Buckapound, You have me thinking. I threw away the packaging for the taps already, so I'm not sure if they are cobalt or carbide. I thought they were carbide. I'll have to look at them again when I'm at the hardware store.

-David

-David

Want Boards, can't WIKI

Hello Peter,

I'd like 2 boards and info on the ps boards (I saw you had some but not where). I cannot figure out how to add to the table you built. Is there more info...or is it a Mac problem?

Anyways....2 boards and PS info please.

Thanks!

Hello Peter,

I'd like 2 boards and info on the ps boards (I saw you had some but not where). I cannot figure out how to add to the table you built. Is there more info...or is it a Mac problem?

Anyways....2 boards and PS info please.

Thanks!

Re: Want Boards, can't WIKI

I edited the Wiki for you.

Here is the Direct Link.

http://www.diyaudio.com/wiki/index.php?page=F1

David is the PCB designer, Peter is doing on some other work on F3-F5 PCB's on another list. David will be distributing the F1 boards.

Peter has power supply PCBs available.

The F3 model from him will work.

belkinmousepad said:Hello Peter,

I'd like 2 boards and info on the ps boards (I saw you had some but not where). I cannot figure out how to add to the table you built. Is there more info...or is it a Mac problem?

Anyways....2 boards and PS info please.

Thanks!

I edited the Wiki for you.

Here is the Direct Link.

http://www.diyaudio.com/wiki/index.php?page=F1

David is the PCB designer, Peter is doing on some other work on F3-F5 PCB's on another list. David will be distributing the F1 boards.

Peter has power supply PCBs available.

The F3 model from him will work.

I too would like a pair of the boards. I tried to add my order to

the list but was not sucessful could you add my name to it.

I just occured to me that I ordered a pair of Pass A40 boards

about 30 years ago a day or 2 before newyears also.

the list but was not sucessful could you add my name to it.

I just occured to me that I ordered a pair of Pass A40 boards

about 30 years ago a day or 2 before newyears also.

Woody, I added you name to the wiki for 2 boards. Please check the Wiki to make sure your order is accurate.

-David

-David

A multi-turn vertical pot option was added to P1. Also the board was adjusted for a larger Wima cap foot print for both C1&C2.

The details are in the design thread on the Pass Labs forum. Also if we get 100 boards in this GB, the price will drop from $13 to $11 each plus shipping.

-David

The details are in the design thread on the Pass Labs forum. Also if we get 100 boards in this GB, the price will drop from $13 to $11 each plus shipping.

-David

Extending the GB deadline to Jan 9th

F1 GB participants,

The GB is scheduled to close Dec. 31st, 2008. Since we are so close to 100 boards and a price break, I'd like to extend the GB deadline to January 9th. If no one objects, this gives us a chance to get a few more participants and the board cost drops to $11 plus shipping.

-David

F1 GB participants,

The GB is scheduled to close Dec. 31st, 2008. Since we are so close to 100 boards and a price break, I'd like to extend the GB deadline to January 9th. If no one objects, this gives us a chance to get a few more participants and the board cost drops to $11 plus shipping.

-David

How long do they need to run these boards and do they need

payment before they start this order? The group buy stands at

82. When the total reaches 85 it will be cheaper to order 100

than 85 boards. I sure hope you can take paypal!

payment before they start this order? The group buy stands at

82. When the total reaches 85 it will be cheaper to order 100

than 85 boards. I sure hope you can take paypal!

Hi Woody,

I'm going to start taking payment shortly via PayPal. I bet we'll get a bunch more board orders next week after everyone's back from Winter vacation.

We only need 9 more pairs ordered to get the next level of discount to get the cost down another couple of bucks per board.

I have samples scheduled to arrive today. We will be ready as soon as they are verified.

Happy New Year,

-David

I'm going to start taking payment shortly via PayPal. I bet we'll get a bunch more board orders next week after everyone's back from Winter vacation.

We only need 9 more pairs ordered to get the next level of discount to get the cost down another couple of bucks per board.

I have samples scheduled to arrive today. We will be ready as soon as they are verified.

Happy New Year,

-David

Current Total

{in Spock Voice}

Captain,

According to my calculations - 100 boards are on the Wiki, allowing us further economies of scale.

{in Spock Voice}

Captain,

According to my calculations - 100 boards are on the Wiki, allowing us further economies of scale.

{in Scotty voice}

Captain, Board quantity at full power for 100 unit break. The PCB mfg will now do $11 a board!

-David

Captain, Board quantity at full power for 100 unit break. The PCB mfg will now do $11 a board!

-David

Just a reminder, this F1 GB closes January 9th 2009.

Register on the wiki to be included. If you are wiki challenged, then ask for help here and someone will add you.

-David

Register on the wiki to be included. If you are wiki challenged, then ask for help here and someone will add you.

-David

samsagaz said:IM in for other Pair 🙂

Great, go ahead and ad your name to the wiki.

-David

He everyone,

The F1 GB Price is now $11usd plus shipping. We have met the minimum quantities.

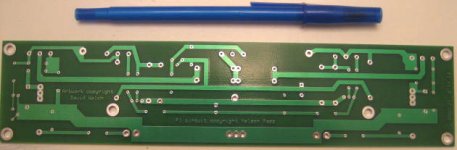

Attached is the prototype F1 v1.0 board received from the board house. Some minor tweaks have been made and the production board will be based on version 1.2.

-David

The F1 GB Price is now $11usd plus shipping. We have met the minimum quantities.

Attached is the prototype F1 v1.0 board received from the board house. Some minor tweaks have been made and the production board will be based on version 1.2.

-David

Attachments

Buckapound said:One thing to think about for those of you who are having trouble with broken taps is that "forming" taps are a little harder to break that cutting taps. They essentially re-flow the metal rather than cut out chips and are great for softer materials like aluminum. They just look like standard screw threads that have a little cam or lobe shape, without the cutting flutes of a standard tap

As always whit taps, be sure to drill the exact right size hole, which is different for a forming tap than a cutting one. Best to use number drills. And there is a specific lubricant made for tapping aluminum, although most any lubricant is a lot better than none.

In my experience carbide is a terrible material for taps, unless you are tapping abrasive materials like fiberglas. DW8083, are you sure they're carbide and not cobalt? Big difference. Murder to get a broken one out, too. With HSS taps you can just fill the hole with acid and wait for the tap to rust out.

--Buckapound

Typically in the fabrication and machine shops I have owned we used rubbing alcohol for tapping aluminum.......it prevents the tap binding up and thus breaking where as oil based lubricants tend to clog up .....best bet is a water soluable based tapping fluid

just my 2 cents

Happy New Year everyone

JOE DIRT® said:

Typically in the fabrication and machine shops I have owned we used rubbing alcohol for tapping aluminum.......it prevents the tap binding up and thus breaking where as oil based lubricants tend to clog up .....best bet is a water soluable based tapping fluid

just my 2 cents

Happy New Year everyone

What would you recommend for 0-80 holes in copper pipe fittings? I have tried 4-40 set screws for some DIY mics but they are just too big to catch the short piece of the capsule that sets in the pipe fitting.

scott wurcer said:

What would you recommend for 0-80 holes in copper pipe fittings? I have tried 4-40 set screws for some DIY mics but they are just too big to catch the short piece of the capsule that sets in the pipe fitting.

I would use an epoxy based resin if I am getting what your asking about correct ??

- Status

- Not open for further replies.

- Home

- Group Buys

- F1 Group Buy