Photo View 360. Too simplified for my taste. Do you know CAD which takes a surface and makes a flat sketch?

Let's not get so far away from the thread topic OK. jzagaja a little discussion of your project is fine, but otherwise please start your own thread.

I think so as well. I enjoyed the thread when almost all discussions were about wave guides/horns. Now it seems we're getting forced to look at cosmetics.🙄Let's not get so far away from the thread topic OK. jzagaja a little discussion of your project is fine, but otherwise please start your own thread.

...there has been some talk about the need to "optimize" the junction between the CD driver and horn...for what it's worth, maybe I've been sucked into an area of diminishing returns...along with that, YMMV

Working with the B&C DE250 & a 90 x 40 QSC waveguide, this is what I've found:

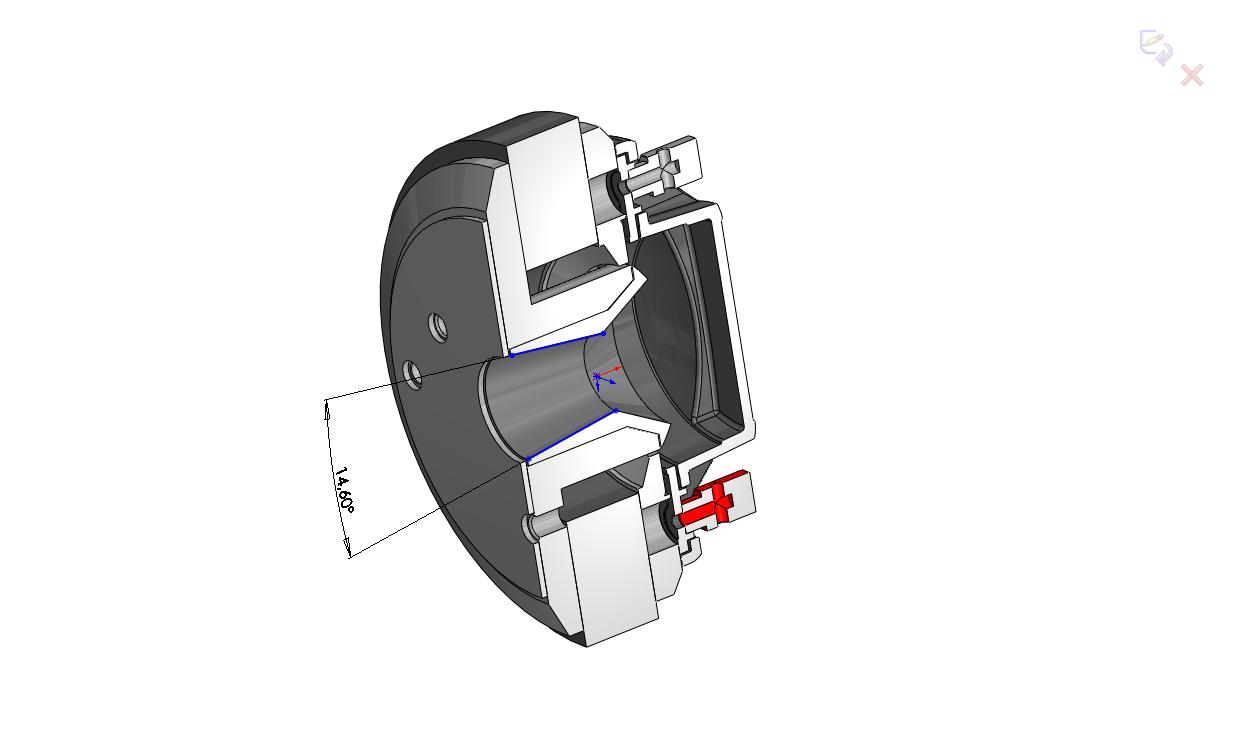

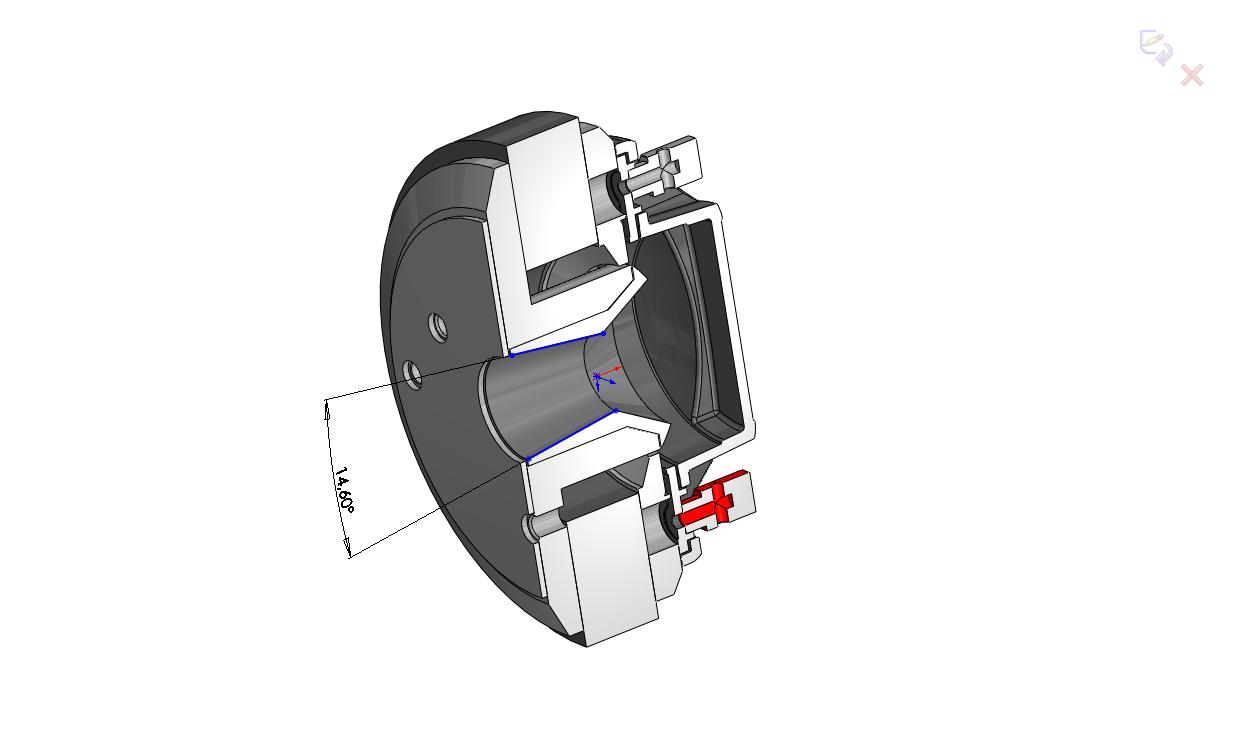

I removed the bug screen from the cd to determine the exit angle and allow a better fit to the horn. I found the exit angle to be reasonably close (+/- 0.25 degree) to 14.6 degrees (7.3 degrees from axis)...confirming the info provided in post 3583 and the image provided by mabat:

The throat includes 2 ridges roughly (how appropriate...) located @ the third points along its length. The ridges go all the way around the throat...they look like mold joints. The throat shows some scratch/sanding marks. I'm guessing these are the result of some QC(?) to smooth the ridges. I'll get back to them later. ...no sense fiddlin' with them before the concept has been proven, eh?

The studs provided with the DE250 are too short to extend through the QSC horn to allow nuts and lockwashers any purchase. They need to be at least 3/8" longer.

The throat of the QSC horn is (very)slightly oversize. In spite of this, I'm considering making a mandrel to sand/shape/refine the QSC profile to improve the match with the cd. Along with this, a spacer between the cd & horn may be necessary to ease/replace the loss of material.

Working with the B&C DE250 & a 90 x 40 QSC waveguide, this is what I've found:

I removed the bug screen from the cd to determine the exit angle and allow a better fit to the horn. I found the exit angle to be reasonably close (+/- 0.25 degree) to 14.6 degrees (7.3 degrees from axis)...confirming the info provided in post 3583 and the image provided by mabat:

