I actually buy it at Amazon but it is fulfilled by Parts Express. They work well, not fancy but functional. They come with eva foam gasket.

Amazon.com: Banana 5-Way Speaker Wire Binding Post Terminal: Electronics

Amazon.com: Banana 5-Way Speaker Wire Binding Post Terminal: Electronics

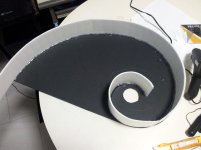

Details of Flatter is Better BIB build in the Terry Cain BIB thread. I thought since it is a foam core build, better to post final pix and sound clip here though.

G'day X,

Why not put a link in the BIB thread back to your post here?

Cheers,

Alex

G'day X,

Why not put a link in the BIB thread back to your post here?

Cheers,

Alex

Done. 🙂

I forgot to mention that I also double up on the glue by liberally applying white, or in your case, yellow glue on top of the hot melt just in case there are any cracks that need to be sealed, plus it ensures that if hot melt ever gives you have a backup bond.

Solid idea. When I build a conventional cabinet, despite a [apparently] air-tight joint, I always seal the inside of the joint with white glue or sealant.

Speaking of which, might silicone sealant work faster, better rather than white/yellow/green/blue/pink 😀 glue?

Try Walmart. The $5 a sheet stuff has really thick paper and is a pain to cut with a razor actually - I think they put glass fibers in the foam and it doesn't cut cleanly.

I think the trick is use a fresh blade, and keep re-newing the blade.

Silicone certainly works to seal, smells bad though during drying. I now use hot melt to seal joints that I have access to and use my fingernail to tool it smooth to a fillet. I sharpen my xacto on a ceramic now before each build. Important to have sharp razor.

Are you building anything Kmossman? Welcome aboard!

Are you building anything Kmossman? Welcome aboard!

What do you think of it versus your Cornu derivative?Details of Flatter is Better BIB build in the Terry Cain BIB thread. I thought since it is a foam core build, better to post final pix and sound clip here though.

They sound great and have the ability to fill the room with some nice bass. I like how they ended up looking too. I just need to decorate them now.

I segmented the back and hot melt glued in sections before glue hardens. Having two hot melt guns and four hands would make this easier as I had to lay down the bead of hot melt furiously fast.

Maybe try this:

1) spot 'weld' using the hot glue

2) seal and hold using [silicone] sealant [the sticky stuff that dries and bonds]

You will find your happy place once you do one. Trust me it won't be the only one but it will help you find your comfort level.1) spot 'weld' using the hot glue

[silicone] I am hoping this is a generic term for the many caulks you have the option of using. Silicone base is the last one I would use. The one the seems best suited to this application has to be the cheapest one you can buy. Available everywhere. I spend funny money on a lot of things but as a caulk this one is very successful.2) seal and hold using [silicone] sealant

Alex® Painter's Acrylic Latex Caulk | Canadian Tire

Silicone certainly works to seal, smells bad though during drying. I now use hot melt to seal joints that I have access to and use my fingernail to tool it smooth to a fillet. I sharpen my xacto on a ceramic now before each build. Important to have sharp razor.

Are you building anything Kmossman? Welcome aboard!

Silicone certainly works to seal, smells bad though during drying.

yep! use in a well-ventilated area

I now use hot melt to seal joints that I have access to and use my fingernail to tool it smooth to a fillet.

you use your fingernail to 'push' and smooth the hot glue!

shades of Lawrence of Arabia!

I sharpen my xacto on a ceramic now before each build. Important to have sharp razor.

maybe I am not 'green' but I use a box cutter aka utility knife

just snap for a fresh, sharp blade

Are you building anything Kmossman?

I am really interested in this thread as building conventional [speaker] cabinets is impossible for me at present.

My last speaker project [many years ago] was the tri-amped LH transmission line speakers using KEFs [damn tweeters kept blowing so replaced them with .............damn forgot!] They were fantastic until some freaking brat poked the woofers all over with a sharp pencil !

Am building a test power supply especially for my projects....nothing exciting there.

A modest switch box with a simple op-amp booster for use with my desktop speaker system

And some potentially commercial e-bike projects! sadly, all are non-audio - although I am [just for me] installing a WICKED set of sirens on my e-bike to act as an auxiliary horn.

AS WELL [!] a commercial venture [can I say that?] with a local guy here in Suzhou, China. He has been hand-crafting valve amps for 15 years. I am one picky SOB on electronics - I NEVER saw commercial work that I could not fault - until I saw his work. This will show him and some of his work Flickr: KJ_Electronics' Photostream

Welcome aboard!

