From what I've read, it mimics a conical horn. You aren't limited to compression drivers, as you can see in JLH's video, and it works as a Synergy horn-like source by combining multiple drivers.

X, it may be completely inappropriate, but could you try something with the drivers used in the Trynergy horn?

X, it may be completely inappropriate, but could you try something with the drivers used in the Trynergy horn?

From what I've read, it mimics a conical horn. You aren't limited to compression drivers, as you can see in JLH's video, and it works as a Synergy horn-like source by combining multiple drivers.

X, it may be completely inappropriate, but could you try something with the drivers used in the Trynergy horn?

I am waiting for some compression drivers to arrive and will give this a try. I suppose I could even try the 3FE22 as the driver but don't see the advantage as it will probably limit bandwidth and SPL. What I can see happening is using a cheap high fs mid(s) and a CD to fit into the existing Trynergy throat. Then still use the same 6.5 in woofers where they are currently. It will be a3-way then. I think adding a volume insert into the cone space between the woofer and the port will extend its HF cutoff for a smoother XO. This can be made by stacked foam core discs and rings.

Yes, it seemed to lend itself quite well to foam core as a material, especially with the smooth surfaces, and clean edges with some nice clean cuts!

I'm tempted to try making one too. I think the goal for me would to use it to create a point source of all of the drivers (reducing time delay issues?), making the building of the horns easier.

Dare I say it, you could use non-square or rectangular shapes!

Here's a picture that I've pulled from the patent of Tom Danley's, with multiple drivers. To me, the holes look a little like those on a Synergy horn, but flattened.

I'm tempted to try making one too. I think the goal for me would to use it to create a point source of all of the drivers (reducing time delay issues?), making the building of the horns easier.

Dare I say it, you could use non-square or rectangular shapes!

Here's a picture that I've pulled from the patent of Tom Danley's, with multiple drivers. To me, the holes look a little like those on a Synergy horn, but flattened.

Yes, it seemed to lend itself quite well to foam core as a material, especially with the smooth surfaces, and clean edges with some nice clean cuts!

I'm tempted to try making one too. I think the goal for me would to use it to create a point source of all of the drivers (reducing time delay issues?), making the building of the horns easier.

Dare I say it, you could use non-square or rectangular shapes!

Here's a picture that I've pulled from the patent of Tom Danley's, with multiple drivers. To me, the holes look a little like those on a Synergy horn, but flattened.

The foam edges may even provide some level of damping to reduce chamber resonances. The harder part is the eye shaped unit with the two arc shaped slots. More material will be need to support the floating eye. Maybe even add a thin layer of stiff cardboard on top.

This is a useful view of what it may look like if we copy how JLH did it:

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Ah yes, and JLH's paraline gave quite a clean response and good representation of it in his video, though I haven't looked to see if he'd made any measurements of it.

Sounds like a good idea! If it can be run without a horn bell attached to it, maybe the only piece that would require not to be foam core would be the driver mount...though I suppose the air pressure flexing the panels might be an issue. Patrick Bateman did add some small ribs in his version, so maybe cutting thin strips and gluing them into the gaps in a radial pattern would suffice?

Sounds like a good idea! If it can be run without a horn bell attached to it, maybe the only piece that would require not to be foam core would be the driver mount...though I suppose the air pressure flexing the panels might be an issue. Patrick Bateman did add some small ribs in his version, so maybe cutting thin strips and gluing them into the gaps in a radial pattern would suffice?

This may be a nice application to put in the top portion of the reduced length slot Karlson aperture (where is is closed off normally). It is very thin and has wide dispersion horizontally.

I wonder if the Woden Lance could be built with FC or the 'pink stuff'... Might be a simple build, with integral bracing.

http://wodendesign.com/downloads/Woden-FF85-Lance-Laby-1v01-180214.pdf

http://wodendesign.com/downloads/Woden-FF85-Lance-Laby-1v01-180214.pdf

Yes, something like that can be easily adapted to FC. I think kenLBird built the "tunnel" TL for a Visaton FR10 that looks similar. I like how small this design is. I might adapt it to a 3FE22 that I have on hand.

