How does John curl avoid bad solder connections? Does he spot weld?🙄DC offset 50 mV over temp is not a concern for me.

But back to the original 500 mV values, quite a few such problems are solder

connections, which happens to everyone (except John Curl).

Try re-soldering all the connections on that channel.

😎

As I understand it, John goes to great lengths to clean the surfaces and

such before he makes a connection. Probably takes him a long time to

build something.

Me, I use clip leads....

😎

such before he makes a connection. Probably takes him a long time to

build something.

Me, I use clip leads....

😎

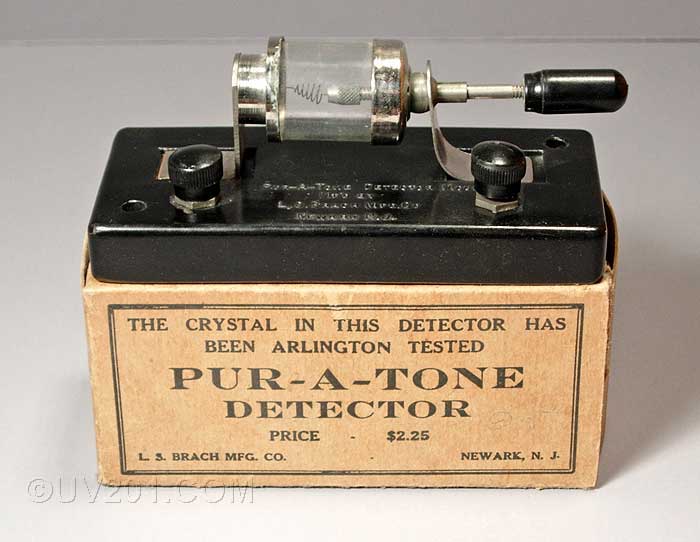

Oh yeah! Good price!

sorry picture now working.....

seems to work... but took a long time!

Attachments

May be F15 looks like this,

only one wire and one crystal.....! And does only work when you have P😎ssing a heavy thunderstorm outside.....😀😀

only one wire and one crystal.....! And does only work when you have P😎ssing a heavy thunderstorm outside.....😀😀

Last edited:

He physically scrapes each component (acttually he instructs a tech to do it) in the area of the connection and solder fillet for contaminant, oxidation free tin'ed surface to be soldered to. He then uses typical good 'ol lead solder. I don't remember the particular solder alloy/flux but, if you read the last 30 pages it's probably there amongst the total OT smelly sheet...How does John curl avoid bad solder connections? Does he spot weld?🙄

Of coarse his techs are expected to be solder experts already, unlike many of the people here...

Just watch, the JC Blowtourch thread fools will come attack me for saying anything at all...

Well, as long as we are on the subject of possible frivolous efforts to make everything as close to perfect... After cleaning the solderable area of the leads, bending thru hole devices in a proper jig, or with the proper needle or round nose pliers is also advised, so as not to stress the lead to R or C connection, or even work harden the copper lead to much 😀

- Home

- Amplifiers

- Pass Labs

- F6 Amplifier