Hmm, so it looks like the pipe width would be about 7.5 inches if there are 4 segments going back and forth along the 19.2 inch dimension. The only drawback seems to be that the PE driver can't be in the centre of the baffle.

Without modification, the pipe length would be 76.8 inches, so we could start the pipe 4.8 inches 'later', which would offset the PE driver hopefully into a more desirable location (e.g. at 24 inches, if a third of the way down the pipe is acceptable).

Without modification, the pipe length would be 76.8 inches, so we could start the pipe 4.8 inches 'later', which would offset the PE driver hopefully into a more desirable location (e.g. at 24 inches, if a third of the way down the pipe is acceptable).

The folding would not be the same and might be closer to a single angled divider for a tapered TL and length only 60in.

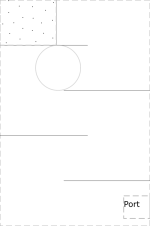

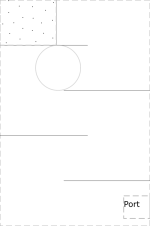

When I was originally thinking of the idea I thought that too. Sorry, I didn't explain the idea clearly, so here's a picture of what I was trying to describe 🙂

The dotted area at the top-left is unused space to make the pipe length 72 inches. I might have put the speaker hole in the wrong place, but I'd guess it should be around 24 inches from the closed end of the pipe. Hopefully that makes sense!

The dotted area at the top-left is unused space to make the pipe length 72 inches. I might have put the speaker hole in the wrong place, but I'd guess it should be around 24 inches from the closed end of the pipe. Hopefully that makes sense!

By all means use all the space and make the TL longer if you have the room. The need for 1/3rd placement of driver is not strict. You can move around a bit and it will be fine. Thanks for the sketch.

Thanks for humouring me @xrk971 🙂 Yes, doing it like that seems to end up with quite a long path - I might be measuring it wrong, but even with the inset at the top a rudimentary measurement of the whole path is still around 96 inches. I might be measuring incorrectly, though.

Thanks for the detail on the placement of the speaker a third of the way down the pipe not being necessary; I wasn't sure. I don't really have any materials to fit this, so I'll most likely end up creating a 24x24x4 inch box like you'd originally calculated if I can make it over to a supplier of plywood soon 🙂

Thanks for the detail on the placement of the speaker a third of the way down the pipe not being necessary; I wasn't sure. I don't really have any materials to fit this, so I'll most likely end up creating a 24x24x4 inch box like you'd originally calculated if I can make it over to a supplier of plywood soon 🙂

