Looks interesting - what's the product and how did you form it?

Thanks...

It's sticky backed felt. Cut into a long triangle then rolled up to produce that spiral. Very easy to make.

It's sticky backed felt. Cut into a long triangle then rolled up to produce that spiral. Very easy to make.

I like it ! Great idea !

I believe felt is the wrong material if it has to compressed a lot ! it will give almost no damping isolation but coupling instead! Rubber stays one of the best material then close synthethic rubber ! Defintly no th emost easy material to work with then it comes to putt around Something : screw, tube, etc !

I believe felt is the wrong material if it has to compressed a lot ! it will give almost no damping isolation but coupling instead! Rubber stays one of the best material then close synthethic rubber ! Defintly no th emost easy material to work with then it comes to putt around Something : screw, tube, etc !

Hi Eldam, the felt wasn't for a gasket!

See the picture!!

Is it for the internal circular walls of the enclosure like the inverted pyramid (zigurat I should write)?

Why not EVA foam instead ?

For internal reverbs : https://www.amazon.fr/Barbecue-grill-Nettoyant-tampons-r%C3%A9sistant/dp/B003NU60OE ???? Metal, better for thermal dissipation = not change the internal air density because heat ??? (while distribute the heat in time in a different way as it's internal enclosure ??). I assume there is also the goal to dissipate the heat with bracing ? without adding reflection (which metal enclosure can't = bad choice... and the metal is an Accelerator of sound speed at its surface : so a speaker itself ! but Inside like metal wool is maybe an other story : it's not a plane surface....)

Imho, as far EVA foam is not radiating sound from it's external side, it's one of the best material : it can be shaped with heat, it can be mixed in diferent density, you can mix it with cork material. There are also coco isolation felt for low density as well... and bitumed carpet for acoustic isolation of heavy machines (washing machine, Professional tool, etc) which can be shaped if not too small (bad for a cylindrical shape for a mid or tweet because too thick most of the time) ?! I use this bitumed/ruber carpet between two layer of very hard matrial as speaker stand with good result to avoid my wood floor to act as a "speaker" in the frequencies involved (low mid , high bass)!

Was it the asking of Bwaslo or was it to constraint a driver to the bafle fro the Inside ? I believe I didn't understood well his asking ?!😱

Why not EVA foam instead ?

For internal reverbs : https://www.amazon.fr/Barbecue-grill-Nettoyant-tampons-r%C3%A9sistant/dp/B003NU60OE ???? Metal, better for thermal dissipation = not change the internal air density because heat ??? (while distribute the heat in time in a different way as it's internal enclosure ??). I assume there is also the goal to dissipate the heat with bracing ? without adding reflection (which metal enclosure can't = bad choice... and the metal is an Accelerator of sound speed at its surface : so a speaker itself ! but Inside like metal wool is maybe an other story : it's not a plane surface....)

Imho, as far EVA foam is not radiating sound from it's external side, it's one of the best material : it can be shaped with heat, it can be mixed in diferent density, you can mix it with cork material. There are also coco isolation felt for low density as well... and bitumed carpet for acoustic isolation of heavy machines (washing machine, Professional tool, etc) which can be shaped if not too small (bad for a cylindrical shape for a mid or tweet because too thick most of the time) ?! I use this bitumed/ruber carpet between two layer of very hard matrial as speaker stand with good result to avoid my wood floor to act as a "speaker" in the frequencies involved (low mid , high bass)!

Was it the asking of Bwaslo or was it to constraint a driver to the bafle fro the Inside ? I believe I didn't understood well his asking ?!😱

Last edited:

Was it the asking of Bwaslo or was it to constraint a driver to the bafle fro the Inside ? I believe I didn't understood well his asking ?!😱

I think you are on the wrong thread! Bwaslo's thread is here:

http://www.diyaudio.com/forums/multi-way/295467-box-damping-bracing-question-maybe-idea.html

I've been using square pyramids for most midrange designs for a few years. Idea stolen directly from B&W. With some care and thought in the early design stages I've done one inverted J that need to bend to get the length. I'll be using this in the large 4 way design that's been slowly moving along for a while now.

