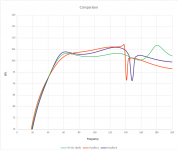

Hey but flatter is better....right?Brian is right. ODTL trumps a TH when you choose small and low.

Light = ODTL.

Dark = straight flare TH.

Both enclosures are the same dimensions L x W x H.

View attachment 1128298

View attachment 1128318

View attachment 1128319

View attachment 1128321

Peaky responses are not very praised

Anyway you need to add DSP to tame the peak hill from 60-90 on the ODTL

I say this with full respect to JBell - the choice to use 1/2" plywood would be made as a balance of compromises as they saw fit for intended purpose.

Many of their builds were for highest performance on a budget, and they had the experience to understand what would've been compromised by the thinner panels, but that choice and other design compromises might not suit a first time builder.

Many of their builds were for highest performance on a budget, and they had the experience to understand what would've been compromised by the thinner panels, but that choice and other design compromises might not suit a first time builder.

So your ODTL vs the SS15 , what you think.

The furybox I think it needed one and a half sheet of ply.

The ss15 is a bigger and louder enclosure.

My ODTL is only 167 liters internally. 32.25" H x 17.5" W x 24" D externally.

I based the volume of the 2 enclosure off your 2ft3 cube double fold TH enclosure that equals 168 liters internally.

My ODTL is only 167 liters internally. 32.25" H x 17.5" W x 24" D externally.

I based the volume of the 2 enclosure off your 2ft3 cube double fold TH enclosure that equals 168 liters internally.

Last edited:

I don't mean to be fixed by the cube volume, still evaluating options and the fury and the apache we're bigger , but I will like to use one sheet of ply lf possible , freq range 40 to 100 or 30 to 90 , or any in between. Depending on the design.The ss15 is a bigger and louder enclosure.

My ODTL is only 167 liters internally. 32.25" H x 17.5" W x 24" D externally.

I based the volume of the 2 enclosure off your 2ft3 cube double fold TH enclosure that equals 168 liters internally.

Driver is the 3015LF

So don't get me wrong , if you need to get more volume you can, as long we can coax a cabinet with one sheet of ply.

FWIW, I just couldn't get a "straight TL" to work with the 3015. Yes, it's possible to sim something, but from the time I started to fold said sim into a box (or in my case, I start with the box first and then derive the sim), I started to run into problems, like the CSA for the path being too shallow to hold the driver, or the box dimensions ending up being weird and most likely unwieldly for portable PA use. Certainly not something with a 40 Hz or higher Fb.The ss15 is a bigger and louder enclosure.

My ODTL is only 167 liters internally. 32.25" H x 17.5" W x 24" D externally.

I based the volume of the 2 enclosure off your 2ft3 cube double fold TH enclosure that equals 168 liters internally.

With car drivers maybe?FWIW, I just couldn't get a "straight TL" to work with the 3015. Yes, it's possible to sim something, but from the time I started to fold said sim into a box (or in my case, I start with the box first and then derive the sim), I started to run into problems, like the CSA for the path being too shallow to hold the driver, or the box dimensions ending up being weird and most likely unwieldly for portable PA use. Certainly not something with a 40 Hz or higher Fb.

freq range 40 to 100 or 30 to 90 , or any in between. Depending on the design

Taking some additional models as additional example as well, all use 15" driver size.

THAM Martinsson design has 187L

Jbell SS15 design has 260L

ROAR Martinsson design has 390L

Danley TH115 design has 420L

Considering 3015LF driver you choose it might be hard to achieve 40Hz, 30hz is no go. Don't create false expectation. A good goal is to achieve Fs, generally speaking.

How can you compare too many options with different volumes?

In addition, If you check BP1Fanatic simulation he use different voltage (Eg) while comparing ODTL vs TH. I think he was keeping Diaphragm displacement at the same level. Did you compare the voltage simulation with your amplifier max output voltage?

All models can be adjusted to a desired volume. I personally like to compare performance for the same volume and also for the same voltage (Eg). Each person has it's own preferences, what are yours maxoline?

In general, increasing volume, you go lower in frequency but you also go higher in terms of diaphragm displacement, and the driver you choose is an important constrain in this sense: 9,6mm Xmax.

There is no magic, all designs are good options by definition, an optimized design for a particular driver is a different story. Pick any design using rational thinking like easy to build. Them with the design defined, lets optimize it for your driver and achieve the best results. If you don't like, you can try to evaluate a second option, and so on.

Lets consider that the 3015LF can achieve a peak of 1800W, the average power for a recorded/mixed/mastered music as DJ might be 1800/8 = 225W, what is the SPL the box deliver at this power level? the division for 8 is because this kind of sound reproduction has 9dB as crest factor, going to live music, Crest Factor is going to increase 12dB~16dB? what are going to be your average power and SPL in this condition? will be even lower, right? if your amplifier is not capable to deliver the 1800w peak......

