The homage to the FH3 (which is about same size as FH lite) sounds better. I was told FH3 would not scale well to 3.5in drivers back then. Compare dimensions of FH lite with my build and you will see how close Ingor by scaling.

PMC style TL monitor with DC130A-8 and DC28F-8

I always thought PMC's 2-way TL's were cool looking. I designed this TL to reach 60Hz or 90Hz depending on amount of stuffing in the last leg before the terminus. Very light stuffing will hot 52Hz but group delay will be significant. Dense stuffing case has less than 5ms group delay at 50Hz.

Thread started here:

http://www.diyaudio.com/forums/multi-way/281281-pmc-tl-stuffing-11.html#post4496722

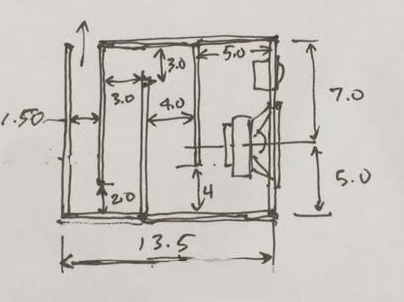

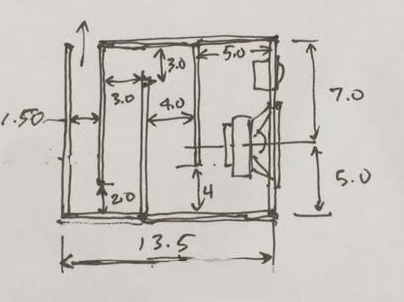

Sketch with vent going up (I built it with vent going forward):

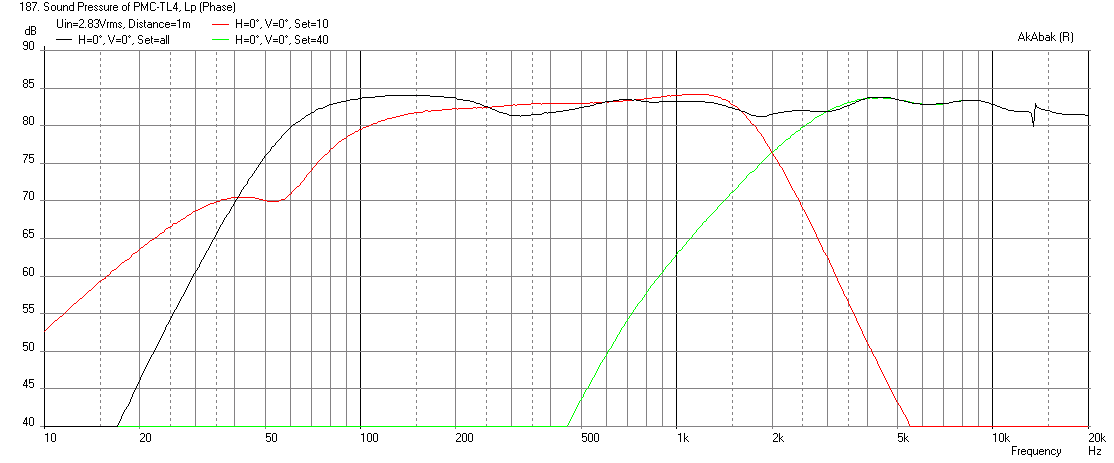

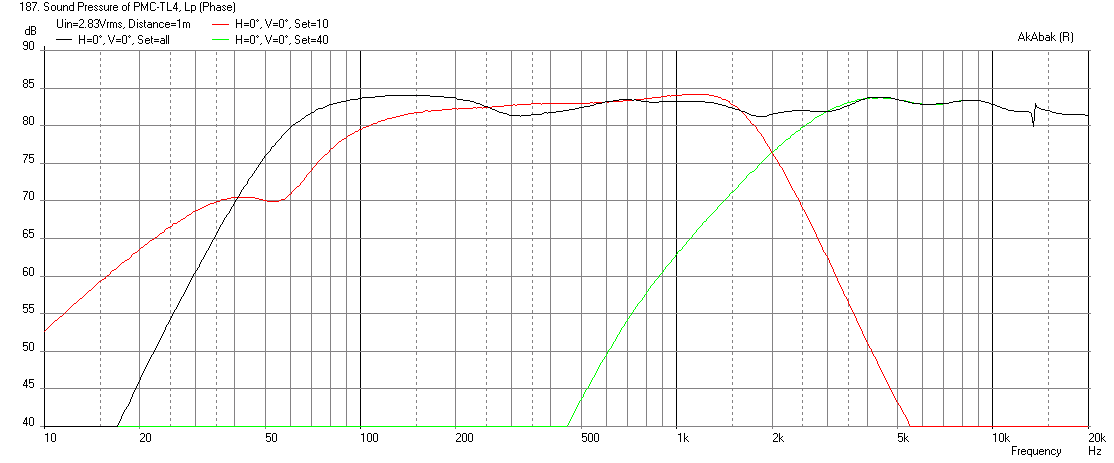

Sims for moderate stuffing show:

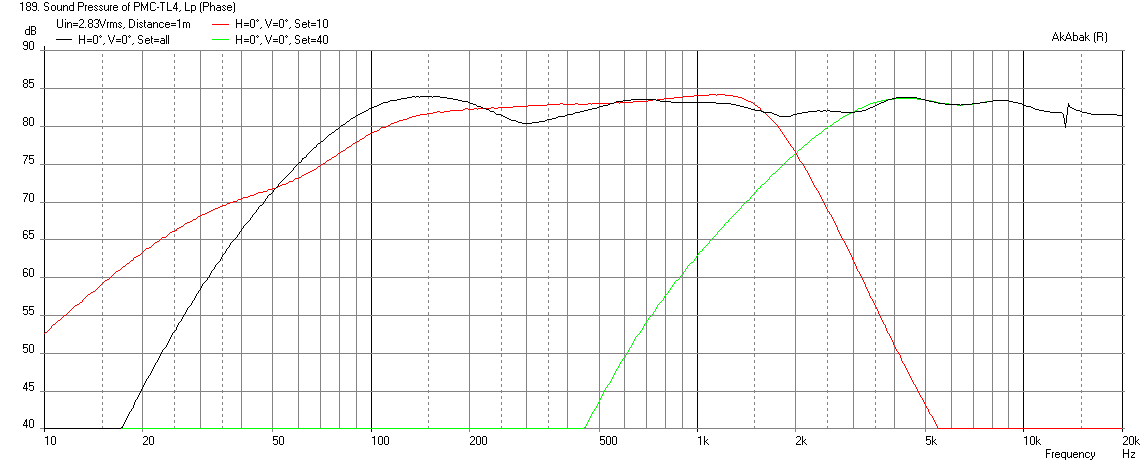

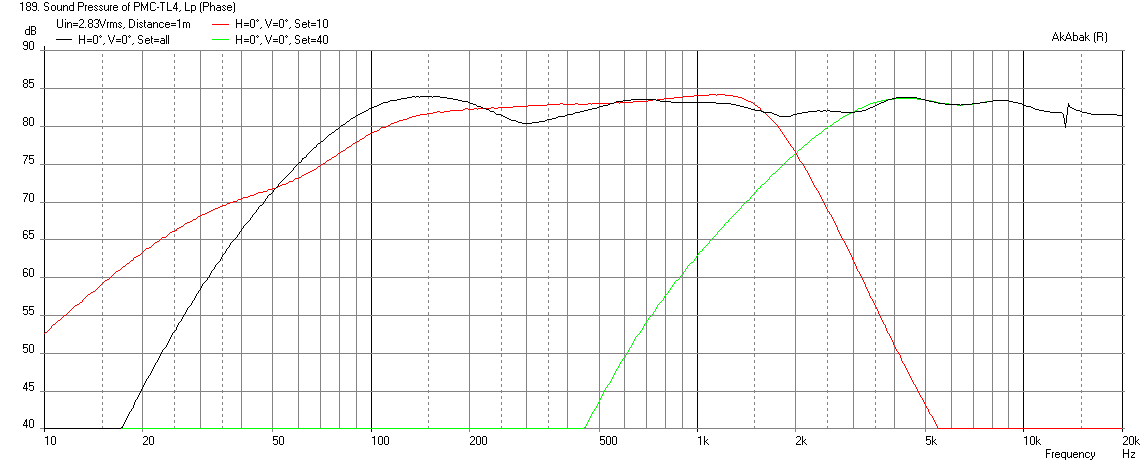

Dense stuffing:

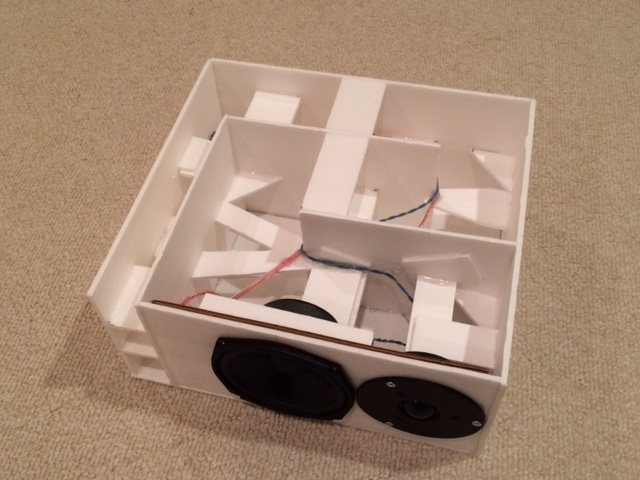

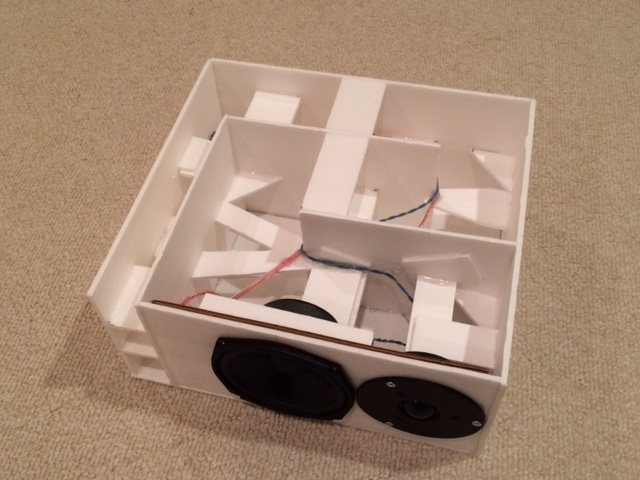

Speaker not completed yet - I will glue second side wall on when I return from travel.

