@mdpaudio : hi,

What is gauge magnet wire, please ? Any illustration. Not sure such a thing is easy to find where I am for less than an air coil or at least I do not understand what you descfribe exactly bt lack of technical culture.

I have been purchased this week a little LC with autocalibration. It is low cost and make only Henri measurement at 15k hz and 750 hz band at 2.5V. I measure the DCR of the coil with a simple DVM two digits, not sure precision is ggod enough to sort out two coils resistance.

What is gauge magnet wire, please ? Any illustration. Not sure such a thing is easy to find where I am for less than an air coil or at least I do not understand what you descfribe exactly bt lack of technical culture.

I have been purchased this week a little LC with autocalibration. It is low cost and make only Henri measurement at 15k hz and 750 hz band at 2.5V. I measure the DCR of the coil with a simple DVM two digits, not sure precision is ggod enough to sort out two coils resistance.

When hyper precise FM tuner where build by real masters of the art. No one cared about foil, wax or liz coils, as there was nothing to gain there. They used the right part, air coil or ferrite core, at the correct position. This was with high frequency!

Now the clever marketing of Munsdorp an Co. has made low frequency coils so expensive, that the passive x-over often cost's more than the high end speaker chassis used. Just the same with capacitors and resistors. Only profit optimisation on the oldest and most basic and simple parts we have in electronics. Snake oiled voodoo at it's best. The profits made on x-over boutique parts are far multiples of what chassis manufacturers, which do a lot of expensive research, make.

When an air coil is too large to use, take a ferrite core. They are fine until too much current is used, then distortion starts.

It is a very simple calculation what to use at which point.

If we look in most expensive commercial speakers we often find very basic industrial parts in the x-over. That is what I use. solid industrial quality at resonable cost. If you feel better with silver-gold-oil filled parts, make yourself happy.

Now the clever marketing of Munsdorp an Co. has made low frequency coils so expensive, that the passive x-over often cost's more than the high end speaker chassis used. Just the same with capacitors and resistors. Only profit optimisation on the oldest and most basic and simple parts we have in electronics. Snake oiled voodoo at it's best. The profits made on x-over boutique parts are far multiples of what chassis manufacturers, which do a lot of expensive research, make.

When an air coil is too large to use, take a ferrite core. They are fine until too much current is used, then distortion starts.

It is a very simple calculation what to use at which point.

If we look in most expensive commercial speakers we often find very basic industrial parts in the x-over. That is what I use. solid industrial quality at resonable cost. If you feel better with silver-gold-oil filled parts, make yourself happy.

About a sorta rule of thumb about filter coils construction and in order of importance :

A) : lowest DCR, good enough for disto at average spl and time to time hgher spl : iron ferous cores (no sintered ferites) above 1 mH ?

B) : for < 1mH or tweeter shunt coils: air coils with higher diameter wire to lowish impedance ? Or simple i-core with ferite, good enough (i.e. : if they distorss only at highish spll only) ?

I let apart the discussion about foil core.

We often talk aboutt gauge size related to the RMS max. What is the need here with low efficienty drivers/filter combo, please.?1.4 mm diameter ? More ? Proof for 3000 W RMS amps with low efficienty drivers <= 86 db/2.83V ? Which is covering the peaks demands without too much hearable disto ?

As far I understand most of t<he good enough iron core are not distorsing at spl home level, so the ferrous core coil are good enough with the good plus of low DCR. Air coils a plus for // with the drivers : serie LCR, or high pass of some drivers like mid or tweeter ?

A) : lowest DCR, good enough for disto at average spl and time to time hgher spl : iron ferous cores (no sintered ferites) above 1 mH ?

B) : for < 1mH or tweeter shunt coils: air coils with higher diameter wire to lowish impedance ? Or simple i-core with ferite, good enough (i.e. : if they distorss only at highish spll only) ?

I let apart the discussion about foil core.

We often talk aboutt gauge size related to the RMS max. What is the need here with low efficienty drivers/filter combo, please.?1.4 mm diameter ? More ? Proof for 3000 W RMS amps with low efficienty drivers <= 86 db/2.83V ? Which is covering the peaks demands without too much hearable disto ?

As far I understand most of t<he good enough iron core are not distorsing at spl home level, so the ferrous core coil are good enough with the good plus of low DCR. Air coils a plus for // with the drivers : serie LCR, or high pass of some drivers like mid or tweeter ?

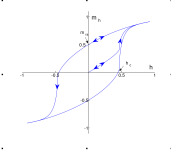

There's two types of distortion associated with the core materials. I'm assuming you're referring to saturation distortion, which only occurs when a large enough current flows through the inductor, and likely won't happen at home SPL as you say. But there is also hysteresis distortion, as it takes an amount of energy to flip the magnetic polarisation on the core material. This energy can be pictured as the area under the signal power curve, when you have a low frequency there is a long period t, and so a large area occurs, for a high frequency there is a small area, assuming both signals have the same RMS power. So the proportion of energy being used to counteract hysteresis increases with frequency and therefore waveform distortion, the area in the hysteresis loop is analogous to the energy lost as heat. This is in addition to the nonlinear magnetic response to the field being generated by the inductor wire, as the coercivity of the magnetic material causes the magnetization of the core material to be opposite that of the input signal, up until the coil field is more than the coercive field required to flip the polarisation. Air cores don't have either the saturation or hysteresis issues, air is paramagnetic so linear magnetization with external field, ideal as long is you ignor the lower susceptibility of air, thereby requiring a longer wire for the same inductance, so cored are much better for low freq applications.As far I understand most of t<he good enough iron core are not distorsing at spl home level, so the ferrous core coil are good enough with the good plus of low DCR.

