A baffle is a flat plane into which the waveguide terminates. It is a bad idea to use a free standing waveguide. "a" is the radius, not the diameter. I just draw a waveguide terminated into a flat plane and then radius this junction. The radius is arbitrary, but bigger is better. You are making it much too complicated.

now it is clear without doubt what it is "a" thanks 🙂

sorry that I might souds complicated, but I simly dont hesitate to ask when is not clear enough...

thanks again 🙂

.

But I will use not arbitrary radiused end, rather with smoothed tangent angle to 90deg

it is a bit bigger than "as is" end

sorry that I might souds complicated, but I simly dont hesitate to ask when is not clear enough...

thanks again 🙂

.

But I will use not arbitrary radiused end, rather with smoothed tangent angle to 90deg

it is a bit bigger than "as is" end

Last edited:

now it is clear without doubt what it is "a" thanks 🙂

sorry that I might souds complicated, but I simly dont hesitate to ask when is not clear enough...

thanks again 🙂

.

But I will use not arbitrary radiused end, rather with smoothed tangent angle to 90deg

it is a bit bigger than "as is" end

Hi Zoran,

May be I can read some words about the Jean Michel on LeCleac'h horns

http://www.diyaudio.com/forums/multi-way/140190-jean-michel-lecleach-horns.html#post1770248

so You can see that he has suggested to use the horns that are not finished with the baffle wall, but some kind of 'mouth lips like' role.

May be a kind of combination OSWG and JMMLC curve can give use a kind of almost constant directive horn (CD) horn with low reflection from the horn mouth.

Some experiences from the other members have shown that JMMLC horn starts to 'beam' on higher frequency, but sounding very nice .

Regards

Ivica

regards

ivica

Yes Ivica

thats right but that we can "count" from 90deg radiused end like

4th part - reverse back angle... 🙂

So "folding" back to throat can be arranged in LeCleach concept from tangent angle of 90deg after the radiused end

.

I will putting together OSWG from "leaves"

Probably 24 per horn look like old school horns, just right shaped. did that before

with great accuracy.

.

So I have to have each function of the 2D horn shape to merge and calculate ONE Leave

thats right but that we can "count" from 90deg radiused end like

4th part - reverse back angle... 🙂

So "folding" back to throat can be arranged in LeCleach concept from tangent angle of 90deg after the radiused end

.

I will putting together OSWG from "leaves"

Probably 24 per horn look like old school horns, just right shaped. did that before

with great accuracy.

.

So I have to have each function of the 2D horn shape to merge and calculate ONE Leave

Hyperbolic (OS) Petal-Horn Notes

For best acoustical results, avoid extending the "leaves" into the horn neck, where the principal transition (curvature) to the asymptotic cone occurs. Here, keep the aperture circular. For the rest, including mouth lips, you may want to use a segment of Euler's spiral [1] & [2] to loft the petal profile.

Regards,

WHG

References

[1] http://www.lems.brown.edu/vision/publications/Kimia's_Publication/Journals/Euler_spiral-IJCV.pdf

[2] http://www.math.zju.edu.cn/yxn/papers/EulerArcSplines.pdf

Yes Ivica

thats right but that we can "count" from 90deg radiused end like

4th part - reverse back angle... 🙂

So "folding" back to throat can be arranged in LeCleach concept from tangent angle of 90deg after the radiused end

.

I will putting together OSWG from "leaves"

Probably 24 per horn look like old school horns, just right shaped. did that before

with great accuracy.

.

So I have to have each function of the 2D horn shape to merge and calculate ONE Leave

For best acoustical results, avoid extending the "leaves" into the horn neck, where the principal transition (curvature) to the asymptotic cone occurs. Here, keep the aperture circular. For the rest, including mouth lips, you may want to use a segment of Euler's spiral [1] & [2] to loft the petal profile.