I always thought PMC's 2-way TL's were cool looking. I designed this TL to reach 60Hz or 90Hz depending on amount of stuffing in the last leg before the terminus. Very light stuffing will hot 52Hz but group delay will be significant. Dense stuffing case has less than 5ms group delay at 50Hz.

Thread started here:

http://www.diyaudio.com/forums/multi-way/281281-pmc-tl-stuffing-11.html#post4496722

Sketch with vent going up (I built it with vent going forward):

Sims for moderate stuffing show:

Dense stuffing:

Speaker not completed yet - I will glue second side wall on when I return from travel.

Last edited:

Build completed:

More info here:

http://www.diyaudio.com/forums/multi-way/281281-pmc-tl-stuffing-11.html#post4499692

More info here:

http://www.diyaudio.com/forums/multi-way/281281-pmc-tl-stuffing-11.html#post4499692

BP1Fan,

Thanks! That speaker has its own thread now:

http://www.diyaudio.com/forums/multi-way/281778-low-cost-pmc-inspired-tl-monitor-dc130a-dc28f.html

Looks like a 5FE120 can work well with a slightly smaller cabinet width of 5.5in.

I like the looks, the size, and how it sounds. The response of the raw woofer and tweeter are so clean and smooth I may use this as a teaching opportunity to force myself how to design a passive XO using PCD.

