I have tried more than once with felt in baffle. Maybe felt was not thick enough. To memory it was 4-5 mm hard pure wool. Whole baffle covered - that had optimized facets.

My conclusion is that a proper HARD/non-absorbing surface is the Way to go. I have no longer the measurements - but Can say without wool measered better.

Drivers should be flush to baffle.

If a grill is used felt Can improve frq. So I like to use felt in some instances.

My conclusion is that a proper HARD/non-absorbing surface is the Way to go. I have no longer the measurements - but Can say without wool measered better.

Drivers should be flush to baffle.

If a grill is used felt Can improve frq. So I like to use felt in some instances.

I can only speak in general, but I believe all the following are valid.

1. Any hard edge that is greater than a fraction of a given wavelength (usually 1/4 wave) at a given frequency, that is in the direct radiation path, is likely to cause diffraction.

2. Most felt treatments -- probably -- are insufficient to adequately address the issue of diffraction at all, or at the most important, frequencies. Consider that the human ear is most sensitive at the range (approx) 300 Hz to 3 KHz. At lower frequencies, those longer wavelengths are into the 6"-12" range. This, in part, explains the extreme rounding that some cabinet makers use for their speakers. Sorry to break the news to you fellas, but even a 1/4" ring of top quality felt made from the hair of unicorns won't do very much for you. On the other hand, such tweaks are rarely all or nothing; it's more likely that some incremental improvement might result, but it might be far from the optimum.

Corollary: adding felt on the surface of a flat cabinet, or on edges not in the direct radiation path, are probably of limited value. Even if they were, the wavelengths involved dictate that the felt would need to be rather deep (inches), not a fraction of an inch, to have much effect.

For further reading: although the application is quite different, consider some of the issues and proposed solutions with horns/waveguides: the "towel mod" and the Geddes foam plug. There may be some overlap in potential application with direct radiators.

Note the even flush mounting your drivers won't save you; you still have a sharp edge (transition from "horn" to open air.)

Although it will definitely work against neat cabinet appearance, I hazard that smaller versions of the "towel mod" may have a beneficial effect: a "fuzzy" ring around a midrange or tweeter would be a prime candidate for experimentation. Note that it "should" partially extend into the open space and thus the direct sound path. Even though a typical direct radiator is not normally thought of as a horn, most of them are in fact cone shaped and thus will have some undesired resonances. One of the arguments for the towel

mod is that it provides a smoother transition than the usual hard termination at the horn mouth. Strictly speaking the towel mod alleviates the cavity resonance issue of a horn. I see no reason why this wouldn't work on a smaller cone speaker.

I suspect this may be one of those trade-offs: You can have a nice rectangular box with an attractive grill on the front, or you can have something that looks like a mouse nest glued onto the front baffle, but you probably can't have both 🙂

1. Any hard edge that is greater than a fraction of a given wavelength (usually 1/4 wave) at a given frequency, that is in the direct radiation path, is likely to cause diffraction.

2. Most felt treatments -- probably -- are insufficient to adequately address the issue of diffraction at all, or at the most important, frequencies. Consider that the human ear is most sensitive at the range (approx) 300 Hz to 3 KHz. At lower frequencies, those longer wavelengths are into the 6"-12" range. This, in part, explains the extreme rounding that some cabinet makers use for their speakers. Sorry to break the news to you fellas, but even a 1/4" ring of top quality felt made from the hair of unicorns won't do very much for you. On the other hand, such tweaks are rarely all or nothing; it's more likely that some incremental improvement might result, but it might be far from the optimum.

Corollary: adding felt on the surface of a flat cabinet, or on edges not in the direct radiation path, are probably of limited value. Even if they were, the wavelengths involved dictate that the felt would need to be rather deep (inches), not a fraction of an inch, to have much effect.

For further reading: although the application is quite different, consider some of the issues and proposed solutions with horns/waveguides: the "towel mod" and the Geddes foam plug. There may be some overlap in potential application with direct radiators.

Note the even flush mounting your drivers won't save you; you still have a sharp edge (transition from "horn" to open air.)

Although it will definitely work against neat cabinet appearance, I hazard that smaller versions of the "towel mod" may have a beneficial effect: a "fuzzy" ring around a midrange or tweeter would be a prime candidate for experimentation. Note that it "should" partially extend into the open space and thus the direct sound path. Even though a typical direct radiator is not normally thought of as a horn, most of them are in fact cone shaped and thus will have some undesired resonances. One of the arguments for the towel

mod is that it provides a smoother transition than the usual hard termination at the horn mouth. Strictly speaking the towel mod alleviates the cavity resonance issue of a horn. I see no reason why this wouldn't work on a smaller cone speaker.