Last edited:

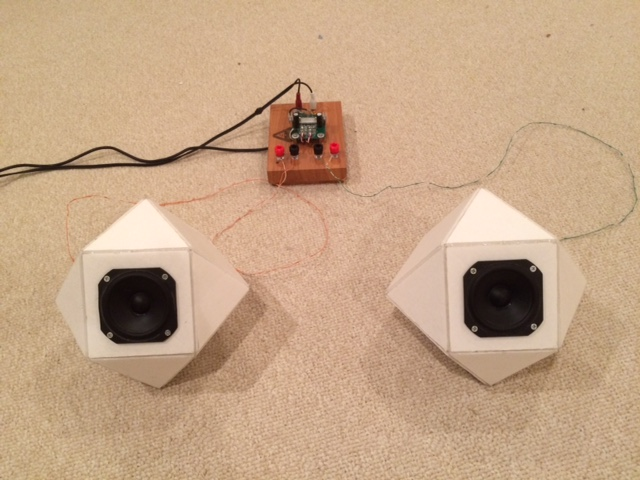

Hypercube Foam Core Speaker

Here is my latest foam core speaker. More details here:

http://www.diyaudio.com/forums/full-range/265053-hypercube-loudspeakers-12.html#post4128571

A very easy and fast speaker to make. Sounds great and would be an excellent satellite for a HT or a FAST.

