This post is to update where I am at with the speed stability of my Oracle Delphi. While I am not clear about the role of the thermistor in the motor control circuit I don't think it's contributing to the problem. As previously noted, I have replaced most of the active components in the circuit and the passive components all seem to check out okay. I am also comfortable that the power supply is not a factor - I can vary the voltage on the bench power supply from 20 - 40Vdc without affecting motor speed. Even the very basic original Oracle wall-wart supply works fine.

My latest efforts have focused on the main bearing. I have carefully cleaned the bearing bushings and spent some time polishing the spindle to a mirror finish. I have also experimented with higher viscosity oils and am currently using Sonic Super Oil, an ISO48 grade synthetic oil sold for in-line skate bearings. The end result is that the platter speed is now significantly more consistent at +/-0.2% and wow has reduced from +/-0.08% to +/-0.04%. While I am pretty happy with these numbers I anticipate better results with higher viscosity oil and have some ISO22 synthetic oil on order.

I have read elsewhere that the bearing on these TT's can cause problems. It seems that over time, without proper regular maintenance, the ptfe composite bushings can become too tight. I would like to be able to accurately ream/hone/lap these bushings to achieve better clearances but this would require some fairly sophisticated gear/techniques without doing damage.

My latest efforts have focused on the main bearing. I have carefully cleaned the bearing bushings and spent some time polishing the spindle to a mirror finish. I have also experimented with higher viscosity oils and am currently using Sonic Super Oil, an ISO48 grade synthetic oil sold for in-line skate bearings. The end result is that the platter speed is now significantly more consistent at +/-0.2% and wow has reduced from +/-0.08% to +/-0.04%. While I am pretty happy with these numbers I anticipate better results with higher viscosity oil and have some ISO22 synthetic oil on order.

I have read elsewhere that the bearing on these TT's can cause problems. It seems that over time, without proper regular maintenance, the ptfe composite bushings can become too tight. I would like to be able to accurately ream/hone/lap these bushings to achieve better clearances but this would require some fairly sophisticated gear/techniques without doing damage.

The PTFE bearings are intended for long life, keep them lubricated.

There are available graphite coated metal shell bearings for injection moulding mahines, they are shrunk in place using argon gas to contract them.

See if a similar product is available as a thrust bearing.

Ceramic bearings are also available, measure what you have, then look for one on line.

There are available graphite coated metal shell bearings for injection moulding mahines, they are shrunk in place using argon gas to contract them.

See if a similar product is available as a thrust bearing.

Ceramic bearings are also available, measure what you have, then look for one on line.

PTFE bearings/bushings are normally not lubricated. Not in the machines I know. There it is even in the service manuals not to do so.

PTFE bearings are almost universally described as self-lubricating, however, that doesn't mean lubricants can't be used and can actually improve performance.

SKF of Sweden says :

"PTFE composite bearings have good dry sliding characteristics and do not require lubrication. However, the presence or continuous supply of oil or other fluid may be advantageous." and goes on to say: "lubrication has a very favourable effect on the wear behaviour of the bearing and considerably extends bearing life."

SKF of Sweden says :

"PTFE composite bearings have good dry sliding characteristics and do not require lubrication. However, the presence or continuous supply of oil or other fluid may be advantageous." and goes on to say: "lubrication has a very favourable effect on the wear behaviour of the bearing and considerably extends bearing life."

OK that is 1 manufacturer of bearings. What oil do they recommend?

It is strange that manufacturers of machines with teflon bearings say not to lubricate them and a manufacturer of bearings says to lubricate them. The manufacturer of the machine does not benefit from defective machines. The manufacture of bearings will sell more bearings when they wear out faster🙂

It is strange that manufacturers of machines with teflon bearings say not to lubricate them and a manufacturer of bearings says to lubricate them. The manufacturer of the machine does not benefit from defective machines. The manufacture of bearings will sell more bearings when they wear out faster🙂

Last edited:

Problem is in description, there are many types of bearings, not all are pure PTFE, for example I had to find Delrin 500CL grade, for a tiny pneumatic cylinder, the CL stands for Chemically Lubricated, that particular grade contained some amount of PTFE, the rest was POM (Poly Oxy Methylene, or polyacetal, same type of compounds).

MoS2 is also added as a lubricant in Nylon compounds.

