Thanks for diepieolet (is it French Basque?), markw4 and Jneutron for their solid mix of good theory background, practical hands-on experience and long careers, an unbeatable combination for solid repeatable good results.

No, American-Irish/Sioux. Heavy on the American part. 🙂.diepieolet (is it French Basque?)

Regards

It can be unfortunate when the job (or upper management) does not treat you well. I can say honestly, that my current "job" is not a job at all, it is fun to do, I enjoy doing it as everyday has different challenges as I do work for three different divisions on an as need basis.Let me make it simple. I'm all tested out.. LOL When I retired the tools actually jumped out of my hand and into Tool Boxes. Good riddance. The job did not treat me or any other mechanic I know well.

The biggest challenge I've had in the last 19 years was the constant arguing with upper management in all three divisions to hire people I can train to replace me.

I suspect that doesn't happen too often, many try to hold the knowledge close to the vest for job security.

They need to remember, when I'm gone, I'm gone. Either carried out in a body bag, or fed up...(well, I don't see the latter happening).

Your HD work sounds unbelievable, it would have been fun to learn about it. The closest I get is the occasional youtube video or megamachines.

John

ps..blackfoot (or more likely snakepit) tribe outta cali. Dad said one thing, websearch said another.

EXCEPT: the heat, the weight, the sand, the mud, the grout, the blood, the HOT hydraulic oil and the operator in the portaloo, everything was fine. LOL Did I mention they make 250K a year.Your HD work sounds unbelievable, it would have been fun to learn about it.

I have no regrets, it was a choice. I'm also glad it's over. I still get calls every now and then. I sure don't encourage it though.

The neighbors learned VERY quick, the tools on my service truck usually weighed more than they did. LOL Tooling for drilling is heavy, so is drill steal, casing, casing crowns and drilling bits. Top and down the hole hammers are heavier still. They drill through Basalt or Granite and still pull the tooling back out of the hole. That's the tricky part. Easy to drill a hole, it can be hard to recover the tooling. Noisy too. Mercy, the noise when they use both top and DTH hammers. Pile driving on steroids. LOL

The bigger deal was the burners on the new PP. Not uncommon to see a 50-100K engine. 5X the cost of non re-burners and they blew up. LOL They were big polished 50K - 100K turds for a while. I really miss making up 10 hydraulic hoses in a night and installing them on a boom covered in 4" of grout top to bottom.

Operators could break an anvil, some were heaven sent.

I'm pretty sure heaven will have a two part plan, operators on the left, mechanics on the right. I'm not sittin' with them for at least a couple thousand years. I'll have to cool off for a while. 🙂

I learned about crappy cabling in very harsh conditions, man oh man, harsh.

Last edited:

I've been planning to build a powered speaker project to be used as a small P.A. system or personal monitor at our music jams. To keep things simple and avoid having to futz with crossover design (which is quite hard to get right), I wanted a couple of full-range speakers for it. Speaker drive units with reasonably smooth frequency response, decent efficiency, at a reasonable price.One example, simply because it was mentioned a couple days ago, the Visaton BG17

https://www.visaton.de/en/products/drivers/fullrange-systems/bg-17-8-ohm

Guess what drivers I picked? Yup, two Visaton BG17s. 🙂

-Gnobuddy

Guess us three are tuned to the same Radio Station 😉

Liked it very much, and will probably clone them, what I see is very doable and cost will be low.

My minimum batch is 100 of anything to make it worthwhile, in any case I think I will easily sell most of them in, precisely, mini vocal monitors and ultra compact PAs.

They saved me a ton of development cost since they practically gave me the blueprint of a good product.

Only doubt is about the cone edge; does not look like foam at all, not too convinced about rubber, suspect treated accordion folded impregnated cloth but it might simply be impregnated paper.

120Hz resonant frequency is highish, even for a 6.5" speaker, an makes me suspect the latter but that´s easy to test, willmaje one each and measure parameters.

Liked it very much, and will probably clone them, what I see is very doable and cost will be low.

My minimum batch is 100 of anything to make it worthwhile, in any case I think I will easily sell most of them in, precisely, mini vocal monitors and ultra compact PAs.

They saved me a ton of development cost since they practically gave me the blueprint of a good product.

Only doubt is about the cone edge; does not look like foam at all, not too convinced about rubber, suspect treated accordion folded impregnated cloth but it might simply be impregnated paper.

120Hz resonant frequency is highish, even for a 6.5" speaker, an makes me suspect the latter but that´s easy to test, willmaje one each and measure parameters.

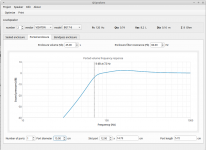

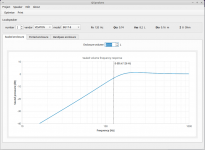

I haven't tried to measure the Thiele-Small parameters of the two Visaton BG17-8s I have, but just for kicks, I stuck the factory datasheet values into Qspeakers, a simple speaker box simulation software for Linux.