The throat includes 2 ridges roughly (how appropriate...) located @ the third points along its length. The ridges go all the way around the throat...they look like mold joints. The throat shows some scratch/sanding marks. I'm guessing these are the result of some QC(?) to smooth the ridges. I'll get back to them later. ...no sense fiddlin' with them before the concept has been proven, eh?

The studs provided with the DE250 are too short to extend through the QSC horn to allow nuts and lockwashers any purchase. They need to be at least 3/8" longer.

The throat of the QSC horn is (very)slightly oversize. In spite of this, I'm considering making a mandrel to sand/shape/refine the QSC profile to improve the match with the cd. Along with this, a spacer between the cd & horn may be necessary to ease/replace the loss of material.

Last edited:

B&C DE250...cThe throat includes 2 ridges roughly (how appropriate...) located @ the third points along its length. The ridges go all the way around the throat...they look like mold joints. The throat shows some scratch/sanding marks.

An externally hosted image should be here but it was not working when we last tested it.

The throat includes 2 ridges roughly (how appropriate...) located @ the third points along its length. The ridges go all the way around the throat...they look like mold joints.

This is entirely correct and I have complained to B&C about this many times, to no avail. This is the reason why no matter how well I match the plate and waveguide to the driver, some form of clay or filler is always required.

I have some of those QSC 90x50 horns as well but I haven't done anything with them yet. The throat is a bit big, not completely round, and the initial angle is steeper than 7 deg. I thought I'd add a ~1/4" wooden spacer with a hole to match the outlet of the CD and then sand the transition smooth. I don't think the sanding would need to be too high-tech -- just glue some sandpaper to a 1/4 section of a 1" dowel and blend it in with smooth strokes.The throat of the QSC horn is (very)slightly oversize. In spite of this, I'm considering making a mandrel to sand/shape/refine the QSC profile to improve the match with the cd. Along with this, a spacer between the cd & horn may be necessary to ease/replace the loss of material.

Last edited:

Earl,

Wondering how waveguide compares to a beam steered linear array (9, 12, 18,24 speakers) in churches? Do you know any real world example?

