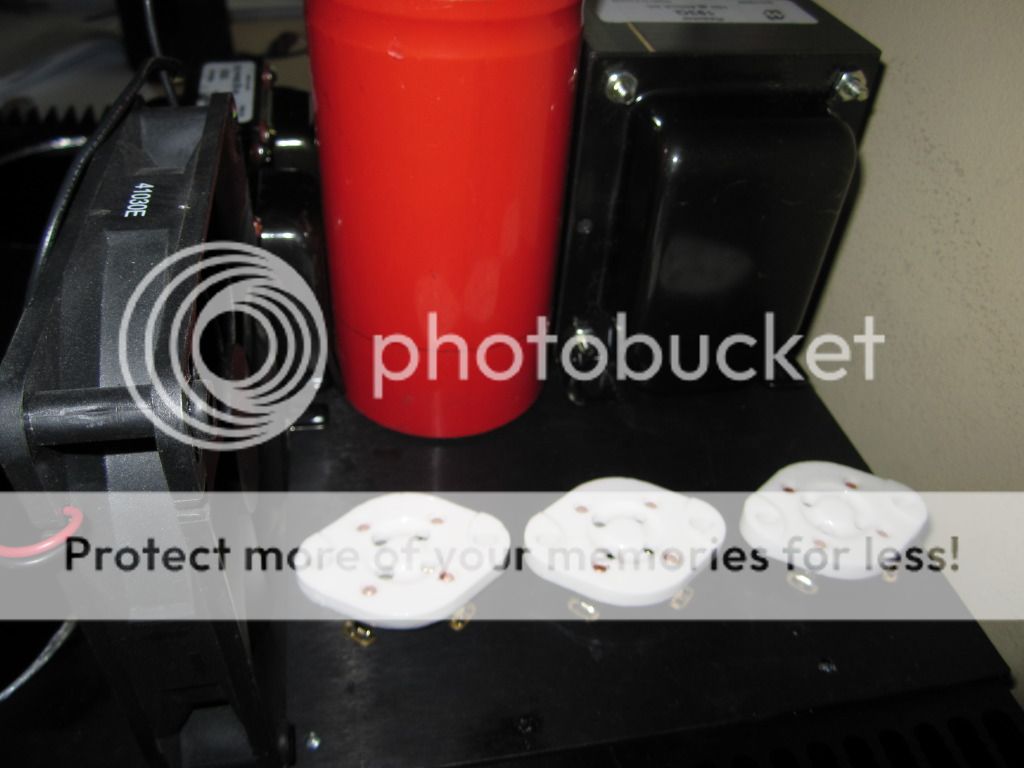

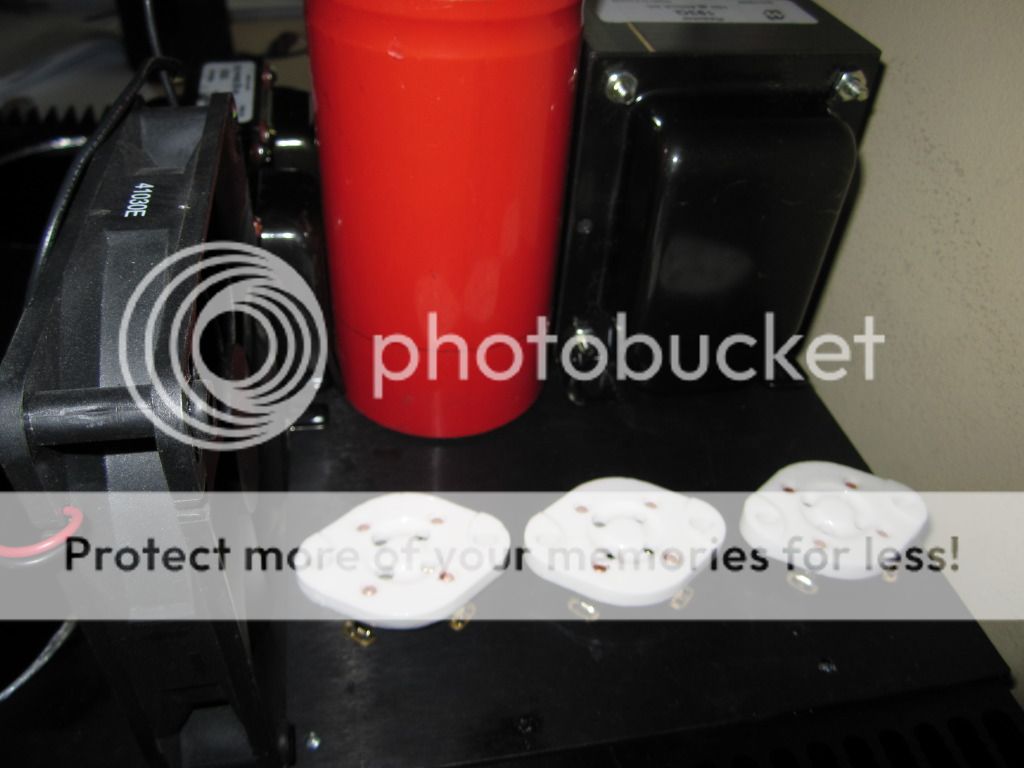

one side:

front view..

what you see are the 2x 200mA chokes (anode voltage for driver section) and 1x 500mA for gu81m screen voltage.

2x 4700uf 385v caps for screen voltage.

The three 4 pin sockets are for 3 (per side) 866A type rectifiers.

interesting feature is a fan (8/12cm) which will be hidden behind the gu81m and will provide cooling around the gu81m, between the gu81m and driver tubes and cool the rectifiers all at the same time!

I am very happy with this layout and definitely think this is one of the final (if not the final) layout.

Any observations?

Thanks

one side:

front view..

what you see are the 2x 200mA chokes (anode voltage for driver section) and 1x 500mA for gu81m screen voltage.

2x 4700uf 385v caps for screen voltage.

The three 4 pin sockets are for 3 (per side) 866A type rectifiers.

interesting feature is a fan (8/12cm) which will be hidden behind the gu81m and will provide cooling around the gu81m, between the gu81m and driver tubes and cool the rectifiers all at the same time!

I am very happy with this layout and definitely think this is one of the final (if not the final) layout.

Any observations?

Thanks

cold start for the tubes #300mA with 280v transformer. No arcs

some flickering but it stop after 30secs.

some flickering but it stop after 30secs.

....and I laughed too soon. The 866A seems to be flaking. Here are some macros:

it's not mercury...it loos like dandruff actually and is increasing with use of the tube.

Can someone confirm it is flaking?

it's not mercury...it loos like dandruff actually and is increasing with use of the tube.

Can someone confirm it is flaking?