My apologies to ask, but are you sure you can see the full picture?

With some fiddling around, I was able to come up with this - a series-tuned 6th order BP design that has a decent response and an Ok size (net Vb is around that of an SS15, and as it requires less panels, it might just be possible to build it with one sheet of ply.

Caveats are that, unlike the case with THs and TLs, I haven't had the opportunity to do a POC based on Hornresp's bandpass sims, so I can't say how close the actual response would be to what the sim suggests. The other catch is how to convert this sim into an actual box. Note that it calls for offset driver arrangement (i.e. none of the vents should be pointing directly at the driver), and the offsets will likely have to be adjusted once you try to "box" this sim.

Caveats are that, unlike the case with THs and TLs, I haven't had the opportunity to do a POC based on Hornresp's bandpass sims, so I can't say how close the actual response would be to what the sim suggests. The other catch is how to convert this sim into an actual box. Note that it calls for offset driver arrangement (i.e. none of the vents should be pointing directly at the driver), and the offsets will likely have to be adjusted once you try to "box" this sim.

Most car audio subwoofer drivers are not good matches for pro audio duty. Too inefficient.With car drivers maybe?

This is good information ...Lets consider that the 3015LF can achieve a peak of 1800W, the average power for a recorded/mixed/mastered music as DJ might be 1800/8 = 225W, what is the SPL the box deliver at this power level? the division for 8 is because this kind of sound reproduction has 9dB as crest factor, going to live music, Crest Factor is going to increase 12dB~16dB? what are going to be your average power and SPL in this condition? will be even lower, right? if your amplifier is not capable to deliver the 1800w peak......

That bandpass looks promising, I read somebody that said " efficiency is not as important as displacement" can't recall on what thread and was something about car drivers vs PA, and I don't remember what type of cabinet it was. Geezz anyway , once we were set on a design I will get to build one and measure , if all go according to the projected sims and I like, I will build another till I get 4 , that's my medium term goal to have 4, short term one cab, long term 8 cabs.Most car audio subwoofer drivers are not good matches for pro audio duty. Too inefficient.

Last edited:

Very interesting eye opener dissertation Sansui.Taking some additional models as additional example as well, all use 15" driver size.

THAM Martinsson design has 187L

Jbell SS15 design has 260L

ROAR Martinsson design has 390L

Danley TH115 design has 420L

Considering 3015LF driver you choose it might be hard to achieve 40Hz, 30hz is no go. Don't create false expectation. A good goal is to achieve Fs, generally speaking.

How can you compare too many options with different volumes?

In addition, If you check BP1Fanatic simulation he use different voltage (Eg) while comparing ODTL vs TH. I think he was keeping Diaphragm displacement at the same level. Did you compare the voltage simulation with your amplifier max output voltage?

All models can be adjusted to a desired volume. I personally like to compare performance for the same volume and also for the same voltage (Eg). Each person has it's own preferences, what are yours maxoline?

In general, increasing volume, you go lower in frequency but you also go higher in terms of diaphragm displacement, and the driver you choose is an important constrain in this sense: 9,6mm Xmax.

There is no magic, all designs are good options by definition, an optimized design for a particular driver is a different story. Pick any design using rational thinking like easy to build. Them with the design defined, lets optimize it for your driver and achieve the best results. If you don't like, you can try to evaluate a second option, and so on.

Lets consider that the 3015LF can achieve a peak of 1800W, the average power for a recorded/mixed/mastered music as DJ might be 1800/8 = 225W, what is the SPL the box deliver at this power level? the division for 8 is because this kind of sound reproduction has 9dB as crest factor, going to live music, Crest Factor is going to increase 12dB~16dB? what are going to be your average power and SPL in this condition? will be even lower, right? if your amplifier is not capable to deliver the 1800w peak......

My apologies to ask, but are you sure you can see the full picture?

Thanks for sharing your knowledge, and apologies accepted 😀 .

My goal is to use this planned subs for live band PA, 80's and 90's pop rock, but also DJ.

Right now I have 2 xls 2500 and 1 xls 2000

Class D lower end crowns.

Later on I will get the sanway clones.

More powerful at the same price of the crowns

Also contemplating to do plate amps, so to have active cabinets.

But that's not my priority right now, i want to use what I have and utilize my modest budget to build some cabinets with the 3015LF , i guess is the most bang for your buck on neodymium below the 300;usd mark.

Screamerusa used a CA12 to drive 3 fury subs per channel (6 total)

So maybe I can do the same or at least 2 per side for a total of 4 per amp.

In addition, If you check BP1Fanatic simulation he use different voltage (Eg) while comparing ODTL vs TH. I think he was keeping Diaphragm displacement at the same level. Did you compare the voltage simulation with your amplifier max output voltage?

All models can be adjusted to a desired volume. I personally like to compare performance for the same volume and also for the same voltage (Eg). Each person has it's own preferences, what are yours maxoline?

