Maybe a silly question

taccodude, what kind of mains filter are you referring to?

EMI

Common Mode Noise

something else?

I feel like a complete noob asking, but I want to avoid making the same error. 😉

Last Night I found the Problem ,I tried a lot and found out that FO with SMPS doesn`t like a Main Filter in Front.

taccodude, what kind of mains filter are you referring to?

EMI

Common Mode Noise

something else?

I feel like a complete noob asking, but I want to avoid making the same error. 😉

What do you guys think of this heatsink?

I have been entertaining the possibility of piecing together my own chassis.

I like the Dissipante U3 chassis offered at the diyAudio store, however, I really like what Lazy Cat designed, esp in terms of size, specifically height. There is a good chance that I will be building more then one stereo amp. In fact, I can easily see having three to four power amps powering my dream 4.4 system. So for the sake of space and air circulation, I would prefer to find ways to lessen the height of my chassis.

I learned quite a bit about heatsinks from this article by Rod Elliott, ESP:

ESP - Heatsink design and transistor mounting

It is amazing how many heatsinks have the fins going the wrong way! 😱

I also came across a First One build in progress at HiFiDuino. Scroll about half way down, and there are some additional ideas about selecting heatsinks, esp estimating C/W or K/W visually using examples from fischerelektronik:

https://hifiduino.wordpress.com/category/amplification/

The main difference I see between the Dissipante 3U and Lazy's Chassis, is Lazy used a heatsink with higher fins which allows a slimmer chassis height.

As I can not find anything with a 300 mm length here in the US, I am limited to 250-260 mm, which means I need to consider atleast 100 mm overall chassis height - which is 30 mm less then the Dissipante height. Four chassis at 100 mm each (total 400 mm) is only 10 mm higher then three 3U dissipante at 130 each (total 390 mm). See where I am going?

I do know heatsink length is more effective then heatsink height, but with the First One mosfets being so centralized, is the length as effective?

Also, being the First One mosfets are so centralized, would this particular amp module benefit from a heatsink with a thicker baseplate? Not much is mentioned in the resources above about baseplate thickness.

I found a 260 X 200 mm heatsink on ebay, that looks really nice. My plan would be to cut it in half for two 260 X 100 mm pieces, one for each module. Note the 16 mm baseplate.

Here is the heatsink: There is a technical drawing - fourth picture

Aluminum Black Heat Sink Large 10 25" x 8 125" x 2 66" 11 275 lbs Large Mass | eBay

I have also been contemplating this heatsink:

10.080" Wide Extruded Aluminum Heatsink - HeatsinkUSA

Again, I would go 100 mm high. The down side to this heatsinkusa option, is it is not anodized.

I have also asked fischerelektronik for a quote for two heatsinks similar to the ones Lazy used. 🙂 Bit worried on price on that one.

Bear in mind also, that the front and back of the chassis I build will be 10 mm aluminium, which should add more area to the heatsinks. I am also contemplating 5 mm thick aluminium top and bottom perforated plates which will have 10 mm circular holes throughout.

Here is one possible source, although I have not shopped around much:

https://www.metalsdepot.com/

This will cost less the Dissapante when all is said and done, yet will requite some Tender Loving Care to manifest, so I will need to decide if:

A - the heatsink will indeed be effective for these modules

B - if the height reduction is worth this effort. I enjoy building things, so this is less of a concern.

Thoughts anyone?

I hope someone else viewing this thread finds the above resources helpful for their builds. 😀

Thanks for bearing thru my long post!

Allen 😉

I have been entertaining the possibility of piecing together my own chassis.

I like the Dissipante U3 chassis offered at the diyAudio store, however, I really like what Lazy Cat designed, esp in terms of size, specifically height. There is a good chance that I will be building more then one stereo amp. In fact, I can easily see having three to four power amps powering my dream 4.4 system. So for the sake of space and air circulation, I would prefer to find ways to lessen the height of my chassis.