Teflon is weaker in wear in comparison to many plastic and metal materials, so it is used as either a thin coating, or as a blended material, and all have different characteristics, there are also brass bushes with dimples on the working surface coated with PTFE.

And they are mostly described with the PTFE part being prominent.

I would advise prospective buyers to take a close look, and decide if the product is worth obtaining, at times the part is cheap, the shipping is expensive.

PTFE wears out in lumpy particles, like sand, and so there is a benefit from lubrication washing away the waste material, but that is not always the case, I have seen it most as the pin in a reciprocating mechanism, which is not perfectly at right angles to the motion.

So lubrication is not always necessary, depends where the part is being used, and how.

MoS2 is also added as a lubricant in Nylon compounds.

Teflon is weaker in wear in comparison to many plastic and metal materials, so it is used as either a thin coating, or as a blended material, and all have different characteristics, there are also brass bushes with dimples on the working surface coated with PTFE.

And they are mostly described with the PTFE part being prominent.

I would advise prospective buyers to take a close look, and decide if the product is worth obtaining, at times the part is cheap, the shipping is expensive.

PTFE wears out in lumpy particles, like sand, and so there is a benefit from lubrication washing away the waste material, but that is not always the case, I have seen it most as the pin in a reciprocating mechanism, which is not perfectly at right angles to the motion.

So lubrication is not always necessary, depends where the part is being used, and how.

Sorry for the delay - I did not find the motor.I will have a look at the tantalums tomorrow.

The two tantalum caps as fitted on the pcb comply with the pcb print indication for polarity.

The schematic (post 29) is in accordance with the board.

I can check with another motor if necesary.

Thanks for that, it confirms what I am seeing as well. It just seems an unusual arrangement to me.

tiefbassuebertr also commented on the polarity of these two caps in his own schematic of the motor circuit in post #32 above.

tiefbassuebertr also commented on the polarity of these two caps in his own schematic of the motor circuit in post #32 above.

Yes, Tief writes "wrong polarity" in his lovely schematic, but

who is he to decide ? Papst sold thousands of motors like this.

The whole construction is "unusual". If in doubt I will apply

supply voltage and check it.

who is he to decide ? Papst sold thousands of motors like this.

The whole construction is "unusual". If in doubt I will apply

supply voltage and check it.

Last edited:

Yes, I agree, it's not really for others to decide.

As reyma noted in post #43 "We should be able to assume they knew what they were doing with the capacitor polarity"

As reyma noted in post #43 "We should be able to assume they knew what they were doing with the capacitor polarity"

I fired up the motor today and can confirm that the polarity of both tantalum

caps 10 and 11 is right, considering pcb print, actual mount and schematic.

Anyway, there is less than 1V dc on both caps (only one Vbe drop across 11).

caps 10 and 11 is right, considering pcb print, actual mount and schematic.

Anyway, there is less than 1V dc on both caps (only one Vbe drop across 11).

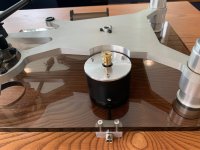

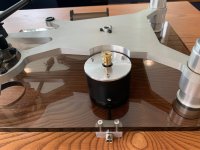

An update on where things are at with this turntable and motor:

- Motor : I finally gave up on the old Papst motor, there was nothing I could do to get it run at a consistent speed. Every time it was turned on it ran at a slightly different speed.

I replaced it with a 3 phase BLDC motor driven by a sine wave generator and 3 phase class D amp.

(www.diyaudio.com/community/threads/diy-4-phase-sinewave-generator-for-turntable-motor-drive.298018/ and www.diyaudio.com/community/threads/3-phase-class-d-amp-for-diy-bldc-motor-drive.307918/

The result is a very quiet, virtually vibration free and accurate solution. I am very happy with the end result.

- Turntable : After spending some time attempting to get the best out of the platter shaft and bearings I decided to replace the bearing bushes. It turns out they are fairly standard composite PTFE split bearing bushes. With some care it was possible to press the old bushes out and replace them. When I say "some care" it did involve fabricating specific mandrels for the task!

The advice with these type of bearings is that after a run-in period some of the PTFE will transfer to the shaft and performance will be optimized.