In general, increasing volume, you go lower in frequency but you also go higher in terms of diaphragm displacement, and the driver you choose is an important constrain in this sense: 9,6mm Xmax.

That's exactly what I did. I had to "keep it real" for a fair comparison. I designed the 2 enclosures within the 9.6mm xmax and 450 wrms for the 3015's maximum limits.

TH = 325 watts.

ODTL = 450 watts.

What about a type C classic with dual 12"?That's exactly what I did. I had to "keep it real" for a fair comparison. I designed the 2 enclosures within the 9.6mm xmax and 450 wrms for the 3015's maximum limits.

TH = 325 watts.

ODTL = 450 watts.

Honestly I think this will take more than planned 4me, there is so much info floating and I need to funnel it with my constraints to leave just 2 or 3 contenders.

FWIW, I just couldn't get a "straight TL" to work with the 3015. Yes, it's possible to sim something, but from the time I started to fold said sim into a box (or in my case, I start with the box first and then derive the sim), I started to run into problems, like the CSA for the path being too shallow to hold the driver, or the box dimensions ending up being weird and most likely unwieldly for portable PA use. Certainly not something with a 40 Hz or higher Fb.

D@mn it B, you caught another mistake. With both enclosures, the speaker plate needs to be doubled. The 3015 mounting depth it 7.25".

722.58cm2 = 7" x 16".

The new external depth is 24.75".

Of course, you could do 7.25" x 15.75" from throat to mouth or 7.5" x 15.5" and still equal 722.58cm2, but the enclosure depth increases. The 3015 outer diameter is 15.39". I prefer to go up to the next inch (12" to 13", 15" to 16", etc) when designing BP boxes for easier driver installation and removal.

Take a look at this comparison:

TH-SS1 (Jbell) vs Paraflex C vs Paraflex R

The Paraflex R is even easier to build compared to the C type and you can achieve better results because you can tune the "ducts" with different sizes.

For TH-SS and Paraflex C you can use Brian boxplan in excell or FreeCAD model, for the Paraflex R only FreeCAD model is available.

Box Volumes:

TH-SS1 (Jbell) = 260L

Paraflex C = 260L

Paraflex R = 295 L

The diaphragm displacement are basically equal for all three simulations at the same voltage.

TH-SS1 (Jbell) vs Paraflex C vs Paraflex R

The Paraflex R is even easier to build compared to the C type and you can achieve better results because you can tune the "ducts" with different sizes.

For TH-SS and Paraflex C you can use Brian boxplan in excell or FreeCAD model, for the Paraflex R only FreeCAD model is available.

Box Volumes:

TH-SS1 (Jbell) = 260L

Paraflex C = 260L

Paraflex R = 295 L

The diaphragm displacement are basically equal for all three simulations at the same voltage.

Attachments

With the 3015LF?Take a look at this comparison:

TH-SS1 (Jbell) vs Paraflex C vs Paraflex R

The Paraflex R is even easier to build compared to the C type and you can achieve better results because you can tune the "ducts" with different sizes.

For TH-SS and Paraflex C you can use Brian boxplan in excell or FreeCAD model, for the Paraflex R only FreeCAD model is available.

Box Volumes:

TH-SS1 (Jbell) = 260L

Paraflex C = 260L

Paraflex R = 295 L

The diaphragm displacement are basically equal for all three simulations at the same voltage.

All?

The R is bigger so I guess more than I sheet of ply?

With the 3015LF?

All?

Yes, all using 3015LF.

The R is bigger so I guess more than I sheet of ply?

Don't know, you will need to adjust the design and use CAD to find the answer. If you consider bracing, and they requires wood, the TH-SS design, as point previously, requires braces with trapezoidal shape witch makes hard to optimize sheet cut, so considering a rectangular brace shape for Paraflex R, it is much more easier for you to check and to optimize the cut in order to keep it under 1 sheet plywood. Orthogonal panel also make it easier, If you have angle panels, you need 2-steps cut at least, a rectangular one, and then the angles one to precise adjust it, you loose more woods doing that and it's easier to make mistakes. If your panels are not precisely cut, the joints might not be good enough so there is a chance for the box to leak air (internally or externally) and you end up with difference SPL curve than simulated.

You can use software to optimize the cut for you too, automatically, but I do mine manually.

Just posting questions pushes people to work for you while in the Do it Yourself forum I would expect a different approach. You are going to need to start working with your hand to get more precise answers and to get things done. How can I help you without doing it for you? so I'm going to invert the question.

Maxoline, can you build a Paraflex R type for 3015LF using a single sheet of ply?

You not even simulate one, so my last suggestion for you is to start from the beginning, once you already defined the driver, it's time to define the box type because you will need to adjust the box dimensions and the cut sheet.

- Home

- Loudspeakers

- Subwoofers

- Furysub, Apache H15, or Jbell 2' cube