I learned quite a bit about heatsinks from this article by Rod Elliott, ESP:

ESP - Heatsink design and transistor mounting

It is amazing how many heatsinks have the fins going the wrong way! 😱

I also came across a First One build in progress at HiFiDuino. Scroll about half way down, and there are some additional ideas about selecting heatsinks, esp estimating C/W or K/W visually using examples from fischerelektronik:

https://hifiduino.wordpress.com/category/amplification/

The main difference I see between the Dissipante 3U and Lazy's Chassis, is Lazy used a heatsink with higher fins which allows a slimmer chassis height.

As I can not find anything with a 300 mm length here in the US, I am limited to 250-260 mm, which means I need to consider atleast 100 mm overall chassis height - which is 30 mm less then the Dissipante height. Four chassis at 100 mm each (total 400 mm) is only 10 mm higher then three 3U dissipante at 130 each (total 390 mm). See where I am going?

I do know heatsink length is more effective then heatsink height, but with the First One mosfets being so centralized, is the length as effective?

Also, being the First One mosfets are so centralized, would this particular amp module benefit from a heatsink with a thicker baseplate? Not much is mentioned in the resources above about baseplate thickness.

I found a 260 X 200 mm heatsink on ebay, that looks really nice. My plan would be to cut it in half for two 260 X 100 mm pieces, one for each module. Note the 16 mm baseplate.

Here is the heatsink: There is a technical drawing - fourth picture

Aluminum Black Heat Sink Large 10 25" x 8 125" x 2 66" 11 275 lbs Large Mass | eBay

I have also been contemplating this heatsink:

10.080" Wide Extruded Aluminum Heatsink - HeatsinkUSA

Again, I would go 100 mm high. The down side to this heatsinkusa option, is it is not anodized.

I have also asked fischerelektronik for a quote for two heatsinks similar to the ones Lazy used. 🙂 Bit worried on price on that one.

Bear in mind also, that the front and back of the chassis I build will be 10 mm aluminium, which should add more area to the heatsinks. I am also contemplating 5 mm thick aluminium top and bottom perforated plates which will have 10 mm circular holes throughout.

Here is one possible source, although I have not shopped around much:

https://www.metalsdepot.com/

This will cost less the Dissapante when all is said and done, yet will requite some Tender Loving Care to manifest, so I will need to decide if:

A - the heatsink will indeed be effective for these modules

B - if the height reduction is worth this effort. I enjoy building things, so this is less of a concern.

Thoughts anyone?

I hope someone else viewing this thread finds the above resources helpful for their builds. 😀

Thanks for bearing thru my long post!

Allen 😉

Hi Allen

If you would be using SMPS1200A400, no additional mains filter is needed, onboard filter already present and serves the purpose very well, since there's no sign of any HF disturbances on any appliances anywhere I use or brought my amps. Also vice versa no mobile phone could disturb or inject HF to either SMPS or First One PCB alone to modulate with symptomatic annoying buzz sound. Connect everything as per User manual schematic, no brainer and it works.

Regarding heatsinks, simple rule of thumb in all cases it has to be 0,5K/W max. and the wider it is, the thicker base plate it has to have. Since I like slim cases SK157 was my preferred choice and SK519 for monoblock chassis. Check the prices at Fischer Elektronik, I think they'll be competitive also in US.

Regards, L.C.

If you would be using SMPS1200A400, no additional mains filter is needed, onboard filter already present and serves the purpose very well, since there's no sign of any HF disturbances on any appliances anywhere I use or brought my amps. Also vice versa no mobile phone could disturb or inject HF to either SMPS or First One PCB alone to modulate with symptomatic annoying buzz sound. Connect everything as per User manual schematic, no brainer and it works.

Regarding heatsinks, simple rule of thumb in all cases it has to be 0,5K/W max. and the wider it is, the thicker base plate it has to have. Since I like slim cases SK157 was my preferred choice and SK519 for monoblock chassis. Check the prices at Fischer Elektronik, I think they'll be competitive also in US.

Regards, L.C.

