Hi,

I am repairing a Technics amp with a shorted transistor in the mosfet class aa module RSN6000B

Anyone know what it is or suggest a replacement?

Cheers

Steve

I am repairing a Technics amp with a shorted transistor in the mosfet class aa module RSN6000B

Anyone know what it is or suggest a replacement?

Cheers

Steve

If you look at the top surface of the transistor package, you may see a code etched into the surface.Hi,

I am repairing a Technics amp with a shorted transistor in the mosfet class aa module RSN6000B

Anyone know what it is or suggest a replacement?

Cheers

Steve

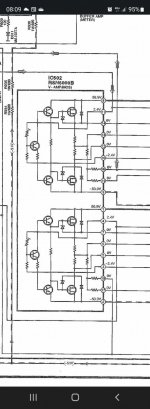

View attachment 1048924

If so, what is that code?

It's a thick film hybrid module. Hence, no detailled information to be expected from the SM. Even worse: Most probably it was made by Sanyo, hence, no more valid replacements available.

Best regards!

Best regards!

I think you could use a general purpose bjt device for that purpose one that has enough Vce rating in a sc-59 Package maybe even a sot-23

Try a mmbt5551

Try a mmbt5551

Going by the block diagram in post #5 and the photo in the 1st post, it maybe one of the diodes across the output Mosfet rather than a transistor.

It could be either a Zener or a TVS diode.

You may need to reverse engineer the pcb tracks to determine which diode it is.

I found some SMD codes here and here

It could be either a Zener or a TVS diode.

You may need to reverse engineer the pcb tracks to determine which diode it is.

I found some SMD codes here and here

Kay is right. That module is not intended to be repaired by anyone, ever. Therefore everything in it is a secret.

If you can trace it out you can at least get an idea of what it really is, then attempt to replace it. If you are a service technician, this job is not worth the time and effort. Your customer would never appreciate your work enough to pay you what it is worth. It is a losing proposition especially if you have to warranty the job.

Your best bet is to replace the entire module if at all possible.

If you can trace it out you can at least get an idea of what it really is, then attempt to replace it. If you are a service technician, this job is not worth the time and effort. Your customer would never appreciate your work enough to pay you what it is worth. It is a losing proposition especially if you have to warranty the job.

Your best bet is to replace the entire module if at all possible.

It isn't any problem. Remember the days before the internet and everything had "house numbers"? You looked at the circuit and supply voltages, then made an intelligent substitution (not ECG!) and moved on.

This is when i was trained and learned. It is a skill that has become important once again.

This is when i was trained and learned. It is a skill that has become important once again.

Ok, had a quick trace and using the right hand side as a reference it is connected to pins 8 and 11 and the fet. Using the schematic as a reference it would appear its the npn transistor on the upper right.

Hi Stegtir,

I'm sorry, but I can't invest the time to investigate this in detail. I can provide some guidance, but I am an overworked technician with a full dance card. I only have so much time.

If the voltage and current ratings make sense, you probably have the right part. I wish I could give you a more informed answer.

I'm sorry, but I can't invest the time to investigate this in detail. I can provide some guidance, but I am an overworked technician with a full dance card. I only have so much time.

If the voltage and current ratings make sense, you probably have the right part. I wish I could give you a more informed answer.

Cheers to you solving the smt part mystery. See, even me being an old smt fart I learnt of this device that maybe obsolete product by PanasonicAnnnd after some digging, I believe its a panasonic 2sd814, datasheet shows markings PR, PS which ties in with the 2 different markings I've seen on the web. What do you reckon?

Of course this RSN6000B device was never intended for service but cheers to you for taking it on and pursuing it

My suggestion is to remove the ? device and test out of circuit to verify that it is a failed bjt, use the 6 way diode test with the DMM in diode test mode. Not so easy but small probes or clips can work.

For a replacement you could try a 2n5551 in a TO-92, not sure if it would fit or you could try to find the original 2sd814 or 814A or MMBT5551LT or FMMT495. To be certain, buy parts from authorized distributors only unless you have ways to verify authenticity.

To remove the device you can form some small gauge solid copper wire to touch the 3 leads at once, pre-tin, heat up so all leads heat at same time, use tweezers to remove, clean off excess solder with solder wick, their should be enough solder on one pad to use to tack down a new device, re-solder, test. I use Glow-core no-clean 15 mil Sn/Pb but you can take your existing solder and give it a stretch to thin it out to ~15 mil or just before it breaks 🙂

Good Luck

Seriously dude, you are a lot of help = NOT!!That's why I hate SMD crap.

Being so old, have you not learnt that everything has its place. Try to design a cell phone using tht, what a joke. FYI, I first learnt smt at the Motorola Comm factory in the 1980's and have designed using smt technology ever since. But I am still designing power supplies today using tht, everything has its place and purpose.