Regards,

WHG

References

[1] http://www.lems.brown.edu/vision/publications/Kimia's_Publication/Journals/Euler_spiral-IJCV.pdf

[2] http://www.math.zju.edu.cn/yxn/papers/EulerArcSplines.pdf

Last edited:

Alternative

This tack does not avoid the diffraction edges presented later by the surrounding bass enclosure.

Alternatively, the horn lips (top and sides) may be extended to the rear to form the top half of the bass driver enclosure, mitigating somewhat the attendant diffraction.

Of course, the interference between driver outputs above and below is unavoidable.

Regards,

WHG

A baffle is a flat plane into which the waveguide terminates. It is a bad idea to use a free standing waveguide. "a" is the radius, not the diameter. I just draw a waveguide terminated into a flat plane and then radius this junction. The radius is arbitrary, but bigger is better. You are making it much too complicated.

This tack does not avoid the diffraction edges presented later by the surrounding bass enclosure.

Alternatively, the horn lips (top and sides) may be extended to the rear to form the top half of the bass driver enclosure, mitigating somewhat the attendant diffraction.

Of course, the interference between driver outputs above and below is unavoidable.

Regards,

WHG

It will be a close to the circular shape, but with 24 leaves polygon... 🙂 (not the rectangular)

for 16 pieces of leaves, mouth end is too wide, and will be maybe too rigid to bend

and for 32 pieces, it is a too small length at the horn throath to manipulate with fingers...🙁

So I think 24 will be good.

.

Thanks for the links / excellent 🙂

Maybe I will use it like "backwards" from end horn mouth shape?

.

thanks

for 16 pieces of leaves, mouth end is too wide, and will be maybe too rigid to bend

and for 32 pieces, it is a too small length at the horn throath to manipulate with fingers...🙁

So I think 24 will be good.

.

Thanks for the links / excellent 🙂

Maybe I will use it like "backwards" from end horn mouth shape?

.

thanks

It will be a close to the circular shape, but with 24 leaves polygon... 🙂 (not the rectangular)

for 16 pieces of leaves, mouth end is too wide, and will be maybe too rigid to bend

and for 32 pieces, it is a too small length at the horn throath to manipulate with fingers...🙁

So I think 24 will be good.

.

Thanks for the links / excellent 🙂

Maybe I will use it like "backwards" from end horn mouth shape?

.

thanks

Hi Zoran,

I would suggest You to try to model your horn using HORNRESP simulation program, so You can see what would be the expectable horn behavior in dispersion domain, frequency domain etc...

Hornresp

regards

ivica

mac osx user... But maybe I will tryout Hornesp via parallels?

I am using Adopted version of Matlab code software core by Bjørn Kolbrek

And some of the my sheets in MatCad

Also M.J.K. MatCad sheets for horn analysis... 🙂

I am using Adopted version of Matlab code software core by Bjørn Kolbrek

And some of the my sheets in MatCad

Also M.J.K. MatCad sheets for horn analysis... 🙂

Believe or not, it is not simple at all to calculate one "Leave" for desired horn shape

and then when bend all - to acheive right horn...

.

and then when bend all - to acheive right horn...

.

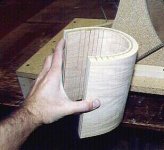

Kerf-It

This will allow use of thicker material to form the horn bell.

Regards,

WHG

Believe or not, it is not simple at all to calculate one "Leave" for desired horn shape

and then when bend all - to acheive right horn...

.

This will allow use of thicker material to form the horn bell.

Regards,

WHG

Attachments

I'm not so sure that Earl would call that sectional horn a true Oblate spheroid? Perhaps an approximation but not truly following the correct surfaces.

It may be benficial

The polygonal section might reduce HOM Q a bit because any horn aperture section does not have a single diameter. However, in the neck, where the apertures are small, recommend the sections remain circular. In the low pressure bell section, the polygon presence should not be a issue except for LF wall vibration there. Use fillets for the transition from round to polygonal.

