Well, the build started, or at least I hope it did 🙂

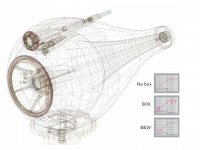

Goal : build a B&W shaped enclosure for the Fostex driver. Mould is from styrofoam, and will be fiberglassed. I think you know some of the pics, so will be adding new as the build progresses.

top part:

back part construction:

more to come

Goal : build a B&W shaped enclosure for the Fostex driver. Mould is from styrofoam, and will be fiberglassed. I think you know some of the pics, so will be adding new as the build progresses.

top part:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

back part construction:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

more to come

instead of Styrofoam which will melt once you apply fiberglass and is also a pain to shape and sand..

Go to a craft store and purchase the green potting fake soil... that or 2 part foam...

Go to a craft store and purchase the green potting fake soil... that or 2 part foam...

trusound:

there are resins that wont melt the styrofoam, so I'll be using that. I know the green fake soil, could be a good material, but the front shape is a round ball, and i don't think there is this material in that shape. But anyway thanks for the comment.

Danny

there are resins that wont melt the styrofoam, so I'll be using that. I know the green fake soil, could be a good material, but the front shape is a round ball, and i don't think there is this material in that shape. But anyway thanks for the comment.

Danny

Here is some progress, I've been away for a while (business trips, holiday)

This is the rough shape, dry fit, I think I have to fill the voids with some sort of filler, that can be sanded.You have any idea of a good soft filler? that can be like a glue as well?

dry fit (slight oversize on the ball part, had to cut new one)

this one is much better fit

Any suggestions welcome.

Next - buy new half of ball, filler and sand and sand and sand.....then, fiberglass.

Danny

This is the rough shape, dry fit, I think I have to fill the voids with some sort of filler, that can be sanded.You have any idea of a good soft filler? that can be like a glue as well?

dry fit (slight oversize on the ball part, had to cut new one)

An externally hosted image should be here but it was not working when we last tested it.

this one is much better fit

An externally hosted image should be here but it was not working when we last tested it.

Any suggestions welcome.

Next - buy new half of ball, filler and sand and sand and sand.....then, fiberglass.

Danny

Last edited:

Ready for fiberglassing 🙂

Some filler aplied and sanded, don't has to be really smooth

An externally hosted image should be here but it was not working when we last tested it.

Some filler aplied and sanded, don't has to be really smooth

This looks very good! Will you be using this with an additional bass speaker? What kind of internal volume will this be when completed?

Good luck with the fibreglassing! I look forward to seeing it

Good luck with the fibreglassing! I look forward to seeing it

This looks very good! Will you be using this with an additional bass speaker? What kind of internal volume will this be when completed?

Good luck with the fibreglassing! I look forward to seeing it

Yes, additional woofers will have enclosures. probably 2 per side.this is still open to suggestions.

The volume is calculated at 18,99L - the driver volume. Well, fiberglassing will be fun 🙂 I've never done it before.I have three cloth types, 220g/m2 140g/m2 and 33g/m2 the last one will be for finishing, this is just a mold, I will make a fiberglassed shape with 2-3 layers, and that will serve as the actual mold, so I can make more of them if anyone is interested 😀

Danny

I could not resist 🙂 it just looks good 🙂

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

This may be a bit off topic, but is it okay to build a cabinet out of PS/PU foam strengthened by fibre glass or carbon fibre? I mean will there be problems with the resonance/ energy storage etc?

borispm>

Have no idea, but as I will be using the driver only from 100-150Hz up I dont think that there will be any issues with strength, the wall thickness will be something like 10mm...perhaps enough

Have no idea, but as I will be using the driver only from 100-150Hz up I dont think that there will be any issues with strength, the wall thickness will be something like 10mm...perhaps enough

Hi there Barackuda: Fantastic project, can hardly wait for you futher posts on construction, mounting, wiring and listening experiences. Is this a sealed enclosure, aperiodic or a vented type? ...regards, Michael

Hi Michael,

I will leave it closed, the back of the enclosure will serve as a binding post (still to figure out how) .....

Mounting will be interesting, because I don;t know yet what kind of woofer enclosure will be used. Perhaps the same shape as B&W 😀

Somehow I have to solve all problems as I go 🙂 I think this happens when you do something totally new...

Guys, what kind of internal wiring cable would suite the 168E Sigma?

