Yeah, like JCN and Freedom666 suggest isn't it that a series capacitor of high pass filter that raises impedance in the circuit enough so that no electronic damping at the resonance happens in the driver itself? This would have the "impedance peak affects response", driver resonating at Fs unless electronic/acoustic damping added. If analyzing the circuit from drivers perspective a small parallel resistor like in L-pad, or leaving the series cap out from a high pass network to leave low enough impedance through amplifier output ought help. Target is to have low impedance between driver terminals at Fs for the driver to dampen its own resonance. Leaving series capacitor out and having parallel inductor needs series resistor not to short amplifier output, which would lower sensitivity and so on so perhaps acoustic solution would work better if found.

Last edited:

Does the metamaterial concept also "neutralize" the impedance peak as Fs?

I could not find that in the publication.

I could not find that in the publication.

I have been working with wool in the past a lot. What i did was start with empty box, measure resonance freq and Q. Add a known amount of wool and measure again, etc.in.

In a graph i plot yhe results, typically the Fs drops with increase of wool up to a certain amount, then it bottoms and with further increase of wool would rise again. The Q also drops and close to the "bottoming" the Q would be 0.7. In the bottoming it can drop to 0.5 or close.

The wool i used is a wool from New Zealand (after a research into wool) , is short fibre and completely cleansed, so just the bare fibre. This fibre structure reacts to air pressure variations thus adding extra damping in the low frequencies. ( not unlike how a pine cone reacts to moisture.)

The wool filling itself was with ramdomly sized flocks, and this plucking into these flocks was the most laborious part.

This random structure of the filling helps very well in damping the cavity resonances .

We tested then also other fibrous materials but none were as effective. Note that carded wool did not damp cavitiy resonances.

In a graph i plot yhe results, typically the Fs drops with increase of wool up to a certain amount, then it bottoms and with further increase of wool would rise again. The Q also drops and close to the "bottoming" the Q would be 0.7. In the bottoming it can drop to 0.5 or close.

The wool i used is a wool from New Zealand (after a research into wool) , is short fibre and completely cleansed, so just the bare fibre. This fibre structure reacts to air pressure variations thus adding extra damping in the low frequencies. ( not unlike how a pine cone reacts to moisture.)

The wool filling itself was with ramdomly sized flocks, and this plucking into these flocks was the most laborious part.

This random structure of the filling helps very well in damping the cavity resonances .

We tested then also other fibrous materials but none were as effective. Note that carded wool did not damp cavitiy resonances.

I used these fibers for damping the cavity of tweeters, mostly piezo tweeters which usually have no damping behind the diaphragm at all

The way I do the damping:

- a cabinet is not to be designed in a way that damping is needed for lower fs/Qe.

- measure the TSPs of the driver in closed cabinet. BR constructions are also measured regarding Zmin at Fc, the lower the value, the better the BR works.

- measurement regarding resonances in the cabinet, e.g. acoustical nearfield measurement and search for small spikes on the impedance trace which where not there in free space conditions.

I can tell from listening experience because I tried it: you can put a bass (or any other driver) in a smaller enclosure and with dsp assistance you get it to sound correct. This works well for ventilated systems. With closed box systems not as good if they become much too small due to compression of the air.

I agree with you regarding the dacron polyfill. Its not a good material for dampening considering its performance and linearity. Cabinets that require alot of dampening are usually using it as a bandaid to make up for poor cabinet design. The shape of the enclosure itself has alot to do with the performance, specifically with LF drivers covering some of the midrange, especially in a vented application. Its difficult to get a larger 2 way BR design to sound good. That is so much the case with just about all 2 way PA cabs, as most of them sound pretty bad IMO.Then the challenge is to find the best compromise, but a midrange cabinet is usually quite easy. A surprisingly lot depends on the damping materials, after doing some research I usually do not use the white fibre material any more.

Not enough cabinet volume causes alot of issues which can't be corrected with any amount of dsp or eq....with dsp assistance you get it to sound correct. This works well for ventilated systems. With closed box systems not as good if they become much too small due to compression of the air.

Once the Vas/Vb ratio goes up, things start sounding irreversibly bad. That seems to magnify LF driver BL non linearity much quicker when the driver is required to displace an unreasonable amount of air compared to the box volume. This situation actually varies Vb itself and becomes a significant IM distortion mechanism, sending odd order HD through the roof.

