Atharva,

The initial bias at power up is not as important as the terminal bias level when the amp is fully warmed up and the temperature stabilized. To do that you make measurements and periodic adjustments to nudge the bias value towards your desired target, and at the same time, trim the dc offset. You need to keep the lid on the amp on during the process, except briefly off for quick adjustments to the trim pots. Practically this means having multiple meters attached, for bias and dc offset measurements, and the meters outside the case during the entire process. After each adjustment you put the lid back on and wait for the change to take effect and the temperature to stabilize. This may take a few hours.

The dc offset may drift a bit but anything staying within +/-50mV is quite acceptable. (Note that even 50mV corresponds to less than 0.16 mW RMS into 8 ohms)

The initial bias at power up is not as important as the terminal bias level when the amp is fully warmed up and the temperature stabilized. To do that you make measurements and periodic adjustments to nudge the bias value towards your desired target, and at the same time, trim the dc offset. You need to keep the lid on the amp on during the process, except briefly off for quick adjustments to the trim pots. Practically this means having multiple meters attached, for bias and dc offset measurements, and the meters outside the case during the entire process. After each adjustment you put the lid back on and wait for the change to take effect and the temperature to stabilize. This may take a few hours.

The dc offset may drift a bit but anything staying within +/-50mV is quite acceptable. (Note that even 50mV corresponds to less than 0.16 mW RMS into 8 ohms)

Atharva,

Congratulations on your successful build! And it's a pretty one too. 🙂

What chassis did you use? The pattern on the top cover looks different to most of the other chassis I've seen.

Congratulations on your successful build! And it's a pretty one too. 🙂

What chassis did you use? The pattern on the top cover looks different to most of the other chassis I've seen.

As ColinA123 stated.

Set the bias to 0.5V. let it run for about an hour to fully warm up. Then re-check the bias and set to desired value. I usually spend a good portion of a day letting it idle and checking/setting the bias. The idea is to get it set for steady-state operation.

Set the bias to 0.5V. let it run for about an hour to fully warm up. Then re-check the bias and set to desired value. I usually spend a good portion of a day letting it idle and checking/setting the bias. The idea is to get it set for steady-state operation.

Thanks @ColinA123 and @Dennis Hui.

Dennis, a special thanks to you. I had PM'd you a year back for the J2 and you patiently answered all my questions. I gave that up due to the exhorbitant cost of the Semisouth. But love the F6 so far.

Thanks for the kind words @zman01. It's not a ready made chassis. I got the heatsinks and sketched the rest of the plates in CAD and got them CNC cut in 3mm aluminium. I saw the top pattern in a Youtube video and liked it. Just sketched it in CAD.

Dennis, a special thanks to you. I had PM'd you a year back for the J2 and you patiently answered all my questions. I gave that up due to the exhorbitant cost of the Semisouth. But love the F6 so far.

Thanks for the kind words @zman01. It's not a ready made chassis. I got the heatsinks and sketched the rest of the plates in CAD and got them CNC cut in 3mm aluminium. I saw the top pattern in a Youtube video and liked it. Just sketched it in CAD.

Something as simple as a fan or air conditioner blowing on one part of the amp can throw the DC offset off a little bit. Most manufacturers like to see under 50mv. Realistically, up to 100mv is just fine. Get it as close to zero as you can with the lid on and the amp sitting for about 20 minutes (in addition to warm up time). If the DC offset starts to move again, you can nudge it back to zero within that time frame. Most people here seem to get it to float around +-15mv

Enjoy the amp! Best of luck!

Enjoy the amp! Best of luck!

Atharva,

You build is nicely done and I'm happy you are enjoying the F6.

Given your high summer ambient temperature, I recommend you look into something like Zen Mod's 'babysitter' to help with the thermal dissipation:

https://www.diyaudio.com/community/threads/babysitter-for-papas-koan.186554/

Have fun!

Dennis

You build is nicely done and I'm happy you are enjoying the F6.

Given your high summer ambient temperature, I recommend you look into something like Zen Mod's 'babysitter' to help with the thermal dissipation:

https://www.diyaudio.com/community/threads/babysitter-for-papas-koan.186554/

Have fun!

Dennis

@6sX7 thanks for the appreciation. There were many inspirational builds that I took cues from.

Thanks @Mikerodrig27 and @Dennis Hui.

Just like the babysitter I had thought of installing one of those large silent PC fans inside the amp blowing air out from the top. I've got vents in the bottom plate as well. Since I've got 2 rows of vents on top I could try two 3" fans on each side to keep both sides balanced. Although I can see a 3" 24V DC fan I'm thinking it may be better to use fans that work directly on supply voltage so as to not pollute the DC of the PSU?

Thanks @Mikerodrig27 and @Dennis Hui.

