Hi everyone,

This is my first post.

I want to build my own turntable. I've read through ALL the threads (including one on an oil-damped platter & unipivot bearing -- which took me at least a day to get through and digest. ). The conclusion I had from the long DIY TT thread was that the great ideas on oil damping/uinpivot etc were not quite up to scratch. Therefore the bearing is causing be problems.

). The conclusion I had from the long DIY TT thread was that the great ideas on oil damping/uinpivot etc were not quite up to scratch. Therefore the bearing is causing be problems.

On my DIY TT, here is where I am now:

Motor:

Have the plan for a cheapo PLL-DC solution ($10)

( http://rcswww.urz.tu-dresden.de/~cs838136/krishu/dc2.htm )

Tonearm:

unipivot DIY...

( http://rcswww.urz.tu-dresden.de/~cs838136/krishu/uni.htm )

( http://www.altmann.haan.de/tonearm/default.htm )

( http://www.freewebs.com/stereobass/funwithtonearms.htm )

...but I still have to work out anti-skating, and maybe I'll have to go for an RB300/250 from audiogon (around $300)

Platter:

Hardwood, sandwiched, made with a router or a lathe. Not the difficult bit.

BUT the one thing that is bugging me

is the spindle bearing. So far I've only found the teres bearing ($290 - ouch), and a nice one here with no details on source and price.

is the spindle bearing. So far I've only found the teres bearing ($290 - ouch), and a nice one here with no details on source and price.

( http://rcswww.urz.tu-dresden.de/~cs838136/krishu/bear.htm )

SO, to cut a long story short, does anyone know of sources / parts lists / ideas / whatever for a good DIY bearing? Basically one where it is possible to buy the parts and not have to do machining.....

And if anyone has tried the Altmann arm, I'd love to hear about it!

thx in advance,

ssmith

This is my first post.

I want to build my own turntable. I've read through ALL the threads (including one on an oil-damped platter & unipivot bearing -- which took me at least a day to get through and digest.

). The conclusion I had from the long DIY TT thread was that the great ideas on oil damping/uinpivot etc were not quite up to scratch. Therefore the bearing is causing be problems.

). The conclusion I had from the long DIY TT thread was that the great ideas on oil damping/uinpivot etc were not quite up to scratch. Therefore the bearing is causing be problems.On my DIY TT, here is where I am now:

Motor:

Have the plan for a cheapo PLL-DC solution ($10)

( http://rcswww.urz.tu-dresden.de/~cs838136/krishu/dc2.htm )

Tonearm:

unipivot DIY...

( http://rcswww.urz.tu-dresden.de/~cs838136/krishu/uni.htm )

( http://www.altmann.haan.de/tonearm/default.htm )

( http://www.freewebs.com/stereobass/funwithtonearms.htm )

...but I still have to work out anti-skating, and maybe I'll have to go for an RB300/250 from audiogon (around $300)

Platter:

Hardwood, sandwiched, made with a router or a lathe. Not the difficult bit.

BUT the one thing that is bugging me

is the spindle bearing. So far I've only found the teres bearing ($290 - ouch), and a nice one here with no details on source and price.

is the spindle bearing. So far I've only found the teres bearing ($290 - ouch), and a nice one here with no details on source and price. ( http://rcswww.urz.tu-dresden.de/~cs838136/krishu/bear.htm )

SO, to cut a long story short, does anyone know of sources / parts lists / ideas / whatever for a good DIY bearing? Basically one where it is possible to buy the parts and not have to do machining.....

And if anyone has tried the Altmann arm, I'd love to hear about it!

thx in advance,

ssmith

http://www.scheu-analog.de/preisliste.htm

They have a great bearing, but this one is € 210,-

You might want to get a second-hand Thorens or something, use that bearing. Has been done loads of times..

They have a great bearing, but this one is € 210,-

You might want to get a second-hand Thorens or something, use that bearing. Has been done loads of times..

a bearing...

I am in the same situation as you. I decided on making my own unipivot arm (can't wait to try it).I have no reason yo believe that it will not sound good. Hard anodized aluminium arm tube, sliding weight, and a fine tune screw. No anti skating for now.