In the image H represents the field provided by the coil and M represents the magnetization aka the field generated in the material as a response to H. Hc- coercive field and Mrs- remenant magnetization at zero external field H.

Attachments

Last edited:

The rules of thumb are more like this:

See also this guide from Troels

- for mid and tweeter use only air core coils, DCR is of less importance, you probably need to attenuate the mid and tweeter

- for woofers use coils with lowest DCR, gives better damping factor, good ones are for example the Jantzen c-coils

See also this guide from Troels

Well, by comparison changing to air coil increases inter-turn capacitance as a design factor.Iron core (any) is to be avoided at all cost as I see it.

Enameled Copper wire, is a more common name for "magnet wire", fairly easily available everywhere wether cheap from China with recycled copper, or expensive materials made in Germany.@mdpaudio : hi,

What is gauge magnet wire, please ? Any illustration. Not sure such a thing is easy to find where I am for less than an air coil or at least I do not understand what you descfribe exactly bt lack of technical culture.

I have been purchased this week a little LC with autocalibration. It is low cost and make only Henri measurement at 15k hz and 750 hz band at 2.5V. I measure the DCR of the coil with a simple DVM two digits, not sure precision is ggod enough to sort out two coils resistance.

The enamel insulation is much thinner which is needed for a tight winding. Also the enamel tolerates more heat then normal insulation materials, even beats teflon insulation with its usual 180 deg celsius rating.

Air coils is usually the best option, but for LF use they get big, heavy and expensive if you need a low DCR. 4mm2 or larger wire does it usually, but it is no longer small, or suited for a small XO PCB or similar.

A laminated core tends to be better distortion-wise, as they are harder to saturate than simple ferrite pot cores.

Toroidal cores don't tend to be great either.

And despite all the fanciful 'audiophile' marketing, producers generally don't specify distortion, hysteresis, saturation information etc.

There is of course differences in quality of design and product between mfgs. and product series etc.

Since Litz wire is pretty much useless for the hearable audio band (to 20k). And give more capacitive effects, due to the much larger amount of insulation and multiple wires, also gets bigger and distorts more easily generally, because of the lack of winding tightness due to extra insulation.

Larger diameter wires for tweeters is pretty much wasted unless you need low DCR, depending on the XO frequency.

Check a Skin depth calculator and you will see what i mean.

A 1,5 khz signal have "roughly a skin depth of 1,5mm, while a 20khz ca 0,5 mm using 'standard values for copper resistivity and so on. Depends on material, purity, temperature of course.

Of all the components we use for passive XOs the inductors, from an electrical standpoint at least, is the least 'ideal components'.

clearly air coils better than core coils as already described. From personal experience air foils coils sound best eg mundorf.it is more important in tweeter circuit . For bass core coils are a necessary evil. Take your pick.enjoy the journey

The rules of thumb are more like this:

- for mid and tweeter use only air core coils, DCR is of less importance, you probably need to attenuate the mid and tweeter

- for woofers use coils with lowest DCR, gives better damping factor, good ones are for example the Jantzen c-coils

See also this guide from Troels

I read it, just the thing I don't understand here at chosing the DCR of the coil as a part of the spl attenuation for the mid or the treble is : which DCR I choose from the coil as it changes with the frequency in its filter pass band. For instance I have an steel I-core coil which DCR is 0.3 ohms at 100 hz and 0.8 ohms at 1500 hz. So if used at a woofer/midrange low pass, which number do you take here ?

Does the low DCR of a coil in high pass at relative low frequency for midranges with more than second order high pass (the // coil with the driver) matters also ? With for instance a high pass at 200 hz, the dynamic behavior of an iron core coil not better thanks to the very low DCR ?

As HEEXA said, most of the time the coil will not saturate that much at home level ?! I also wonder cause most of passive filter area in loudspeakers is tinny and air coil exhibit much more magnetic field and coupling with the often neighoor coils that are at less than 5 cm gap ? Trade offs ?

clearly air coils better than core coils as already described. From personal experience air foils coils sound best eg mundorf.it is more important in tweeter circuit . For bass core coils are a necessary evil. Take your pick.enjoy the journey

Well Mundorf... if needing something between 1.2 mH and 1.5 mH, good luck ! And unwinding a foil core or a baked i-core is likely to mess the expensive coil !

I don not understand why Mundorf has so few little choice in coils Henri values !

You seem to choose between DCR or iron core hysteresis... hysteresis is one of the worst distortion types there is. The added DCR has only temperature problem at most. Try to get rid of your boutique desires and invest in thick big air coils if you really need them - and your DCR problems is mostly gone. Mundorf love is love of looks and feeling... which is not necessarily wrong if its for the right reasons... 😉

//

//

I have a suspicion wire at the corners would be effected differently inductively speaking, more concentrated flux. It would be interesting to test.Has anyone marketed square wire wound coils yet?

Only if volume vs resistance is of importance - like in a voice coil... For a x-over inductor... hopefully not to the same extent... at all.

//

//

Surely some quartzite crystals could be added to alleviate any stray earthly polarizing spectral fields from dominating the upper harmonic infractions.

- Home

- Loudspeakers

- Multi-Way

- filter coils quality