I’m no expert and as I mentioned earlier… I’m understanding enough of this to be dangerous, but this calculator helps illustrate wavelengths at different frequencies. At a certain baffle size (really large) it would seem it becomes less of an issue, but I do think it’s important. I assume that’s why a lot of speakers are designed the way they are. The baffle is either really wide or really narrow. There aren’t many cabinets with 6” drivers and 12” baffles because it appears that area becomes problematic. The baffle is either slightly wider than the biggest driver or a lot wider than the biggest driver.That surprises me.

I expect a dome tweeter to light up the cabinet edges, but not a 4" full range driver.

But, I may be wrong.

http://www.mcsquared.com/wavelength.htm

Sorry not to jump the topic or subject. If am not mistaking the seas fullrange driver does well in a sealed enclosure. Dave sorry for putting you on the spot. Do you still have the pictures of the seas fullrange driver you put in a older kef sealed box’s? To my Remembering? A speaker in a sealed enclosure has to have a heathy xmax? Please correct me if am wrong?🤔.

One need only look upon generations of speakers that used sound absorptive materials on the front baffles. All the way back to the JBL L100/4311 WX , we saw a foam "ring" surrounding the old-school phenolic tweeter. Acoustic Research's big flagship AR-9 has panels all over the front baffles...the current near-field KRK studio monitors have odd looking beveled & radiused front baffles.The pile up concept makes a lot of sense. Thanks for sharing that. I've read a lot of theories over the last few weeks. I understand a lot of them, but a lot of it is admittedly over my head. This is the first I've heard of sound-sound-absorbant exterior surfaces. Are you suggesting that wrapping your speakers in a bat of "safe n sound" would be beneficial? If that's the case I get it. I wouldn't do it, but I get it. Is it safe to assume that in large part there's not anything realistic you can do that will create a noticeable difference there? In this regard plywood might be considered better than aluminum but not as good as say... vinyl? Interesting to think about. Not sure it's going to be a large influence on my decisions for this project, but interesting to think about none the less.

Apart from making a 3/4 meter sized sphere, (definitely not esthetic), for more traditional rectangles, some absorptives & a generous 75mm radius would be in order...every little bit helps.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------Rick...

There’s no doubt in my mind regarding the radius, I’m asking specifically regarding the material, but consider my question answered. I get it.One need only look upon generations of speakers that used sound absorptive materials on the front baffles. All the way back to the JBL L100/4311 WX , we saw a foam "ring" surrounding the old-school phenolic tweeter. Acoustic Research's big flagship AR-9 has panels all over the front baffles...the current near-field KRK studio monitors have odd looking beveled & radiused front baffles.

Apart from making a 3/4 meter sized sphere, (definitely not esthetic), for more traditional rectangles, some absorptives & a generous 75mm radius would be in order...every little bit helps.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------Rick...

Yes Dave! Awesome that’s the pair I was thinking about😁. Thanks for posting this picture. I appreciate it.

dave

@planet10 from previous posts I’ve noticed that you’re no stranger to local marina stores. Have you ever done a fiberglass enclosure or reinforced plywood with fiberglass? I ask because it can be made made stiff and it can be light weight which seems like two qualities you prioritize. If not, do you have an opinion on the use of either technique?

I have not been allowed to build speaker enclosures for over 2 decades.

But yes, fiberglass resins and such added both sides will stiffen the outside layers, but it can be messy.

I do have a scheme for estern red cedar, a vacuum kiln, and penetrating epoxy.

dave

But yes, fiberglass resins and such added both sides will stiffen the outside layers, but it can be messy.

I do have a scheme for estern red cedar, a vacuum kiln, and penetrating epoxy.

dave

Yes, stranded bamboo is the “best” sheet material we have built with.

I can’t wait for similar rplywood made fro hemp.

dave

I can’t wait for similar rplywood made fro hemp.

dave

passive baffle step gets pricy as baffle width goes up.

I think people try for as small of a baffle as possible.

Room acceptance factor and such, my 3' tall x 2' wide was fugly.

And double 15 + horn stack was intimidating at 24" wide x 53" tall.

Seeing radiation angles for driver size, say an 8" being 90 degrees at 2khz, I don't see how past 2khz (on an 8") that rounding would do squat.

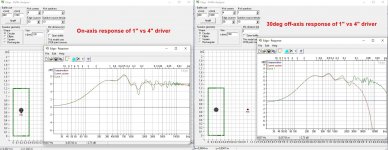

I can see a 4" doing more than an 8", but I'd like to see some charts.

Even rounding for a dome tweet, you need a bunch, like 3/4"

http://murphyblaster.com/content.php?f=cabinets.html

A wider baffle to me, you wouldn't have 1khz wrapping around to bounce off the wall behind it as much.

Perhaps more "You are there" than "they are here".

I like wide baffles and I can not lie........................

I think people try for as small of a baffle as possible.

Room acceptance factor and such, my 3' tall x 2' wide was fugly.

And double 15 + horn stack was intimidating at 24" wide x 53" tall.

Seeing radiation angles for driver size, say an 8" being 90 degrees at 2khz, I don't see how past 2khz (on an 8") that rounding would do squat.

I can see a 4" doing more than an 8", but I'd like to see some charts.