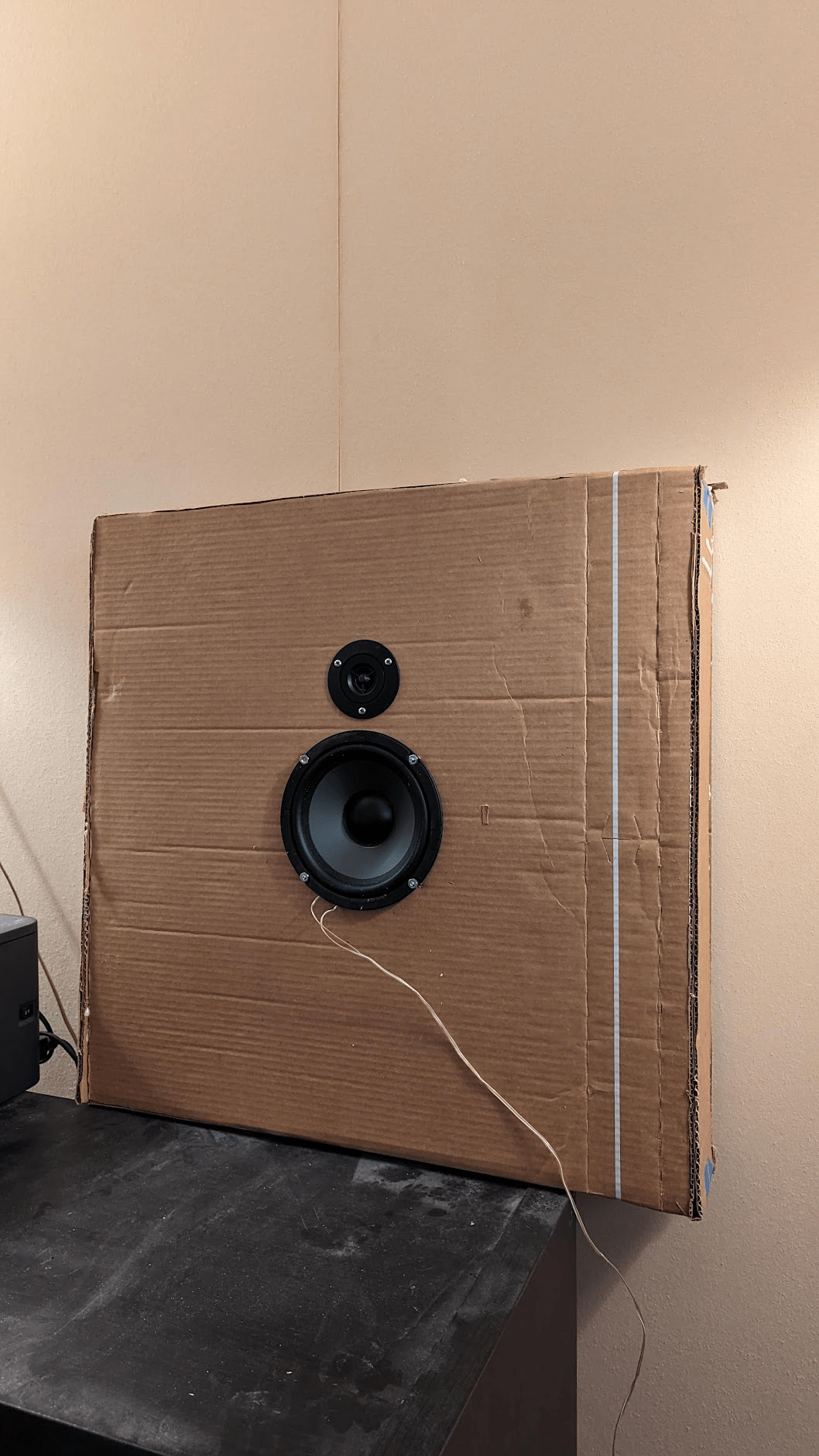

@xrk971 - I decided to take your design recommendations and fabricate it in carboard, for the 6.5" Polycone Woofer from Parts Express.

The front panel is two sheets of cardboard, laminated together with wallpaper paste (because I had it on hand 🙂 ), and then I had some thick honeycomb bits of cardboard I could cut down for the inner walls of the 'pipe'.

I also had some closeout tweeters from Parts Express - the 1/2" mylar tweeters (though the exact part number isn't available from them any more), and I remember getting them because the frequency response of both drivers meant for a crossover between the two drivers without any circuitry. Plus, they're cheap! About $12 in total for a woofer and tweeter.

I've just plugged this in and tried it out, and it's quite impressive - that experience of the deep Bass emerging about 6 feet from the wall was definitely noticed. I'll try it with some more listening material, but it works really well so far! I bet a stereo pair would sound better 😉

The front panel is two sheets of cardboard, laminated together with wallpaper paste (because I had it on hand 🙂 ), and then I had some thick honeycomb bits of cardboard I could cut down for the inner walls of the 'pipe'.

I also had some closeout tweeters from Parts Express - the 1/2" mylar tweeters (though the exact part number isn't available from them any more), and I remember getting them because the frequency response of both drivers meant for a crossover between the two drivers without any circuitry. Plus, they're cheap! About $12 in total for a woofer and tweeter.

I've just plugged this in and tried it out, and it's quite impressive - that experience of the deep Bass emerging about 6 feet from the wall was definitely noticed. I'll try it with some more listening material, but it works really well so far! I bet a stereo pair would sound better 😉

That’s a very nice wallmount speaker. I bet the bass is impressive. The midrange from that polycone is actually excellent. Very smooth as I recall.

Great work! If you get some 3/16in subfloor plywood (luaan) and glue that on with more wallpaper cement, it would look pretty good.

What is the thickness or depth of the speaker you ended up at?

Great work! If you get some 3/16in subfloor plywood (luaan) and glue that on with more wallpaper cement, it would look pretty good.

What is the thickness or depth of the speaker you ended up at?

I ended up with a depth of 4 inches, and the port length was 1.77cm 🙂

You're right, the Bass is definitely there! Just by ear the whole system seems to be quite even.

Another random thought, could a design like this be implemented for a planar driver, like the GRS ones? I don't know if there'd be any excursion issues, but I thought I'd throw that out there.