Putzing around with something that was designed as a "throw-away" product, or requiring complete board replacement is nonsense in the professional service industry.Of course this RSN6000B device was never intended for service

Seriously dude, you are a lot of help = NOT!!

Being so old, have you not learnt that everything has its place. Try to design a cell phone using tht, what a joke. FYI, I first learnt smt at the Motorola Comm factory in the 1980's and have designed using smt technology ever since. But I am still designing power supplies today using tht, everything has its place and purpose.

And you have to understand that fact, because us bench technicians do not have the luxury of having all the time in the world to mess with something like that.

With other "service-friendly" products flowing through the door, we can't cause a backlog and annoyed customers by holding up their repairs.

But you go ahead and try to explain that to them.

Thanks for all the input, I don't have much experience nor success reworking smt.

However this looks very easy and I kinda disagree with it being unrepairable. It was a straightforward stripdown and I'd rather repair it rather than butcher another to salvage the part. Naturally in a professional setting, time is money and I understand its a fine balance sometimes. I have got a new DCA75 I might try on the working side just to confirm.

I can only see 814 here for £15 each! So will look into the alternatives, tbh not sure what parameters other than vce voltage that would need to be a match

However this looks very easy and I kinda disagree with it being unrepairable. It was a straightforward stripdown and I'd rather repair it rather than butcher another to salvage the part. Naturally in a professional setting, time is money and I understand its a fine balance sometimes. I have got a new DCA75 I might try on the working side just to confirm.

I can only see 814 here for £15 each! So will look into the alternatives, tbh not sure what parameters other than vce voltage that would need to be a match

No point in saying "SMD is garbage", it's here to stay.. and there are some very nice parts available... plus the smaller size means more compact layouts are doable with less THD etc as a result

Nothing wrong with smt. I use it, design with it and have had to service large chips and transistors, resistors and caps. I stock many, but not nearly to the levels I stock leaded parts.

The problem here is simple. Without a schematic, if you have a resistor or capacitor that is bad, if you don't have another to compare to you are pretty much finished. That is unless yu are a designer / engineer and know what a reasonable value would be. In this case, there is no schematic in the wild I am aware of.

As a hobbyist you do have the luxury of time on your side. You don't have to account for your time and you don't need to make a living doing this repair. So, that's great. By all means - go for it. We can try to help as you have seen. But because there isn't a schematic for us to refer to, there is a limit to how much help we can be. So while wiseoldtech has valid points for a service environment they don't always apply directly to you. Still, as you work on this, do consider some of these points and if you do find another good chip, consider grabbing it if it is reasonable money.

Way back in time when some earlier STK modules were discontinued, and some failed due to poor manufacturing, we did try to repair some. It was a painful and mostly unsuccessful venture. Then came those wonderful Fosgate thick film modules. I did repair some of those. But it was extremely clear that these were developed in order to prevent servicing while also making manufacturing less expensive. Running a large service shop I could not afford to fight the industry and accepted that manufacturers did not want products repaired past warranty. Today many have succeeded by instituting "repair by replacement". They dropped their service costs, eliminated service and parts departments in Canada and forced people to buy new. Gee, like that is in our best interests!

You are fighting this trend. You can do it, a service shop or professional technician can't.

The problem here is simple. Without a schematic, if you have a resistor or capacitor that is bad, if you don't have another to compare to you are pretty much finished. That is unless yu are a designer / engineer and know what a reasonable value would be. In this case, there is no schematic in the wild I am aware of.

As a hobbyist you do have the luxury of time on your side. You don't have to account for your time and you don't need to make a living doing this repair. So, that's great. By all means - go for it. We can try to help as you have seen. But because there isn't a schematic for us to refer to, there is a limit to how much help we can be. So while wiseoldtech has valid points for a service environment they don't always apply directly to you. Still, as you work on this, do consider some of these points and if you do find another good chip, consider grabbing it if it is reasonable money.

Way back in time when some earlier STK modules were discontinued, and some failed due to poor manufacturing, we did try to repair some. It was a painful and mostly unsuccessful venture. Then came those wonderful Fosgate thick film modules. I did repair some of those. But it was extremely clear that these were developed in order to prevent servicing while also making manufacturing less expensive. Running a large service shop I could not afford to fight the industry and accepted that manufacturers did not want products repaired past warranty. Today many have succeeded by instituting "repair by replacement". They dropped their service costs, eliminated service and parts departments in Canada and forced people to buy new. Gee, like that is in our best interests!

You are fighting this trend. You can do it, a service shop or professional technician can't.

- Home

- Amplifiers

- Solid State

- Help identify replacement SMD transistor