I've been using square pyramids for most midrange designs for a few years. Idea stolen directly from B&W. With some care and thought in the early design stages I've done one inverted J that need to bend to get the length. I'll be using this in the large 4 way design that's been slowly moving along for a while now.

Hi Brett,

it's great to hear that you did experimented and your experimentations turn with good result like xrk , I bought a pair of satori driver and I'm interested to do the same thing after Xrk talked to me about his experimentation.

I have little difficulty to arrive with a "normal" lenght for the pyramide. I wanted a q close to .6 but I have difficulties to evaluate how many acoustilux sheets I would be able to put in the pyramide to compensate the volume/lenght of the pyramide.

Do you have any picture of your design that you can share with us ?

thank you in advance

I have little difficulty to arrive with a "normal" length for the pyramid. I wanted a q close to .6 but I have difficulties to evaluate how many acoustilux sheets I would be able to put in the pyramid to compensate the volume/length of the pyramid.

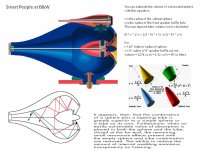

I use the free transmission line modeling program from Leonard Audio which supports tapered volumes and variable density stuffing. A conical (pyramid) shaped rear taper using flat sides works well, an eliptical curved taper will model slightly better at smoothing reflections but the benefits of this complex construction are very small. Both B&W and Vivid put a volume around/behind the driver which is large enough with modest on-wall absorption material to reduce early reflections back to the rear cone, and attach the tapered tube/pyramid behind this.

http://www.diyaudio.com/forums/software-tools/220421-transmission-line-modelling-software.html

Both B&W and Vivid put a volume around/behind the driver which is large enough with modest on-wall absorption material to reduce early reflections back to the rear cone, and attach the tapered tube/pyramid behind this.

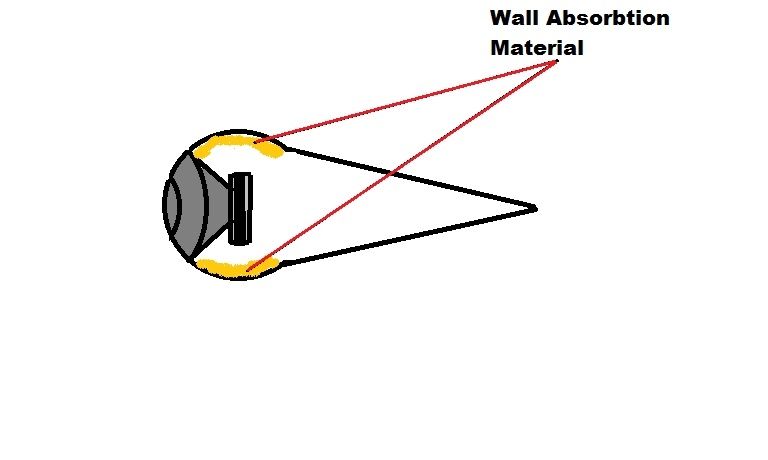

Do you mean they only put the "wall absorption material" near the driver? Like this:

Sorry for the bad picture.

In the best constructions:

The expansion chamber around the speaker has a thin layer of absorption material glued to the walls to absorb the higher frequencies. The rear tapered chamber is filled with low density absorption material like Poly-Fill, loose wool, or fiber glass ... similar to a transmission line ... to attenuate a wide range of mid frequencies with reduced resonances. Some engineers leave a very small opening(aperiodic loading) at the end of the taper.

Some companies create similar (volume+stuffed_taper) using bent boards, or internal V-bracing.