Maybe a MLTL isn't appropriate for a planar, but it would be interesting to use the back-wave somehow.

You're right, the Bass is definitely there! Just by ear the whole system seems to be quite even.

Another random thought, could a design like this be implemented for a planar driver, like the GRS ones? I don't know if there'd be any excursion issues, but I thought I'd throw that out there.

Maybe a MLTL isn't appropriate for a planar, but it would be interesting to use the back-wave somehow.

I've read this thread from beginning to end more time than I can remember. I chose XPS for my first ever build, for the ease, and also to save (a lot of) money. I think I may have built the biggest XPS cabinets out there, or close. I don't remember seeing something this big in the thread of elsewhere. It's a 70-ish liters bass reflex with a SB20FRPC30 8" fullrange driver.

They are 94 x 42 x 28cm. Built out of a mix of 40 and 30mm 'URSA' XPS that can be found here in Belgium. It may be slightly less dense than the pink kind you guys can find in the US.

Mistakes were made during the build. My glue (high quality white wood glue) wouldn't set at all. It would take a long time before things became sturdy enough to move on with the build. I don't think I braced the thing quite enough. I'll make sure to fix that once I get started on the second one.

It's also so light that it vibrates where it starts unloading sub 100Hz frequency. I implemented a cuttoff around 35Hz, and after adding some weight on top of the speaker, I can blast it at unreasonably loud level without any audible vibrations.

How does it sound? Awesome, clean and big. I'm verry happy with it. I initially had some leak issues, but after some more time under heavy clamping, I seem to have tamed the leak.

