We have decided on a daybed instead of regular sofa for movie watching as we all like to cuddle up

I am working on the design now and stuck on n the working surface for the bass exciters. What is optimal? A regular slat system or slats on suspended rails? I can place 20x20mm rubber on the rails before putting the slats down. As well on slat ends

I can also mount squares of ply under the slats for the exciters. Never done anything like this so some guidance on bass exciters would be very appreciated

Ample class d power available with many types of modules on hand

Thanks and regards

Randy

I am working on the design now and stuck on n the working surface for the bass exciters. What is optimal? A regular slat system or slats on suspended rails? I can place 20x20mm rubber on the rails before putting the slats down. As well on slat ends

I can also mount squares of ply under the slats for the exciters. Never done anything like this so some guidance on bass exciters would be very appreciated

Ample class d power available with many types of modules on hand

Thanks and regards

Randy

The new baby kicked us out of the normal listening/bed area........must improviseA vibrating, bed to snuggle on..…. Someones gonna get ’lucky’ 😀

Beginnings of a tentative BOM, click to see item details

Form Ply 1 sheet

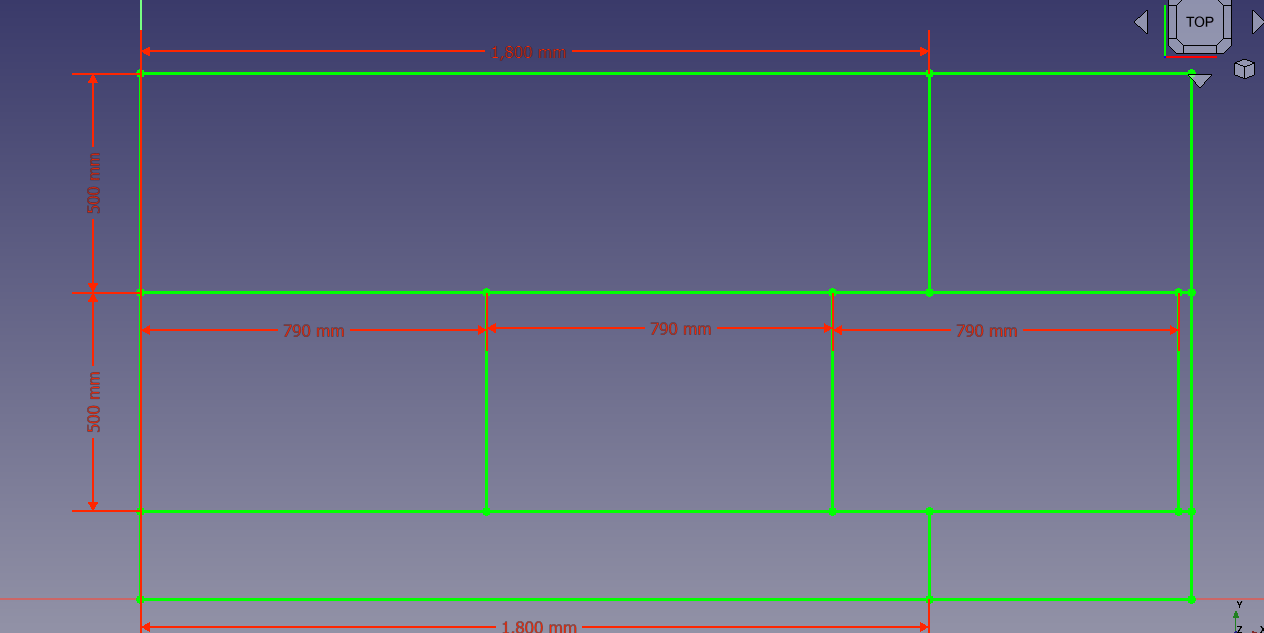

Cutting plan (nesting) for the sheet, taking blade width into account. All ply parts to come off one sheet 2400mm x 1200mm x 17mm. Will get Bunnings to cut this up on their panel saw. It's not going to be an intricate build, so a fair amount of tolerance is ok

Form Ply 1 sheet

Cutting plan (nesting) for the sheet, taking blade width into account. All ply parts to come off one sheet 2400mm x 1200mm x 17mm. Will get Bunnings to cut this up on their panel saw. It's not going to be an intricate build, so a fair amount of tolerance is ok