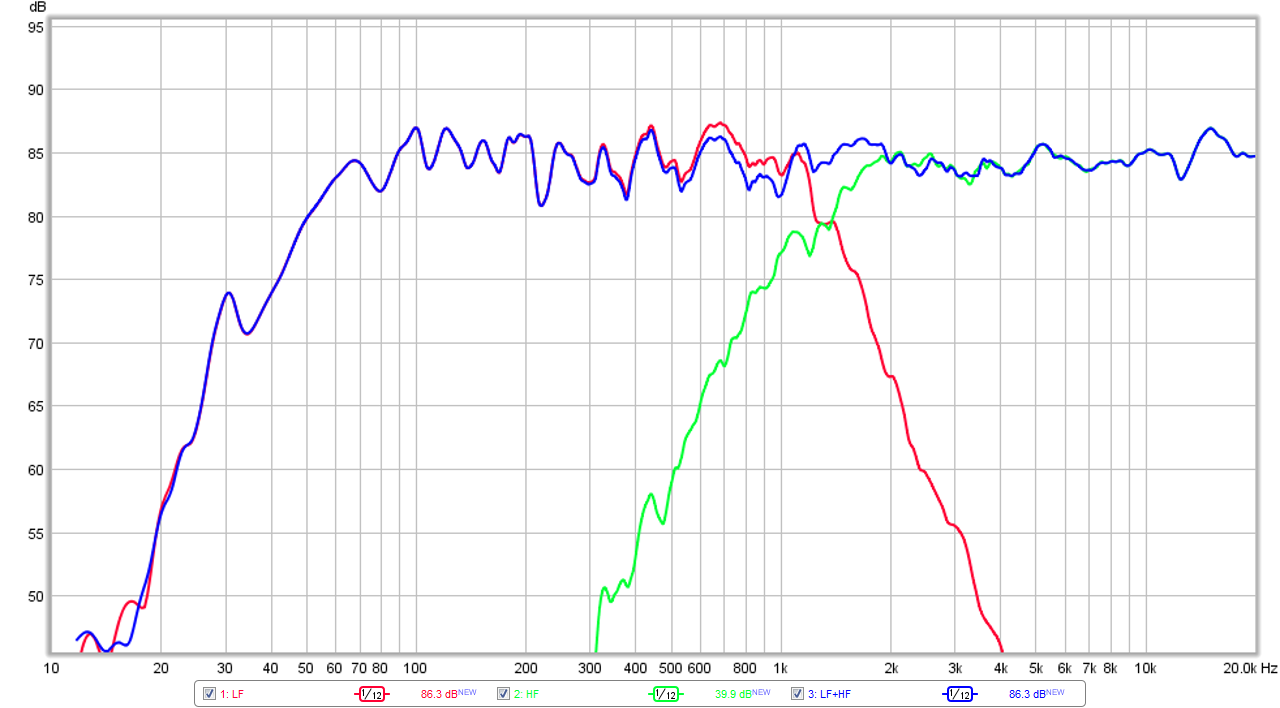

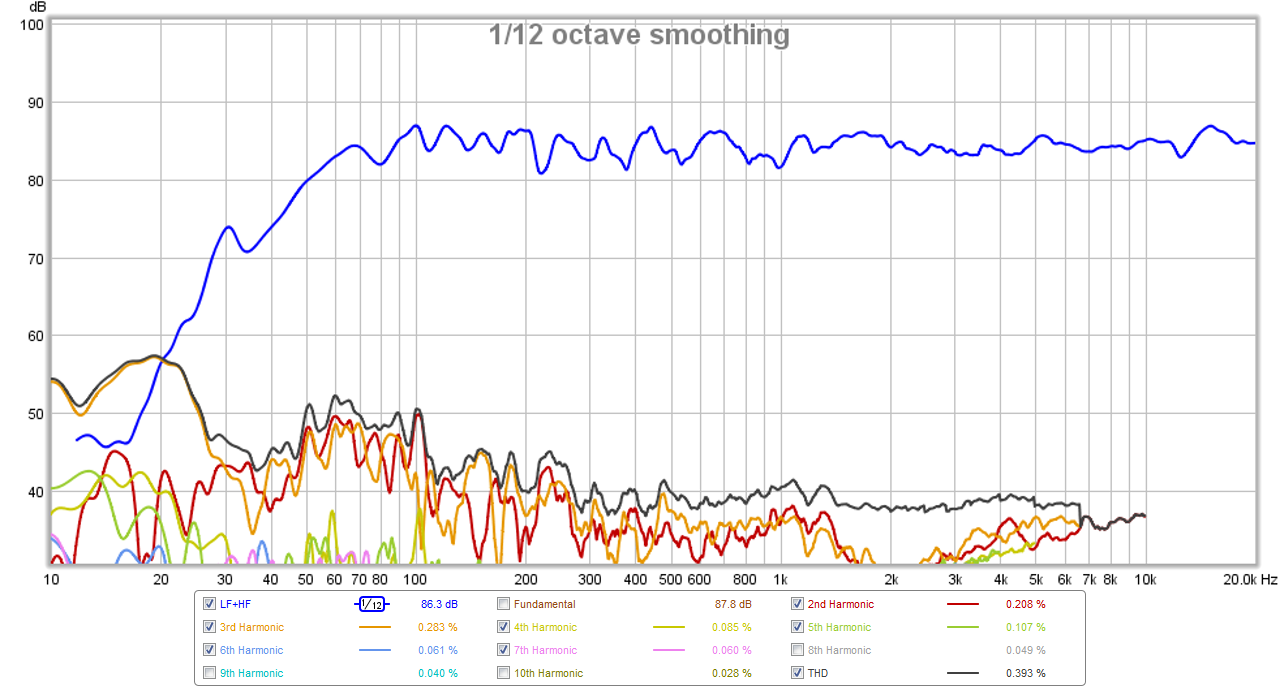

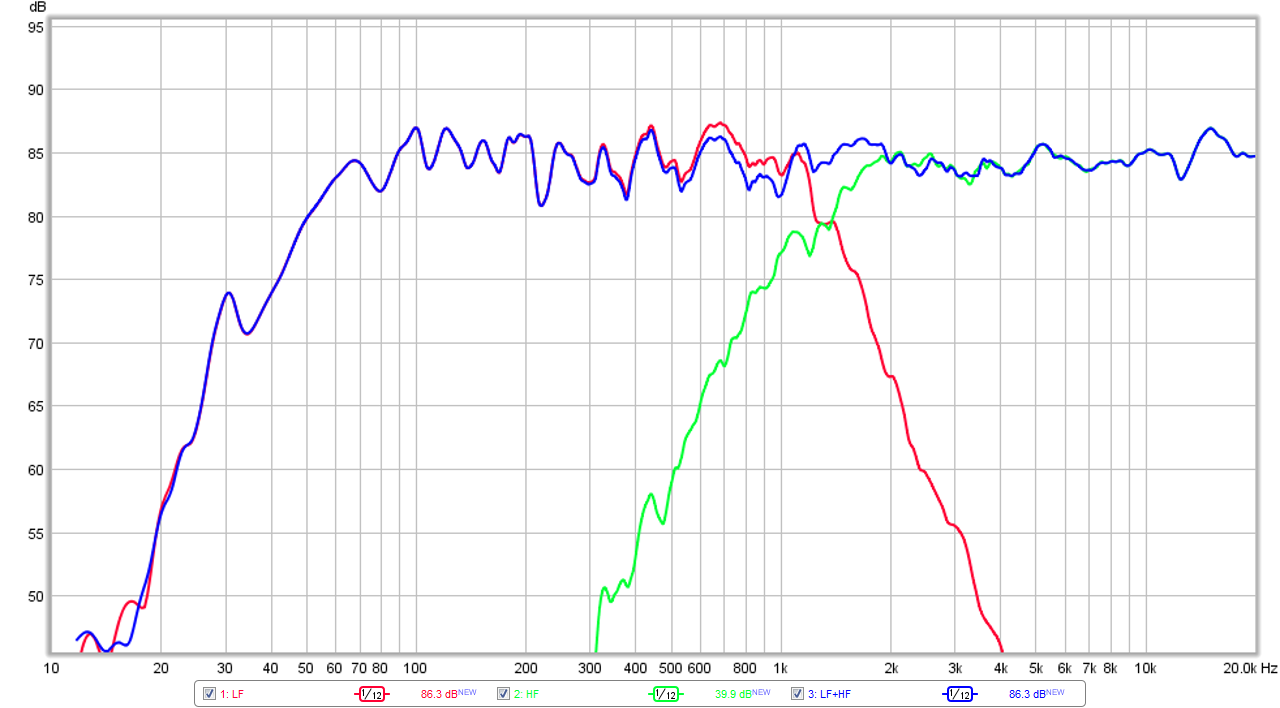

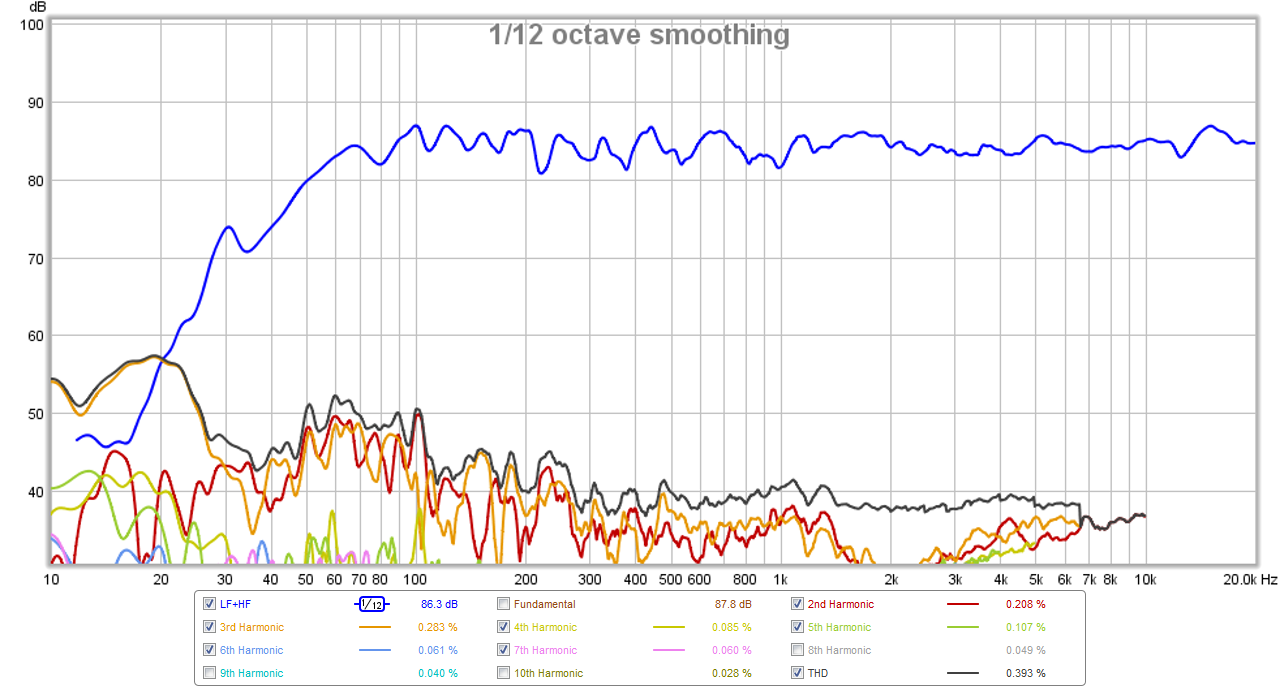