Thank you!

Squeak,

I had to pull the drivers from the Cornu's to put in the FIB's so I have not been able to do a true A/B comparo. But, my impression is that the BIB's have lower bass extension than the 20 in Cornu's, however they do not sound as "expansive" as the Cornu's. I think for certain music where a harder driving bass sound is needed, the FIB's are better, but for most music, the Cornu's sound better, especially jazz or anything with horns or woodwinds. I may pull the drivers from my cardboard MLTL's and put them in the Cornu's so that I can do a true A/B test and update this response. One thing that I have found with the FIB is that it is very sensitive to stuffing, I had to play with it quite a bit to get the sound I wanted. Maybe I just got lucky with how I did the stuffing on the Cornu's because it was good the first time.

I had to pull the drivers from the Cornu's to put in the FIB's so I have not been able to do a true A/B comparo. But, my impression is that the BIB's have lower bass extension than the 20 in Cornu's, however they do not sound as "expansive" as the Cornu's. I think for certain music where a harder driving bass sound is needed, the FIB's are better, but for most music, the Cornu's sound better, especially jazz or anything with horns or woodwinds. I may pull the drivers from my cardboard MLTL's and put them in the Cornu's so that I can do a true A/B test and update this response. One thing that I have found with the FIB is that it is very sensitive to stuffing, I had to play with it quite a bit to get the sound I wanted. Maybe I just got lucky with how I did the stuffing on the Cornu's because it was good the first time.

Last edited:

[silicone] I am hoping this is a generic term for the many caulks you have the option of using.

ops! yep, you are right. I got stuck in the silicone rut. I usually buy the silicone stuff [here, in China] because:

- it's available

- can use it for 'anything', 'anywhere'

- i know it works

I do MISS Canadian Tire, Home Depot, ....................

China is a DIY desert !

Maybe try this:

1) spot 'weld' using the hot glue

2) seal and hold using [silicone] sealant [the sticky stuff that dries and bonds]

I think the point of that post was to see if one could build a Cornu using nothing but hot melt glue. I was impatient and wanted to have an instant Cornu without waiting more than 20 seconds for the hot melt glue to harden. The first Cornu I built I indeed used the hot melt glue to tack, and then used PVA to seal and glue as I was down to my last 5 sticks of hot glue! The final capping off procedure of gluing the face was always the slowest as it required waiting for the PVA to dry over 6 hours.

If you are abroad, this style of DIY is perfect as it can be done in a hotel desk with a knife and hot melt glue gun.

I sharpen my xacto razor mainly because it is one of those fine point triangular tips that I like for precise control and I am too lazy to go buy more. It actually works quite well to sharpen rather than discard each time.

Finally, here's a photo of my 20" Vifa TC9FD masonite/foam hybrid with banana leaf paper. My third foamcore build. I still need to get a photo of the birch ply pair that I built for a friend. He's re-discovering his music collection. Still amazed at how good these can sound.

Now I need to order some more drivers and decide what to build next! 🙂

Now I need to order some more drivers and decide what to build next! 🙂

Nice, surface tension. What's your supply of banana leaf paper? It's cool. Oooh, and is that a Lux PD264 or 284?

Paper was purchased at Paper Arts in Dallas TX. Lots of unusual hand made papers and such. Hard to decide what to use.

PD 264

PD 264

Seems like I've bought the wrong foam board... it is melting under the heat of the hot glue...

Ravener,

Looks good! I have never heard of the glue melting the foam. Are you talking about the foam on the white channel or the black back panel? My gun is only 10 watts if that matters.

Looks good! I have never heard of the glue melting the foam. Are you talking about the foam on the white channel or the black back panel? My gun is only 10 watts if that matters.

Finally, here's a photo of my 20" Vifa TC9FD masonite/foam hybrid with banana leaf paper. My third foamcore build. I still need to get a photo of the birch ply pair that I built for a friend. He's re-discovering his music collection. Still amazed at how good these can sound.

Now I need to order some more drivers and decide what to build next! 🙂

View attachment 327919

Very nice, I like the banana paper look! You and Prezden have nicely decorated speakers. Glad you friend loves the sound. I am still amazed at wht these little Vifa's can do everytime I turn them on and listen. 🙂

If you are looking for the next project, may I suggest this?

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?