Wagner in Sydney have a good range of shakers: https://www.wagneronline.com.au/bass-shaker/ps/

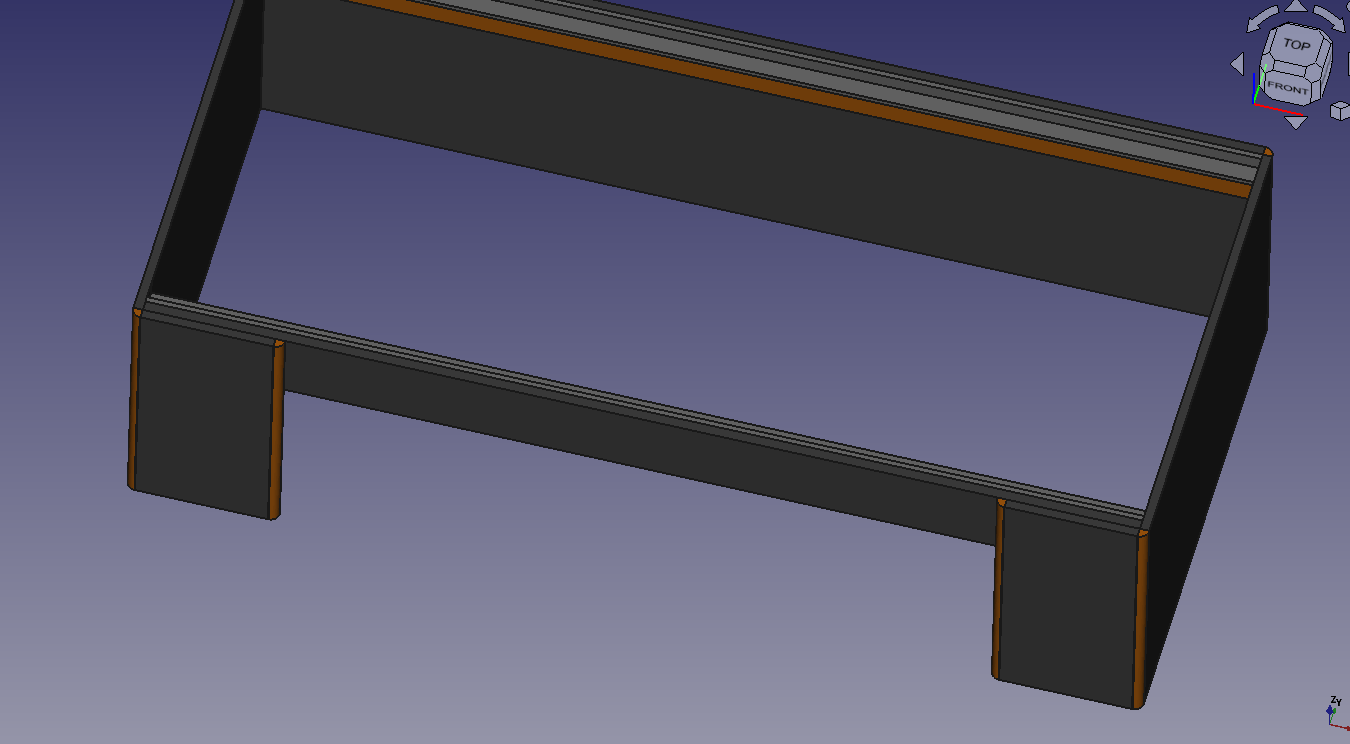

This one is coming along well in design phase. I have created a working model of the day bed. It's 1800mm wide x 834mm deep x 500mm tall. The mattress will be 100mm thick. The black in the pic is the ply, the brown is wood and the grey is 10mm PE foam. These are standard Bunnings items. Not drawn are a pair of rubber rails on the foam to complete the suspension for the rails. Planning to glue the wood and ply edges as well as inside corner battens to bring it all together