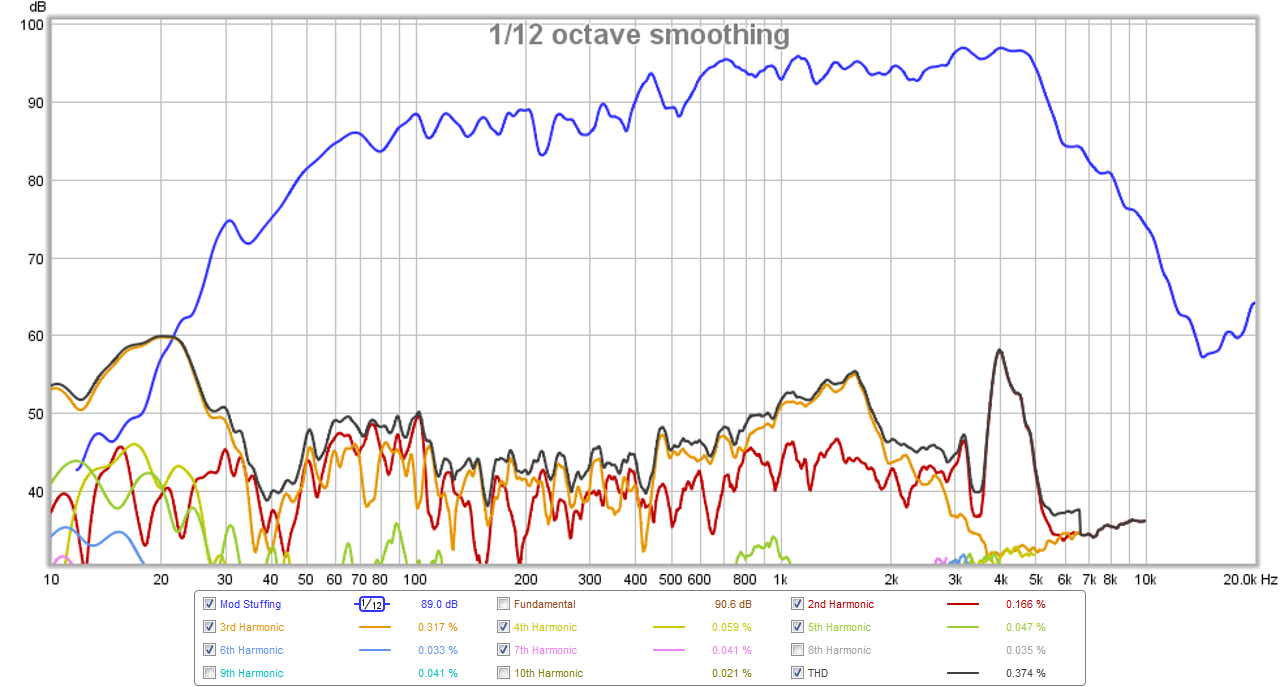

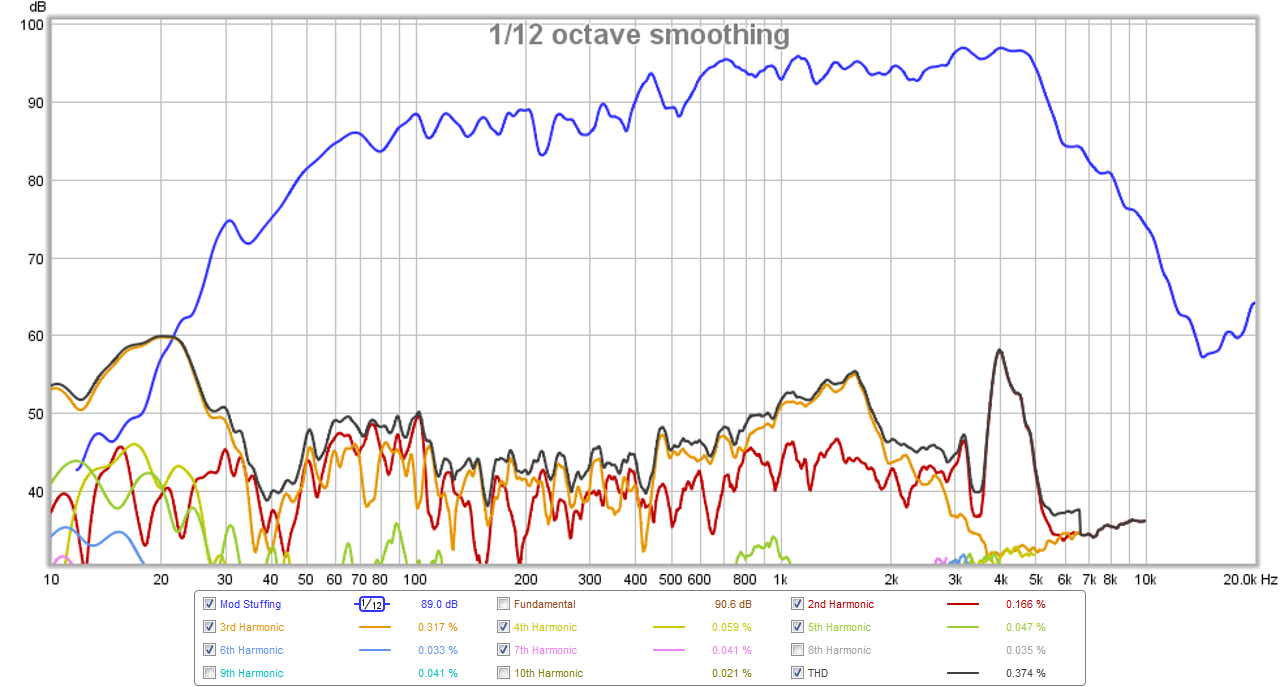

Here is the raw woofer-TL response running full range:

Thanks! That speaker has its own thread now:

http://www.diyaudio.com/forums/multi-way/281778-low-cost-pmc-inspired-tl-monitor-dc130a-dc28f.html

Looks like a 5FE120 can work well with a slightly smaller cabinet width of 5.5in.