Hi PAX1

Perfect dual-mono with linear PSU, congratulations. Hopefully fans are silent ones with temperature on switch, maybe even with speed control. Calibration check would be easy since modules are in horizontal position, certainly perform measurements after heatsinks gets warm to app. 40-45°C.

Do not spare us with sound quality report of course after burn-in period is over.

Regards, L.C.

Perfect dual-mono with linear PSU, congratulations. Hopefully fans are silent ones with temperature on switch, maybe even with speed control. Calibration check would be easy since modules are in horizontal position, certainly perform measurements after heatsinks gets warm to app. 40-45°C.

Do not spare us with sound quality report of course after burn-in period is over.

Regards, L.C.

Thanks Lazy

It is always great hearing from the master himself! - the nugget being "the wider [a heatsink] is, the thicker base plate it has to have.

The irony of this "truth" Lazy has shared, is that many of the heat sinks available, the ones at 250 mm have thicker base plates then the ones at 300 mm!.. ...The ones at 400 mm are thinner still! 😱 (the higher end fischers have thicker plates - second link)

SK 479, Standard extruded heatsinks, Heatsinks f.cool, Fischer Elektronik

http://www.fischerelektronik.de/web...dard extruded heatsinks/PR/SK533_/index.xhtml

The good news, is SK 622 at Fischer has similar dimensions to the Ebay heatsink above. (The ebay one has taller fins)

http://www.fischerelektronik.de/web...dard extruded heatsinks/PR/SK622_/index.xhtml

At the 100 mm target height of my chassis, the K/W of this heatsink comes in 0,48. The heatsinkUSA option above would be very similar also... So, this is doable, but I would not mind trying for a lower K/W - a little overkill as a safety margin. 😉

It looks like the Dissapante uses something similar to SK 501. That being the case, I could get the 2U chassis and have a K/W of 0,44, out preforming both hand made options I have so far - 90 mm of overall height in a pre-assembled chassis. The 3U would be closer to the spec of 0,4 K/W, which Lazy designed his chassis. I do not want to jump to any conclusions here, as I need to investigate this farther.

I will keep You posted on my progress...

Regarding heatsinks, simple rule of thumb in all cases it has to be 0,5K/W max. and the wider it is, the thicker base plate it has to have.

It is always great hearing from the master himself! - the nugget being "the wider [a heatsink] is, the thicker base plate it has to have.

The irony of this "truth" Lazy has shared, is that many of the heat sinks available, the ones at 250 mm have thicker base plates then the ones at 300 mm!.. ...The ones at 400 mm are thinner still! 😱 (the higher end fischers have thicker plates - second link)

SK 479, Standard extruded heatsinks, Heatsinks f.cool, Fischer Elektronik

http://www.fischerelektronik.de/web...dard extruded heatsinks/PR/SK533_/index.xhtml

The good news, is SK 622 at Fischer has similar dimensions to the Ebay heatsink above. (The ebay one has taller fins)

http://www.fischerelektronik.de/web...dard extruded heatsinks/PR/SK622_/index.xhtml

At the 100 mm target height of my chassis, the K/W of this heatsink comes in 0,48. The heatsinkUSA option above would be very similar also... So, this is doable, but I would not mind trying for a lower K/W - a little overkill as a safety margin. 😉

It looks like the Dissapante uses something similar to SK 501. That being the case, I could get the 2U chassis and have a K/W of 0,44, out preforming both hand made options I have so far - 90 mm of overall height in a pre-assembled chassis. The 3U would be closer to the spec of 0,4 K/W, which Lazy designed his chassis. I do not want to jump to any conclusions here, as I need to investigate this farther.

I will keep You posted on my progress...

Last edited:

If my above assumptions are right:

I could go with the 2U Dissapante 400 mm chassis. I need to contact diyAudio to see if the base of those heatsinks are larger, so I know those heat sinks will radiate effectively for the centrally located FO modules. The 400 mm width at eh 2U height "appears" to have a K/W of 0,4. That would be the ticket right there...