Just like the babysitter I had thought of installing one of those large silent PC fans inside the amp blowing air out from the top. I've got vents in the bottom plate as well. Since I've got 2 rows of vents on top I could try two 3" fans on each side to keep both sides balanced. Although I can see a 3" 24V DC fan I'm thinking it may be better to use fans that work directly on supply voltage so as to not pollute the DC of the PSU?

Just for peace of mind, I would not drive a fan off any power supply for the amp.

Also, It's a Pass class A amp. It's intended to run hot!

No need to over cool it with too many fans, just lower it slightly from ambient.

In my experience, in the UK, the F6 does not run too hot anyway. Less than some other designs.

Also, It's a Pass class A amp. It's intended to run hot!

No need to over cool it with too many fans, just lower it slightly from ambient.

In my experience, in the UK, the F6 does not run too hot anyway. Less than some other designs.

Hey folks, so I have enjoyed 2 weeks enjoyable listening. I return with a few niggles.

1. Heat. So in my obsession to manage heat (having read that Papa's gear runs hot) I added a primary heat sink to help spread the thermal load. I thought a copper (3x the thermal transfer of Aluminium) bar would help take the heat out of the transistors and make a bigger transfer to the main heatsink. I have a thermistor with my multi-meter and that is consistently giving a 42 deg C temp on the outside of heat sink. I don't get a consistent reading on the transistors (pin 2) - I had seen up to 72 deg C and a range of other temps between that and 40's. I've got a blob of heat sink grease on the themistor.

How are folks doing this easily/consistently? I'm biased at 0.6V on R2 and 0V DV offset (when well warmed up), so should be good temp wise.

Does anyone have any experience with my heat sink method, should I worry about the additional copper making it worse?

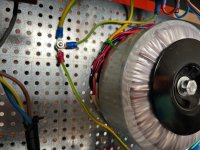

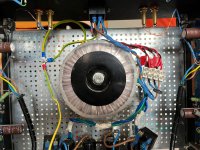

2. Hum. My other issue is a slight - mains I think - hum. The transformer buzzes audibly if you had your head near it and, if you held you head near the speaker (I've some Brynns and FH3s) but not loud - same tone as transformer. So, I thought I should put the transformer in a can. It's a snug fit - not interference, but needed helping on - don't know if that is good or bad. Before I went to trim the rest of the cables I thought I should turn it on. It appeared to me to be louder (albeit I have the base and the top off). I wondered if t was the can vibrating so touched the top (one hand in the pocket and gently) and I couldn't decide if it was hot or live - I let go and powered down... It had been on maybe 10 seconds. I've added some pics of the can on, and off. The can showed a tiny witness mark where it has touched the top of the bolt holding it to the base - just a nick of paint removed.

The blocks and rectifiers were zip tied down before I moved them to ease the can fitting. And the wires are all long as wanted to play around before I did a final trim. I do wonder if by keeping the wires close the transformer (almost under it) and that's the issue. Any wire husbandry guidance will be gratefully received.

Cheers, Al

1. Heat. So in my obsession to manage heat (having read that Papa's gear runs hot) I added a primary heat sink to help spread the thermal load. I thought a copper (3x the thermal transfer of Aluminium) bar would help take the heat out of the transistors and make a bigger transfer to the main heatsink. I have a thermistor with my multi-meter and that is consistently giving a 42 deg C temp on the outside of heat sink. I don't get a consistent reading on the transistors (pin 2) - I had seen up to 72 deg C and a range of other temps between that and 40's. I've got a blob of heat sink grease on the themistor.

How are folks doing this easily/consistently? I'm biased at 0.6V on R2 and 0V DV offset (when well warmed up), so should be good temp wise.

Does anyone have any experience with my heat sink method, should I worry about the additional copper making it worse?

2. Hum. My other issue is a slight - mains I think - hum. The transformer buzzes audibly if you had your head near it and, if you held you head near the speaker (I've some Brynns and FH3s) but not loud - same tone as transformer. So, I thought I should put the transformer in a can. It's a snug fit - not interference, but needed helping on - don't know if that is good or bad. Before I went to trim the rest of the cables I thought I should turn it on. It appeared to me to be louder (albeit I have the base and the top off). I wondered if t was the can vibrating so touched the top (one hand in the pocket and gently) and I couldn't decide if it was hot or live - I let go and powered down... It had been on maybe 10 seconds. I've added some pics of the can on, and off. The can showed a tiny witness mark where it has touched the top of the bolt holding it to the base - just a nick of paint removed.

The blocks and rectifiers were zip tied down before I moved them to ease the can fitting. And the wires are all long as wanted to play around before I did a final trim. I do wonder if by keeping the wires close the transformer (almost under it) and that's the issue. Any wire husbandry guidance will be gratefully received.

Cheers, Al

Attachments

I would first make sure that your preamp (or whatever you are using is not to blame, or adding to the hum.

