OK, so I am not so crazy in trying to make an OB with foam core board. I ran across this thread: http://www.diyaudio.com/forums/full-range/68920-diy-open-baffle-full-range-speakers-wal-mart-4.html

I may be the first to try a line array in a foam core board OB 🙂

I may be the first to try a line array in a foam core board OB 🙂

I HIGHLY recommend a hole saw for such a task. It can cut holes in foam board by hand, or use a cordless drill in reverse to control cutting speed. 76mm is about right for a 3" driver.

I can cut clean holes with an x-acto very quickly in foam core. I am afraid the hole saw will leave jagged edges and collapse foam at point of cut. You are right, there are a lot of holes but 2 minutes a piece is not so bad if I am making modular sections of 6 holes at a time. The real issue right now is WAF for such a large speaker at 6.5 ft and about 2 ft wide including wings.

Does "stacked" mean only three active horns per segment?

Bob,

We are talking about stacking modular open baffle foam core units with 6 drivers each. No horns here 🙂

This was all sparked by the sale on the 3 inch Aurasound drivers for $1ea if you buy 50. I thought it was a cheap way to experiment with a wall of sound approach of line arrays.

Speakers at Dollar Store - or are you talking about the foam boards? I was asking about the $50 speaker deal.

This is about as inspiring as any project I can remember on this blog.

Vifa, board, new blades and hot melt on hand. Fantastic instructions available throughout this blog but somehow I missed how to attach the driver.

Info would be appreciated.

Vifa, board, new blades and hot melt on hand. Fantastic instructions available throughout this blog but somehow I missed how to attach the driver.

Info would be appreciated.

Bjohng,

Welcome on board! There are several ways to attach the driver to the rather soft foam core board. The way I do it is to hot melt glue 4 small pieces of wood on the back side (in the driver chamber) where the screws go - say 0.5 in x 0.5 in x 0.25 in thick. Drill a small hole through the foam core at screw locations and then attach driver with wood screws. I think recently, Fenris posted his technique of building a very nice "cage" out of thin plywood that resides inside the driver chamber. But then this defeats the point of not having to use a saw. I used tin snips to cut my wood to size 🙂 Anyhow, it holds the driver just fine. You may want to seal the interface between the foam core and the driver with something like putty or gasket foam. A tight seal is essential to good sound.

Good luck and keep us posted.

Welcome on board! There are several ways to attach the driver to the rather soft foam core board. The way I do it is to hot melt glue 4 small pieces of wood on the back side (in the driver chamber) where the screws go - say 0.5 in x 0.5 in x 0.25 in thick. Drill a small hole through the foam core at screw locations and then attach driver with wood screws. I think recently, Fenris posted his technique of building a very nice "cage" out of thin plywood that resides inside the driver chamber. But then this defeats the point of not having to use a saw. I used tin snips to cut my wood to size 🙂 Anyhow, it holds the driver just fine. You may want to seal the interface between the foam core and the driver with something like putty or gasket foam. A tight seal is essential to good sound.

Good luck and keep us posted.

Last edited:

After seeing the cardboard fonken in the w5-1611SAF thread, it's a tempting thought to build one out of foam board. 😀 I guess it would take three or four sheets laminated together to get the proper thickness. Who's with me??

Chaz,

I missed that post - where is the cardboard Fonken? The Fonken needs a pretty stiff box - I am not sure that the foam core would work well here as it is more of a bass reflexish speaker. I am thinking of doing a scaled down Frugel Horn Mk3 out of foam. It can be scaled down to 30 in high to match foam core stock and use a good but cheap 3.5 inch driver. I think the FH3 can be made with 3 sheets of 20x30 inch board each and the sizes scale nicely for a 3.5 in driver (I am thinking TC9FD of course, the Fountek FR85 is also a possibility). It will look pretty cool plus the foam core has a neat trick in that it can be curved. This allows us to make a nice curved flare of the rear horn which increases the horn mouth area and doubles as nice looking built-in stabilization feet for the rather narrow cabinet.

I missed that post - where is the cardboard Fonken? The Fonken needs a pretty stiff box - I am not sure that the foam core would work well here as it is more of a bass reflexish speaker. I am thinking of doing a scaled down Frugel Horn Mk3 out of foam. It can be scaled down to 30 in high to match foam core stock and use a good but cheap 3.5 inch driver. I think the FH3 can be made with 3 sheets of 20x30 inch board each and the sizes scale nicely for a 3.5 in driver (I am thinking TC9FD of course, the Fountek FR85 is also a possibility). It will look pretty cool plus the foam core has a neat trick in that it can be curved. This allows us to make a nice curved flare of the rear horn which increases the horn mouth area and doubles as nice looking built-in stabilization feet for the rather narrow cabinet.

Last edited:

This also just came to mind:

http://www.diyaudio.com/forums/full-range/124449-desktop-tl-3-driver-real-bass.html

http://www.diyaudio.com/forums/full-range/124449-desktop-tl-3-driver-real-bass.html

xrk971,

Thanks for input - 2 projects successfully completed!

First was making an end cap for an 18" length of 4" dia pipe to test my ability to cut the foam board, try your attachment detail and burn in the driver. Stuffed with fiberfill and stood it on end on the carpet.