I just bought a Sugden Connoisseur, without tonearm. I have a couple of arms here, but wanted to try my hand at building one. I have $5 CDN invested in total. I think I will need to dampen the arm tube with a balsa wood insert.

As for the bearings, I am also in the process of building a "DIY" turntable, and am using an old Garrard Lab 80 as a starting point. The centre of the platter has a pressed in insert, and is precision balanced. I am having a machine shop make a centre spindle that will be supported by 2 ABEC 7 roller blade style bearings in a hollow housing, and a flange on the platter side to allow installation. Don't know if it will work but willing to give it a try. I guess if Garrard got away with loose ball bearings the precision electric motor style ABECs should be OK. It seems that the bearing is the single largest hurdle to jump in building your own table. Planning on having a single Rollerblade wheel turned down for the idler wheel. Not sure if I will drive the inside or outside of the platter. Good luck.

I am in the same situation as you. I decided on making my own unipivot arm (can't wait to try it).I have no reason yo believe that it will not sound good. Hard anodized aluminium arm tube, sliding weight, and a fine tune screw. No anti skating for now.

I just bought a Sugden Connoisseur, without tonearm. I have a couple of arms here, but wanted to try my hand at building one. I have $5 CDN invested in total. I think I will need to dampen the arm tube with a balsa wood insert.

As for the bearings, I am also in the process of building a "DIY" turntable, and am using an old Garrard Lab 80 as a starting point. The centre of the platter has a pressed in insert, and is precision balanced. I am having a machine shop make a centre spindle that will be supported by 2 ABEC 7 roller blade style bearings in a hollow housing, and a flange on the platter side to allow installation. Don't know if it will work but willing to give it a try. I guess if Garrard got away with loose ball bearings the precision electric motor style ABECs should be OK. It seems that the bearing is the single largest hurdle to jump in building your own table. Planning on having a single Rollerblade wheel turned down for the idler wheel. Not sure if I will drive the inside or outside of the platter. Good luck.

Yep, the bearing is a real headache. There was a long thread about building a floating platter, but in the end it seems the best bet is a bearing along the lines of Scheu or Teres. Looking at the whole difficulties involved -- including finding a machiner who could make a bearing -- I may just opt for a Scheu set-up..

But then there is this:

http://rcswww.urz.tu-dresden.de/~cs838136/krishu/bear.htm

he's promised to "also publish drawings, prices as well as name the sources" - so I guess I may wait for that!!!

Thanks for the tips.

But then there is this:

http://rcswww.urz.tu-dresden.de/~cs838136/krishu/bear.htm

he's promised to "also publish drawings, prices as well as name the sources" - so I guess I may wait for that!!!

Thanks for the tips.

ssmith, your welcome to email me if your interested in a diy teres type bearing crafted by a professional research machinist.

Let me know 🙂

stylinlp@cox.net

Let me know 🙂

stylinlp@cox.net

Why not build a air-bearing ? I don`t think it is any more complicated to build by the average DIY`er than a ordinary TT-bearing.

A suitable compressor could be from an old refrigiator and of course you should fit a Ladegard arm...😉

Cheers

JB

A suitable compressor could be from an old refrigiator and of course you should fit a Ladegard arm...😉

Cheers

JB

Would a high quality part from a bicycle be good to use? Just a thought. You'd have to cur off the quick-release of course

Link to Shimano

Link to Shimano

The highest quality bearing that I know of that can be had for no money is the one found in dead harddrives. There is an added advantage that it is already attached to a machined aluminium base which would make attachment/mounting easier. ( The motor might even be usable ).

A while ago I came across a floppy based turntable but thought at the time a HDD would be a better base to start from.

A while ago I came across a floppy based turntable but thought at the time a HDD would be a better base to start from.

rif! A bicycle hub? Actually I'd kind of thought of it, having in the past been a cyclist and wheel builder. The link you gave -- for dura-ace -- shows you know your cycling too... they are smoooooth hubs. But the problem is mounting to a plinth and fitting it into a platter. Will have to give that one more thought!

and thx for the hardrive tip cyteen.. I'm wondering if it can hold a heavy platter though?