I like the looks, the size, and how it sounds. The response of the raw woofer and tweeter are so clean and smooth I may use this as a teaching opportunity to force myself how to design a passive XO using PCD.

Here is the raw woofer-TL response running full range:

Thanks, Prezden! It's all in the braces - what FC lacks in strength, it makes up by having copious bracing, and the placement of the bracing typically takes 2x the amount of time to make the main walls. This was a 3 hr box (1hr main walls, 2hrs brace work). Waiting for the glue to dry on the final capping operation not included. The final speaker, without the drivers weighs about 250 grams maybe. You could throw it and it floats to the ground like a paper airplane, but is stiff enough to have similar HD figures as a more conventional wooden box. Although a multi-layer CLD wooden box would probably be better.

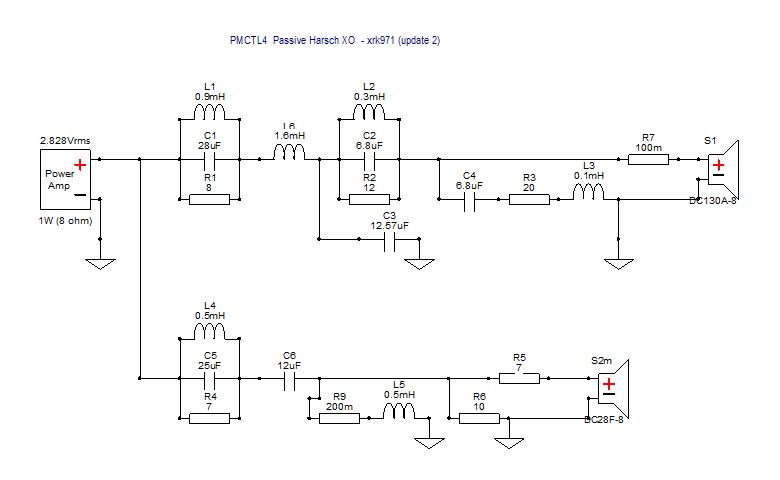

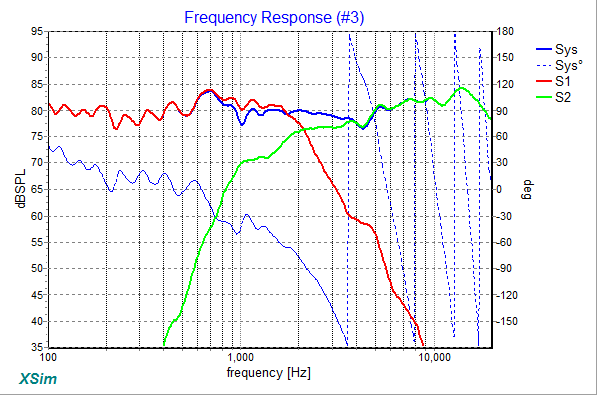

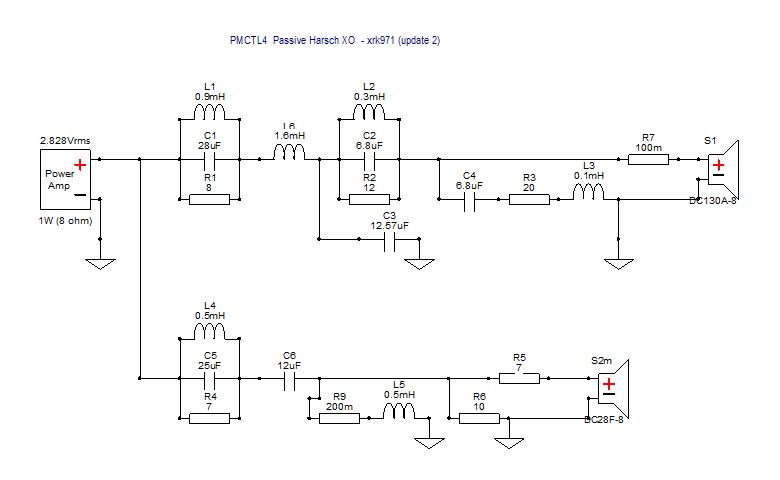

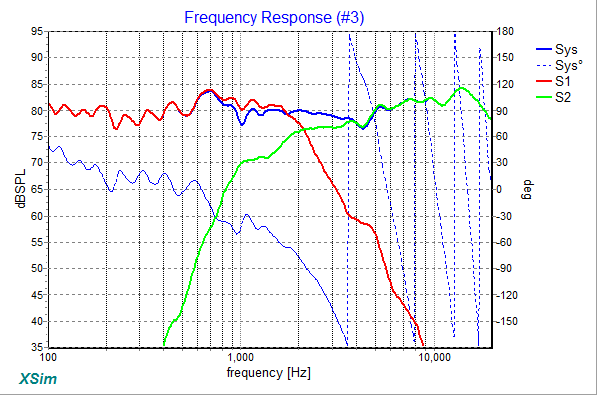

I ended up designing a passive Harsch XO for the TL:

yes, that's a lot of parts - but ended up like that for a quasi transient perfect response and flat with +/-3dB over range.