I suspect this may be one of those trade-offs: You can have a nice rectangular box with an attractive grill on the front, or you can have something that looks like a mouse nest glued onto the front baffle, but you probably can't have both 🙂

Last edited:

You make a great point about the depth of the felt and the frequency that it can slow down/reduce... I wonder if there is any math behind that, if we look at wavelength distance for frequencies to be amplified/nulled maybe there is an amplitude/frequency for depth! In other words maybe 1/4 felt at 1000 hz would dampen it at 85db but not at 95 db? Maybe felt at a lower frequency would need deeper felt all together and what is that depth, maybe I'll try it when I get my felt!I can only speak in general, but I believe all the following are valid.

1. Any hard edge that is greater than a fraction of a given wavelength (usually 1/4 wave) at a given frequency, that is in the direct radiation path, is likely to cause diffraction.

2. Most felt treatments -- probably -- are insufficient to adequately address the issue of diffraction at all, or at the most important, frequencies. Consider that the human ear is most sensitive at the range (approx) 300 Hz to 3 KHz. At lower frequencies, those longer wavelengths are into the 6"-12" range. This, in part, explains the extreme rounding that some cabinet makers use for their speakers. Sorry to break the news to you fellas, but even a 1/4" ring of top quality felt made from the hair of unicorns won't do very much for you. On the other hand, such tweaks are rarely all or nothing; it's more likely that some incremental improvement might result, but it might be far from the optimum.

Corollary: adding felt on the surface of a flat cabinet, or on edges not in the direct radiation path, are probably of limited value. Even if they were, the wavelengths involved dictate that the felt would need to be rather deep (inches), not a fraction of an inch, to have much effect.

For further reading: although the application is quite different, consider some of the issues and proposed solutions with horns/waveguides: the "towel mod" and the Geddes foam plug. There may be some overlap in potential application with direct radiators.

Note the even flush mounting your drivers won't save you; you still have a sharp edge (transition from "horn" to open air.)

Although it will definitely work against neat cabinet appearance, I hazard that smaller versions of the "towel mod" may have a beneficial effect: a "fuzzy" ring around a midrange or tweeter would be a prime candidate for experimentation. Note that it "should" partially extend into the open space and thus the direct sound path. Even though a typical direct radiator is not normally thought of as a horn, most of them are in fact cone shaped and thus will have some undesired resonances. One of the arguments for the towel

mod is that it provides a smoother transition than the usual hard termination at the horn mouth. Strictly speaking the towel mod alleviates the cavity resonance issue of a horn. I see no reason why this wouldn't work on a smaller cone speaker.

I suspect this may be one of those trade-offs: You can have a nice rectangular box with an attractive grill on the front, or you can have something that looks like a mouse nest glued onto the front baffle, but you probably can't have both 🙂

The towel mod is new to me I'll check it out but I would argue that any reflection from the cabinet is a not wanted addition to the response so you have to get rid of them somehow, and what better way than to capture them.

There is a good link in this thread to a guy that did some good measurements with felt, check them out if you have not already, felt does do some good just have to find the wisdom behind it.

And we are going through inches of material before the hf hits a baffle edge.

I think it is better to absorb it, versus staggering the distances from dome tweet to top / left / right baffle edge.

Stop the reflections, not stagger them so the 2khz+ measures flatter.

Picture from here

https://www.css-audio.com/single-post/2018/09/14/understanding-baffle-step-and-diffraction

I think it is better to absorb it, versus staggering the distances from dome tweet to top / left / right baffle edge.

Stop the reflections, not stagger them so the 2khz+ measures flatter.

Picture from here

https://www.css-audio.com/single-post/2018/09/14/understanding-baffle-step-and-diffraction

Attachments

The thickness (as seen by the sound wave) of the absorbtion matter detemines the lowest freqency (its quarter wave length) it will provide its maximum absorbtion. The sound level has little to do with its damping, at least in the range we use in audio.You make a great point about the depth of the felt and the frequency that it can slow down/reduce... I wonder if there is any math behind that, if we look at wavelength distance for frequencies to be amplified/nulled maybe there is an amplitude/frequency for depth! In other words maybe 1/4 felt at 1000 hz would dampen it at 85db but not at 95 db? Maybe felt at a lower frequency would need deeper felt all together and what is that depth, maybe I'll try it when I get my felt!

The towel mod is new to me I'll check it out but I would argue that any reflection from the cabinet is a not wanted addition to the response so you have to get rid of them somehow, and what better way than to capture them.

There is a good link in this thread to a guy that did some good measurements with felt, check them out if you have not already, felt does do some good just have to find the wisdom behind it.

Having said this, you have to get the soundwave in the matter, which is not trivial.