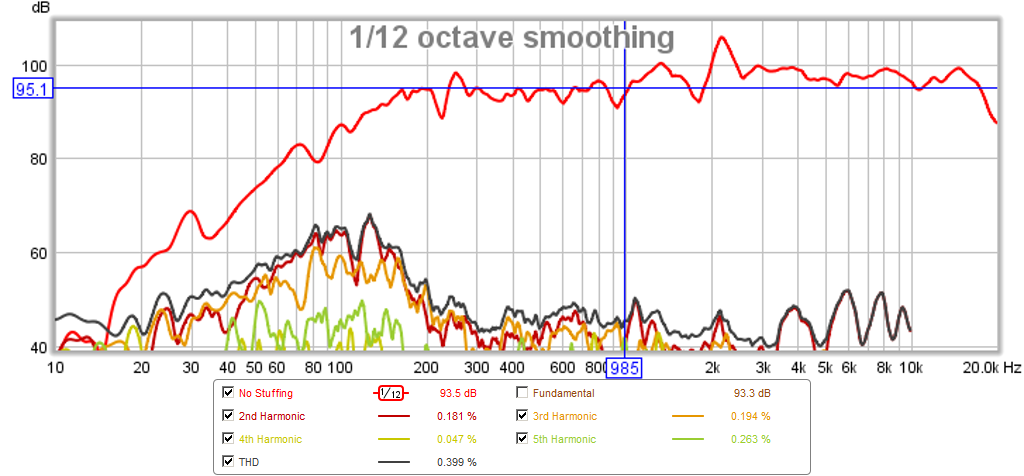

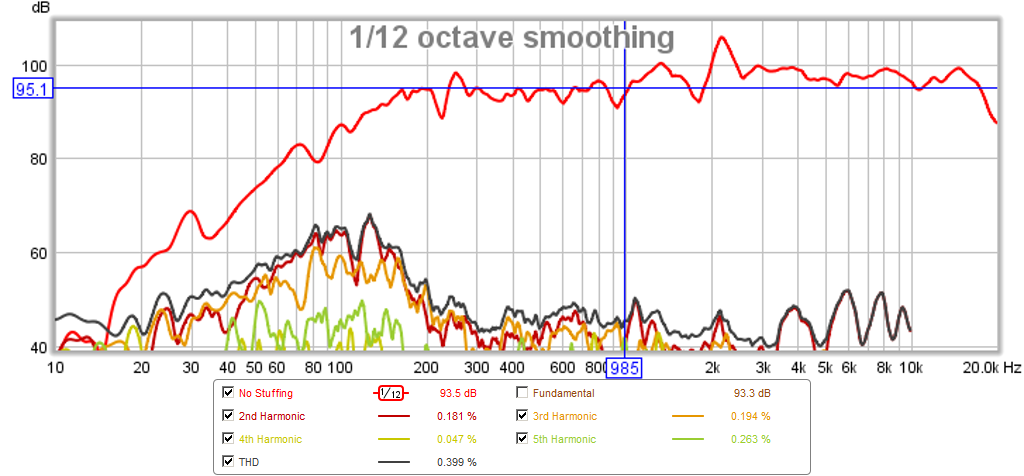

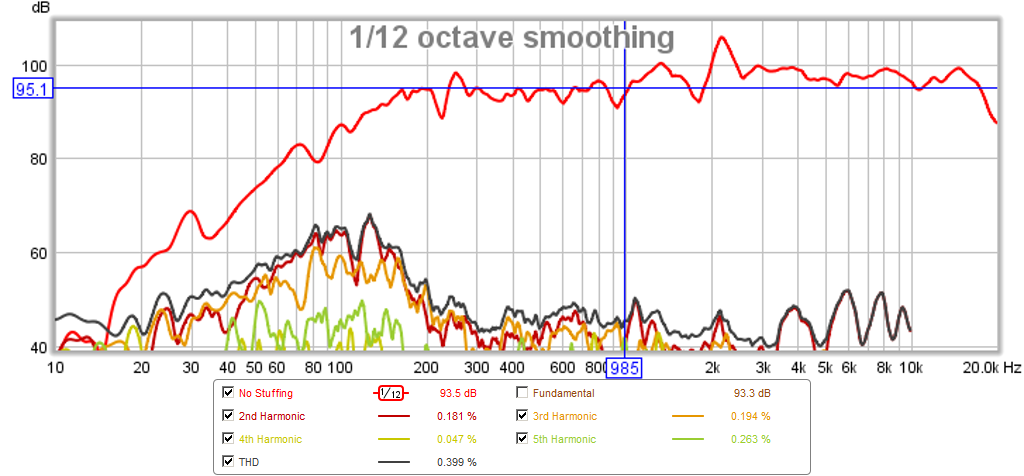

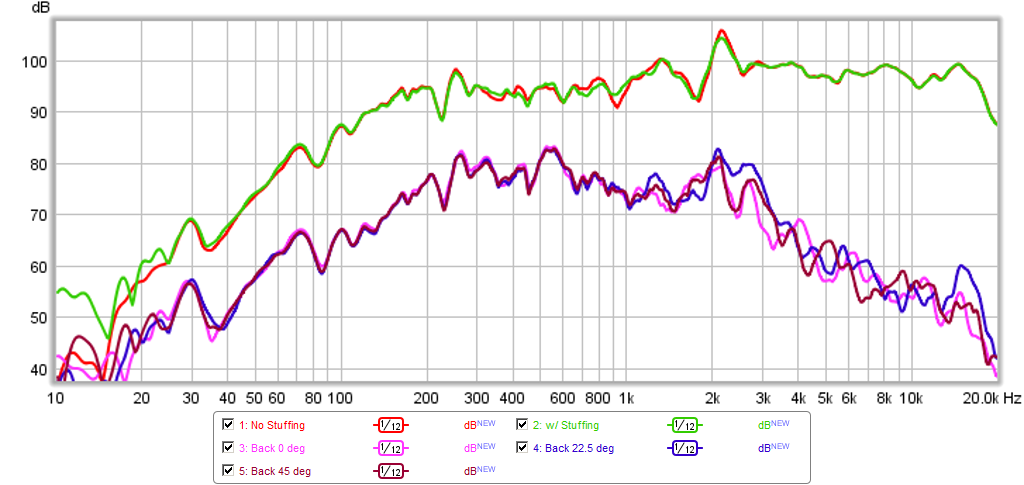

Here is the measured response without any stuffing:

Here is my latest foam core speaker. More details here:

http://www.diyaudio.com/forums/full-range/265053-hypercube-loudspeakers-12.html#post4128571

A very easy and fast speaker to make. Sounds great and would be an excellent satellite for a HT or a FAST.

Here is the measured response without any stuffing:

Nice! I can't believe you've only built foamcore speakers!

Don't forget cardboard and XPS foam sheathing. 🙂

Anything that cuts with a razor blade.

One day I hope to have a workshop with a table saw.