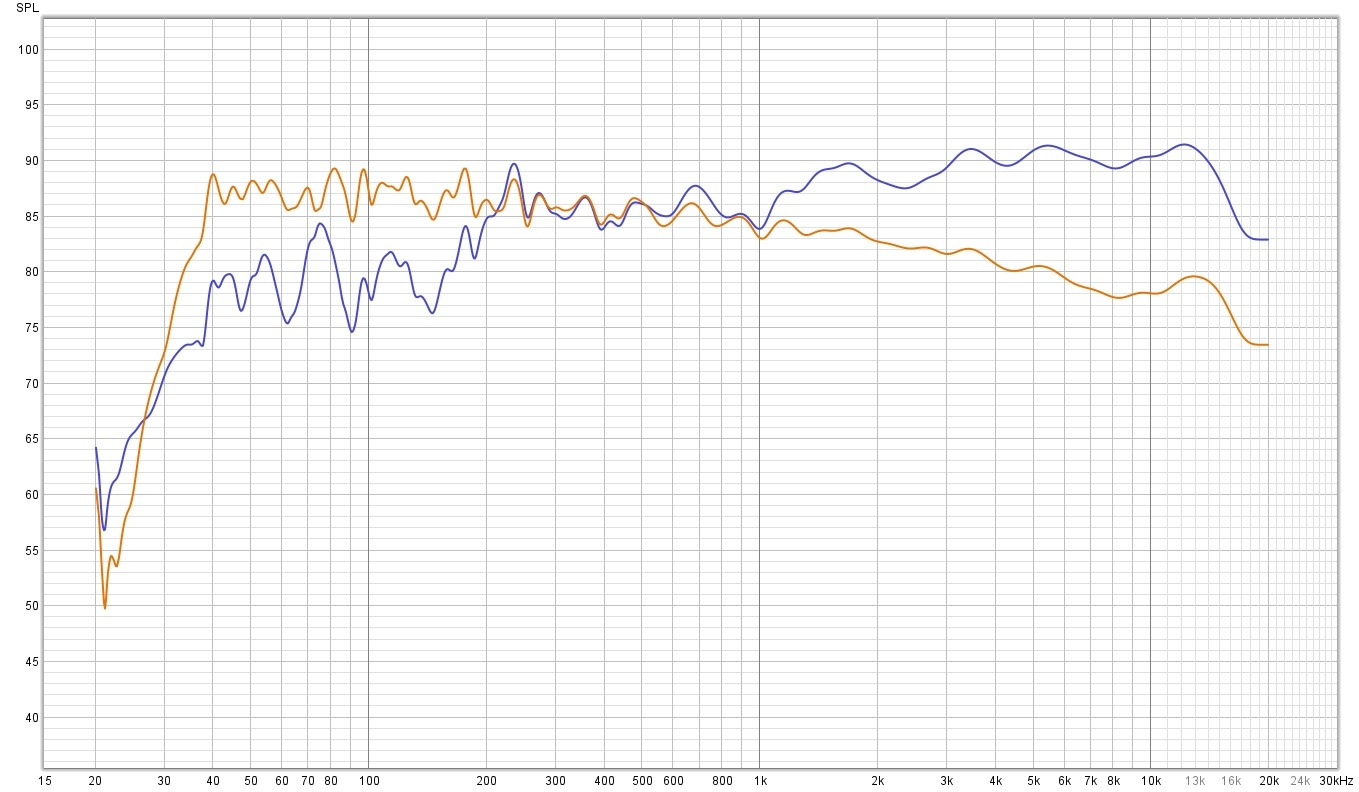

Here are the uncorrected (blue) and corrected (orange) measurements at 1 meter.

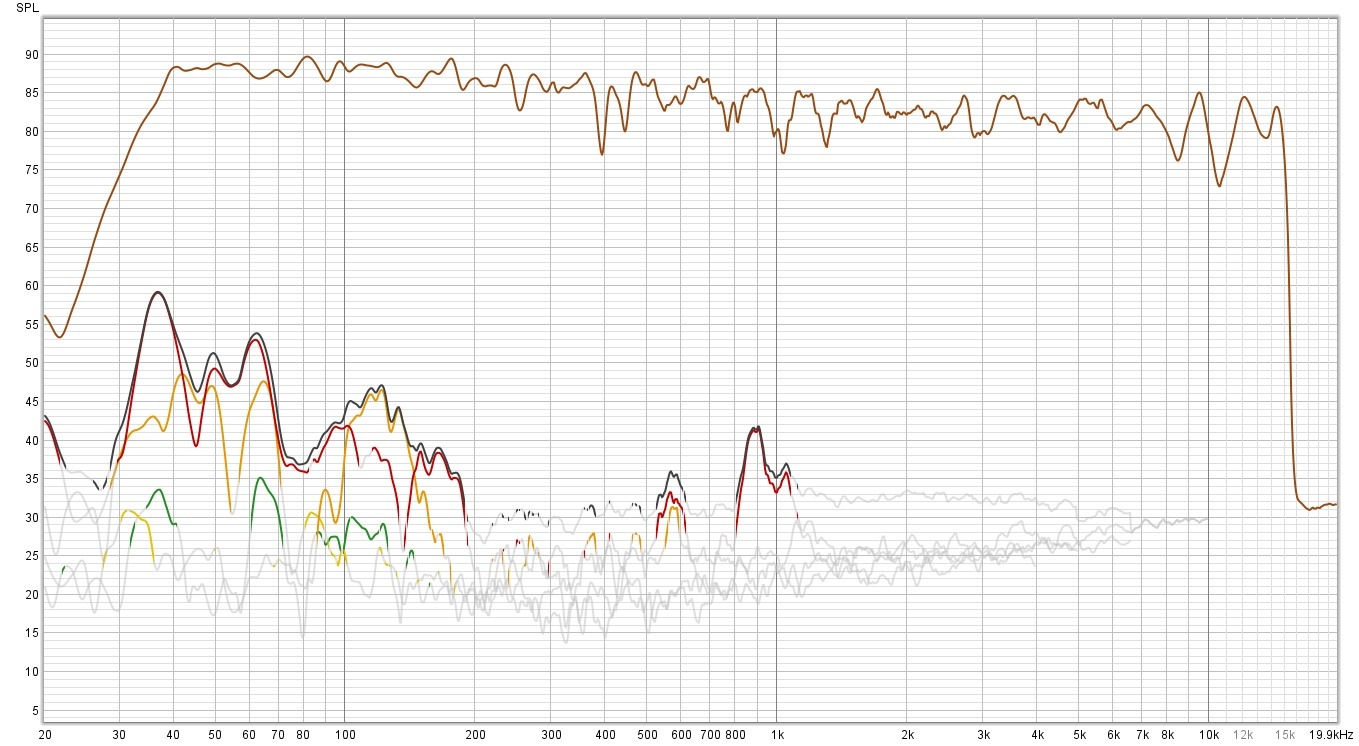

Distorsion numbers (which I don't really know if they're good or not, but it sure sounds clean).

They are 94 x 42 x 28cm. Built out of a mix of 40 and 30mm 'URSA' XPS that can be found here in Belgium. It may be slightly less dense than the pink kind you guys can find in the US.