Possibly my last posts were unclear. The cold start was still preceded by warmup time (30 minutes). I simply meant the voltage was not ramped but switched on (simulating a system with heavy initial load and no softstart).

The flaking is not due to the current since at 280v the tube should be able to conduct almost 500mA of current.

The flaking is not due to the current since at 280v the tube should be able to conduct almost 500mA of current.

sorry for the soldering I'll pass over the joints once I get my alligator clips locked in position to keep the frame from opening up.

You might want to consider voltage equalizing resistors in parallel with those caps. The rectifier diodes too. Just good practice.

All good fortune,

Chris

All good fortune,

Chris

I actually equalised the resistors with 2w 100k resistors just after posting the first photos...

what I don't know exactly is how to balance the diodes. 400k resistors in parallel?

what I don't know exactly is how to balance the diodes. 400k resistors in parallel?

^1meg resistors shunted with each diode will do, you are merely ensuring equal voltage divisions, current is no problem since you are operating reversed bias....

This will be truly spectacular. Unknown mercury rectifiers blooming under 1.5A current and 2.5A @ 50v 33r load 10nf Cap single wave

🙂

next find will be a mercury pool rectifier.....😀

🙂

next find will be a mercury pool rectifier.....😀

I am going to machine my own caps:

3x4x40cm rod made of teflon..

last piece (had to clean it thoroughly). I paid it 10 euros 😀

(yes it's teflon. The weight is correct)

3x4x40cm rod made of teflon..

last piece (had to clean it thoroughly). I paid it 10 euros 😀

(yes it's teflon. The weight is correct)