Wondering how waveguide compares to a beam steered linear array (9, 12, 18,24 speakers) in churches? Do you know any real world example?

Earl,

Wondering how waveguide compares to a beam steered linear array (9, 12, 18,24 speakers) in churches? Do you know any real world example?

Of a beam steered array? Sure, I have designed a couple. OK for churchs, but not for homes. My speakers in a church work a lot better than the line arrays, but the line arrays "look better".

That is exactly the point - the look.

Every driver must have it's own delay and low pass or we could use only four or eight instances and group drivers? How long are the delays more or less? Wish to discuss these things on Epiphany.

Every driver must have it's own delay and low pass or we could use only four or eight instances and group drivers? How long are the delays more or less? Wish to discuss these things on Epiphany.

I see no reason that frequency makes a difference. The important part is that the directivity not change radicaly with frequency, no matter where the crossover is. That requires that the directivity matches.

If I'm not mistaken, a larger waveguide requires the listener to sit further away. A member of this forum is using waveguides down to 500hz, but his listening room appears to be the size of a basketball court.

If you're listening room isn't gargantuan, I think there are benefits to a smaller waveguide.

I believe this is one of the reasons that you found the smaller models to sound surprisingly good in a real room.

If I'm not mistaken, a larger waveguide requires the listener to sit further away. A member of this forum is using waveguides down to 500hz, but his listening room appears to be the size of a basketball court.

If you're listening room isn't gargantuan, I think there are benefits to a smaller waveguide.

I believe this is one of the reasons that you found the smaller models to sound surprisingly good in a real room.

Not sure - but I see what you mean. I suppose it would be true that a larger speaker has a greater near field and thats not really a good place to listen.

Not sure - but I see what you mean. I suppose it would be true that a larger speaker has a greater near field and thats not really a good place to listen.

Yes, exactly. Due to the large center-to-center spacing, the Summa needs to be listened to from a distance. I have a room downstairs that's almost 800sf, and the Summas sounded noticeably smoother when listened to from a great distance.

Then again, I seem to be sensitive to this. When I listen to a line array in the nearfield, it makes me want to run screaming from the room.

I'm just bringing this up, because I see a lot of the same questions repeated over and over in this thread. People asking how to build a bigger waveguide, or asking how much gain the waveguide has. These are silly goals IMHO. Every speaker in the line has efficiency to burn, and making the Summa any bigger would make it unusable in 90% of the rooms out there. (If someone happens to have their listening room inside of a basketball, I stand corrected 😉 )

While a large waveguide can control directivity down to a lower frequency, it's an academic exercise if you don't have a room large enough to sit at least ten feet back.

Last edited:

While a large waveguide can control directivity down to a lower frequency, it's an academic exercise if you don't have a room large enough to sit at least ten feet back.

I agree, but there are other reasons as well. It's all that testosterone based "mine is bigger than yours" stuff.

The Summa is too big now. If I do another 15" speaker it will be smaller. Since I only do closed box designs now, I don't need a cabinet as large as the Summa has. It was originally ported.

If I do another 15" speaker it will be smaller.

Yes but the driver spacing won't change unless you go with an eliptical. The woofer diameter, waveguide diameter and roundovers is what's setting the baffle size. Could you realy make one significantly smaller??

Rob🙂

While a large waveguide can control directivity down to a lower frequency, it's an academic exercise if you don't have a room large enough to sit at least ten feet back.

Why 10 ft? How did you calculate or measure that number?

High directivity of frequencies as low as possible is a goal. Especially in small rooms.

If I do another 15" speaker it will be smaller. Since I only do closed box designs now, I don't need a cabinet as large as the Summa has.

If it has an elliptical waveguide I'd like to subscribe to the preorder list now 😉

Best, Markus

Yes but the driver spacing won't change unless you go with an eliptical. The woofer diameter, waveguide diameter and roundovers is what's setting the baffle size. Could you realy make one significantly smaller??

Rob🙂

Thats not really true. The Summa has more spacing than required, and elliptic might help, although I am still very leary of elliptical because of the huge costs involved in its fabrication. The value does not seem to be there, i.e. large costs with small benefits. What was done at Ai was to cut the roundovers and woofer into the waveguide a little bit. This droped the volume quite a bit without making any significant difference in the performance. I cannot do that with my current manufacturing techniques however - thats the real problem.

So yes, I believe that I could cut the Summa volume in half without much trouble. I just can't make it right now.

If it has an elliptical waveguide I'd like to subscribe to the preorder list now 😉

Best, Markus

And how much of a premium would you pay for the elliptical - and put down the cash of course, not just say $XXXX

Keep in mind the current cost of a Summa and the cost differences due to size of the other models. Now add a premium to that because of the elliptical tooling costs and you are looking at a pretty big number. Make your proposal above big enough and you'll have your speakers by spring🙂

Make your proposal above big enough and you'll have your speakers by spring🙂

The proposal! YouTube - Doctor evil- One Million Dollars

😀

- Home

- Loudspeakers

- Multi-Way

- Geddes on Waveguides