Try it with the F6 inputs shorted, or with nothing connected.

Unfortunately, it may just need things / wires moving until it minimises.

Also, in pic 4 the NTC thermistor is in what appears to be a plastic connector block. That would be better in a ceramic one to minimise any risk from heat.

Try it with the F6 inputs shorted, or with nothing connected.

Unfortunately, it may just need things / wires moving until it minimises.

Also, in pic 4 the NTC thermistor is in what appears to be a plastic connector block. That would be better in a ceramic one to minimise any risk from heat.

I want to check up on some things as my building progresses. I have the amp boards done and the PSU mostly done. Right now I'm obsessing over what wire to use.

My thinking is along these lines. I am spending plenty of money and effort so I'm really don't want to cheap out on anything. Im doing this for the experience, the learning, the end product etc but not to save money. Having said all that I have to constantly reel myself in when I see claims about plated wire made by topless angels in Bavaria out of materials brought back from the last lunar landing. I see both sides of the argument and want to be where most sane people do - in the middle. I, obviously, don't know enough about things to make many informed decisions so Im asking.

Is a quality stranded copper wire with a PTFE jacket good enough for the power and speaker connections. Im thinking of some that I have left over from boating projects and extra speaker wire. I'll buy it if need be no problem, but I have a lot extra in the drawer.

For signal wire is twisted solid copper in 18 or 20 gauge good. Is coaxial better?

I used 14awg bare copper to jumper the PSU board. Good enough?

Im putting terminal blocks everywhere I can to facilitate swapping in other firstwatt boards to the chassis in the future, is that a mistake vs soldering to the board?

Hopefully my mindset is clear. I realize this design is meant to sound exceptional, so I want to pursue that end. I just don't want to be wasteful. It's in my nature to get overwhelmed by choices and keep stretching in the name of buying the best thing first. There are a ton of choices and a ton of opinions as I'm sure you know.

As always thank you for your time

John

My thinking is along these lines. I am spending plenty of money and effort so I'm really don't want to cheap out on anything. Im doing this for the experience, the learning, the end product etc but not to save money. Having said all that I have to constantly reel myself in when I see claims about plated wire made by topless angels in Bavaria out of materials brought back from the last lunar landing. I see both sides of the argument and want to be where most sane people do - in the middle. I, obviously, don't know enough about things to make many informed decisions so Im asking.

Is a quality stranded copper wire with a PTFE jacket good enough for the power and speaker connections. Im thinking of some that I have left over from boating projects and extra speaker wire. I'll buy it if need be no problem, but I have a lot extra in the drawer.

For signal wire is twisted solid copper in 18 or 20 gauge good. Is coaxial better?

I used 14awg bare copper to jumper the PSU board. Good enough?

Im putting terminal blocks everywhere I can to facilitate swapping in other firstwatt boards to the chassis in the future, is that a mistake vs soldering to the board?

Hopefully my mindset is clear. I realize this design is meant to sound exceptional, so I want to pursue that end. I just don't want to be wasteful. It's in my nature to get overwhelmed by choices and keep stretching in the name of buying the best thing first. There are a ton of choices and a ton of opinions as I'm sure you know.

As always thank you for your time

John

Al, if the metal can touches transformer's centre mounting bolt, you can get a shorted turn.

See fig 7 here: https://www.bicronusa.com/resources/tech-guide-toroidal-power-transformers

See fig 7 here: https://www.bicronusa.com/resources/tech-guide-toroidal-power-transformers

Thanks Colin, it was both plugged in and unplugged, should have mentioned that. So probably mains and everything need moving round carefully.I would first make sure that your preamp (or whatever you are using is not to blame, or adding to the hum.

Try it with the F6 inputs shorted, or with nothing connected.

Unfortunately, it may just need things / wires moving until it minimises.

Also, in pic 4 the NTC thermistor is in what appears to be a plastic connector block. That would be better in a ceramic one to minimise any risk from heat.

Not sure I understand re the ceramic block and where the heat is coming from. Surely a ceramic would transfer the ambient/base temp more readily as opposed to the mains wire temp? Have I missunderstood it’s purpose?

Thanks Dennis, clearly heat and electrocution. I can rectify that with washers to stand the can up a bit and some insulation to cover the exposed bolt (I will see if I can shorten that too).Al, if the metal can touches transformer's centre mounting bolt, you can get a shorted turn.

See fig 7 here: https://www.bicronusa.com/resources/tech-guide-toroidal-power-transformers

I vaguely recall my electronic and ‘complications of toroids’ from uni, but that was 30 years ago and was studying mech Eng. The basic message was tighten stuff up as it will vibrate. Electronics was voodoo and wouldn’t catch on 🤣

- Home

- Amplifiers

- Pass Labs

- F6 Illustrated Build Guide