Last edited:

Can you elaborate on "sound wave in the matter, which is not trivial" I am just thinking about diffraction so doesn't the sound automatically go into the material if its on the front of the baffle?The thickness (as seen by the sound wave) of the absorbtion matter detemines the lowest freqency (its quarter wave length) it will provide its maximum absorbtion. The sound level has little to do with its damping, at least in the range we use in audio.

Having said this, you have to get the soundwave in the matter, which is not trivial.

How much of the sound (energy) is entering the absorbing matter and hoe much is reflected? Why are the absorbing matter in shape of wedges in anechoic room?Can you elaborate on "sound wave in the matter, which is not trivial" I am just thinking about diffraction so doesn't the sound automatically go into the material if its on the front of the baffle?

Hmm very good thought experiment there!How much of the sound (energy) is entering the absorbing matter and hoe much is reflected? Why are the absorbing matter in shape of wedges in anechoic room?

In an anechoic chamber we are looking to capture 100% of the sound if we can, more though, its to reduce the energy by reflecting what is left so by the time it hits the mic its so low in energy it doesn't matter much, at least what is not absorbed. In this case the diffraction waves are already reduced by X amount, if you look at other felt experiments it can reduce peaks and dips by as much as 3db from what I can tell.

Your point is well taken, if you look at Wilson Audio speakers they do a triangle cutout over their tweeter, this leads one to theorize that they are trying to average the frequencies they are eliminating/reducing? Or it could have something to do with off axis response?

I have more testing to do when I get my felt! I wonder if we do triangle cutouts if it reduced diffraction in the same way that the wedges in rooms do?

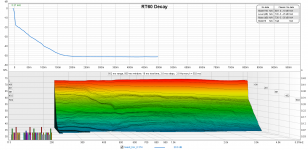

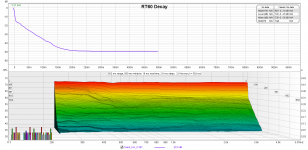

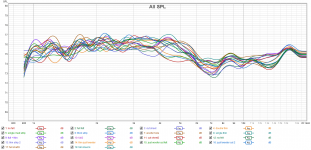

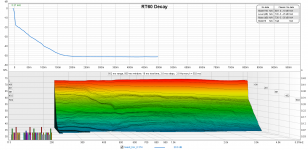

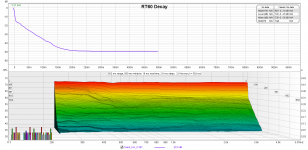

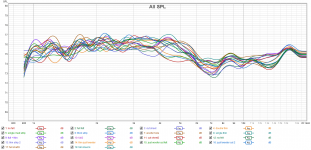

Felt will show up in the decay more than the power:

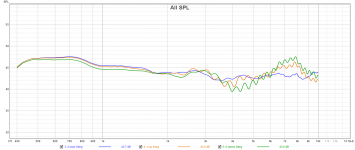

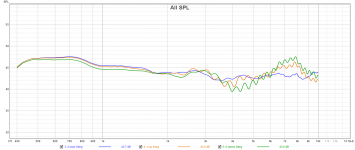

Here is a baffle with many layers and EQd to 3 layers. As I remove each layer you can see how the shape is changing the response.

Next is the same baffle with many diff. felt shapes on it and layers.

One last thing.. a quote from a paper:

Here is a baffle with many layers and EQd to 3 layers. As I remove each layer you can see how the shape is changing the response.

Next is the same baffle with many diff. felt shapes on it and layers.

One last thing.. a quote from a paper:

You need felt + an air gap for it to work best. The above baffle has a 10mm gap with 5mm of melamine in it.Nevertheless, it is common practice to mount sound absorptive

layers directly against a wall, because it is very convenient to do so.

We must, however, realize that, in such cases, only the outer one-third of the thickness of the layer is effective in absorbing sound.

The rest of the material is simply acting as a convenient support!

Damping material is different to the air, it isn't just soft and absorptive. Running into damping material is like running into a wall.. there will be a reflection. The wedges help to make it happen gradually.if you look at Wilson Audio speakers they do a triangle cutout over their tweeter, this leads one to theorize that they are trying to average the frequencies they are eliminating/reducing? Or it could have something to do with off axis response?

I have more testing to do when I get my felt! I wonder if we do triangle cutouts if it reduced diffraction in the same way that the wedges in rooms do?

Very true, The wedges in an anechoic room also interact so that any reflected sound will hit opposite wedge and so on.Felt will show up in the decay more than the power:

View attachment 1083676View attachment 1083677

Here is a baffle with many layers and EQd to 3 layers. As I remove each layer you can see how the shape is changing the response.

View attachment 1083674View attachment 1083675

Next is the same baffle with many diff. felt shapes on it and layers.