It needs the tweeter to be a waveguide though for time alignment.

yes, that's a lot of parts - but ended up like that for a quasi transient perfect response and flat with +/-3dB over range.

It needs the tweeter to be a waveguide though for time alignment.

Turk,

Very cool! How does the sound on the back side of the cone get outside to the main horn? I don't see slots or holes. Or is is a very thin slot along the perimeter? Did you use any model to design or was this an educated guess design? I bet it sounds good. What driver is that?

Very cool! How does the sound on the back side of the cone get outside to the main horn? I don't see slots or holes. Or is is a very thin slot along the perimeter? Did you use any model to design or was this an educated guess design? I bet it sounds good. What driver is that?

X

take a look at the 4th thumbnail down the 3 slats are spaced with single layer thickness foam core blocks. i'll have to try changing lighting conditions and upload a better pic.

half educated guess, half failed attempt at a horn response model(really gotta get a handle on that) i choose a path length that introduced cancellation at around 400hz(playing with a 31 band eq loosely confirms that)

the driver is a rescued Morse Electrohome from an old console i picked it for it's sensitivity and tone.

subjective impression: turned out way better than i thought, just wish i could have gotten the dip lower and a bit broader

take a look at the 4th thumbnail down the 3 slats are spaced with single layer thickness foam core blocks. i'll have to try changing lighting conditions and upload a better pic.

half educated guess, half failed attempt at a horn response model(really gotta get a handle on that) i choose a path length that introduced cancellation at around 400hz(playing with a 31 band eq loosely confirms that)

the driver is a rescued Morse Electrohome from an old console i picked it for it's sensitivity and tone.

subjective impression: turned out way better than i thought, just wish i could have gotten the dip lower and a bit broader

Ok, I understand now. 400Hz cancellation implies about 8.5in deep main horn? One thing to try is to put a mid/HF petal horn (literally like a flower petal so that there are variable radius contours to broaden cancellation dip) around the front of the full range driver and that will extend the response.

"extend the response." of the "dip" or the upper end?

there a bit more to the structure then meets the eye.

i think i managed to create an approximation of variable radius contours with the support structure for the louvers. if varying path length and aperture size has the same effect (lately i can't seem to trust what i thought i knew about horn design or what my ears tell me (measurement metrics and sofware sims be damned!)

there a bit more to the structure then meets the eye.

i think i managed to create an approximation of variable radius contours with the support structure for the louvers. if varying path length and aperture size has the same effect (lately i can't seem to trust what i thought i knew about horn design or what my ears tell me (measurement metrics and sofware sims be damned!)

View attachment 515468

View attachment 515469

View attachment 515470

View attachment 515471

View attachment 515472

View attachment 515473

hey XRK

finally had the chance to upload the pic's of the experiment i mentioned in the "advantages of karlsonator" thread. sorry i still don't have measurements but they did turn out sounding the way i wanted them to.

Wow! Nice looking speakers!

i'd like to thank the members of the academy....

i'm i supposed to make an acceptance speech.

i'd hate to have whatever little statue or t-shirt is issued to inductees taken away from me after i submit measurements...

and yes it is 8.5 inches deep. mouth size is 30x30

the other thing i can say is despite rather large unsupported free spans of foam core it's behaves nicely, appears well damped no audible % of FCD

i'm i supposed to make an acceptance speech.

i'd hate to have whatever little statue or t-shirt is issued to inductees taken away from me after i submit measurements...

and yes it is 8.5 inches deep. mouth size is 30x30

the other thing i can say is despite rather large unsupported free spans of foam core it's behaves nicely, appears well damped no audible % of FCD

Last edited:

You have braces in the important places so that's why it behaves. Add a layer of latex caulking and another layer of foam core on areas that you feel vibrations coming from and it will improve the tone further. I got the depth right on based on clue of 400Hz cancellation. I guess physics still works on foam core 🙂

Your award, a custom gold colored hand crafted foam core statue of a Western Electric miniature horn will be arriving via Express delivery any day now. The academy thanks your for a lifetime of contributions to the art of speaker prototyping.

Your award, a custom gold colored hand crafted foam core statue of a Western Electric miniature horn will be arriving via Express delivery any day now. The academy thanks your for a lifetime of contributions to the art of speaker prototyping.

You have braces in the important places so that's why it behaves. Add a layer of latex caulking and another layer of foam core on areas that you feel vibrations coming from and it will improve the tone further.

CLD is in their future. i would like to get a measurement pre and post for comparison

I got the depth right on based on clue of 400Hz cancellation. I guess physics still works on foam core 🙂

and in general for a while there i almost bought in to a new "metric" 😉

Your award, a custom gold colored hand crafted foam core statue of a Western Electric miniature horn will be arriving via Express delivery any day now. The academy thanks your for a lifetime of contributions to the art of speaker prototyping.

this is going to worse then waiting for X-mas😀

NO DRIVERS OR COMPONENTS where harmed or in the making of this loudspeaker

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?