I could go with the 2U Dissapante 400 mm chassis. I need to contact diyAudio to see if the base of those heatsinks are larger, so I know those heat sinks will radiate effectively for the centrally located FO modules. The 400 mm width at eh 2U height "appears" to have a K/W of 0,4. That would be the ticket right there...

Still looking...

Jason has just posted the heatsink specs for the diyAudio chassis:

40mm Heatsink Information – diyAudio Store (BETA)

The 400 mm chassis uses two pairs of 200 mm heatsinks glued? together. Of course, this raises another question: does joining the two heatsinks together actually lower the C/W rating?

Based on the heatsink information provided by Jason, it does not. The 400 mm 5U chassis uses two 200 x 210 heatsinks rated @ 0.28 C/W each. When joined together to 400 mm, they are still rated @ 0.28 C/W. 🙁

So the 2U 400 mm chassis is not going to work being rated at 0.68 C/W.

The 2U 300 mm chassis is rated at 0.45 C/W, however, another diyAudio member was kind enough to share that he needed active cooling with his First One project using the modushop version of this chassis. 😱 I would prefer not to go that route.

Jason also reported that the base plate thickness for their heatsinks is 8 mm. Most of the other heatsinks I have researched are at least 10 mm. I have a feeling base thickness is important for the First One Modules, as the output stages are so centralized, compared to the Nelson Pass designs (which seems to be the market for the diyAudio chassis). This could also explain why one would need additional active cooling even though the heatsink is rated at 0.45 C/W.

In light of this new information, I am not sure if even the higher chassis (3U), as nicely crafted as they are, are the best match for the First One Design...

Also looking into US Fischerelectronik distributors: CTrends or Espectro Technologies. I am just... aaaa... Allen. - Not a Fortune 500 company who wants to buy one million parts of SK 157! 😱

We will see where this goes...

Jason has just posted the heatsink specs for the diyAudio chassis:

40mm Heatsink Information – diyAudio Store (BETA)

The 400 mm chassis uses two pairs of 200 mm heatsinks glued? together. Of course, this raises another question: does joining the two heatsinks together actually lower the C/W rating?

Based on the heatsink information provided by Jason, it does not. The 400 mm 5U chassis uses two 200 x 210 heatsinks rated @ 0.28 C/W each. When joined together to 400 mm, they are still rated @ 0.28 C/W. 🙁

So the 2U 400 mm chassis is not going to work being rated at 0.68 C/W.

The 2U 300 mm chassis is rated at 0.45 C/W, however, another diyAudio member was kind enough to share that he needed active cooling with his First One project using the modushop version of this chassis. 😱 I would prefer not to go that route.

Jason also reported that the base plate thickness for their heatsinks is 8 mm. Most of the other heatsinks I have researched are at least 10 mm. I have a feeling base thickness is important for the First One Modules, as the output stages are so centralized, compared to the Nelson Pass designs (which seems to be the market for the diyAudio chassis). This could also explain why one would need additional active cooling even though the heatsink is rated at 0.45 C/W.

In light of this new information, I am not sure if even the higher chassis (3U), as nicely crafted as they are, are the best match for the First One Design...

Also looking into US Fischerelectronik distributors: CTrends or Espectro Technologies. I am just... aaaa... Allen. - Not a Fortune 500 company who wants to buy one million parts of SK 157! 😱

We will see where this goes...

Last edited:

Artsy,

I am no expert on heat sinks but I think a few things you need to consider are that the base thickness increase really has a limitation in that it is what it sounds like, it sinks the heat and at some point it will just get hotter and hotter. It is the surface area of the fins that is dissipating the heat that you are trying to remove. You are better off with taller or more fins than adding more mass in the base of the sink. You want to remove the heat not heat soak a large mass over time. Surface area is your friend much more than mass. If you want to spread the heat out over a larger surface area use a copper sub plate between the output devices and the aluminum heat sink, that will spread the heat faster over a wider area and make it more effective.