View attachment 1083678

View attachment 1083679

One last thing.. a quote from a paper:

You need felt + an air gap for it to work best. The above baffle has a 10mm gap with 5mm of melamine in it.

I would think the felt needs to like that used the original ROGERS LS3/5a.

VERY soft and thick.

FALCON ACOUSTICS has an equivalent material for sale on their website. They say it is. I have never seen it.

I have never found felt for sale anything like what was in the old ROGERS. I would tend to trust that FALCON's material is the same.

If the felt is hard it is doing nothing useful. It needs to be hairy and squishy.

VERY soft and thick.

FALCON ACOUSTICS has an equivalent material for sale on their website. They say it is. I have never seen it.

I have never found felt for sale anything like what was in the old ROGERS. I would tend to trust that FALCON's material is the same.

If the felt is hard it is doing nothing useful. It needs to be hairy and squishy.

I got felt from ponoko. It is all acoustic grade and you just need to send an AI or SVG file to make a laser-cut part.I would think the felt needs to like that used the original ROGERS LS3/5a.

VERY soft and thick.

FALCON ACOUSTICS has an equivalent material for sale on their website. They say it is. I have never seen it.

I have never found felt for sale anything like what was in the old ROGERS. I would tend to trust that FALCON's material is the same.

If the felt is hard it is doing nothing useful. It needs to be hairy and squishy.

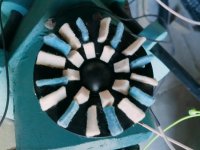

The image shows some random experiments plus the base felt layers and the layers that go past the tweeter.

here is a paper on wool:

https://www.researchgate.net/public...ials_with_Improved_Sound-Absorbing_Properties

How would you air gap felt? Little support legs or something? Or maybe just use thicker felt or make the drivers deeper in the baffle?Felt will show up in the decay more than the power:

View attachment 1083676View attachment 1083677

Here is a baffle with many layers and EQd to 3 layers. As I remove each layer you can see how the shape is changing the response.

View attachment 1083674View attachment 1083675

Next is the same baffle with many diff. felt shapes on it and layers.

View attachment 1083678

View attachment 1083679

One last thing.. a quote from a paper:

You need felt + an air gap for it to work best. The above baffle has a 10mm gap with 5mm of melamine in it.

And here is a wool on paper: https://happyhooligans.ca/simple-and-beautiful-yarn-art-with-paper-plates-and-twigs/here is a paper on wool:

https://www.researchgate.net/public...ials_with_Improved_Sound-Absorbing_Properties

🙂

True, also the amount of reflected sound can vary with the sides of a blanket. With fibrous absorption blankets more so that with foam based like basotect. Just touching can already give an indication.Damping material is different to the air, it isn't just soft and absorptive. Running into damping material is like running into a wall.. there will be a reflection. The wedges help to make it happen gradually.

Even then there ere some reflections, the wedges in an anechoic room are such that reflected sound hits an opposite wegdek side and so on, going deeper and deeper.

Do you really want a gap in this instance? The felt is there to avoid diffraction off of the corners from sound waves that travel over the baffle.How would you air gap felt? Little support legs or something? Or maybe just use thicker felt or make the drivers deeper in the baffle?

If you leave a gap there, the soundwave will travel over the baffle and reach the edge. Think about in what direction the sound wave hits the felt in this case.

I cannot compare it to a damping panel in front of a wall as the sound would hit that panel from an entirely different direction i.m.h.o.

A dense enough layer of felt can still create a reflection (like AllenB mentioned) so be aware that you reduce the diffraction, not adding to it.

Yes I have heard that before as well, there are good points all around.

1. You cannot eliminate diffraction at all frequencies so what is your target frequency and how thick does the felt have to be at what softness to accomplish this

2. The air gap is interesting and I get the point but the whole point of it was to not waste felt, basically.

3. I guess understanding the overall goal is important but there is no hard science to guide us. Have to test ourselves!

4. The softness of the felt sure will have a factor, I haven't found any good research papers that really do a good a/b/c/d/e/f ... comparison inregards to felt thickness, type and spl reduction by frequency. All of the papers don't go all the way down the rabbit hole!

1. You cannot eliminate diffraction at all frequencies so what is your target frequency and how thick does the felt have to be at what softness to accomplish this

2. The air gap is interesting and I get the point but the whole point of it was to not waste felt, basically.

3. I guess understanding the overall goal is important but there is no hard science to guide us. Have to test ourselves!

4. The softness of the felt sure will have a factor, I haven't found any good research papers that really do a good a/b/c/d/e/f ... comparison inregards to felt thickness, type and spl reduction by frequency. All of the papers don't go all the way down the rabbit hole!

- Home

- Loudspeakers

- Multi-Way

- Felt to help with baffle diffraction