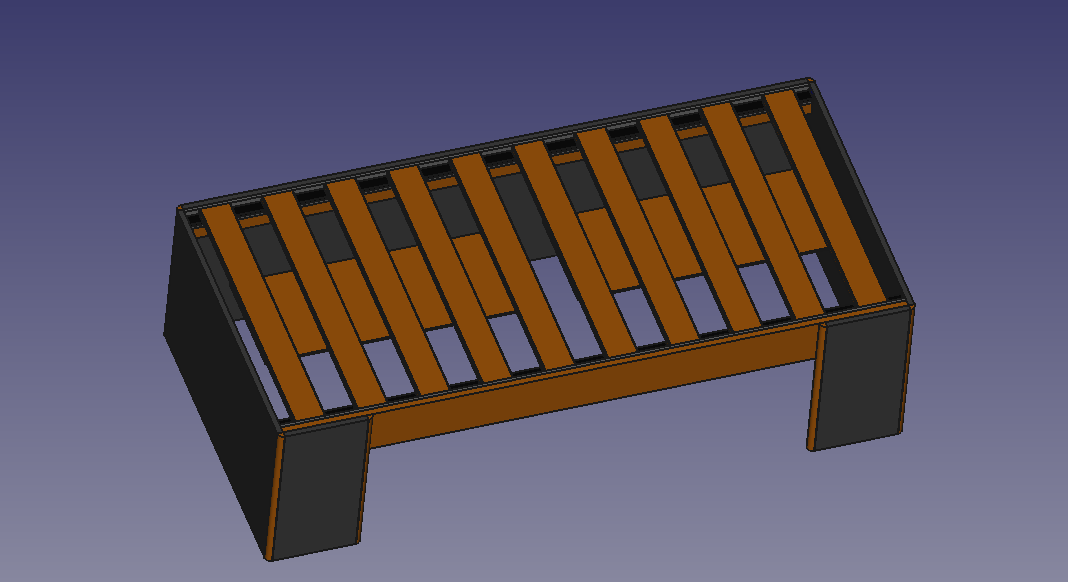

The complete working model. All the brown represent solid timer. I will be using prefinished Merbau decking planks from Bunnings and some pine for the rails. The pair of flat panels under the rails are 7mm ply and for attaching the exciters and will be used to implement independent level control. The idea here is to tune for comfort

The entire project is designed around minimal construction and does away with traditional furniture making practices. The ply surface is already finished in a quality hard black and also makes a perfect base for vinyl wraps

The slats sit on a 12mm rubber layer which sits on 10mm PE foam liner on the rail flats and sides. This is to form a suspension for the exciters. PE foam has shape memory and high durability. The slats will be floating on the rubber and foam and between foam to avoid any hard contact with the rails. A further refinement is the gap at the last slats to form 'toe rails'

Space under the slats can be used to build in a cabinet with doors or drawers. I will be placing a childproof gate there and store projects underway there out of sight and harms way

Time to look for exciters for this. I will be using a FFA001 stereo module for amp so 150wrms x2 @4R and @8R on tap so plenty of power available. This will be used with one of the subs from the Tiny40s project for audible response down to 40hz and hopefully the exciters can extend even lower. I should mention that this will be part of very quiet night use

BOM - items are clickable

Form ply - 1 sheet 1800mm x 1200mm x 17mm

Merbau - 10 slats 90mm x 19mm

Merbau - 1800mm x 90mm x 19mm fascia

Pine - 2 rails 42mm x 42mm x 1800mm

PE foam - 2 strips 150mm x 10mm x 1800mm

Rubber - 1 roll 9mm x 25mm x 5000mm

The rails and PE foam are already at the required lengths at Bunnings. Foam will need trimming along one side after applying. The Merbau and ply will be cut at Bunnings. The Rubber will need cutting to size while installing. There will be enough left over to apply some at the slat ends to increase suspension height and travel, but the rails would need to be lowered another 9mm. I might do this during assembly

There are additional BOM items that will be added later such as fasteners and the back rest as well as the foam for the mattress and fabrics. Total cost not including the electronics is expected to be under $400 AUD........will call the design "Cosyvibes"

Form ply - 1 sheet 1800mm x 1200mm x 17mm

Merbau - 10 slats 90mm x 19mm

Merbau - 1800mm x 90mm x 19mm fascia

Pine - 2 rails 42mm x 42mm x 1800mm

PE foam - 2 strips 150mm x 10mm x 1800mm

Rubber - 1 roll 9mm x 25mm x 5000mm

The rails and PE foam are already at the required lengths at Bunnings. Foam will need trimming along one side after applying. The Merbau and ply will be cut at Bunnings. The Rubber will need cutting to size while installing. There will be enough left over to apply some at the slat ends to increase suspension height and travel, but the rails would need to be lowered another 9mm. I might do this during assembly