I am no expert on heat sinks but I think a few things you need to consider are that the base thickness increase really has a limitation in that it is what it sounds like, it sinks the heat and at some point it will just get hotter and hotter. It is the surface area of the fins that is dissipating the heat that you are trying to remove. You are better off with taller or more fins than adding more mass in the base of the sink. You want to remove the heat not heat soak a large mass over time. Surface area is your friend much more than mass. If you want to spread the heat out over a larger surface area use a copper sub plate between the output devices and the aluminum heat sink, that will spread the heat faster over a wider area and make it more effective.

Hi Allen,

There are a couple of things that I don't think you have got right and they are causing you some headaches!

The First thing is that these amps are going to run hot in comparison to many amplifiers that people have bought before. LC actually wants the heatsink to stabilise at about 45 degrees with idle dissipation which is why the spec for the heatsink is at 0.5c/w maximum per module. The 0.45C/W of the 2U modushop chassis is actually very close to ideal.

I don't know who told you they needed active cooling with those heatsinks but I think they have the wrong idea about how hot these amps are meant to be or they have an implementation issue. LC specified thin kapton washers to be used as these will allow maximum heat transfer, this is important.

As Kindhornman said don't get too hung up on the base plate thickness. That is useful information that LC provided but the C/W rating is what you need to look for.

I think the information from diyaudio is confusing you about the modushop heatsinks each 210 x 200mm heatsink is rated at 0.28 C/W. That means you could use two First One modules per 210 x 200 sink which is four per side. This is the information on the heatsinks from the modushop site where they are all listed Dissipatori

Adding two 0.28C/W modules together doesn't give a single 0.14C/W heatsink but it does give you 2 x 0.28C/W heatsinks if this makes sense.

I have built a 4 channel module for use with active amplifiers and used two modules per heatsink that were 110mm x 300mm. I used the lower voltage Hypex supply but they still use a lot of idle current. At idle these amplifiers are already putting out most of the heat, they don't get that much hotter as the power is increased.

http://www.diyaudio.com/forums/vendors-bazaar/248996-first-one-mosfet-amplifier-module-183.html#post4261200

There are a couple of things that I don't think you have got right and they are causing you some headaches!

The First thing is that these amps are going to run hot in comparison to many amplifiers that people have bought before. LC actually wants the heatsink to stabilise at about 45 degrees with idle dissipation which is why the spec for the heatsink is at 0.5c/w maximum per module. The 0.45C/W of the 2U modushop chassis is actually very close to ideal.

I don't know who told you they needed active cooling with those heatsinks but I think they have the wrong idea about how hot these amps are meant to be or they have an implementation issue. LC specified thin kapton washers to be used as these will allow maximum heat transfer, this is important.

As Kindhornman said don't get too hung up on the base plate thickness. That is useful information that LC provided but the C/W rating is what you need to look for.

I think the information from diyaudio is confusing you about the modushop heatsinks each 210 x 200mm heatsink is rated at 0.28 C/W. That means you could use two First One modules per 210 x 200 sink which is four per side. This is the information on the heatsinks from the modushop site where they are all listed Dissipatori

Adding two 0.28C/W modules together doesn't give a single 0.14C/W heatsink but it does give you 2 x 0.28C/W heatsinks if this makes sense.

I have built a 4 channel module for use with active amplifiers and used two modules per heatsink that were 110mm x 300mm. I used the lower voltage Hypex supply but they still use a lot of idle current. At idle these amplifiers are already putting out most of the heat, they don't get that much hotter as the power is increased.

http://www.diyaudio.com/forums/vendors-bazaar/248996-first-one-mosfet-amplifier-module-183.html#post4261200

does joining the two heatsinks together actually lower the C/W rating?

Of course, for mine 400mm chassis I've put thermal paste between the two heatsinks.

Also the FirstOne module is placed in the middle of the heatsinks, so each heatsink has one mosfet.

See PDF for correct dissipation figures.

My heatsinks from Hifi2000 have a curved surface, so the surface area is larger than their size.