I'm sure I have a dead one somewhere, so will pull it apart...

and thx for the hardrive tip cyteen.. I'm wondering if it can hold a heavy platter though?

I'm sure I have a dead one somewhere, so will pull it apart...

er ..ok I got my bearing

(actually bearing housing and shaft), back from the machinist. A little pricey ($240 USD), but beautifully finished. No pictures but similar to the Teres bearing housing except that the housing is in the plinth, not the platter (a regular non-inverted type), but I can easily move it from one turntable to another, and replacing ahigher grade bearings is very easy, as they are "electric motor" sealed types. Maybe I can make a sketch and post it....

(actually bearing housing and shaft), back from the machinist. A little pricey ($240 USD), but beautifully finished. No pictures but similar to the Teres bearing housing except that the housing is in the plinth, not the platter (a regular non-inverted type), but I can easily move it from one turntable to another, and replacing ahigher grade bearings is very easy, as they are "electric motor" sealed types. Maybe I can make a sketch and post it....

Attachments

thanks nanook!

Congratulations on the bearing. I guess I'll have to find a machinist...

Have you tried your unipivot arm yet? I'm looking at a similiar design, using either wood or aluminium. Do you find the lack of anti-skating is a problem?

Congratulations on the bearing. I guess I'll have to find a machinist...

Have you tried your unipivot arm yet? I'm looking at a similiar design, using either wood or aluminium. Do you find the lack of anti-skating is a problem?

DIY unipivot...for ssmith and others...

No I actually haven't tried the DIY 12" arm yet, I have two turntable projects on the go....a Sugden Connoisseur BD1 in a Chinese Oak plinth and the arm board ( held at the appropriate distance from the main turntable with adjoining Aluminium bars. If I can get some photos when it is done I'll post them...) and my Garrard "LAb 80 manual", which is what I had the bearing made for. The lab motor will be attached to a granite sub-plint, with a maple mainplinth supporting the platter and tonearm. I'd like to do a sort of Roksan TMS or Xerses 10 clone...

I have used RadioShack magnat wire as tonearm wire and even the 33 guage stuff creates it's own lateral resistance . As the arm pivots a small torsional force outward is exerted by the wire on the tonearm. I have tried everything to minimize or remove this effect to no avail. It is quite small in magnitude.

I used an Easton arrow shaft that I bought at a local archery range as a "practice" arrow for $1USD. I may have to dampen the arm tube with some foam or balsa wood inserted into the tube. I think I have $5 CDN into it....I will post pictures or a hand made sketch if I can...

No I actually haven't tried the DIY 12" arm yet, I have two turntable projects on the go....a Sugden Connoisseur BD1 in a Chinese Oak plinth and the arm board ( held at the appropriate distance from the main turntable with adjoining Aluminium bars. If I can get some photos when it is done I'll post them...) and my Garrard "LAb 80 manual", which is what I had the bearing made for. The lab motor will be attached to a granite sub-plint, with a maple mainplinth supporting the platter and tonearm. I'd like to do a sort of Roksan TMS or Xerses 10 clone...

I have used RadioShack magnat wire as tonearm wire and even the 33 guage stuff creates it's own lateral resistance . As the arm pivots a small torsional force outward is exerted by the wire on the tonearm. I have tried everything to minimize or remove this effect to no avail. It is quite small in magnitude.

I used an Easton arrow shaft that I bought at a local archery range as a "practice" arrow for $1USD. I may have to dampen the arm tube with some foam or balsa wood inserted into the tube. I think I have $5 CDN into it....I will post pictures or a hand made sketch if I can...

Hi Nanook,

Good idea to use an arrow shaft.

I've decided to try rolled up balsa wood, see this thread, which means I can also run the wiring on the inside and maybe damp the wires using teflon plumbers tape. I think it would also be possible to roll up that balsa wood in a way that it is tapered.