There are additional BOM items that will be added later such as fasteners and the back rest as well as the foam for the mattress and fabrics. Total cost not including the electronics is expected to be under $400 AUD........will call the design "Cosyvibes"

Bunnings has a special on dressed pine atm. AUD $5 and $10 each for 1.8m and 2.4m lengths for widths up to 184mm. So instead of using the ply, I picked up a whole bunch of planks. The drawn design accommodates planks or boards and my layout is such that board or plank thickness changes do not change the cutting sizes. Will stack three 184mm planks for now increased height by 52mm and this is the only dimension affected by the change in material

Haven’t been very happy recently with the cutting at Bunnings so decided to add a dual slide compound mitre saw to the workshop. Should be awesome for this project and other bevel cuts for ply and planks for speaker boxes. The unit has a 210mm blade and 310mm travel so a bevel cut to 600 odd mm can be done

https://www.bunnings.com.au/ozito-1...le-bevel-sliding-mitre-saw-scms-1621_p6290587

Haven’t been very happy recently with the cutting at Bunnings so decided to add a dual slide compound mitre saw to the workshop. Should be awesome for this project and other bevel cuts for ply and planks for speaker boxes. The unit has a 210mm blade and 310mm travel so a bevel cut to 600 odd mm can be done

https://www.bunnings.com.au/ozito-1...le-bevel-sliding-mitre-saw-scms-1621_p6290587

Just finished cutting up all the wood for this project. Wanted to assemble today as well but had forgotten to pick up the correct size screws. My wife’s long weekend starts tomorrow so will have help and hopefully will be in use before the weekend ends

The cutting went just fine and I don’t foresee any assembly issues. Will polish up the CAD file for this and post here for any other new parents getting kicked out of the bedroom and looking to wind down (or up) Late nights in front of the screen

The cutting went just fine and I don’t foresee any assembly issues. Will polish up the CAD file for this and post here for any other new parents getting kicked out of the bedroom and looking to wind down (or up) Late nights in front of the screen

Attached is the FreeCAD model for Cosyvibes. This DIY is geared towards eliminating as much of the difficult tasks as possible. In example, there are no visible end grains to take care off and the design does not use any specialist wood working joints. Simple screwed and glued battens from the inside and trims from outside

Can be made with any combination of planks and boards, and thickness does not require any changes in cutting specs. Board or plank widths determine the overall height. In my build, I am using 184mm wide planks for the back and sides in a stack of three. This totals 552mm overall height for the bed frame. The mattress will add another 100 odd mms

The file only contains the bed frame. The back rest and hand/toe rails will be separate files created after the frame is built

After the frame is done, I intend to mess with the bass exciters. I have a feeling that dropping a perpendicular board from the two under the slats might be better, as the drivers will then be oriented regularly, and the new boards will act as levers for extra heave. Two exciters for dual zone to tune for upper and lower body

Can be made with any combination of planks and boards, and thickness does not require any changes in cutting specs. Board or plank widths determine the overall height. In my build, I am using 184mm wide planks for the back and sides in a stack of three. This totals 552mm overall height for the bed frame. The mattress will add another 100 odd mms

The file only contains the bed frame. The back rest and hand/toe rails will be separate files created after the frame is built

After the frame is done, I intend to mess with the bass exciters. I have a feeling that dropping a perpendicular board from the two under the slats might be better, as the drivers will then be oriented regularly, and the new boards will act as levers for extra heave. Two exciters for dual zone to tune for upper and lower body

Attachments

My fasteners and suspension items order is ready to collect at Bunnings be good to get the mattress off the floor

Thinking about picking up some finish while I am there. Not a fan of how pine looks under the usual poly finishes, even when stained. Might try oil, a white lime type finish that shows some grain is also attractive

Thinking about picking up some finish while I am there. Not a fan of how pine looks under the usual poly finishes, even when stained. Might try oil, a white lime type finish that shows some grain is also attractive

- Home

- Loudspeakers

- Subwoofers

- Heaving bed