There is some tough material out there...while I don't suggest building an enclosure from it, I recently bought an on-sale pumpkin ($2.49 at Target) with the idea of eating it (also have a cat and a guinea pig that eat the canned stuff). This "decorative pumpkin" resisted even a kitchen knife, so I got out my trusty electric jigsaw and sliced it up 🙂

Thank heavens I have divorced women friends to ask for advice: 350 F for one hour and it's quite tasty. Odd: the pets won't eat the fresh or cooked product.

I relent: you probably could make a decent enclosure out of a pumpkin but I'm not sure about the life span. Would be an excellent outdoor speaker for Halloween sound effects 🙂

Thank heavens I have divorced women friends to ask for advice: 350 F for one hour and it's quite tasty. Odd: the pets won't eat the fresh or cooked product.

I relent: you probably could make a decent enclosure out of a pumpkin but I'm not sure about the life span. Would be an excellent outdoor speaker for Halloween sound effects 🙂

Here is my latest foam core speaker. More details here:

http://www.diyaudio.com/forums/full-range/265053-hypercube-loudspeakers-12.html#post4128571

A very easy and fast speaker to make. Sounds great and would be an excellent satellite for a HT or a FAST.

Here is the measured response without any stuffing:

Some sound clips with this speaker running fullrange and a sub with a passive line level XO (PLLXO) at about 200Hz. There is no EQ or any DSP, source straight from CD player to TPA3116D2 amp for Hypercubes and Yamaha RX360 amp for subs via PLLXO.

More info on PLLXO here:

http://www.diyaudio.com/forums/subwoofers/265383-sub-crossover-design-college-budget-help-please.html#post4135114

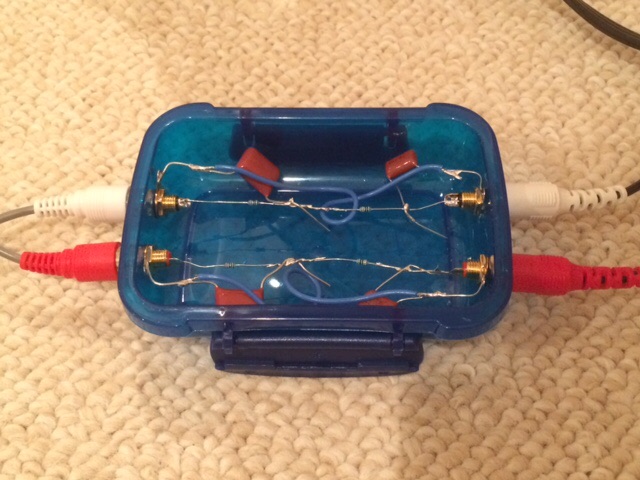

Photo of sub XO high pass filter -12dB/oct at 200Hz:

The speaker has radiated emission from the walls of the housing, as seen here in measurements. This contributes to some ambiance and a sense of a larger soundstage:

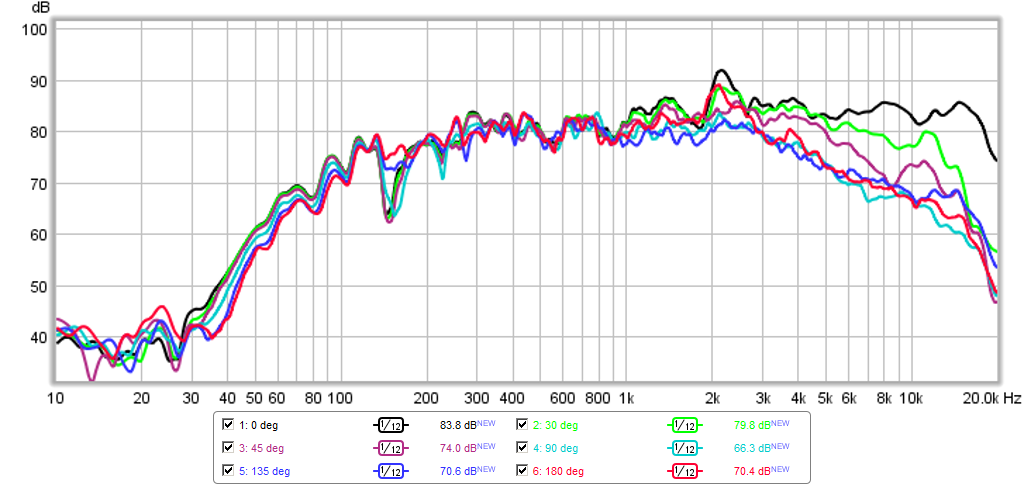

Here are the polar measurements:

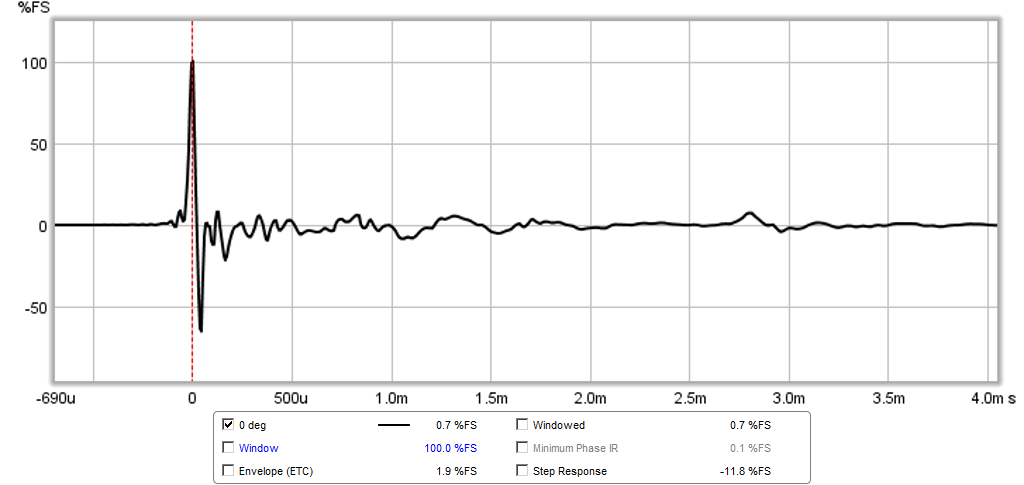

Here is the on-axis Impulse:

Here is the stereo setup: (for listening and measurements they were placed on stands):

Sound clips are below in attached zip files.

Attachments

This thread is pure gold.

Congratulations on all those successful builds and on the discovery of this building method.

The TC9FD seems to be THE bang for the bug fullranger.

I´m sure it is somewhere hidden i this thread, but what material thickness of the foam core board is used for those cabinets?

Congratulations on all those successful builds and on the discovery of this building method.

The TC9FD seems to be THE bang for the bug fullranger.

I´m sure it is somewhere hidden i this thread, but what material thickness of the foam core board is used for those cabinets?

This thread is pure gold.

Congratulations on all those successful builds and on the discovery of this building method.

The TC9FD seems to be THE bang for the bug fullranger.

I´m sure it is somewhere hidden i this thread, but what material thickness of the foam core board is used for those cabinets?

Hey thanks for the kind words Buehegemeiste. 🙂

The TC9FD is one of the best sounding drivers at any price. The foam core that is sold in the US comes in a standard 3/16in thickness (0.1875in). The dollar store variety is very light and brittle with thin paper. The Elmer's brand is much stiffer and stronger at 5x the price. There is really thick 1/2in and 3/4in stuff available for industrial signs but that stuff costs more than plywood.

...foam core from the dollar store...

that definitely proves:

dollar store > euro store

euro store only sells plastic flowers, lighters and toys that all children hate.

i'll make out a cheap source of foam core board and reproduce some of your creations.

i was thinking about a pair of TL9FD's for the needles.

but those mltl's seem to be an even better reason.

that definitely proves:

dollar store > euro store

euro store only sells plastic flowers, lighters and toys that all children hate.

i'll make out a cheap source of foam core board and reproduce some of your creations.

i was thinking about a pair of TL9FD's for the needles.

but those mltl's seem to be an even better reason.

The 0.4x scale Karlsonator is an easy to do great sounding first project. Lots of satisfied builds on that one.

http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html

http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html

A TC9FD costs 14€ in germany atm.

If somebody is looking for a nice christmas present:

A pair of those would make me a happy presentee.

If somebody is looking for a nice christmas present:

A pair of those would make me a happy presentee.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?