Even rounding for a dome tweet, you need a bunch, like 3/4"

http://murphyblaster.com/content.php?f=cabinets.html

A wider baffle to me, you wouldn't have 1khz wrapping around to bounce off the wall behind it as much.

Perhaps more "You are there" than "they are here".

I like wide baffles and I can not lie........................

Now that would be awesome Dave. I hope it’s soon?Yes, stranded bamboo is the “best” sheet material we have built with.

I can’t wait for similar rplywood made fro hemp.

dave

Note the absorbent strip to damp/disrupt the driver created corner diffraction plus the baffle's eigenmodes in this critical area.This is the first I've heard of sound-sound-absorbant exterior surfaces.

Now that would be awesome Dave. I hope it’s soon?

People are shipping hemp based building materials, but the potential is just strating to be tapped. I haven’t seen any hemp-ply yet.

The stranded bamboo outer plys are bamboo strands in a matrix. These are 3mm thick. One should be able to take 5 and make their own 15mm plywood. It should be exceptional.

The idea is the same with hemp. But the fibres are longer in hemp (and maybe stronger), if one could harvest that, orient it, and press it together with a similar matrix (which you might be able to make from the soft parts removed), then make plywood it would be very interesting.

Hemp grows almost anywhere, and improves the soil… i imagine sections of 20 foot high hemp growing in Saskatchewan…

And it is useful to make a zillion things. We just need to figure them out again.

dave

Right, I misunderstood what was being said. I was envisioning an enclosure being wrapped in something. This makes sense.Note the absorbent strip to damp/disrupt the driver created corner diffraction plus the baffle's eigenmodes in this critical area.

'Blast from the Past'Does your bracing touch the back of the Alpair driver? If so, is it bare wood or do you put some kind of gasket material over it?

I’m just trying to build the best enclosure for me and have a little fun doing it. There’s no passive baffle step in this design. To your point about the 8” speaker and 2khz, from what I could gather from using the calculator, that wave length is about 7” long. When I was choosing what design philosophy’s to implement, the ideas misguided or otherwise I decided to follow include that the baffle would somewhat arbitrarily extend out 10” past the edge of the driver opening or no more than 1.5”: That not me trying to be smart or say I’m right, it’s a hypothesis based on a few things I’ve read. So the minimum baffle width that I was willing to employ with a 4” driver was going to be 7”. (Driver in center and pinned to the top of the baffle). If I wanted to go wider I would have tried 14.5” ( driver pinned to top corner) or 24 (driver pinned to top and centered left to right). It makes sense to me that if there is no baffle to interact with it’s hard to create problems (why I would keep the driver close to the edges) in the case of the “ten inch rule” it’s wide enough to not exacerbate problems for everything above 1300hz (10 inch wavelength) This isn’t me flexing. This is a hypothesis created from reading a few hundred posts in this forum and some general observations made about speaker design. Formulate a hypothesis and create an experiment. The next logical question is “are you going to measure it?”. I will and I won’t. I’ll measure for the sake of subwoofer integration. When I do that by ear I always give too much weight to the bass. So I’ll measure that to get in the ballpark and fine tune by ear. The LS50 metas these are replacing are plenty flat. What I learned from that experiment is that just because something measures flat does not make it the best. The radius on the teardrop shaped speakers I’m working on will be far greater than 3/4” I assure you.passive baffle step gets pricy as baffle width goes up.

I think people try for as small of a baffle as possible.

Room acceptance factor and such, my 3' tall x 2' wide was fugly.

And double 15 + horn stack was intimidating at 24" wide x 53" tall.

Seeing radiation angles for driver size, say an 8" being 90 degrees at 2khz, I don't see how past 2khz (on an 8") that rounding would do squat.

I can see a 4" doing more than an 8", but I'd like to see some charts.

Even rounding for a dome tweet, you need a bunch, like 3/4"

http://murphyblaster.com/content.php?f=cabinets.html

A wider baffle to me, you wouldn't have 1khz wrapping around to bounce off the wall behind it as much.

Perhaps more "You are there" than "they are here".

I like wide baffles and I can not lie........................

It’s a game of compromises right? I’m in a smallish room sitting relatively close to my speakers (6 feet) and really struggled to get a good balanced sound stage which was what I was after. I’m closer to one side wall than the other and the close wall (about 3 feet from the edge of the speaker ) was reinforcing that speaker and ultimately pulling the center image. Did some googling and learned about diffusers and came to understand that my room wasn’t really large enough for diffusers to “work properly” and that I ran the risk of creating comb filtering. I decided to build them anyway and I was blown away by how much better everything was and my center image locked right into place. Did I introduce comb filtering? Not to the degree that I notice it, but the science would suggest it’s there. Either way I like it a lot better than the effect of speaker imbalance that I perceived from the boundary reinforcement.

Hit my 100 hours laying on the magnets and decided to cobble together an open baffle out of wood clamps and ceiling tile. And they’re perched directly on top of subwoofers. For lots of reasons this isn’t ideal not the least of which is that this room doesn’t lend itself to an OB configuration, but I must say that they’re already doing a lot of things better than the ls50 metas. Plywood is being delivered tomorrow and then I’ll get to work on the 16L sealed enclosures.

Attachments

- Home

- Loudspeakers

- Full Range

- Full range sealed box design