Regards,

WHG

I'm not so sure that Earl would call that sectional horn a true Oblate spheroid? Perhaps an approximation but not truly following the correct surfaces.

The polygonal section might reduce HOM Q a bit because any horn aperture section does not have a single diameter. However, in the neck, where the apertures are small, recommend the sections remain circular. In the low pressure bell section, the polygon presence should not be a issue except for LF wall vibration there. Use fillets for the transition from round to polygonal.

Regards,

WHG

Last edited:

The closer one is to the throat the more of an effect non-round will have. Out at the mouth it won't make any difference.

Hey Zoran, consider using an odd number of paper sections to reduce the reflections that can occur between parallel sides of the horn at the throat area.

Last edited:

with a higher number of laves, say 16 or more,

the area shape is approaching to circumference.

that can be seen with sketching simple rectangular inside the circumference

And when it going to 8 side polygon, again dividing to

16 it is hard to draw. With 24 or 32 leaves it is almost full circle

And calculated diffefence in area are minor.

But I can calculate for even number, why not? 🙂

.

these pictures are from 16 leaves

black paper exp-hyp (T=0.68) horn...

the area shape is approaching to circumference.

that can be seen with sketching simple rectangular inside the circumference

And when it going to 8 side polygon, again dividing to

16 it is hard to draw. With 24 or 32 leaves it is almost full circle

And calculated diffefence in area are minor.

But I can calculate for even number, why not? 🙂

.

these pictures are from 16 leaves

black paper exp-hyp (T=0.68) horn...

I still think that a mold should be used to make it round at least at the throat. If i were to make waveguides out of paper i would definitely make something like this:

DIY Paper Horn - The Paper Horn by Inlow Sound

Looking forward to listen to them when you finish the paper mascheing 🙂

DIY Paper Horn - The Paper Horn by Inlow Sound

Looking forward to listen to them when you finish the paper mascheing 🙂

"fill" the sectional shape with car body filler to achieve a smoothly curved region near the Throat.

The mold is good thing, even if one piece is required... 🙂

not so much complicated to achieve with classic mold style / plaster...

It is only light "dirty" but without aggressive chemistry / only plaster, water, Kalijum-soap

But for filling the mold, taking a print - deserves harder "chemistry"

it is little bit "dirty" and there is a need for outside space too.

Also retouching tha piece is "dusty" job with also chem. particles... (outside + mask...)

Than at last, spraying a lack, also some poly-xxx. (outside + mask...)

.

So only the mold is ECO - from there is "dirty"

And increases the need of pro space, tools, and skils.

.

And All this for the test specimen. minimum 1 piece.

.

I prefer old school outfit from the horn rather than kontemporarry uniform white mostly.

So I will give at the try with quality paper/cardboard.

And maybe if I have enough currage, with furniture thin wood sheets 🙂

depends how it will taking a cut curvature leave...

And I can accomplish all work at the kitchen table - with all not so hard acryl based glues

and with quick drying time 🙂

.

not so much complicated to achieve with classic mold style / plaster...

It is only light "dirty" but without aggressive chemistry / only plaster, water, Kalijum-soap

But for filling the mold, taking a print - deserves harder "chemistry"

it is little bit "dirty" and there is a need for outside space too.

Also retouching tha piece is "dusty" job with also chem. particles... (outside + mask...)

Than at last, spraying a lack, also some poly-xxx. (outside + mask...)

.

So only the mold is ECO - from there is "dirty"

And increases the need of pro space, tools, and skils.

.

And All this for the test specimen. minimum 1 piece.

.

I prefer old school outfit from the horn rather than kontemporarry uniform white mostly.

So I will give at the try with quality paper/cardboard.

And maybe if I have enough currage, with furniture thin wood sheets 🙂

depends how it will taking a cut curvature leave...

And I can accomplish all work at the kitchen table - with all not so hard acryl based glues

and with quick drying time 🙂

.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Geddes on Waveguides