The expansion chamber around the speaker has a thin layer of absorption material glued to the walls to absorb the higher frequencies. The rear tapered chamber is filled with low density absorption material like Poly-Fill, loose wool, or fiber glass ... similar to a transmission line ... to attenuate a wide range of mid frequencies with reduced resonances. Some engineers leave a very small opening(aperiodic loading) at the end of the taper.

Some companies create similar (volume+stuffed_taper) using bent boards, or internal V-bracing.

Attachments

Interesting.

Russel K speakers are getting good reviews. They have no damping material but they do have at least one - Quote "acoustic loading bracing shelf with multiple (8) apertures mounted above the woofer" whatever that means?

Russel K speakers are getting good reviews. They have no damping material but they do have at least one - Quote "acoustic loading bracing shelf with multiple (8) apertures mounted above the woofer" whatever that means?

Just found this review of the Russel K RED 100 (the-ear.net)

Quote "The cabinet differs from most others, for one the walls are thin enough to vibrate, in a controlled fashion with bracing and boards inside the cabinet. They are not covered with heavy damping pads, quite the opposite, there’s no damping material to be found anywhere in the box. The cabinet construction is based on Russell’s theory that damping material absorbs micro details, reduces dynamics and makes a loudspeaker sound slow. Without damping the cabinet walls move in time with the main driver. The walls are strong enough not to weaken the bass response, but light enough to stop vibrating quickly."

Quote "The cabinet differs from most others, for one the walls are thin enough to vibrate, in a controlled fashion with bracing and boards inside the cabinet. They are not covered with heavy damping pads, quite the opposite, there’s no damping material to be found anywhere in the box. The cabinet construction is based on Russell’s theory that damping material absorbs micro details, reduces dynamics and makes a loudspeaker sound slow. Without damping the cabinet walls move in time with the main driver. The walls are strong enough not to weaken the bass response, but light enough to stop vibrating quickly."

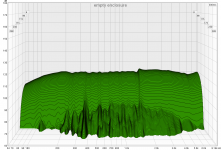

Do not try "Hypercube Loudspeaker", it is almost the same as spherical enclosure - only one, but giant internal resonance.

Please elaborate (perhaps not in this thread) on your experience with this enclosure. My measurements do not seem to indicate that this problem exists. The attached waterfall plots show the effect of stuffing a hypercube enclosure which in this case damps a structural resonance (related to panel stiffness) at 1.5khz. With adhesive vinyl damping sheets applied to the interior surfaces, the difference becomes even smaller.

Attachments

Last edited:

I use the free transmission line modeling program from Leonard Audio which supports tapered volumes and variable density stuffing. A conical (pyramid) shaped rear taper using flat sides works well, an eliptical curved taper will model slightly better at smoothing reflections but the benefits of this complex construction are very small. Both B&W and Vivid put a volume around/behind the driver which is large enough with modest on-wall absorption material to reduce early reflections back to the rear cone, and attach the tapered tube/pyramid behind this.

http://www.diyaudio.com/forums/software-tools/220421-transmission-line-modelling-software.html

thank you for your replies linesource, I'll play with that software and see what can I do.

At first glance, bushmeister found a realy quick and wise way of doing this concept . The only thing that bugs me in his concept is the thickness of the pvc pipe. I don't understand this part. I heard that Vivid used also a thickness close to a pvc pipe. I guess that we can use a box with that thick because all the standing wave are eliminate with this box concept, can someone confirm my guess?

Doing a cone in wood/epoxy/concrete(?) can be complex and consume of lot of time. I might do a compromise in the simulation and do a square box + a pyramide, or I'll try to simulate something like bushmeister did, which seem very fast to do.

The only thing that bugs me in his concept is the thickness of the pvc pipe. I don't understand this part. I heard that Vivid used also a thickness close to a pvc pipe. I guess that we can use a box with that thick because all the standing wave are eliminate with this box concept, can someone confirm my guess?

It can be thin because the cylindrical shape is extremely rigid.

dave

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Help with midrange chamber design