Mistakes were made during the build. My glue (high quality white wood glue) wouldn't set at all. It would take a long time before things became sturdy enough to move on with the build. I don't think I braced the thing quite enough. I'll make sure to fix that once I get started on the second one.

It's also so light that it vibrates where it starts unloading sub 100Hz frequency. I implemented a cuttoff around 35Hz, and after adding some weight on top of the speaker, I can blast it at unreasonably loud level without any audible vibrations.

How does it sound? Awesome, clean and big. I'm verry happy with it. I initially had some leak issues, but after some more time under heavy clamping, I seem to have tamed the leak.

Here are the uncorrected (blue) and corrected (orange) measurements at 1 meter.

Distorsion numbers (which I don't really know if they're good or not, but it sure sounds clean).

I was thinking of these: https://www.parts-express.com/GRS-PT6825-8-8-Planar-Mid-Tweeter-8-Ohm-272-126 as I've got a pair of them. They work really well in a front-loaded horn, but I wondered if anything could be done with the back-wave. 250Hz is probably too high for anything based on a transmission line, but you know - I like to ask dumb questions 🙂Planars are tweeters I think. You need to use the ones with a back cup and not dipole.

I can take a measurement of the box as well, and get it on YouTube. I'm not sure how flat the response is, but it's still pretty pleasing to the ear!

@pardon - that's a really nice speaker!

@pardon really nice build. I'm surprised to find 30/40mm thick XPS has trouble handling deeper bass 🙂 Perhaps sandwiching different materials is the way to go. I think you could do better than using an ugly weight to hold it down, like putting a sand bag or multiple of them inside the cabinet, as outlined by TNT Audio:

The box itself is tuned to match the bass driver and give a particular bass response whether in a sealed box or ported box. By altering the volume of the box you can bring large changes to the sound. The simplest way of doing this is to take a freezer bag, measure out say 1 litre of sand and seal it in the bag. (then put another bag round it for safekeeping!).

Then just put the bags into the boxes and see the difference – it will be big! There is a side benefit to this in that in putting all that sand in you are increasing the weight of the speaker substantially and damping it to a certain extent. Just make sure the sand can't leak out and that the bags have the air pushed out, so they won't rustle.

I was thinking of these: https://www.parts-express.com/GRS-PT6825-8-8-Planar-Mid-Tweeter-8-Ohm-272-126 as I've got a pair of them. They work really well in a front-loaded horn

@pardon - that's a really nice speaker!

Please post the build!

@xrk971 - that's correct, though i crossed it with an eminence alpha 8a at 700Hz, just so there was a midbass to connect this horn with the sub: https://www.diyaudio.com/community/...dbass-box-for-indoor-listening-levels.380561/

As mentioned, Bill Waslo's spreadsheet was used to design the horn for the planar driver, and it's a great design - even if you're not making a Synergy-like horn, the design works really well.

As mentioned, Bill Waslo's spreadsheet was used to design the horn for the planar driver, and it's a great design - even if you're not making a Synergy-like horn, the design works really well.

Random thought: is there a rule of thumb as to how small you can go with the Vas of the enclosure before it 'doesn't work' any more?You can make a pretty small reflex speaker with a 0.04 cu ft Vas driver. That’s 1.1L Vas so about. 2.2L (milk carton size) cabinet makes a nice speaker that reaches down to fs of driver easily. With AMTL you can go deeper. So the volume can be bigger, but if smaller that 1.1L then probably not good to make it a reflex box.

@xrk971 - i've just completed a second one of the on-wall MLTL in post 3466, just to try out a stereo pair before I committed to buying any wood.

There's seriously something magical about this design, even with that $8 woofer and the $3 tweeter. There's no crossover circuitry involved, yet the midrange is very present, the stereo imaging is great, and there's a lot of Bass - there's absolutely no need for a sub!

Thanks for helping me with the dimensions, and I'll post the wooden enclosures when I complete them! If you want to cross-post to the AMLTL thread, by all means do 🙂

There's seriously something magical about this design, even with that $8 woofer and the $3 tweeter. There's no crossover circuitry involved, yet the midrange is very present, the stereo imaging is great, and there's a lot of Bass - there's absolutely no need for a sub!

Thanks for helping me with the dimensions, and I'll post the wooden enclosures when I complete them! If you want to cross-post to the AMLTL thread, by all means do 🙂

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?