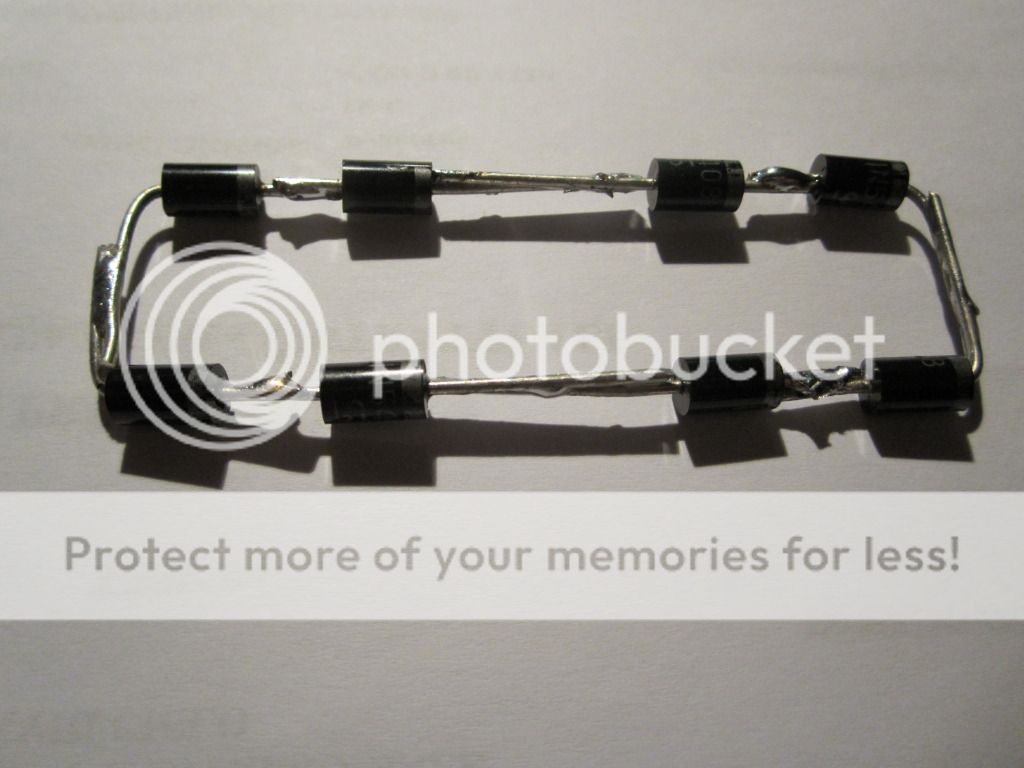

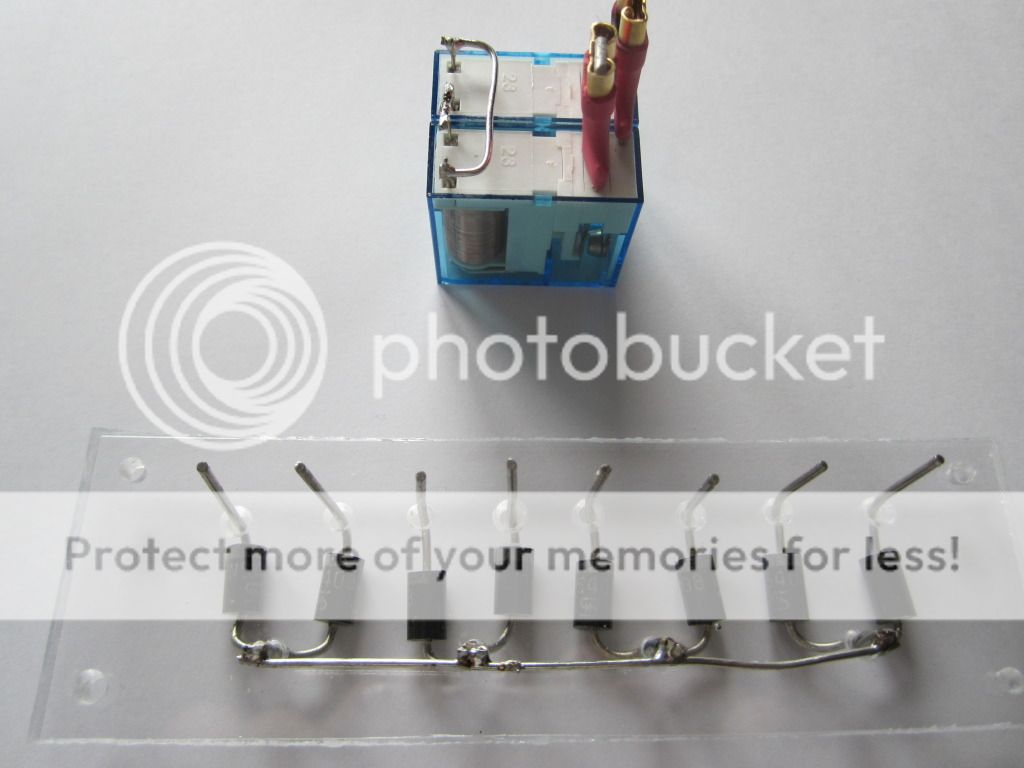

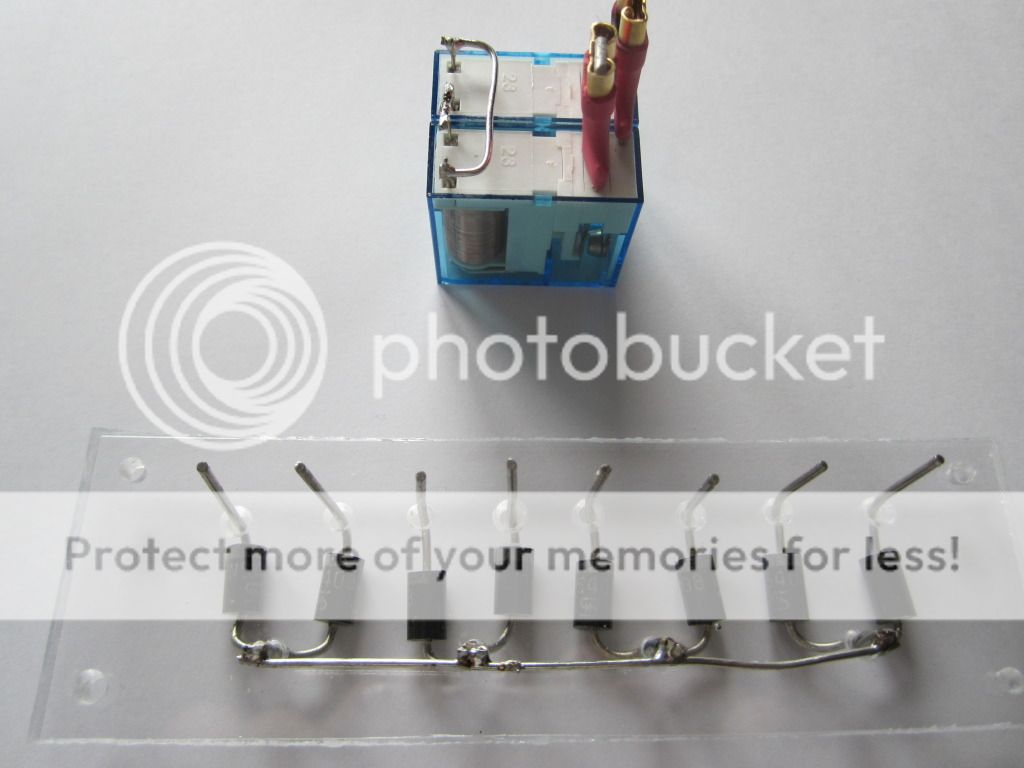

To increase HV efficiency, the transformer will require bridges. with gas rectifiers that can be accomplished either with tube based design or using a hybrid solution. I prepared a board to accomodate the "half bridge" required for hybrid operation. The common bus goes to main PWR ground.

The two relays above are soldered in parallel so that both will close upon power on. The main switch will not power the filament transformers to avoid sparks/damage. It will power a sall supp,ementary transformer which will in turn power on all the transformers and driver stage bias (-12v).

The two relays above are soldered in parallel so that both will close upon power on. The main switch will not power the filament transformers to avoid sparks/damage. It will power a sall supp,ementary transformer which will in turn power on all the transformers and driver stage bias (-12v).

don't mind the small lead on the faston connector...it just stuck there from the rectifier board assembly.

I actually equalised the resistors with 2w 100k resistors just after posting the first photos...

what I don't know exactly is how to balance the diodes. 400k resistors in parallel?

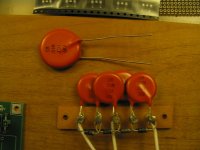

I think capacitors are much better for reverse voltage balancing and snubbing at the same time. 10nF@3KV and the big one is 10nF@6KV

Attachments

I really hope the tube/diode bridge works well...I don't have space of power for an all tube based bridge.

The again a 2500VA transformer with 0 taps would have required a 4900VA core!

The again a 2500VA transformer with 0 taps would have required a 4900VA core!

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- High voltage driver for AB2 operation GU81m tubes