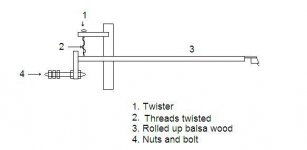

For the anti-skating, I'm going to try to dangle the tonearm from a few threads twisted together (like silk or fishing line), which can be twisted by some kind of nut at the top to provide the lateral tension. I've done a diagram -- which is not very good (I used Microsoft Paint...).

Of course its all theory at the moment -- just need to sort out the bearing.

Good idea to use an arrow shaft.

I've decided to try rolled up balsa wood, see this thread, which means I can also run the wiring on the inside and maybe damp the wires using teflon plumbers tape. I think it would also be possible to roll up that balsa wood in a way that it is tapered.

For the anti-skating, I'm going to try to dangle the tonearm from a few threads twisted together (like silk or fishing line), which can be twisted by some kind of nut at the top to provide the lateral tension. I've done a diagram -- which is not very good (I used Microsoft Paint...).

Of course its all theory at the moment -- just need to sort out the bearing.

Attachments

Hi ssmith,

I'm using a standart off the shelf shaft and sleeve.

a 3/4" and 5" long thompson shaft cost me about $10. its polished and hardend to 60 Rc. a bronze sleev was harder to find with high tolerance & with an exact .750" ID I used 2 of them forced into the plater and had to grove one to add a snap-ring on top.

I can send an Autocad 14 drawing if you need.

Total cost was under $15

Cheers,

I'm using a standart off the shelf shaft and sleeve.

a 3/4" and 5" long thompson shaft cost me about $10. its polished and hardend to 60 Rc. a bronze sleev was harder to find with high tolerance & with an exact .750" ID I used 2 of them forced into the plater and had to grove one to add a snap-ring on top.

I can send an Autocad 14 drawing if you need.

Total cost was under $15

Cheers,

Hi IZHAKKATZ,

Sounds interesting -- and would love to see the autocad drawing -- either PM it to me via the board or enclose it on the thread -- maybe useful for other people.

Your off the shelf solution sounds great. I've been looking at the McMaster-Carr site, and they have tonnes of shafts, sleeves, bearings, collars and so on (and all fairly cheap) -- would useful to know what fits what and how to put something together that attaches well to a simple plinth and platter...

Sounds interesting -- and would love to see the autocad drawing -- either PM it to me via the board or enclose it on the thread -- maybe useful for other people.

Your off the shelf solution sounds great. I've been looking at the McMaster-Carr site, and they have tonnes of shafts, sleeves, bearings, collars and so on (and all fairly cheap) -- would useful to know what fits what and how to put something together that attaches well to a simple plinth and platter...

Hi ssmith,

I've tryed to attache an Autocad file but it wasn't valid.

If you have an email i can mail you the file.

cheers

Izhak

I've tryed to attache an Autocad file but it wasn't valid.

If you have an email i can mail you the file.

cheers

Izhak

Autocad files. and tonearm bearing.....oops did I pay too much?

I don't think so because of course it is absolutely beautiful and the machinist donated quite a bit of his time to my cause...and I have to rationalize the expense somehow🙂

$15 for a turntable bearing is absolutely great, an inexpensive alternative for turntable DIYs....

IZHAKKATZ could you email me the drawing? I may be able to convert it to another format (maybe PDF) and repost it here if you would so choose.

ssmith, I think that the anti skate mechanism using twisted pairs of string or thread or whatever is quite simple, and dare I say a little clever...good for you.

I know some arms have used magnets to provide the anti-skate force, and that can be pretty easy to implement too, recall that the Fb is proportional to r^2 or the distance between the two magnets ,if I remember physics correctly (it's been a long time....). so two small magnets, one attached to the arm, another attached to a non moving stand, both near the pivot point . The one on the non moving part could be adjusted for distance to the other so that anti-skating force is greatest near the end of the record, a little trial and error may be needed. I am not convinced that subjecting the tonearm wires to a fluctuating magnetic field (and hence produce a small current) is what I would want to do, though the aluminum shaft of my tonearm would help to magnetically shield the wired from the magnets.

