it would be the ultimate if i could create the block/guide with variable angle as well as "depth" adjustment.

and yeah sharp blades are a must but my lack of ability to keep my "strokes" consistent is what i'm trying to circumvent.

and yeah sharp blades are a must but my lack of ability to keep my "strokes" consistent is what i'm trying to circumvent.

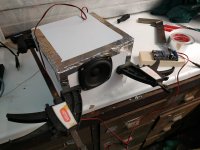

On the first build I used hot glue as the sealant. I then realized how inefficient that was. I now use the hot glue to spot adhere and use caulk to seal. So much faster and same result.

Yes, I was quite pleased with the glue guide. If I had to freehand that 48" unit, I think I would have been infirmary bound half way through. Amazing what a paperclip and hockey tape will do for you. 🙂

Yes, I was quite pleased with the glue guide. If I had to freehand that 48" unit, I think I would have been infirmary bound half way through. Amazing what a paperclip and hockey tape will do for you. 🙂

i guess the tacky or set point of hot melt is to short for long beads tracks...i guess looking at different adhesives is in order...i just hate giving up the speed at which i can commence to play with my creations....to much TV growing up makes me a part of the "instant gratification generation" i guess.

holy crap i want one...but if their no longer available i'll have to send them a "scathing e-mail"(my way of honoring Sheldon Cooper, so long Big Bang Theory!)

holy crap i want one...but if their no longer available i'll have to send them a "scathing e-mail"(my way of honoring Sheldon Cooper, so long Big Bang Theory!)

Looks like someone appropriated the design:

Amazon.com: Raih 45&90deg Angle Easy Mat Cutter with 6 Spare Blades Card Foam Mat Board Cutting

Do you put the caulk on the edges before putting them in place, or in the corners after glueing?

I was planning to seal the corners with tape (perhaps aluminium tape, for added sandwich plate stiffness). Is the caulk better?

I was planning to seal the corners with tape (perhaps aluminium tape, for added sandwich plate stiffness). Is the caulk better?

i still want variable angle, 90 and 45 are nice but the angles i want are sort of dictated by shape as in two different angles on edges to create new angles (making complex shapes that need more surface area for bonding and joining)

LZ. I pre-curve the board to allow for quick installation. Use a spot of glue at 2" to 12" apart depending if you are going around a corner or a straight line. Work outward from the centre and remember to caulk the corners as you go because you can't get the caulk gun in there if you add too many spirals at one time.

If you end up with rough edges (as shown) there's another trick I learned to make it work but that's for later. Just make good cuts like you see in the black board I showed and there's no need for the trick.

If you end up with rough edges (as shown) there's another trick I learned to make it work but that's for later. Just make good cuts like you see in the black board I showed and there's no need for the trick.

Attachments

Last edited:

Hi Folks,

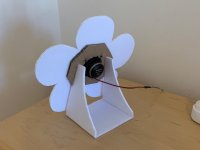

It’s been a long time since I made a foam core speaker. Had a few hours to make one today and they turned out rather nice sounding. Super easy. Following the idea by Mattes in Jeshi’s thread on EVA speakers. It’s a flower petal shaped open baffle. The flower shape reduces edge diffraction effects. It’s about a 12in diameter 5 petal flower with a support base. Using the FR58EX drivers which have an excellent flat response. Paired with a TPA3116 2.1 amp driving my own XKi sub fitted with dual 5.25in Tang Band sub drivers.

The spatial imaging is great and vocals are nice and clear. There is good top end reach on these too like an aluminum dome tweeter.

Almost any 2.5in to 3.5in full range driver can work here. TC9FD, PS95-8, 3FF25, etc.

It’s been a long time since I made a foam core speaker. Had a few hours to make one today and they turned out rather nice sounding. Super easy. Following the idea by Mattes in Jeshi’s thread on EVA speakers. It’s a flower petal shaped open baffle. The flower shape reduces edge diffraction effects. It’s about a 12in diameter 5 petal flower with a support base. Using the FR58EX drivers which have an excellent flat response. Paired with a TPA3116 2.1 amp driving my own XKi sub fitted with dual 5.25in Tang Band sub drivers.

The spatial imaging is great and vocals are nice and clear. There is good top end reach on these too like an aluminum dome tweeter.

Almost any 2.5in to 3.5in full range driver can work here. TC9FD, PS95-8, 3FF25, etc.

Attachments

Last edited:

A little more listening time and surprised by how easy to make and great sounding this was. The little flowers are an an awesome desktop of small bedroom OB.

Yes, that’s my kid’s room. The flower shaped just worked out nicely - still needs to be painted but that’s another project.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?