Most of those typical small.sealed car subs sound horrible because of this, as do many HT subs. You get that telltale nasty sounding "plop, plop" bass.

Not enough cabinet volume causes alot of issues which can't be corrected with any amount of dsp or eq.

Once the Vas/Vb ratio goes up, things start sounding irreversibly bad. That seems to magnify LF driver BL non linearity much quicker when the driver is required to displace an unreasonable amount of air compared to the box volume. This situation actually varies Vb itself and becomes a significant IM distortion mechanism, sending odd order HD through the roof.

Most of those typical small.sealed car subs sound horrible because of this, as do many HT subs. You get that telltale nasty sounding "plop, plop" bass.

I agree that with small closed subs there is definitely a problem. With bass reflex construction / passive radiator constructions I experienced good results.

The electrical argument for big(er) enclosures (heating up of voice coil) is not correct in my eyes.

Here I discuss this:

https://www.diyaudio.com/community/...ow-off-my-new-18in-build.365764/#post-6767025

Big manufacturers for PA systems like RCF today use dsp controlled smaller enclosures because it works well also for public adress systems..

PA use will always accept more compromises in fidelity for sake of most output and efficiency. The heat has to somehow be drawn away from the VC, which is usually done with heatsinking. Home audio focuses on precision and faithful reproduction. An enclosed VC driven hard in a small box will heat quicker, change TS parameters and compression will set in. Its not hard to kill a 3 inch VC with 100 watts if the heat can't go anywhere fast enough. 50 watts is enough to kill a 2 inch VC in a small sealed box.

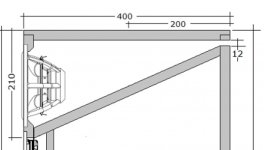

I dont know if it could help you but troels use the mw16tx as a midrange in its latest design called fusion 22. The mid enclosure has a linear slot to have a aperiodic tuning (according to him). He mentioned "if the slot is too much trouble, leave the midrange cabinet closed. It makes a slightly more dry sound compared to the aperiodic midrange cabinet".

I would be curious to see impedance measurement w/o the slot.

I would be curious to see impedance measurement w/o the slot.

Attachments

I highly advise against using the lint from your clothes driers, as this fiber is VERY VERY flammable. Being there is heat generation in drivers and xovers at times, I'd hate to see your investment go up in a big puff of smoke while also jeopardizing your dwelling should it go awry.Did anyone try the extremely fine fibers from drying machines for clothes for closed box systems. It's damping for free and you always have a mix of all sorts of fibers

I agree with profiguy's assessment of sheeps wool.Roving (Merino) sheeps wool stuffing has the advantage of having very non directional fibers that reduces the amplitude of the lower resonance more effectively without killing the "musicality" in the lower mids. I dont advocate over stuffing to the point of substantially lowering Qtc, but rather lightly filling the enclosure just enough to have the wool occupy the entire cavity (can't give you exact oz per cu.ft. numbers, but you would have to dampen "to taste").

Looking at my recent project, I found that when I fully fluffed (teased) loose fiber wool, it had a density of 16 grams per liter. When I stuffed the cabinet, I weighed the wool to make sure I had 16 gram per liter of cabinet volume. This worked out well for both the midrange cavity and the sealed box bass enclosure. The midrange enclosure had a Qtc of about 0.7, and the woofer box had a Qtc of about 0.8 with a DSP Linkwitz transform to extend the bass response with +7 dB of boost.

16 g/l is about the same as 1 lb/ cu ft.

Hello, never thought about this. Yes you never know who pushes his loudspeakers with a lot of watts.... from this point of view stone wool is the most unflammable damping.I highly advise against using the lint from your clothes driers, as this fiber is VERY VERY flammable. Being there is heat generation in drivers and xovers at times, I'd hate to see your investment go up in a big puff of smoke while also jeopardizing your dwelling should it go awry.

Yes, one needs to worry about fire. Even foam will go up in smoke if you get it hot enuff (been there, done that).

Wool is also moth food, and tends to sag. Mix half & half with something like acoustastuff. And seal off from the outside world.

dave

Wool is also moth food, and tends to sag. Mix half & half with something like acoustastuff. And seal off from the outside world.

dave

- Home

- Loudspeakers

- Multi-Way

- Fs impedance correction with only the box?