DIY turntables can be rather inexpensive (the Sugden ) or more expensive (the Garrard based design), but ultimately are fun, and can be easy to do once the hurdle of the bearing is overcome...

PS: the Garrard project itself will be quite expensive (I could have bought something else for less perhaps) but I suspect (am hoping?) that the thing can hold its own against some bigger , badder tables..

I don't think so because of course it is absolutely beautiful and the machinist donated quite a bit of his time to my cause...and I have to rationalize the expense somehow🙂

$15 for a turntable bearing is absolutely great, an inexpensive alternative for turntable DIYs....

IZHAKKATZ could you email me the drawing? I may be able to convert it to another format (maybe PDF) and repost it here if you would so choose.

ssmith, I think that the anti skate mechanism using twisted pairs of string or thread or whatever is quite simple, and dare I say a little clever...good for you.

I know some arms have used magnets to provide the anti-skate force, and that can be pretty easy to implement too, recall that the Fb is proportional to r^2 or the distance between the two magnets ,if I remember physics correctly (it's been a long time....). so two small magnets, one attached to the arm, another attached to a non moving stand, both near the pivot point . The one on the non moving part could be adjusted for distance to the other so that anti-skating force is greatest near the end of the record, a little trial and error may be needed. I am not convinced that subjecting the tonearm wires to a fluctuating magnetic field (and hence produce a small current) is what I would want to do, though the aluminum shaft of my tonearm would help to magnetically shield the wired from the magnets.

DIY turntables can be rather inexpensive (the Sugden ) or more expensive (the Garrard based design), but ultimately are fun, and can be easy to do once the hurdle of the bearing is overcome...

PS: the Garrard project itself will be quite expensive (I could have bought something else for less perhaps) but I suspect (am hoping?) that the thing can hold its own against some bigger , badder tables..

Re: Autocad files. and tonearm bearing.....oops did I pay too much?

That would be a great idea. I'm sure a lot of people would be interested.

Nothing original - I think I got the idea from somewhere in these forums! The key will be to use thread that is rigid, so the arm doesn't wobble from side to side (I think).

you've lost me there.....

True. after all the research, I confess that I'm still wondering whether to just pay the cash and get a scheu or something...

Nanook said:IZHAKKATZ could you email me the drawing? I may be able to convert it to another format (maybe PDF) and repost it here if you would so choose.

That would be a great idea. I'm sure a lot of people would be interested.

Originally posted by Nanook Originally posted by Nanook [/i] ssmith, I think that the anti skate mechanism using twisted pairs of string or thread or whatever is quite simple, and dare I say a little clever...good for you.

Nothing original - I think I got the idea from somewhere in these forums! The key will be to use thread that is rigid, so the arm doesn't wobble from side to side (I think).

Originally posted by Nanook I know some arms have used magnets to provide the anti-skate force, and that can be pretty easy to implement too, recall that the Fb is proportional to r^2 or the distance between the two magnets ,if I remember physics correctly (it's been a long time....).

you've lost me there.....

DIY turntables can be rather inexpensive (the Sugden ) or more expensive (the Garrard based design), but ultimately are fun, and can be easy to do once the hurdle of the bearing is overcome...

True. after all the research, I confess that I'm still wondering whether to just pay the cash and get a scheu or something...

ssmith and all...

ssmith, I "stole" your tonearm sketch and modded it to look like the one I built (I hope it's ok with you to do it, if not I apologize)

Magnets can attract each other (opposite poles towards each other) or repell (same poles towards each other). The magnetic field is related to the distance between them.. I can't remember if it is directly proportional or inversely proportional (I think it is inversely). with a little work, and some playing around it could be interesting to implement it.

ssmith, I "stole" your tonearm sketch and modded it to look like the one I built (I hope it's ok with you to do it, if not I apologize)

Magnets can attract each other (opposite poles towards each other) or repell (same poles towards each other). The magnetic field is related to the distance between them.. I can't remember if it is directly proportional or inversely proportional (I think it is inversely). with a little work, and some playing around it could be interesting to implement it.

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- HELP!!! anyone sourced a DIY bearing?