Danny

I will leave it closed, the back of the enclosure will serve as a binding post (still to figure out how) .....

Mounting will be interesting, because I don;t know yet what kind of woofer enclosure will be used. Perhaps the same shape as B&W 😀

Somehow I have to solve all problems as I go 🙂 I think this happens when you do something totally new...

Guys, what kind of internal wiring cable would suite the 168E Sigma?

Danny

I will leave it closed

Danny

Hi Danny,

Have you found any math to calculate the optimum volume and shape of the sphere and tapered tube? The B&W white paper describes work on math and experiments to find an optimal internal diameter for their midrange sphere, and the optimal shape of the rear taper to an open rear tube. B&W's open rear tube appears to provide a type of aperodic termination loading. I do not know if B&W uses any stuffing. I always thought that speaker transmission line theory could be used for this design. I would probably add stuffing only in the tapered tube with the goal of keeping driver dynamics with minimal rear wave reflections getting to the rear cone.

I think every midrange speaker has a different optimal size and shape sphere based upon the T/S parameters. I suspect most 1" dome tweeters could be installed in a common sphere+tube, and I have seen pictures a few tweeters in teardrop shaped rear chambers.

Thank you for sharing your amazing work. I think a B&W style 3-way cabinet is the optimal solution for a non-horn box speaker.

Attachments

^What's up with the thumbnail with the AE drivers in it? Looks like it would be an interesting setup. The TD6H just came out a short time ago.

Hi LineSource:

No I have not used any math, this is just trial and error. If it wont sound good, it will be scrapped 😀 About the stuffing, I have plans to experiment with different absorbing materials and vibration canceling methods. Like when you install a speaker in a car door...a lot of ringing has to be tamed. So for everybody... This is just TRIAL AND ERROR project. If it will be good, I will be happy 😀

The internal volume can be adjusted with filling the back of the funnel, or I thought about a cone shape in the back of the enclosure, to avoid sphere shape.

Some progress:

ALWAYS WORK WITH EPOXY IN WELL VENTILATED AREAS !

Three layers of 220g/m2 cloth...strong enough to dissolve the styrofoam.

I have to go to a business trip tomorrow (Portugal, Porto), so the other half will be fiberglassed on the weekend.

Danny

No I have not used any math, this is just trial and error. If it wont sound good, it will be scrapped 😀 About the stuffing, I have plans to experiment with different absorbing materials and vibration canceling methods. Like when you install a speaker in a car door...a lot of ringing has to be tamed. So for everybody... This is just TRIAL AND ERROR project. If it will be good, I will be happy 😀

The internal volume can be adjusted with filling the back of the funnel, or I thought about a cone shape in the back of the enclosure, to avoid sphere shape.

Some progress:

An externally hosted image should be here but it was not working when we last tested it.

ALWAYS WORK WITH EPOXY IN WELL VENTILATED AREAS !

Three layers of 220g/m2 cloth...strong enough to dissolve the styrofoam.

An externally hosted image should be here but it was not working when we last tested it.

I have to go to a business trip tomorrow (Portugal, Porto), so the other half will be fiberglassed on the weekend.

Danny

So the other half is fiberglassed 🙂

tomorrow I will somehow get the most of the styrofoam out. Then I will mold the actual shape by putting the two halves together, and pouring in ( I don't know the name in english) the stuff that looks like plaster...but is much harder.

Then there will be some sanding and sanding and sanding....

tomorrow I will somehow get the most of the styrofoam out. Then I will mold the actual shape by putting the two halves together, and pouring in ( I don't know the name in english) the stuff that looks like plaster...but is much harder.

Then there will be some sanding and sanding and sanding....

An externally hosted image should be here but it was not working when we last tested it.

You can use acetone to dissolve the styrofoam inside your mold. Make sure to have plenty of ventilation and wear a mask - acetone is nasty stuff to work with.

Nice project!

Mal

Nice project!

Mal

g-horn thanks, worked great, I just poured in like 0,5L and it eaten up the styrofoam like nothing. So the two halves are clean and ready to be aligned together. Then comes the fun part, casting the actual mold..... but it will have to wait for some time, business first 🙂

Anybody in Amsterdam with a big lathe?????? PLEASEEEEEEEE ?!?!?! ?

Anybody in Amsterdam with a big lathe?????? PLEASEEEEEEEE ?!?!?! ?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- FE168E Sigma teardrop enclosure