Attachments

Im considering testing your amp module, but i need balanced innput. Can i just use 2 modules for each channel to get a balanced innput ?

Thanks guys to help Allen, very valuable advices about heatsinking. It' true that modules dissipate quite a lot at idle just to get W or two in Class A, but as we all know first W is very important. And yes, I want the modules to be at 45 deg C at idle since all the parts at this temp gives best of their gain factors, so it's kinda electronic sweet spot. Hard driving 4 Ohm speakers raise the power dissipation greatly so low Rth needed, which is of course in direct relation with heatsink's surface.

Hi Leikis

Yes of course, two modules and lower supply voltage is the recipe, so an output current stays within mosfet's limit, which is 16 A. You could also use only one First One module and Lundahl, Jensen or any other balanced input transformers or even OP amp un/balanced driver, the choice is upon you. Still, two modules in balanced mode gives that a little bit extra, worth to try.

L.C.

Yes of course, two modules and lower supply voltage is the recipe, so an output current stays within mosfet's limit, which is 16 A. You could also use only one First One module and Lundahl, Jensen or any other balanced input transformers or even OP amp un/balanced driver, the choice is upon you. Still, two modules in balanced mode gives that a little bit extra, worth to try.

L.C.

I think two modules will be best since everything i haven like some power 🙂 what toroid ac you recomend when using two modules together ?

Listening impressions

Hi guys

Anyone finished First One amp, already installed it in a system?

Show what's in the system, please tell us more about your listening impressions.

Thanks, L.C.

Hi guys

Anyone finished First One amp, already installed it in a system?

Show what's in the system, please tell us more about your listening impressions.

Thanks, L.C.

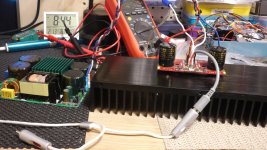

Hello all,

Here are few early pictures of my testing the FO modules this morning early. With very limited time on my bench but they sound so sweeeeeeet. And I haven't adjusted anything yet! I may not they sound so good. Just made sure there was no DC on the output. I'm using the SMPS800RE x 2 from Connexelectronic. Been very happy with his SMPSs over the years. True quality builds.

More testing and pics of my 'first' FO amp build to come. 🙂

Rick

Here are few early pictures of my testing the FO modules this morning early. With very limited time on my bench but they sound so sweeeeeeet. And I haven't adjusted anything yet! I may not they sound so good. Just made sure there was no DC on the output. I'm using the SMPS800RE x 2 from Connexelectronic. Been very happy with his SMPSs over the years. True quality builds.

More testing and pics of my 'first' FO amp build to come. 🙂

Rick

Attachments

Super Rick

Maybe what I miss in all discussions are the plans to use First One modules in a discarded cases of broken amps, maybe in some well known vintage amps with big VU-meters, gorgeous chassis with handles. You could easily bring those nice looking amps back to life just by installing SMPS and FO modules inside, all other things like heatsinks, terminals, chassis, front plates with indicators and switches, etc. are there. That for me would give even more pleasure than just making an amp from the scratch.

Maybe what I miss in all discussions are the plans to use First One modules in a discarded cases of broken amps, maybe in some well known vintage amps with big VU-meters, gorgeous chassis with handles. You could easily bring those nice looking amps back to life just by installing SMPS and FO modules inside, all other things like heatsinks, terminals, chassis, front plates with indicators and switches, etc. are there. That for me would give even more pleasure than just making an amp from the scratch.

Super Rick

Maybe what I miss in all discussions are the plans to use First One modules in a discarded cases of broken amps, maybe in some well known vintage amps with big VU-meters, gorgeous chassis with handles. You could easily bring those nice looking amps back to life just by installing SMPS and FO modules inside, all other things like heatsinks, terminals, chassis, front plates with indicators and switches, etc. are there. That for me would give even more pleasure than just making an amp from the scratch.

Extremely good idea.

And probably very much cheaper than ordering new chassis, terminals etc.

- Home

- Vendor's Bazaar

- First One - mosFET amplifier module