Second was to make an OB top section for my H frame OB. 12" wide with arched top and driver centered. Active x-over at 100Hz.

Cornu next up on my list when I have a better understanding of the stuffing. It seems like a removable face would allow for experimenting with varying amounts of stuffing.

When considering what I have spent over the years on high priced drivers I am even more amazed at my initial listening sessions. Of course it has it's limitations but so do all drivers.

This has certainly brought the fun factor back to our hobby.

Keep the innovation coming.

Thanks for input - 2 projects successfully completed!

First was making an end cap for an 18" length of 4" dia pipe to test my ability to cut the foam board, try your attachment detail and burn in the driver. Stuffed with fiberfill and stood it on end on the carpet.

Second was to make an OB top section for my H frame OB. 12" wide with arched top and driver centered. Active x-over at 100Hz.

Cornu next up on my list when I have a better understanding of the stuffing. It seems like a removable face would allow for experimenting with varying amounts of stuffing.

When considering what I have spent over the years on high priced drivers I am even more amazed at my initial listening sessions. Of course it has it's limitations but so do all drivers.

This has certainly brought the fun factor back to our hobby.

Keep the innovation coming.

Bjohng,

You are very methodical! I like that. I am glad your experiments have worked out. The little Vifa is an amazing piece of technology for $12. It works as the top end in an OB very well as it is used in Manzanita OB. How do you like the sound in the sealed 4 inch tube? Regarding removable face: tough because a good seal is important. You can cut little windows in the back foam panel to access stuffing adjustment. Reseal windows with foam core piece that was cutout with hot melt. Before sealing hold in place with tape to listen.

You are very methodical! I like that. I am glad your experiments have worked out. The little Vifa is an amazing piece of technology for $12. It works as the top end in an OB very well as it is used in Manzanita OB. How do you like the sound in the sealed 4 inch tube? Regarding removable face: tough because a good seal is important. You can cut little windows in the back foam panel to access stuffing adjustment. Reseal windows with foam core piece that was cutout with hot melt. Before sealing hold in place with tape to listen.

xrk971,

Thanks for another easy alternative. It will be a couple of weeks before I get to the Cornu.

In the meantime I took full sheets and centered the drivers to use (OB) with my Home theater later tonight. First test was promising. Report to follow.

No attempt was made to calculate optimum volume for closed tube or density of stuffing. It was the first thing that came to hand. The sound - surprisingly well balanced. The closed box warmed the sound up nicely and gave a very credible full range performance.

This is truly an amazing little speaker.

Thanks for another easy alternative. It will be a couple of weeks before I get to the Cornu.

In the meantime I took full sheets and centered the drivers to use (OB) with my Home theater later tonight. First test was promising. Report to follow.

No attempt was made to calculate optimum volume for closed tube or density of stuffing. It was the first thing that came to hand. The sound - surprisingly well balanced. The closed box warmed the sound up nicely and gave a very credible full range performance.

This is truly an amazing little speaker.

Bjohng,

You might want to offset the drivers from the middle for best performance as OB - golden ratio...

Sounds like fun though, I have wondered how the Vifa sounds in sealed cabinet as I have always used in horns and TL's.

You might want to offset the drivers from the middle for best performance as OB - golden ratio...

Sounds like fun though, I have wondered how the Vifa sounds in sealed cabinet as I have always used in horns and TL's.

Frugel Foam 3 - new build starting up

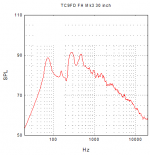

I finally had some time to lay out my homage to the FH3 in foam core. I scaled it to 30 in tall and internal cross sections scaled relative to TC9FD driver Sd. This gives cabinet dimensions of 4.5 in wide x 5.0 in deep (internal dims). Terminus height is 1.33 in and I plan to flare the back horn out in a smooth expansion to 12 in wide. This serves to provide built in stabilization feet and gives horn more lateral expansion. It increases final horn's expansion ratio by almost 3x, hopefully this will boost the weak bass from the tiny 3.5 in Vifa. As usual, cutting or scoring the wings on the horn allows a nice smooth compound curve that looks great and will be quite rigid once glued. I just have to find a bit of time to glue now. I sim'd this in HR and got a reasonable frequency response curve showing the low bass peak at 73 Hz. There is a big dip around 125 Hz but that should be filled in by Vifa's natural peak there as fs is 125 Hz.

I finally had some time to lay out my homage to the FH3 in foam core. I scaled it to 30 in tall and internal cross sections scaled relative to TC9FD driver Sd. This gives cabinet dimensions of 4.5 in wide x 5.0 in deep (internal dims). Terminus height is 1.33 in and I plan to flare the back horn out in a smooth expansion to 12 in wide. This serves to provide built in stabilization feet and gives horn more lateral expansion. It increases final horn's expansion ratio by almost 3x, hopefully this will boost the weak bass from the tiny 3.5 in Vifa. As usual, cutting or scoring the wings on the horn allows a nice smooth compound curve that looks great and will be quite rigid once glued. I just have to find a bit of time to glue now. I sim'd this in HR and got a reasonable frequency response curve showing the low bass peak at 73 Hz. There is a big dip around 125 Hz but that should be filled in by Vifa's natural peak there as fs is 125 Hz.

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?