Somewhat to my surprise, given the rather high Qtc, fiddling around with a ported enclosure sim produced quite interesting results. For a pair of BG-17s, a 45-liter box with a big port tuned to about 84 Hz looks pretty good in the simulation (pic attached). Bass response looks pretty smooth, and the software thinks the speaker will get down to 72 Hz (-3 dB). The port has to be large diameter to get a reasonable port length, though; I don't know if that will turn out to be fussy to tune to the right frequency.

Qspeakers doesn't simulate speaker cone excursion at low frequencies, and this is another thing I'll have to keep an eye on if I do build the ported enclosure.

A 20-litre sealed box for the same pair of speakers is very simple, a lot smaller, and simulated frequency response isn't bad - but, of course, the bass response is a lot more limited, with a simulated lower f3dB at about 125 Hz. That might prove to be quite adequate for my purposes, actually.

If real-world bass response with actual drivers proves to be anywhere close to either simulation, I will be a happy camper. 🙂

The other interesting thing is that if I take a 2'x4' sheet of 3/4" plywood, and cut it up into four equal width strips (about 11 7/8" wide each), and add top and bottom panels, I end up with an internal volume that's in the right ballpark for the vented 45-litre enclosure. I think I have a 2'x4' sheet of 3/4" plywood lying around somewhere, too.

A wedge-shaped enclosure would be really nice, but do I want the additional design and build complexity? I have to think about that one.

-Gnobuddy

Somewhat to my surprise, given the rather high Qtc, fiddling around with a ported enclosure sim produced quite interesting results. For a pair of BG-17s, a 45-liter box with a big port tuned to about 84 Hz looks pretty good in the simulation (pic attached). Bass response looks pretty smooth, and the software thinks the speaker will get down to 72 Hz (-3 dB). The port has to be large diameter to get a reasonable port length, though; I don't know if that will turn out to be fussy to tune to the right frequency.

Qspeakers doesn't simulate speaker cone excursion at low frequencies, and this is another thing I'll have to keep an eye on if I do build the ported enclosure.

A 20-litre sealed box for the same pair of speakers is very simple, a lot smaller, and simulated frequency response isn't bad - but, of course, the bass response is a lot more limited, with a simulated lower f3dB at about 125 Hz. That might prove to be quite adequate for my purposes, actually.

If real-world bass response with actual drivers proves to be anywhere close to either simulation, I will be a happy camper. 🙂

The other interesting thing is that if I take a 2'x4' sheet of 3/4" plywood, and cut it up into four equal width strips (about 11 7/8" wide each), and add top and bottom panels, I end up with an internal volume that's in the right ballpark for the vented 45-litre enclosure. I think I have a 2'x4' sheet of 3/4" plywood lying around somewhere, too.

A wedge-shaped enclosure would be really nice, but do I want the additional design and build complexity? I have to think about that one.

-Gnobuddy

Attachments

This is my first post, I can identify with this fellow. I was fortunate enough to serve my apprenticeships at a time when an AA was considered a step above the average Joe and by no small margin. In a neighboring state at the time the 8th grade was the end of the scholastic road for many a young lady or man. They started their apprenticeships if they were invited.

Some of the best wood workers in the world are located in that state BTW.

I find the assumption that years in a school room some how equates to being better than, when in reality it is missing the same measure of experience the 8th grader had in the neighboring state. I have met many people that have had 35 one year experiences in their lives. That is not the same as 35 years of experience.

Practical application in the mono/stereo world are at most the first and second year OJT for most mechanics on a 5 year program. Every professional labor employees parts of different skill sets from more rigid and defined information provided by our more informed scholastic counterparts. The smartest guys I knew when it came to electronics had a few degrees in engineering, BUT he also teaches an Automotive class to youngsters. I wondered why? It covers everything he learned, he explained to me. I just laughed as I put another band-aid on my smashed thumb.

As a retired HD master mechanic I worked with a few different Electrical EEs, several civil and sound engineers. That doesn't account for the majority that were into fluid dynamics and hydraulic engineers. They all work with 3 mechanics. I really enjoyed their input but it still boiled down to me, to FIX the broken equipment, not the engineers. Their job was already done. Now does it work and keep working? Can we take the data and see fewer issues. That was their job. If they couldn't the company hired different engineers that could. What is an education worth if it doesn't fix anything, improve or reduce cost? That is what it is worth, nothing more nothing less. Follow the $$$$ that is usually where the problem is. LOL

Stereo stuff is pretty simple, why is a cable so controversial and why do people make stereo gear out to be complicated. IT'S NOT. People sure make it complicated though. 15.8 billion different ears in the world. That is 15.8 billion different ways to hear.

Copper ribbon and good ol tan masking tape work really well. Termination was always the biggest issue. I folded the ends back (doubled the conductor thickness. I cut a U in the copper and solder the U with silver solder. I clean the soldered U and they last over 10 years in the 70s. The tape was still good, but you had to be careful. Nothing turned green, BUT this is a pretty dry climate. NO salty fog within 60 miles or so and the Chlorine pools are across the street.

I'm sorry if I left out "The stuff" that explains it all. I'm a pretty simple fellow.

I sure enjoy the site. I've watched for years, but never posted.