To measure relative friction levels I did some very basic tests which involved rotating the platter to 20 rpm then counting the number of revolutions before it stopped. With the original bushes lubricated with ISO 100 synthetic oil the platter would stop after 6 or 7 rev's. With the new bushes and no lubricant I was getting 4 - 5 rev's. Lubricating the bearing with 2.5ml of ISO 100 oil improved this to 20 - 21 rev's.

The other area I was concerned about was the condition of the captive ball in the shaft and the ceramic thrust plate in the bottom of the bearing - both were showing signs of wear. Despite my best efforts involving all sorts of solvents and the application of heat, I wasn't able to remove the ball. However, by gentle tapping the side of the ball with a light hammer and a brass punch I was able to rotate the ball in the socket moving the worn area to one side. I also replaced the thrust plate with an acetal disc the same dimensions as the original plate. I would have preferred Delrin but didn't have any to hand and thought, in this application, the difference would be minimal. After this the 20rpm to zero performance improved to 23 revolutions. I am now reasonably happy that I'm getting as much out of this bearing as reasonably practicable.

- Motor : I finally gave up on the old Papst motor, there was nothing I could do to get it run at a consistent speed. Every time it was turned on it ran at a slightly different speed.

I replaced it with a 3 phase BLDC motor driven by a sine wave generator and 3 phase class D amp.

(www.diyaudio.com/community/threads/diy-4-phase-sinewave-generator-for-turntable-motor-drive.298018/ and www.diyaudio.com/community/threads/3-phase-class-d-amp-for-diy-bldc-motor-drive.307918/

The result is a very quiet, virtually vibration free and accurate solution. I am very happy with the end result.

- Turntable : After spending some time attempting to get the best out of the platter shaft and bearings I decided to replace the bearing bushes. It turns out they are fairly standard composite PTFE split bearing bushes. With some care it was possible to press the old bushes out and replace them. When I say "some care" it did involve fabricating specific mandrels for the task!

The advice with these type of bearings is that after a run-in period some of the PTFE will transfer to the shaft and performance will be optimized.

To measure relative friction levels I did some very basic tests which involved rotating the platter to 20 rpm then counting the number of revolutions before it stopped. With the original bushes lubricated with ISO 100 synthetic oil the platter would stop after 6 or 7 rev's. With the new bushes and no lubricant I was getting 4 - 5 rev's. Lubricating the bearing with 2.5ml of ISO 100 oil improved this to 20 - 21 rev's.

The other area I was concerned about was the condition of the captive ball in the shaft and the ceramic thrust plate in the bottom of the bearing - both were showing signs of wear. Despite my best efforts involving all sorts of solvents and the application of heat, I wasn't able to remove the ball. However, by gentle tapping the side of the ball with a light hammer and a brass punch I was able to rotate the ball in the socket moving the worn area to one side. I also replaced the thrust plate with an acetal disc the same dimensions as the original plate. I would have preferred Delrin but didn't have any to hand and thought, in this application, the difference would be minimal. After this the 20rpm to zero performance improved to 23 revolutions. I am now reasonably happy that I'm getting as much out of this bearing as reasonably practicable.

Delrin is acetal homopolymer which was a DuPont brand.

Celcon by Celanese was acetal co-polymer.

Now both companies are only a small part of the total production, Japanese, Korean and Chinese producers make a lot more of the material.

Delrin is a headache to process, narrow temperature window, finicky about drying, smells even in normal moulding...and turns into 'tear gas' if overheated. Actually, it is poly formaldehyde by another name.

I have been using Japanese and Korean material since 1997, both copolymer and homopolymer are sold, at 10-25% lower price than Delrin, and they do not smell as much, and temperature range is more, so we can concentrate on article quality.

No ties, just personal experience.

Celcon by Celanese was acetal co-polymer.

Now both companies are only a small part of the total production, Japanese, Korean and Chinese producers make a lot more of the material.

Delrin is a headache to process, narrow temperature window, finicky about drying, smells even in normal moulding...and turns into 'tear gas' if overheated. Actually, it is poly formaldehyde by another name.

I have been using Japanese and Korean material since 1997, both copolymer and homopolymer are sold, at 10-25% lower price than Delrin, and they do not smell as much, and temperature range is more, so we can concentrate on article quality.

No ties, just personal experience.

- Home

- Source & Line

- Analogue Source

- Fixing or replacing a Papst GS 38.09 in a HK ST-8?