Regards

Thank you Sir - education has its place - but need more tolerance given to EXPERIENCE.

The Wright Brothers are my Heroes... Test and re-examine.

My partner was what I call a mustang - first a technician in tube and old radio - then an E.E . Florida then USAF RADAR Software F-16 Maintenance.

We were partners for 22 years at Delta Omega Eng. we would work as a team to fix what others would not try to fix. Wilky as the Engineer and my technical radio-RADAR experience we had a great time doing AUDIO research. We made many improvements, but always was founded in provable measurable tests. We had many hot conversations as per the LAWS of Electronics - sound etc. but we agreed we had to be able to see mensurable differences - some how - to keep personal preference-faulty conclusion out.

Our approach was to find ways to test - FIDELITY - indirectly. We had a team of listeners in a local Audio Cable Company.

We could make all simple R-C-L test - then RF measurements-tests, then have the listeners tell what what they heard - mind you

these young men had diverse musical tastes. One dear Lady was a violinist in the local Utah Orchestra helped us learn of professional

musicians - and their listening skills.

Point being our differences in understanding physical 'Laws" made a good team. Many interesting ideas were discovered and

helped win several GOLDEN - EAR awards; One was for a POWER CORD. So Queen Fidelity can be understood - when old concepts are

re-examined in the pursuit of Better audio works and designs.

Cj

.

Me too. What is the award for?Just curious: what is a "Golden Ear Award"?

Who issues it?

Based on what?

I don't get out much. 🙂

Not really, because your link answers NONE of my questions:

Just to refresh them:

Any useful answer?what is a "Golden Ear Award"?

Who issues it?

Based on what?

Hint: just mentioning the words "Golden Ears" adds NOTHING to post #68 ... which also just mentions hem.

More performative BS. The real question is, what was the actual purpose of your question? Do you really want the answers, or is there more to it? Sure looks like it from here. Or maybe LFQA is just a psychotic liar, and has no real cred.....I wish you would stop trying to cut other people down, Mr Fahey. I have no doubt that you are accomplished and knowledgeable in this arena, you could be of great help to those who know less and want to learn, instead of issuing sarcastic and mocking posts.

The Absolute Sound is an audiophile magazine, probably they issue it....but at least the article does nor mention much detail about testing procedures and so on.

I'm just curious, how does this effect the sound, is it just better sensitivity helping transients?ypically "minimum copper" use (small voice coils, only gap depth windings, so short thin wire involved= lowest mass possible)

In Physics: A=F/M Acceleration=Force/Mass

Higher acceleration, both ways (starting and stopping) improves transient response, big way.

Old Alnico magnet speakers had ludicrous magnet systems, yet are known for fast snappy response and high efficiency/sensitivity (compared to Hi-Fi speakers).

They had:"small engines" but very light moving mass.

Just compare it to vehicles: a 600 cc engine is a weak "subcompact car" one, nothing special, but a "devil of the road" mounted in a motorcycle.

Physical difference?

Car > 600kg; bike about 150 kg ... clear enough.

My own speakers do not have monster magnets at all, just what´s normal in their class, but light voice coils and cones, light adhesives, make them snappy and loud.

This is my own "bread and butter" 10" mid weight type, similar to Jensen C12Q, MOD1050, Celestion Tube 10 and many others by Eminence, WGS, Weber, etc. ,a good bang for the buck design:

I can build many different speakers in the same frame, from featherweight 20W paper coil "alnico type " ones to 60W Kapton coil ones to 80W Aluminum former ones to 120W woofers with long heavy coils, either aluminum or flat edgewound epoxy fiberglass formers, with heavy cones,

All sound different, of course.

All have same magnet and structure (duh!) but widely varying moving mass.

Higher acceleration, both ways (starting and stopping) improves transient response, big way.

Old Alnico magnet speakers had ludicrous magnet systems, yet are known for fast snappy response and high efficiency/sensitivity (compared to Hi-Fi speakers).

They had:"small engines" but very light moving mass.

Just compare it to vehicles: a 600 cc engine is a weak "subcompact car" one, nothing special, but a "devil of the road" mounted in a motorcycle.

Physical difference?

Car > 600kg; bike about 150 kg ... clear enough.

My own speakers do not have monster magnets at all, just what´s normal in their class, but light voice coils and cones, light adhesives, make them snappy and loud.

This is my own "bread and butter" 10" mid weight type, similar to Jensen C12Q, MOD1050, Celestion Tube 10 and many others by Eminence, WGS, Weber, etc. ,a good bang for the buck design:

I can build many different speakers in the same frame, from featherweight 20W paper coil "alnico type " ones to 60W Kapton coil ones to 80W Aluminum former ones to 120W woofers with long heavy coils, either aluminum or flat edgewound epoxy fiberglass formers, with heavy cones,

All sound different, of course.

All have same magnet and structure (duh!) but widely varying moving mass.

That is an interesting enclosure!View attachment 1093445You can cheat if you want a wedge-shaped enclosure, you can fold it.

I'm curious - how did you carve the curve into that large solid block of wood?

-Gnobuddy

- Home

- Design & Build

- Construction Tips

- Foil Cable design